Professional Documents

Culture Documents

Modified Release

Uploaded by

JuliusGrandeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Modified Release

Uploaded by

JuliusGrandeCopyright:

Available Formats

971

Introduction

Te development of liquid oral sustained release for-

mulations has gained much interest recently. Tese

formulations eliminate the problems associated with the

solid dosage forms while maintaining the advantages

and convenience of sustained release drug delivery.

Alternative strategies have been adopted to develop

such systems. One of the techniques examined the use of

suspended microspheres which have been incorporated

as a dispersed phase in a suspension

1,2

. Other strategies

investigated the use of ion exchange resins or employing

sparingly soluble salts to prepare oral sustained release

suspensions

3

.

Te use of in situ gelling systems provides another

promising alternative with most of the reported inves-

tigations employing the sol to gel phase transition of

alginate solution after addition of polyvalent cations

as calcium. An early study developed a suspension

of theophylline in presence of sodium alginate. Tis

suspension was reported to form a gel when comes

in contact with simulated gastric fuid

4

. In a more

recent study, a liquid sustained release preparation

RESEARCH ARTICLE

Development of modifed in situ gelling oral liquid sustained

release formulation of dextromethorphan

Gamal M. El Maghraby

1,2

, Ehab M. Elzayat

2

, and Fars K. Alanazi

2,3

1

Department of Pharmaceutical Technology, College of Pharmacy, University of Tanta, Tanta, Egypt,

2

Department

of Pharmaceutics, College of Pharmacy, King Saud University, Riyadh, Saudi Arabia, and

3

Kayyali Chair for

Pharmaceutical Industry, College of Pharmacy, King Saud University, Riyadh, Saudi Arabia

Abstract

Context: Alternative strategies are being employed to develop liquid oral sustained release formulation. These

included ion exchange resin, sustained release suspensions and in situ gelling systems. The later mainly utilizes

alginate solutions that form gels upon contact with calcium which may be administered separately or included in the

alginate solution as citrate complex. This complex liberates calcium in the stomach with subsequent gellation. The

formed gel can break after gastric emptying leading to dose dumping.

Objective: Development of modifed in situ gelling system which sustain dextromethorphan release in the stomach

and intestine.

Methods: Solutions containing alginate with calcium chloride and sodium citrate were initially prepared to select the

formulation sustaining the release in the stomach. The best formulation was combined with chitosan. All formulations

were characterized with respect to fow, gelling capacity, gelling strength and drug release.

Results: Increasing the concentration of alginate increased the gelling capacity and strength and reduced the rate

of drug release in gastric conditions with 2% w/v alginate being the best formulation. However, these formulations

failed to sustain the release in the intestinal conditions. Incorporation of chitosan with alginate increased the gelling

capacity and strength and reduced the rate of drug release compared to alginate only system. The efect was optimum

in formulation containing 1.5% w/v chitosan. The sustained release pattern was maintained both in the gastric and

intestinal conditions and was comparable to that obtained from the marketed product.

Conclusion: Alginate-chitosan based in situ gelling system is promising for developing liquid oral sustained release.

Keywords: Dextromethorphane, liquid controlled release, in situ gelling, polyelectrolyte complex,

alginate-chitosan complex

Address for Correspondence: Gamal M. El Maghraby, Department of Pharmaceutical Technology, College of Pharmacy, University of Tanta,

Tanta, Egypt; Department of Pharmaceutics, College of Pharmacy, King Saud University, Riyadh 11451, P.O. Box: 2457, Saudi Arabia.

E-mail: gmmelmag@yahoo.com

(Received 24 May 2011; revised 18 October 2011; accepted 19 October 2011)

Drug Development and Industrial Pharmacy, 2012; 38(8): 971978

2012 Informa Healthcare USA, Inc.

ISSN 0363-9045 print/ISSN 1520-5762 online

DOI: 10.3109/03639045.2011.634811

Drug Development and Industrial Pharmacy

2012

38

8

971

978

24 May 2011

18 October 2011

19 October 2011

0363-9045

1520-5762

2012 Informa Healthcare USA, Inc.

10.3109/03639045.2011.634811

LDDI

634811

972 G. M. El Maghraby et al.

Drug Development and Industrial Pharmacy

for eradication of Helicobacter pylori was developed

in presence of alginate solution. In this study the in

situ gellation was achieved by separate oral adminis-

tration of calcium solution which was taken immedi-

ately after administration of sodium alginate solution

5

.

Shortly after this authors attempted to prepare systems

containing sodium alginate combined with calcium.

