Professional Documents

Culture Documents

Shear Force

Uploaded by

Muhamed Zaim0 ratings0% found this document useful (0 votes)

288 views9 pagessdsd

Original Title

shear force

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentsdsd

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

288 views9 pagesShear Force

Uploaded by

Muhamed Zaimsdsd

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 9

1

KMEM 1170: Mechanical Engineering Laboratory 1

Title: Shearing Force in Beams

Abstract:

The shearing force in beams experiment gives students a visualisation and proof of the basic theory of

shear force. This provides a sound foundation for further work. The experiments are quick, clear and

accurate, and ideal for students working on their own or in groups. The experiment was conducted by

the demonstrator. The demonstrator guided the groups with the procedure and the calculation method

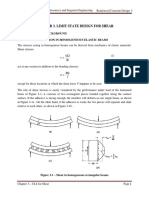

or technic. The experiment was set-up as figure A below. There are two parts of beam and support.

Left hand support and right hand support is placed 300mm and 600mm to the cut section respectively.

Hanger 1 and hanger 2 is positioned to the middle part of left and right part of beam respectively.

While, hanger 3 is placed on the groove near the cut section beam. The two balance springs is used to

adjust the bar until two halves are balanced and take the spring balance reading. Then 10N weight is

placed on hanger 2 and realign it. The reading of spring balance is recorded. Next, the step is repeated

with weight on hanger 3. After that, without any readjustment on the spring, hanger 3 is moved to the

left part beam(place the groove) and the condition is observed. 10N weights is transferred to hanger 1

and the situation is also observed. The steps is repeated by using 20N and 5N weight.

Figure A

2

Introduction

Shearing forces are unaligned forces pushing one part of a body in one direction, and another part of

the body in the opposite direction (William A. Nash, 1 July 1998). For this case, shear force is the

force in the beam acting perpendicular to its longitudinal x-axis. For design purposes, the beam ability

to resist shear force is more important than its ability to resist an axial force. Axial force is the force in

the beam acting parallel to the longitudinal axis. Moving loads on beams are common features of

design. Many road bridges are constructed from beam, and have to be designed to a string of wheel

loads, or a uniformly distributed load. A beam is a horizontal structural element that is capable of

withstanding load primarily by resisting bending The bending force induced into the material of the

beam as a result of the external loads, own weight, span and external reactions to these loads is called

a bending moment. If the ends of a beam are restrained longitudinally by its support or if a beam is a

component of a continuous frame, axial force may also develop. If the axial force is small, the typical

situation for most beams can be neglected when the member is designed. In the case, of reinforced

concrete beams, small values of axial compression actually produce a modest increase (on the order of

5 to 10 percents) in the flexural strength of the member. To design a beam, the engineer must

construct the shear and moment curves to determine the location and magnitude of the maximum

values of these forces. Except for short, heavily loaded beams whose dimensions are controlled by

shear requirements, the proportion of the cross section are determined by the magnitude of the

maximum moment in the span. After a section is sized at the point of maximum moment, the design is

completed by verifying that the shear stresses at the point of maximum shear usually adjacent to a

support are equal to or less than the allowable shear strength of the material. Finally, the deflection

produced by service loads must be checked to ensure that the member has adequate stiffness. Limits

on deflection are set by structural codes. To provide this information graphically, we construct shear

and moment curves. These curves, which preferably should be drawn to scale, consist of values of

shear and moment plotted as ordinates against distance along the axis of the beam. Although we can

construct shear and moment curves by cutting free bodies at intervals along the axis of a beam and

writing equation of equilibrium to establish the values of shear and moment at particular section, it is

much simpler to construct these curves from the basic relationships that exist between load, shear and

moment. The method of solving the problem is to use influence lines. An influence line shows the

variation of an external or internal force as a unit load travels across the length of the structure. For a

beam-type bridge structure, the internal force may be either a transverse shear force or bending

moment acting at some discrete location along the length of the bridge.

e.g of wood bridge.

