Professional Documents

Culture Documents

Alginate Films Deliver Probiotic L. plantarum

Uploaded by

Boorin DbtOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Alginate Films Deliver Probiotic L. plantarum

Uploaded by

Boorin DbtCopyright:

Available Formats

Research Paper

Alginate Films Containing Viable Lactobacillus Plantarum: Preparation

and In Vitro Evaluation

Mariya I. Brachkova,

1

Aida Duarte,

1

and Joo F. Pinto

1,2,3

Received 15 September 2011; accepted 12 January 2012; published online 1 February 2012

Abstract. The objective of the study was to develop calcium alginate films, containing Lactobacillus

plantarum ATCC 8040 with preserved and stable viability and antibacterial activity. L. plantarum-loaded

films containing different calcium concentrations were physically characterized for mechanical and bio-

adhesive properties and lactobacilli release. The viability and antibacterial activity of L. plantarum was

studied before and after processing, and during 6 months of storage. A multiresistant clinical isolate, VIM-

2-metalo--lactamase producing Pseudomonas aeruginosa, was used as an indicator strain. Interference

between L. plantarum and films enhanced films elasticity, water absorption ability, release of lactobacilli,

and decreased films adherence. A decrease of L. plantarum viability in alginate films (1 log unit) was

observed after freeze drying. L. plantarum, at cell concentrations of 10

8

cfu/ml, was inhibitory active. The

viability and antibacterial activity of the immobilized lactobacilli remained stable during 6 months of

storage. The study has proved the potential of alginate films to deliver L. plantarum in high numbers to

individuals.

KEY WORDS: alginate film; antibacterial activity; bacterial viability; immobilization; lactobacilli.

INTRODUCTION

Lactobacilli are probiotic bacteria, considered as Generally

Recognized as Safe organisms (1), which when administered in

adequate amounts confer health benefit on the host (2). Appli-

cation of lactobacilli to replace pathogenic bacteria on skin and

mucosa is an attractive approach for prevention and treatment

of infections (3). Moreover, the use of lactobacilli could be of

particular interest for burn wound treatment (46). Burn

patients treated with Lactobacillus plantarum culture showed

the same recovery as patients treated with silver sulphadiazine,

suggesting that lactobacilli could be used for topical treatment of

burns (5). In addition, we have shown that alginate films loaded

with L. plantarum have a large potential on prevention of burn

wound infections (6). The development of such an application

however, depends strongly on the preservation technologies

applied in the processing of bacteria.

Consequently, the aim of the present study was to opti-

mize the technological conditions in the production of alginate

films containing L. plantarum with preserved and stable via-

bility and antibacterial activity, suitable for topical application.

L. plantarum ATCC 8014 was chosen among lactobacilli

strains based on its activity against multi-resistant clinical iso-

lates including Pseudomonas aeruginosa, Staphylococcus au-

reus, Enterococcus faecalis, Escherichia coli, and Klebsiella

pneumoniae (7) and on its ability to withstand adverse con-

ditions during processing into delivery systems (8). AVIM-2-

metalo--lactamase producing P. aeruginosa FFUL 1396 (6)

was used as an indicator strain. P. aeruginosa is a prevalent

organism in burn patients, resulting in severe complications

due to its high frequency of antibiotic resistance (9). Calcium

alginate was chosen to design the delivery system of L. plan-

tarum as a polymer widely used in burn wound treatment due

to its haemostatic, gel-forming and granulation-encouraging

properties (10). Moreover, according to our earlier experi-

ments (7), lactobacilli immobilization in alginate beads was

favorable in preservation of viable and antibacterially active

lactobacilli.

MATERIALS AND METHODS

Materials

Glycerol, sodium chloride, and calcium chloride (Sigma-

Aldrich, Chemie, Germany), disodium hydrogen phosphate

and potassium dihydrogen phosphate (Pancreac, Barcelona,

Spain), ethylenediaminetetraacetic acid (EDTA, Merck,

Darmstadt, Germany), sodium alginate (Protanal LF 10/60,

FMC BioPolymer, Drammen, Norway), de ManRogosa

Sharpe agar and broth (MRS), and Cetrimide agar (Biokar

Diagnostics, France) were used.