Tese systems retained the fuidity in the bottle but

undergo immediate gellation on coming into contact

with gastric or simulated gastric acidity. To inhibit the

interaction of calcium with alginate in the bottle, cal-

cium ions were sequestered with sodium citrate. Tis

complex breaks immediately in strong acidity librating

free calcium which can interact with alginate resulting

in spontaneous gellation

69

. Te optimum quantities

of calcium chloride and sodium citrate that main-

tain fuidity of the formulation before administration

but gel spontaneously after contact with simulated

gastric fuid (pH 1.2) were determined

10

. It should be

noted that this type of gel is pH sensitive and breaks

in presence of intestinal pH. Accordingly, the release

pattern will depend on the gastric emptying rate which

is highly variable. Tis problem draws the attention to

new in situ gelling system with a stronger gel structure

that can maintain the sustained release pattern after

gastric emptying.

Te gel structure of alginate-based systems was

enhanced by combination with chitosan. Tis combina-

tion was employed in development of controlled release

particulate and other solid drug delivery systems. Te

synergism between alginate and chitosan is due to the

electrostatic interactions between carboxyl groups of

alginate and amino groups of chitosan and existence of

interactive coulomb forces. Tese efects increased the

gel strength

11,12

.

Accordingly, the objective of this work was to develop

and optimize in situ gelling sustained release liquid oral

formulation for the delivery of dextromethorphan. Tis

drug was selected as it has high water solubility and short

half-life. To achieve this objective the alginate-based

system was employed but the in situ gelling efect was

induced with calcium ion and chitosan. Te later was

introduced to the formulation with the goal of increasing

the gel strength and maintaining the sustained release

pattern after gastric emptying.

Materials and methods

Materials

High molecular weight chitosan, Brookfeild viscosity

800,000 cPs, was obtained from Sigma-Aldrich, Inc.,

Chemi GmbH, Germany. Sodium alginate (low viscos-

ity grade with M/G ratio of 1.56) was obtained from

ICN Biomedicals, Inc., Germany. Dextromethorphan

hydrobromide was a gift from TABUK pharmaceutical

company, Tabuk, KSA. Calcium chloride anhydrous and

Tri-Sodium citrate were obtained from WINLAB, GEMINI

house, U.K. Methanol HPLC grade and disodium hydro-

gen phosphate were obtained from BDH, Prolabo, Poole,

England. Potassium dihydrogen phosphate was obtained

from Merk, Darmstadt, Germany. All other reagents were

of analytical grade.

Preparation of in situ gelling systems

In situ gelling liquid formulations containing increas-

ing concentrations of sodium alginate were prepared in

absence and presence of chitosan. Te detailed composi-

tion of these is presented in Table 1. Sodium alginate was

added to ultrapure water containing 0.45% w/v sodium

citrate and 0.15% w/v calcium chloride and 0.6% w/v

dextromethorphan hydrobromide. Tese mixtures were

heated to 60C while stirring. Stirring was continued at

ambient temperature until cooling to less than 40C

7

. For

chitosan containing systems, the chitosan amount of chi-

tosan was levigated gradually with the resulting alginate

solution under continuous stirring using a mortar and a

pestle to produce homogenous dispersion.

Viscosity of in situ gelling solutions

Te fow properties and viscosity of all formulations were

determined using a Brookfeld viscometer RVDV-II+

(Brookfeld, Engineering Laboratories Inc., Stoughton,

MA, USA) with small sample adapter at ambient tem-

perature. A typical run comprised changing the angular

velocity from 0.5 to 100 rpm and recording the fow prop-

erties. Te average of the three readings was recorded.

Evaluation of the gel forming property

Tis study was conducted to measure the gel form-

ing property of the tested formulation. Te formula-

tion (10 ml) was packed into cellulose bag. Tis was

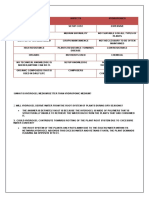

Table 1. Te composition of the prepared in situ gelling systems and the release efciency of dextromethorphan hydrobromide in

simulated gastric and intestinal media.

Formulation Alginate (% w/v) Chitosan (% w/v) RE (%) in the acid phase RE (%) in the intestinal phase

A1 1 0 79.6 (11.4) 99.9 (7.9)

A1.5 1.5 0 35.5 (6.9) 98.9 (7.8)

A2 2 0 33.1 (2.6) 83.1 (0.4)

F1 2 0.5 16.5 (5.0) 91.3 (4.8)

F2 2 1 16.7 (1.0) 77.4 (12.5)

F3 2 1.5 16.9 (2.4) 32.8 (1.7)

CH2 0 2 71.0 (2.9) 91.1 (4.1)

Delsym 5.2 (0.7) 20.3 (3.4)

Values between brackets are SD (n = 3).

Liquid oral sustained release formulation 973

2012 Informa Healthcare USA, Inc.

immersed in 0.1 N HCl (100 ml) and maintained at 37C

for 24 hours. Te fuid content of the cellulose bag was

separated from the gel by sieving through a 355 m sieve

for 30 seconds. Te weight of the gel remaining on the

sieve was determined

13

.