3

Influence lines for truss bridges are commonly used to show the magnitude of the axial force acting in

a truss member as a unit load travels across the panel points of the bottom chord. Furthermore,

influence lines for the reaction forces at external support locations are employed in all bridge types to

determine the amount of load transferred to the bridge bearings. The two common methods for

constructing an influence line are through consideration of equilibrium or by applying the concept of

virtual work (i.e., the Mller- Breslau Principle). There are also Shear Force Diagram (SFD) that is to

indicates how a force applied perpendicular to the axis of a beam is transmitted along the length of

that beam. Also, Bending Moment Diagram (BMD) is to show how the applied loads to a beam create

a moment variation along the length of the beam. These diagrams are used to determine the normal

and shear stresses as well as deflection and slopes. At any point along its length, a beam can transmit

a bending moment M(x) and a shear force V(x). if a loaded beam is changed, the descriptions of a

positive distributed load, shear force and positive bending moment are as figure below.

Where scattered loads acts downward on the beam, internal shear force causes a clockwise rotation of

the beam section on which it acts, and the internal moment causes compression in the top fibers of the

segment, or to bend the segment so that it holds water.

Shear force and bending moment

4

Shear force at left of the section, S

c

= W ( L-a ) ..equation 1

L

Shear force at the right of the cut section, S

c

= -Wa equation 2

L

The shear force at the cut is equal to the algebraic sum of the force acting to the left or right of the

cut.

Objectives

To observe and recognise the action of a shear load in a beam.

To examine how shear force varies at the cut position of the beam for various loading

conditions and compare with the theoretical calculation.

To calculate the shear force at a normal part of loaded beam and to verify its agreement with

principle.

Results

Weight on Hanger / N Spring

force / N

Shear force / N

1 2 3 Experiment Theory

Ratio =

Theory

Experiment

0 0 0 3.5 0 0 0

0 10 0 5.0 1.5 3.33 0.45

0 0 10 9.5 6.0 6.67 0.90

0 20 0 9.5 6.0 6.67 0.90

5 5 5 7.0 3.5 9.17 0.38

5

6

7

8

Discussion

From the experiments done by our group, we found that, there is inconsistent difference between the

values of Experimental Shear Force and the Theoretical Shear Force. Referring to this results, we

conclude that the differences between the value of the experiment and theory was probably cause by

the mistake done by our group member when taking the value for the force when it was hang on the

beam. Also, parallax error occur and the spring balance is not in good condition. Some parts of the

spring balance is rust. The table where we conduct the experiment is slightly unbalanced.

a) When the load was doubled, did the shearing force double?

Yes, the shearing force is doubled.

b) How well did the experimental results agree with the theoretical values? Use the average of

the ratios experiment/theory.

For 10N on hanger 3 and 20N on hanger 2, the values of theory of shear force are almost the

same with the experimental values. Also, for 10N on hanger 2 and 5N on each of the hanger,

the theoritical values of shear force are higher than the experimental values. But the ratio for

10N on hanger 3 is near average. For 10N on hanger 3 and 20N on hanger 2, the ratio are

almost accurate and for 5N on each hanger the ratio is below average at 0.38.

Conclusion

From this experiment, our group managed to examine how shear force varies with an increasing point

load. We also managed to examine how shear force varies at the cut position of the beam for various

loading conditions. From the experiment, we know that the value for the experimental and theoretical

values is totally difference.

References

William A. Nash (1 July 1998). Schaum's Outline of Theory and Problems of Strength of Materials.

McGraw-Hill Professional. p. 82. ISBN 978-0-07-046617-3. Retrieved 20 May 2012.