1

i-Med.UL Research Institute for Medicines and Pharmaceutical Sciences,

Faculdade de Farmcia da Universidade de Lisboa, Av. Prof. Gama

Pinto, P-1640-003 Lisbon, Portugal.

2

Dept. Farmcia Galnica e Tecnologia Farmacutica, Faculdade de

Farmcia da Universidade de Lisboa, Av. Prof. Gama Pinto, P-1640-

003 Lisbon, Portugal.

3

To whom correspondence should be addressed. (e-mail: jfpinto@ff.

ul.pt)

AAPS PharmSciTech, Vol. 13, No. 2, June 2012 (

#

2012)

DOI: 10.1208/s12249-012-9753-z

357 1530-9932/12/0200-0357/0 # 2012 American Association of Pharmaceutical Scientists

Methods

Bacterial Strains and Culture Conditions

L. plantarum ATCC 8040 was grown at 37C for 18 h on

MRS agar and in broth. AVIM-2-metalo--lactamase-produc-

ing P. aeruginosa FFUL 1396, isolated from abdominal wound

of a patient at a Central Hospital in Lisbon, was grown over-

night at 37C for 18 h on its selective agar medium Cetrimide.

The stock cultures produced at the maximum cell growth were

maintained at 80C in growth medium (0.850 ml) supple-

mented with glycerol (0.150 ml).

Preparation and In Vitro Evaluation of L. Plantarum-Loaded

Calcium Alginate Films

Preparation of L. plantarum-loaded calcium alginate

films. Sodium alginate (1 g) was dissolved in L. plantarum

overnight cultures (50 ml). Of the cellalginate suspension,

9.5 ml was poured into a Petri plate (5.5 cm diameter) con-

taining 3 ml of twofold-increasing CaCl

2

concentrations (0.05

12.8 M). The films were cured for 15 h at 4C in the calcium

solutions to reach steady-state equilibrium (11). Ellipse-

shaped films were obtained. The time of film formation was

recorded and film dimensions were measured with calipers

(Dias de Sousa, Portugal; Table I). As the method of prepa-

ration by pouring influences the films dimensions, film strips

(dimensions 3.22.20.5 cm) were cut out to obtain thickness

uniformity across the surface at different points of the film.

After curing, each film was incubated into MRS broth

(50 ml) at 37C/4 h to obtain proliferation of the entrapped

lactobacilli to the films surfaces (7). As we have observed

previously (7), both the alginate matrix and the effective net-

works by the mutual contact of surface and entrapped lacto-

bacilli promote high survival rates during freeze drying. Blank

films, containing only MRS broth and no lactobacilli, were

used as controls.

All types of films were frozen at 80C for 24 h and

dried under vacuum at room temperature, 0.035 mbar for

24 h (Christ Alpha 14, B. Braun Biotech International,

Germany). The films produced were kept over silica gel, at

4C, for a maximum period of 6 months. These films were

considered for further characterisation, including scanning

electron microscopy, films thickness, calcium content, water

absorption capacity, mechanical properties, bioadhesive prop-

erties, release of lactobacilli, and lactobacilli viability and

antibacterial activity (Table II).

Scanning electron microscopy. Samples from the lactoba-

cilli-loaded and blank films were mounted on metal stubs with

double-sided adhesive tape and coated with gold (JEOL JSM-

1200, Japan) under vacuum and 15 mA at room temperature.

The morphology of coated samples was examined by scanning

electron microscopy (JEOL JSM-5200 LV, Japan).

Calcium content. The calcium concentration in the films

is of paramount to their formation and physicochemical prop-

erties. Therefore, amount of calcium remaining in the film

provides information of the properties of the films. The calci-

um content in the prepared films was measured by atomic

absorption analysis (Perkin Elmer AAnalyst700, USA). A

series of standard calcium chloride solutions (0, 1, 2, 4, 6, 8,

and 10 mg/L) was prepared from 0, 0.5, 1, 2, 3, 4, and 5 ml

calcium stock solution (100 mg/L), 10 ml EDTA solution

(37.7 g/L), and deionized water up to 50 ml. Samples

(100 mg) from films were dissolved in sodium citrate solution

(1%, pH 6.0) and then diluted in EDTA solution (7.5 g/L) and

in deionised water. The calcium content in the samples was

determined by comparison with standard solutions.