Determination of in vitro drug release

Te method of evaluation of drug release from enteric

coated systems was adopted (USP 24). In addition, the

study was further extended to monitor drug release at

pH 7.4. Te release experiments employed a USP disso-

lution apparatus (Model: UDT-804, LOGAN Inst. Corp.,

USA) with a paddle stirrer being maintained at 50 rpm.

Te release medium was 500 ml of simulated gastric fuid

without enzymes (0.1 N HCl, pH 1.2) and the tempera-

ture was maintained at 37 0.2C. Te test formulations

(10 ml) were loaded into a Petri dish (2.7 cm, internal

diameter) before immersion into in the dissolution vessel

containing release medium without much disturbance.

Samples (5 ml) were collected at predetermined time

intervals (5, 15, 30, 60, 90 and 120 minutes, respectively).

Fresh release medium was added to replenish for each

sample. Te samples were fltered through 0.45 m flter,

immediately after collection and the fltrate was analyzed

for drug content using the HPLC method (see below).

After the last sample (2 hours), the pH of the release

medium was adjusted to 6.8 to simulate the intestinal

pH (USP 24). Tis was achieved by addition of 200 ml of

0.3 M dibasic sodium phosphate and 25 ml of 1 N sodium

hydroxide. Sampling was then continued for another 4

hours at the end of which the medium was adjusted to

7.4 using 1 N sodium hydroxide and sampling was con-

tinued for another 2 hours. Tese samples were treated

as before.

Te cumulative amounts of the drug released

(expressed as % of the total drug added) were plotted as a

function of time to produce the drug release profles. Te

release efciency (RE) was calculated from the area under

the release curve at time t (determined using the non-

linear trapezoidal rule) and expressed as a percentage

of the area of the rectangle described by 100% release in

the same time

14

. Te results were compared to the release

data of the marketed formulation (Delsym

suspension).

In addition, the release data for each phase were ftted to

diferent kinetic models to determine the release kinet-

ics. Tis included ftting the data to zero order, frst order

and Higuchi difusion system. Each study was conducted

in triplicate.

Assay of dextromethorphan

Te drug concentration in each sample was determined

using the previously developed HPLC method of analy-

sis

15

. Te study employed a high pressure liquid chro-

matograph (Waters

600 controller, USA) equipped with

a variable wavelength detector (SPD-10 AV, Shimadzu,

Kyoto, Japan) and an automatic sampling system

(Waters

717 Plus Autosampler, USA). Te whole system

was under computer contro1. Separation was performed

on a reversed phase column 15 cm 3.9 mm (i.d.) C18,

Bondapak

, Waters

, with an average particle size of 10

m. Te mobile phase comprised methanol and 0.1 M

potassium dihydrogen phosphate bufer (45:55, v/v),

fowing at 1.2 ml/min after being adjusted to pH 3 with

phosphoric acid. Te column efuent was monitored at

220 nm and the chromatographic data analysis was per-

formed with the Millennium

Program (Waters, USA).

Filtered samples were loaded into the HPLC vials before

injecting 30 l into the HPLC.

Statistical analysis

One-way analysis of variance (ANOVA) with was per-

formed using the SPSS 18 software to compare the

mean values of drug released from diferent formulation.

Multiple Range Test (Fishers least signifcant diference

procedure, LSD) was used to test for signifcance

16

. Te

level of confdence was set at 95%.