Hibbeler, R.C. (2004). Mechanics of Materials. New Jersey USA: Pearson Education. p. 32

9

You might also like

- Section III - ShearDocument12 pagesSection III - ShearAlem LoajnerNo ratings yet

- Sidesway Web Buckling of Steel BeamsDocument12 pagesSidesway Web Buckling of Steel BeamsYuth Yuthdanai100% (1)

- Euler-Bernoulli Beam Theory - Wikipedia, The Free EncyclopediaDocument13 pagesEuler-Bernoulli Beam Theory - Wikipedia, The Free EncyclopediabmxengineeringNo ratings yet

- 5.transverse ShearDocument15 pages5.transverse ShearEden HazardNo ratings yet

- CIV6235 - Shear (MG)Document26 pagesCIV6235 - Shear (MG)friendycalls100% (1)

- rc-1 2015-16 Chapter Three 080116Document28 pagesrc-1 2015-16 Chapter Three 080116ABAMELANo ratings yet

- What Is Shear CenterDocument4 pagesWhat Is Shear CenterGidion TurualloNo ratings yet

- Plate Bending Theory and Governing EquationsDocument52 pagesPlate Bending Theory and Governing EquationsLeonardoMadeira11No ratings yet

- SFD & BMDDocument46 pagesSFD & BMDMominul Islam OpuNo ratings yet

- SAMPLE - Shear Force and Bending Moment Influence LinesDocument39 pagesSAMPLE - Shear Force and Bending Moment Influence LinesSammi YongNo ratings yet

- Reinforced Concrete Shear Design PrinciplesDocument27 pagesReinforced Concrete Shear Design PrinciplesFekadu DebelaNo ratings yet

- Design of Flat Slabs For PunchingDocument8 pagesDesign of Flat Slabs For PunchingAli Alskeif100% (1)

- Chapter 5: TorsionDocument106 pagesChapter 5: Torsionprabin gautamNo ratings yet

- Forces in Statically Determinate TrussDocument10 pagesForces in Statically Determinate TrussFarrukhNo ratings yet

- Materials Engineering: Pangasinan State University Urdaneta Campus Mechanical Engineering DepartmentDocument7 pagesMaterials Engineering: Pangasinan State University Urdaneta Campus Mechanical Engineering DepartmentiamjemahNo ratings yet

- Reinforced Concrete Slab DesignDocument29 pagesReinforced Concrete Slab DesignMapanguriSitoeNo ratings yet

- Deflection of BeamsDocument28 pagesDeflection of BeamsishwaryaNo ratings yet

- AD 262 - Unequal Angles and Lateral-Torsional BucklingDocument1 pageAD 262 - Unequal Angles and Lateral-Torsional Bucklingsymon ellimacNo ratings yet

- Chapter 7 PDFDocument16 pagesChapter 7 PDFgilbert850507No ratings yet

- (LECT-21,22) Prestressed Concrete SlabsDocument22 pages(LECT-21,22) Prestressed Concrete SlabsSushil MundelNo ratings yet

- Module 5.1 Influence Lines For Statically Indeterminate StructureDocument3 pagesModule 5.1 Influence Lines For Statically Indeterminate StructureEleonor Pacomios-VirtudazoNo ratings yet

- Timoshenko Beam TheoryDocument7 pagesTimoshenko Beam TheoryAmália EirezNo ratings yet

- Advanced Strength of Materials - GDLC - 8851 PDFDocument12 pagesAdvanced Strength of Materials - GDLC - 8851 PDFabdullahaafaq33% (3)

- Chapter 5Document49 pagesChapter 5ISRAEL HAILUNo ratings yet

- Introduction To Beams: Part ADocument49 pagesIntroduction To Beams: Part AMorad AJNo ratings yet

- Behviour of Box Girder BridgesDocument34 pagesBehviour of Box Girder BridgesChandra KumarNo ratings yet

- Introduction To Shell TheoryDocument45 pagesIntroduction To Shell TheorySurendraBhatta100% (1)

- Thin Wall BeamsDocument32 pagesThin Wall BeamsAllan Marbaniang100% (1)

- Statically Determinate Plane TrussDocument56 pagesStatically Determinate Plane Trussஅருண்ராஜ் கிருஷ்ணன்சாமிNo ratings yet

- How To Design To: Eurocode 2 (EC2)Document1 pageHow To Design To: Eurocode 2 (EC2)Delano KarismaNo ratings yet

- Two-Way Slab 3DDocument55 pagesTwo-Way Slab 3DNisarg SutharNo ratings yet

- Ocw RCD1 5eDocument19 pagesOcw RCD1 5eKousalya MkNo ratings yet

- Chapter 2 - Classification of Cross-SectionDocument20 pagesChapter 2 - Classification of Cross-SectionMuhd Zuhairi100% (2)

- Ce2404-Prestressed Concrete StructuresDocument1 pageCe2404-Prestressed Concrete StructuresDhivya RamachandranNo ratings yet

- Steel - 10-Prof. Zahid Siddiqi PDFDocument71 pagesSteel - 10-Prof. Zahid Siddiqi PDFMuhammad AhmedNo ratings yet

- CVS 325 - Chapter1Document24 pagesCVS 325 - Chapter1salt2009No ratings yet

- Shear Design of BeamDocument46 pagesShear Design of BeamNeha ChauhanNo ratings yet

- Timoshenko Beam TheoryDocument8 pagesTimoshenko Beam Theoryksheikh777No ratings yet

- Beams On Elastic FoundationDocument20 pagesBeams On Elastic FoundationShashi Bhushan KumarNo ratings yet

- Shear CenterDocument8 pagesShear CenterArun BattuNo ratings yet

- Computers and Structures: Hamdolah Behnam, J.S. Kuang, Bijan SamaliDocument17 pagesComputers and Structures: Hamdolah Behnam, J.S. Kuang, Bijan SamaliSayna KellenyNo ratings yet

- Experimental Tests and Numerical Modeling of Cellular Beams With Sinusoidal OpeningsDocument16 pagesExperimental Tests and Numerical Modeling of Cellular Beams With Sinusoidal OpeningscaesarNo ratings yet

- Influence LineDocument7 pagesInfluence Linemr_sam91No ratings yet

- Simply Supported Beam DesignDocument72 pagesSimply Supported Beam Designsiti Hawa100% (3)

- Lecture-Three Moment TheoremDocument17 pagesLecture-Three Moment TheoremIMJ JNo ratings yet

- LRB Non-LinearDocument24 pagesLRB Non-LinearGeEs AnggaNo ratings yet

- Chapter 7 COLUMNSDocument9 pagesChapter 7 COLUMNSPraveen Kumar RNo ratings yet

- Analyzing Indeterminate Beams Using Three Moment TheoremDocument16 pagesAnalyzing Indeterminate Beams Using Three Moment Theoremkalpanaadhi100% (1)

- Eurocodes for steel bridge designDocument118 pagesEurocodes for steel bridge designwearplayNo ratings yet

- PLASTIC ANALYSIS OF STRUCTURESDocument13 pagesPLASTIC ANALYSIS OF STRUCTURESAkshata Deshpande100% (1)

- ENCE 455 Design of Steel StructuresDocument6 pagesENCE 455 Design of Steel StructuresTooraj RoozkhoshNo ratings yet

- Important RCC Questions-Short and LongDocument15 pagesImportant RCC Questions-Short and LongmailjoelsamuelNo ratings yet

- Analytical Behavior of Concrete-Encased CFST Columns Under Cyclic Lateral Loading, 2016 (Wei-Wu Qian)Document15 pagesAnalytical Behavior of Concrete-Encased CFST Columns Under Cyclic Lateral Loading, 2016 (Wei-Wu Qian)Phan Đào Hoàng Hiệp100% (1)

- Lesson 5 C1 ArchDocument28 pagesLesson 5 C1 Archazerai2000No ratings yet

- Week 4 N 5 - Design of Rectangular Beam SectionDocument77 pagesWeek 4 N 5 - Design of Rectangular Beam SectionTeaMeeNo ratings yet

- Chapter Five, Torsion of BeamsDocument7 pagesChapter Five, Torsion of BeamsTemesgenAbiyNo ratings yet