Results and discussion

Viscosity and ow behavior of the in situ gelling

systems

Te study developed and evaluated a modifed alginate-

based in situ gel forming system as liquid oral sustained

release formulation. Te modifcation was performed

with the goal of increasing the gelling strength and con-

trolling the release over extended period of time. Tis was

achieved by incorporation of chitosan. Alginate-based

systems were frst developed and evaluated. Te best

alginate formulation was the combined with increasing

concentrations of chitosan. Tese were compared with

the marketed product (Delsym

suspension). As fuidity

is an essential parameter for development of liquid oral

formulations, it was taken as the frst measure in prepa-

ration of traditional alginate-based systems before incor-

poration of chitosan. Formulations containing sodium

alginate at a concentration of 3% w/v or more were too

viscous. Tus a series of alginate solutions comprising

1, 1.5 and 2% w/v of sodium alginate was prepared and

evaluated. Figure 1 shows the fow behaviour of these

formulations. Te data revealed a dependency of the vis-

cosity on the shear rate with the viscosity reducing upon

application of the shear (Figure 1). Tis shear thinning

behaviour provides an advantage for the administra-

tion process. Shaking of the formulation will enhance its

fuidity pourability. With respect to the recorded viscos-

ity values, they were increased with increasing alginate

concentration. For comparison the values recorded at

a shear rate of 0.47 sec

1

were considered. Te recorded

viscosity values were 100, 250 and 525 mPaS for sols con-

taining alginate at a concentration of 1, 1.5 and 2% w/v,

respectively. Te marketed product showed similar fow

profle but the recorded viscosity values were higher than

the tested alginate-based systems (Figure 1). Similar fow

behaviour was recorded for alginate-based in situ gelling

system

9

. To increase the gelling strength and modify the

release pattern of the drug chitosan was incorporated in

974 G. M. El Maghraby et al.

Drug Development and Industrial Pharmacy

the alginate sol formulation (A2). Chitosan was included

at increasing concentrations of 0.5, 1 and 1.5% w/v to

produce the formulations F1, F2 and F3, respectively

(Table 1). Addition of chitosan did not result in signifcant

increase in the viscosity of the systems with the behaviour

being shear thinning as well (Figure 1). Te viscosity of

the alginate sols was increased from 525 mPaS in absence

of chitosan to 533.3, 566.7 and 650 mPaS in presence of

chitosan at concentrations of 0.5, 1 and 1.5% w/v, respec-

tively. Te lack of signifcant increase in the viscosity after

incorporation of chitosan can be explained on the bases

that the pH of the formulations (pH = 7.2) is not suitable

for dissolution of chitosan which requires acidic envi-

ronment to dissolve

11,12

. Te fnal formulation was a fne

dispersion of chitosan in alginate sol. Tis will exclude

any interaction between chitosan and alginate during

storage in the bottle. Te pH of the formulation (7.2) was

selected to maintain the calcium ions in a complex form

with citrate. Tis ensured the fuidity of the formulation

and will prevent gel formation in the bottle

68

. Te vis-

cosity of the prepared sols in presence and absence of

chitosan was lower than that recorded for the marketed

product, Delsym (Figure 1). Tis ensures the fuidity of

the formulations which allows easy administration of the

tested formulation.

Gel forming property

Te gel forming property of the formulations is another

important factor that can afect the drug release pat-

tern from the liquid formulation. It provides a measure

for the in situ gelling capacity of the formulations. Tis

was monitored by packing the sol into cellulose bags

before incubation in 0.1 N HCl at 37C. Te gelling was

monitored visually and the relative weight of the gel

phase was taken as a measure for the gel strength

13

.

Figure 2 shows photomicrographs of the gel which was

formed in situ after incubation of diferent formulation

in simulated gastric pH. Te photomicrographs revealed

a dependence of the gelling capacity and the gelling

strength on the composition of the sol. Chitosan-free

alginate sols containing alginate at a concentration of 1

or 1.5% w/v (A1 and A1.5) produced very soft gel. Te

gel became relatively frmer on increasing the alginate

concentration to 2% w/v as in formulation A2 (Figure 2).

Tese observations were confrmed further by monitor-

ing the weight of the gel (Figure 3). Te recorded weight

values confrmed the dependence of gelling capacity on

alginate concentration with A2 producing the greatest

gelling capacity compared to A1 and A1.5. Te increase

in the gel forming ability of the in situ gelling system with

increasing alginate concentration indicates the adequacy

of calcium and citrate ions. Te in situ gelling behaviour

of simple alginate-based solutions (A1, A1.5 and A2) can

be explained on the bases that the acidic environment

librated the calcium ions from the citrate complex. Te

free calcium ions interacted with the alginate sols result-

ing in immediate gellation

610

.

Combination of chitosan with the alginate-based sys-

tems enhanced the gel forming property and increased

the in situ gelling capacity. Tis is clearly indicated from

Figure 2 which shows the frm gel with the frmness being

increased upon increasing the concentration of chitosan.

Te efect of chitosan was investigated further by monitor-

ing the weight of the gel. Te data indicated that incorpora-

tion of chitosan into alginate sols resulted in better in situ gel

forming capacity compared with chitosan-free system (A2).

Tis is revealed from the relative increase in the weight of the

gel in presence of chitosan. Tis efect of chitosan depended

on its concentration as well (Figure 3). Tese results sug-

gest a synergistic efect for chitosan. Tis synergism is

due to the formation of polyelectrolyte complex resulting

from electrostatic interactions between alginate and chi-

tosan and existence of interactive coulomb forces. Tese

efects can increase the in situ gelling capacity and gel

strength

11,12

. Te complexing efect of chitosan provided

a synergistic efect for the calcium induced gelation. Te

presence of calcium ion with chitosan in the in situ gell-

ing system can guarantee rapid gelation in acidic envi-

ronment of the stomach due to rapid liberation of the free

divalent calcium ions which interact with the guluronic

acid moieties of alginate. Chitosan will further enhance

the cross-linking by forming polyelectrolyte complex

with alginate but this efect involves initial dissolution

Figure 1. Comparison of the dependency of viscosity profles of

diferent in situ gelling systems on the shear rate. Formulation

details are in Table 1 (Delsym is the commercial suspension).