- Lecture 2 - Steel SectionsDocument45 pagesLecture 2 - Steel Sectionsayoub aliousalahNo ratings yet

- Eccentric LoadDocument6 pagesEccentric LoadAtish Kumar100% (3)

- Celebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985From EverandCelebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985No ratings yet

- New Doc 2017-10-09 22.26.38-20171009222705Document1 pageNew Doc 2017-10-09 22.26.38-20171009222705Muhamed ZaimNo ratings yet

- Unique Selling PointDocument2 pagesUnique Selling PointMuhamed ZaimNo ratings yet

- Scope SisoDocument1 pageScope SisoMuhamed ZaimNo ratings yet

- SadDocument4 pagesSadMuhamed Zaim0% (1)

- Bahagian E Senarai RujukanDocument2 pagesBahagian E Senarai RujukanMuhamed ZaimNo ratings yet

- CL 2016 S1Document2 pagesCL 2016 S1Muhamed ZaimNo ratings yet

- Virtual Instrument: TitleDocument5 pagesVirtual Instrument: TitleMuhamed ZaimNo ratings yet

- Dewan 2Document1 pageDewan 2Muhamed ZaimNo ratings yet

- Cayle y HamiltonDocument5 pagesCayle y HamiltonerdoganaaaNo ratings yet

- Mech Eng Lab Reports 2013/14Document2 pagesMech Eng Lab Reports 2013/14Muhamed ZaimNo ratings yet

- JBWCKZDocument1 pageJBWCKZMuhamed ZaimNo ratings yet

- Part ADocument1 pagePart AMuhamed ZaimNo ratings yet

- Assigment 2Document1 pageAssigment 2Muhamed ZaimNo ratings yet

- SDDocument1 pageSDMuhamed ZaimNo ratings yet

- Bahagian B Bahan 1: Guide For Counsellors, Coaches, and Parents. Englewood Cliffs, NJ Prentice HallDocument3 pagesBahagian B Bahan 1: Guide For Counsellors, Coaches, and Parents. Englewood Cliffs, NJ Prentice HallMuhamed ZaimNo ratings yet

- Bullseye Coverage ErrorDocument1 pageBullseye Coverage ErrorMuhamed ZaimNo ratings yet

- a) π/12 b) z=1/√2 (1-i), z=1/√2 (-1+i), x=4/3, y=5/3: system has unique solution only)Document2 pagesa) π/12 b) z=1/√2 (1-i), z=1/√2 (-1+i), x=4/3, y=5/3: system has unique solution only)Muhamed ZaimNo ratings yet

- Group Assignment PDFDocument1 pageGroup Assignment PDFMuhamed ZaimNo ratings yet

- Rectangular Weir Flow CharacteristicsDocument4 pagesRectangular Weir Flow CharacteristicsMuhamed ZaimNo ratings yet

- Section13 4 PDFDocument8 pagesSection13 4 PDFMuhamed ZaimNo ratings yet

- KXEXDocument6 pagesKXEXMuhamed ZaimNo ratings yet

- Angle DebugDocument1 pageAngle DebugMuhamed ZaimNo ratings yet

- KMEM1170 Impact of Jet: Da N V V V D V T FDocument6 pagesKMEM1170 Impact of Jet: Da N V V V D V T FMuhamed ZaimNo ratings yet

- Tutor Request: Faculty of Engineering SEMESTER I, 2014/2015Document1 pageTutor Request: Faculty of Engineering SEMESTER I, 2014/2015Muhamed ZaimNo ratings yet

- Integration by Parts SolutionsDocument8 pagesIntegration by Parts SolutionsAnonymous yewQtGNo ratings yet

- Jagannath Drekkana AppliedDocument5 pagesJagannath Drekkana AppliedBrijMohanKaushikNo ratings yet

- Analytical ExpositionDocument13 pagesAnalytical Expositionulfatun azizahNo ratings yet