Liquid oral sustained release formulation 975

2012 Informa Healthcare USA, Inc.

of the chitosan in the acidic pH before forming the com-

plex. Tis explains the synergistic efect of calcium and

chitosan in induction of in situ gelation of alginate.

Drug release pattern from dierent in situ gelling

systems

Te release pattern of the drug is the true measure for

the in situ gelling capacity. Te release experiments were

designed to mimic the in vivo conditions. Tus the drug

release was initially monitored in simulated gastric pH

for 2 hours at the end of which the system was adjusted to

simulated intestinal pH (pH 6.8 for 4 hours and pH 7.4 for

another 2 hours). Tis design will monitor drug release

after in situ gellation in the gastric environment with an

investigation of the change in the release pattern after

gastric emptying. Te release profles of the drug from

diferent in situ gelling systems are shown in Figures 4

and 5. Te calculated RE values are presented in Table 1.

Te drug release profle from alginate-based in situ

gelling systems revealed a dependence of drug release on

the concentration of sodium alginate with the release rate

decreasing on increasing alginate concentration (Figure 4),

and Table 1). Te formulation containing 1% w/w alginate

(Formulation A1) showed very rapid release with more

than 63% of the labeled drug being released in the frst 5

minutes. Tis initial rapid release was followed by gradual

release in the rest of the acid phase to liberate more than

94%. Tis rapid release can be attributed to the weak gell-

ing capacity at low alginate concentration. Increasing the

concentration of alginate to 1.5 and 2% w/v (formulations

A1.5 and A2, respectively) resulted in signifcant (P < 0.05)

reduction in the drug release rate with the formulation

librating 55.3 and 40%, respectively of the labeled drug

in the gastric phase. However, both formulations librated

the rest of the labeled drug in the early stage after chang-

ing the pH to 6.8 (Figure 4). Tese results indicate that

the in situ gelling alginate can control drug release in the

stomach only but liberate all the entrapped drug very

shortly after gastric emptying. Tis is further evidenced by

calculating the RE in the gastric and intestinal phase. Te

recorded RE values in the gastric phase were 79.6, 33.5 and

33.1% for A1, A1.5 and A2, respectively. Te later two val-

ues were signifcantly lower (P < 0.05) than that obtained

with A1. In the intestinal phase the RE values were 99.9,

98.9 and 83.1% for A1, A1.5 and A2, respectively (Table 1).

Te release pattern in the gastric phase showed a better

ft to Higuchi release kinetics (Table 2). Similar release

pattern was recorded for alginate-based systems

9

. Higichi

Figure 2. Photomicrographs of the gel formed after incubation of diferent in situ gelling systems in 100 ml of simulated gastric fuid (pH

1.2) at 37C for 24 hours. Formulation details are in Table1.

976 G. M. El Maghraby et al.

Drug Development and Industrial Pharmacy

equation was not applied to alginate based system in the

intestinal phase as the gel dissolved completely shortly

after changing the pH to 6.8. Te reduction in the release

rate after increasing the concentration of alginate can be

attributed to the relative increase in the gelling capacity

and gelling strength. Further increase in alginate was not

possible due to reduced fuidity.

Te failure of pure alginate-based in situ gelling

system to control the release of the drug after gastric

emptying refects the possibility of dose dumping after

administration of such system. Tis highlights the need

for improvement of such systems. To achieve this, the

current study was extended to investigate the efect of

combining chitosan with alginate-based system. Te

formulation containing the highest concentration of

alginate (A2) was selected for this purpose and chitosan

was incorporated at 0.5, 1 and 1.5% w/v (F1, F2 and F3,

respectively). Combination of chitosan with alginate-

based system resulted in a signifcant reduction in the

drug release rate compared to the alginate-based system

(A2). Tis reduction was apparent in the acid phase even

at the smallest tested chitosan concentration (F1) with

the drug release in the intestinal phase depending on

the concentration of chitosan (Figure 5). In the intestinal

phase the drug release reduced gradually with increas-

ing the concentration of chitosan. Te RE was signif-

cantly reduced (P < 0.05) in the intestinal phase in case

of F3 which comprised 1.5% w/v chitosan in combina-

tion with 2% w/v alginate. Te kinetics of drug release

were shown to follow Higuchi matrix difusion system

(Table 2). Tis is expected taking into consideration the

in situ gellation which results in a matrix like network

structure through which the drug has to difuse. Tese

data highlighted the potential of F3 as sustained release

liquid oral system. Accordingly, this formulation was

compared to the marketed product (Delsym) which is an

ion exchange resin based liquid oral sustained release

system of the same drug. Te release profle of the mar-

keted product was conducted at the same experimental

conditions. Te recorded data revealed slow drug release

both in the gastric and intestinal phases (Figure 5 and

Figure 3. Efect of the composition of the in situ gelling systems

on the weight of the gel formed after incubation of the solutions in

0.1 N HCl for 24 hours at 37C. Formulation details are in Table 1.

Figure 4. In vitro release profles of dextromethorphan

hydrobromide from in situ gelling alginate solutions; A1, A1.5

and A2. Release was conducted in simulated gastric fuid, pH 1.2,

for of 2 hours and subsequently in simulated intestinal fuid (pH

6.8, for 4 hours and pH 7.4 for 2 hours). Formulation details are

in Table 1.

Figure 5. In vitro release profles of dextromethorphan

hydrobromide from in situ gelling alginate and alginate-chitosan

based systems and the marketed product (Delsym). Release was

conducted in simulated gastric fuid, pH 1.2, for of 2 hours and

subsequently in simulated intestinal fuid (pH 6.8, for 4 hours and

pH 7.4 for 2 hours). Formulation details are in Table 1.

Liquid oral sustained release formulation 977

2012 Informa Healthcare USA, Inc.

Table 1). Te RE values were 5.2 and 20.3% as compared

from 16.9 and 32.8% which were recorded from F3 in

the gastric and intestinal phases respectively. Te kinet-

ics of drug release from the marketed product followed

zero order kinetics which is expected due to absence of

difusion with the ion exchange resin acting as a depot

providing slow but continuous drug release. Overall the

developed liquid formulation (F3) is simple and can be

a promising substitute for liquid oral sustained release.

Te recorded slow release pattern after combination of

chitosan with the alginate-based system may be further

explained on the bases of increased retention of the gel

in the intestinal environment. Considering the tested in

situ gelling system in absence and presence of chitosan

it is important to emphasize that alginate-based systems

(A1, A1.5 and A2) failed to retain the gel structure in

the intestinal environment. A1 dissolved in the frst few

minutes of the intestinal phase but A1.5 disintegrated

initially and dissolved shortly after that. For A2 which

contained the highest alginate concentration, the gel

eroded gradually before complete disappearance 1.5

hours after adjusting the pH to the intestinal condi-

tion. Incorporation of chitosan increased the intestinal

retention of the gel. At low chitosan concentration (F1)

the gel showed gradual erosion in the frst 2 hours of the

intestinal phase before being disintegrated into small

pieces. Te erosion was slower in formulations contain-

ing higher chitosan concentration with F3 preserving

the intact gel structure throughout the intestinal phase.

F3 retained more than 50% of its size at the end of the

dissolution experiment. Tese results indicate that the

combination of chitosan at optimum concentration with

alginate system can improve the intestinal retention of

the gel. Tis will exclude any possibility of dose dump-

ing and will guarantee sustained drug release before and

after gastric emptying.

Pure chitosan dispersion, 2% w/v (CH2) failed to pro-

vide signifcant control for the drug release with more

than 53% of the drug being liberated in the frst 5 minutes

in the acid phase. Te amount of drug released exceeded

75% at the end of the gastric phase. Te rest of the drug

was rapidly released during the early stage of the intestinal

phase. Tis is clear from the RE values which were 71 and

91.1% in the gastric and intestinal phases respectively

(Table 1). Tese results clearly support the synergistic

efect between chitosan and alginate. Tis synergism can

be attributed to the formation of polyelectrolyte complex

between the carboxylic group of alginate and the amino

group of chitosan. Tis synergism was widely employed

to develop solid controlled release particles. Tese sys-

tems depended mainly on cross-linking of alginate fol-

lowed by coating the beads with chitosan

12,1719

.

Conclusion

Tis study introduced alginate-chitosan based in situ

gelling system as a promising liquid oral sustained

release system for easy administration of dextrometho-

rphan for elderly and child patients. Tis system

employed the complexation process between alginate

and chitosan to sustain the drug release in the stomach

and intestine after gastric emptying. Such system will

thus reduce the possibility of dose dumping after gastric

emptying.

Acknowledgments

Te authors would like to thank Kng Abdulaziz City

for Science and Technology, Riyadh, Saudi Arabia and

SABIC Co., Saudi Arabia for funding the work with an

acknowledgement to Kayyali chair of pharmaceutical

industry for hosting the work.

Declaration of interest

Te authors report no declaration of interest. Tis work

was funded by SABIC Co, Saudi Arabia.

References

1. Dalal PS, Narurkar MM, (1991). In vitro and in vivo evaluation

of sustained release suspensions of ibuprofen. Int J Pharm,

73:157162.

Table 2. Te coefcient of variation (R

2

) obtained after ftting the drug release data to diferent kinetic models.