- 03 - Gee2 - WK9 - Analysis, Application and ExplorationDocument2 pages03 - Gee2 - WK9 - Analysis, Application and ExplorationAeri Shim NoonxrNo ratings yet

- Language, Dialect, and VarietiesDocument14 pagesLanguage, Dialect, and VarietiesTian Dini Agustina50% (2)

- Chapter-1: Research MethodologyDocument45 pagesChapter-1: Research MethodologyAntony AsnaNo ratings yet

- Recognition of Distorted Characters Printed On Metal Using Fuzzy Logic MethodsDocument6 pagesRecognition of Distorted Characters Printed On Metal Using Fuzzy Logic MethodsCrazyRichSapienNo ratings yet

- 75 Ways To Politely Interrupt A ConversationDocument5 pages75 Ways To Politely Interrupt A Conversationrevathy varatharajahNo ratings yet

- 2019 Contexts (Vol 44)Document40 pages2019 Contexts (Vol 44)Haffenreffer Museum of AnthropologyNo ratings yet

- PM620 Unit 4 DBDocument3 pagesPM620 Unit 4 DBmikeNo ratings yet

- 5-The Sigalovada Sutta Is Important As It Shows The Development of Buddhist Education OkDocument1 page5-The Sigalovada Sutta Is Important As It Shows The Development of Buddhist Education OkLong Shi0% (1)

- VARKDocument3 pagesVARKDavid AriasNo ratings yet

- Sc1a Assessment 1Document29 pagesSc1a Assessment 1api-435791379No ratings yet

- British AsiansDocument25 pagesBritish Asiansapi-267656109No ratings yet

- Secrets of SSBDocument19 pagesSecrets of SSBAtomyt0% (1)

- Music and BrainDocument158 pagesMusic and BrainEmma100% (1)

- The History of Inclusion in The United States: Chapter Three 1960-1968: Challenging Traditions in Special EducationDocument19 pagesThe History of Inclusion in The United States: Chapter Three 1960-1968: Challenging Traditions in Special EducationMariaIsabel BorreroNo ratings yet

- The Monastic LifeDocument7 pagesThe Monastic Lifesihastriaputnei9630No ratings yet

- Dictionary of The History of Ideas CrisisDocument41 pagesDictionary of The History of Ideas CrisisThais GonçalvesNo ratings yet

- Shree Satya Narayan Kath ADocument3 pagesShree Satya Narayan Kath Asomnathsingh_hydNo ratings yet

- Human Resources Conference Paper AbstractsDocument67 pagesHuman Resources Conference Paper Abstractssiddhartha venkata tNo ratings yet

- CHAPTER TWO Lady Mary Wortley Montagu's Sapphic VisionDocument24 pagesCHAPTER TWO Lady Mary Wortley Montagu's Sapphic VisionHeidy Gil MoraNo ratings yet

- Macbeth Sleep Walking SceneDocument2 pagesMacbeth Sleep Walking Scenebipradip sahaNo ratings yet

- Sico NotesDocument7 pagesSico NotesZhang KathyNo ratings yet

- Misuse of Domestic Violence Laws CaseDocument36 pagesMisuse of Domestic Violence Laws CaseLatest Laws Team100% (4)

- Teaching Methods and Principles ExplainedDocument25 pagesTeaching Methods and Principles Explainedlittle large2100% (1)

- Ucsp UPDATEDDocument173 pagesUcsp UPDATEDLJ PescaliaNo ratings yet

- Screen - Volume 23 Issue 3-4Document161 pagesScreen - Volume 23 Issue 3-4krishnqaisNo ratings yet

- Growing TogetherDocument187 pagesGrowing Togetherapi-154226943No ratings yet

- MSC 2014Document567 pagesMSC 2014Alexis Black0% (1)

- Future of UNO: An Analysis of Reforms to Strengthen the UNDocument4 pagesFuture of UNO: An Analysis of Reforms to Strengthen the UNPearl Zara33% (3)