Formulation Phase

R

2

Zero order First order Higuchi

A1 Acid 0.783 0.744 0.902

Intestinal NA NA NA

A1.5 Acid 0.922 0.775 0.986

Intestinal 0.957 0.934 NA

A2 Acid 0.883 0.804 0.968

Intestinal 0.785 0.735 NA

F1 Acid 0.965 0.879 0.997

Intestinal 0.935 0.854 0.953

F2 Acid 0.969 0.888 0.998

Intestinal 0.933 0.838 0.963

F3 Both phases 0.963 0.826 0.986

Delsym Both phases 0.996 0.809 NA

978 G. M. El Maghraby et al.

Drug Development and Industrial Pharmacy

2. Emami J, Varshosaz J, Ahmadi F, (2007). Preparation and

evaluation of a liquid sustained-release drug delivery system for

theophylline using spray-drying technique. Research in Pharm

Sci, 2:111.

3. Shah KP, Chafetz L, (1994). Use of sparingly soluble salts to prepare

oral sustained release suspensions. Int J Pharm, 109:271281.

4. Zatz JL, Woodford DW, (1987). Prolonged release of

theophylline from aqueous suspensions. Drug Dev Ind Pharm,

13:21592178.

5. Katayama H, Nishimura T, Ochi S, Tsuruta Y, Yamazaki Y, Shibata

K et al. (1999). Sustained release liquid preparation using sodium

alginate for eradication of Helicobacter pyroli. Biol Pharm Bull,

22:5560.

6. Miyazaki S, Aoyama H, Kawasaki N, Kubo W, Attwood D. (1999). In

situ-gelling gellan formulations as vehicles for oral drug delivery. J

Control Release, 60:287295.

7. Miyazaki S, Kubo W, Attwood D. (2000). Oral sustained delivery of

theophylline using in-situ gelation of sodium alginate. J Control

Release, 67:275280.

8. Miyazaki S, Kawasaki N, Kubo W, Endo K, Attwood D. (2001).

Comparison of in situ gelling formulations for the oral delivery of

cimetidine. Int J Pharm, 220:161168.

9. Kubo W, Miyazaki S, Attwood D. (2003). Oral sustained delivery

of paracetamol from in situ-gelling gellan and sodium alginate

formulations. Int J Pharm, 258:5564.

10. Rohith G, Sridhar BK, Srinatha A. (2009). Floating drug delivery of

a locally acting H2-antagonist: An approach using an in situ gelling

liquid formulation. Acta Pharm, 59:345354.

11. Wang L, Khor E, Lim LY. (2001). Chitosan-alginate-CaCl(2) system

for membrane coat application. J Pharm Sci, 90:11341142.

12. Ribeiro AJ, Silva C, Ferreira D, Veiga F. (2005). Chitosan-reinforced

alginate microspheres obtained through the emulsifcation/

internal gelation technique. Eur J Pharm Sci, 25:3140.

13. Itoh K, Kubo W, Fujiwara M, Watanabe H, Miyazaki S, Attwood D.

(2006). Te infuence of gastric acidity and taste masking agent on

in situ gelling pectin formulations for oral sustained delivery of

acetaminophen. Biol Pharm Bull, 29:343347.

14. Khan KA. (1975). Te concept of dissolution efciency. J Pharm

Pharmacol, 27:4849.

15. Louhaichi MR, Jebali S, Loueslati MH, Adhoum N, Monser

L. (2009). Simultaneous determination of pseudoephdrine,

pheniramine, guaifenisin, pyrilamine, chlorpheniramine and

dextromethorphan in cough and cold medicines by high per-

formance liquid chromatography. Talanta, 78:991997.

16. Alanazi F, Li H, Halpern DS, ie S, Lu DR. (2003). Synthesis,

preformulation and liposomal formulation of cholesteryl carborane

esters with various fatty chains. Int J Pharm, 255:189197.

17. Murata Y, Miyamoto E, Kawashima S. (1996). Additive efect of

chondroitin sulfate and chitosan on drug release from calcium-

induced alginate gel beads. Int J Pharm, 138:101108.

18. Mi FL, Sung HW, Shyu SS, (2002). Drug release from chitosan-

alginate complex beads reinforced by a naturally occurring cross-

linking agent. Carbohydr Polym, 48:6172.

19. Wong TW, Chan LW, Kho SB, Sia Heng PW. (2002). Design of

controlled-release solid dosage forms of alginate and chitosan

using microwave. J Control Release, 84:99114.

Copyright of Drug Development & Industrial Pharmacy is the property of Taylor & Francis Ltd and its content

may not be copied or emailed to multiple sites or posted to a listserv without the copyright holder's express

written permission. However, users may print, download, or email articles for individual use.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Confectionery and Chocolate EngineeringDocument4 pagesConfectionery and Chocolate EngineeringArwa BaccoucheNo ratings yet

- Aerobic plate count pectin gel methodDocument1 pageAerobic plate count pectin gel methodAlvaro NAVARRONo ratings yet

- Self-Healing of Polymers Via Supramolecular ChemistryDocument19 pagesSelf-Healing of Polymers Via Supramolecular ChemistrySerena TorcasioNo ratings yet

- Meyco MP 301 PDFDocument2 pagesMeyco MP 301 PDFFrancois-No ratings yet

- Fundamentals of Food TechnologyDocument153 pagesFundamentals of Food TechnologySumit Thakur50% (2)

- Functional Properties of ProteinsDocument19 pagesFunctional Properties of ProteinsarjunikaNo ratings yet

- Lab Manual 3 CPB 30103 Biochemical Engineering Experiment 3Document5 pagesLab Manual 3 CPB 30103 Biochemical Engineering Experiment 3tusen krishNo ratings yet

- Theoretical Description of Hydrogel Swelling A ReviewDocument25 pagesTheoretical Description of Hydrogel Swelling A ReviewJair Fajrdo LopezNo ratings yet

- Foods As Dispersed Systems. Thermodynamic Aspects of Composition-Property Relationships in Formulated FoodDocument14 pagesFoods As Dispersed Systems. Thermodynamic Aspects of Composition-Property Relationships in Formulated FoodMichael AbdulaiNo ratings yet

- Difco ManualDocument860 pagesDifco ManualArpit BhargavaNo ratings yet

- Rheologic and Physicochemical Properties Used To 11 Cópia 2Document14 pagesRheologic and Physicochemical Properties Used To 11 Cópia 2Thaís SagratzhiNo ratings yet

- Thibault Bertrand, Jorge Peixinho, Shomeek Mukhopadhyay, and Christopher W. MacMinn, Dynamics of Swelling and Drying in A Spherical Gel PDFDocument20 pagesThibault Bertrand, Jorge Peixinho, Shomeek Mukhopadhyay, and Christopher W. MacMinn, Dynamics of Swelling and Drying in A Spherical Gel PDFvicenteNo ratings yet

- Purolite C100Document1 pagePurolite C100hamid vahedil larijaniNo ratings yet

- c23 PDFDocument15 pagesc23 PDFAmit KochharNo ratings yet

- New Microsoft Office Word DocumentDocument3 pagesNew Microsoft Office Word DocumentRameshLoganathanNo ratings yet

- PCM and Hydration UnitsDocument64 pagesPCM and Hydration UnitsBabak Salimifard100% (3)

- Dry Eyes Drug TreatmentDocument3 pagesDry Eyes Drug Treatmentlu100% (1)

- IntroductionDocument29 pagesIntroductionanamendoza1868No ratings yet

- Alginate Hydrogel Delivers Tea Tree Oil MicroemulsionDocument9 pagesAlginate Hydrogel Delivers Tea Tree Oil MicroemulsionmoazrilNo ratings yet

- Radiation crosslinking of polyamide 610 enhances mechanical propertiesDocument4 pagesRadiation crosslinking of polyamide 610 enhances mechanical propertiesecclesiNo ratings yet

- Mastics, Glues For Marble, Granite, StoneDocument6 pagesMastics, Glues For Marble, Granite, StoneNaveen GuptaNo ratings yet

- Pipeline PigsDocument7 pagesPipeline PigsnadNo ratings yet

- Ahmed Et Al, 2020Document14 pagesAhmed Et Al, 2020SABRINA SAL SABILLANo ratings yet

- Phys Chem Chem Phys 2010 12 10365-10372Document8 pagesPhys Chem Chem Phys 2010 12 10365-10372Dulce BaezaNo ratings yet

- Selecting TEMA Heat Exchangers - Alfa LavalDocument2 pagesSelecting TEMA Heat Exchangers - Alfa Lavaldie_1No ratings yet

- NPTEL Solid Catalyst ComponentsDocument254 pagesNPTEL Solid Catalyst Componentsjeas grejoyNo ratings yet

- Confectionery Gum and Jelly Products PectinsDocument31 pagesConfectionery Gum and Jelly Products PectinsercanefeogluNo ratings yet

- American Fireworks News Sept 2015Document14 pagesAmerican Fireworks News Sept 2015Saravana Prabhu SeenivasaganNo ratings yet

- Polymer Flooding: An Overview of Mobility Control and Viscosity BuildingDocument293 pagesPolymer Flooding: An Overview of Mobility Control and Viscosity BuildingoreNo ratings yet

- Silica Gel Technology For Tailor-Made Matting AgentsDocument4 pagesSilica Gel Technology For Tailor-Made Matting AgentsNez ArdenioNo ratings yet