Water absorption capacity. Films (dimensions 3.22.2

0.4 cm) were suspended in 50 ml of phosphate-buffered saline

(PBS; pH 7.4) at room temperature. PBS was prepared by

mixing of 1 ml of phosphate buffer (pH 7.5; 0.33 M) with 29 ml

of sodium chloride (9 g/L) and final pH adjustment. At spec-

ified time intervals (ranging between 1 min and 48 h, depend-

ing on the film), the films were taken out and the excess of

water removed carefully with filter paper, then weighed im-

mediately. The swelling percentage of the films was calculated

by the equation:

Ws Wd

Wd

100 1

where, Ws is the weight of the swollen sample and Wd is the

weight of the dry sample.

Mechanical properties. The mechanical properties of film

strips (3.22.20.4 cm) were measured using a texture analyzer

(TA.XT Plus, Stable Micro Systems, UK) equipped with a 5 kgf

(50 N) load cell and fit with a three-point bending rig appara-

tus. Film strips were hydrated for 5 min to allow comparison

between different films, and placed over the supports, posi-

tioned at a distance of 7 mm. The upper blade moved down

equidistant from the two lower supports at a speed of 3 mm/s.

The breaking force was measured and the tensile strength (12)

and Youngs modulus (13) were calculated as follows:

f

3Fl

2bd

2

2

E

Fl

3

4xd

3

b

3

Table I. Visual Inspection of the Forming Films (mean SD), Before Drying

CaCl

2

formation solution (M) 0.8 1.6 3.2 6.4 12.8

Time for film formation (h) 3 2.5 1 1 0.25

Film major and minor axis (mm) 42.50.7/47.41.2 43.41.3/46.01.9 43.31.2/46.01.3 43.01.3/45.01.5 43.01.2/45.01.3

Film thickness (mm) 5.230.26 5.080.19 5.080.19 4.650.19 4.350.15

358 Brachkova, Duarte and Pinto

where,

f

is the tensile stress at fracture, F is the load at

fracture, l is the distance between the supports, b is the film

width, d is the film depth, E is Youngs modulus, and is the

deflection at the midpoint.

Bioadhesive properties. The bioadhesive strength of the

films was evaluated according to Sezer et al. (14). The mea-

surement was conducted with a texture analyzer (TA.XT

Plus, Stable Micro Systems, UK) fit with a 50 N load cell

and bioadhesion test apparatus which included a cylindrical

Perspex probe. Chicken back skin was used as a model tissue,

after the removal of all fats and debris. The dermal tissue was

fitted on the bioadhesion test apparatus, and then 100 l of

demineralized water was applied on the surface of the tissue

prior to measurements at 37C. The film was cut into small

cylinders shape and attached to probe with double-sided ad-

hesive. The probe was lowered onto the surface of the tissue

with a constant speed of 1 mm/s and constant force of 1 N

applied. After keeping in contact for 30 s, the probe was then

moved vertically upwards at a constant speed of 1 mm/s.

Work of adhesion (Joules per square meter) and peak detach-

ment force (Newton per square meter) were calculated from

the force versus displacement graphic.

Release of lactobacilli. Samples of films (100 mg) were

placed into Falcon tubes (50 ml) containing 10 ml of PBS

(pH 7.4) and then placed into a shaking water bath at 37C

(20 osc/min). At specified time periods (10, 30, 60, 120, 270, 360,

and 600 min), 100 l from every test tube were withdrawn and

replaced with fresh PBS. Serial dilutions were made in sterile

water and plated in duplicate on MRS agar to allow counting of

lactobacilli released. Percentage of bacteria released was calcu-

lated frominitial filmloading (8.510

9

1.4110

8

cfu/g, 8.010

9

2.1210

8

and 8.010

9

2.8310

8

cfu/g for films obtained with

0.8, 1.6, and 3.2 M CaCl

2

, respectively).

Viability of lactobacilli. The lactobacilli viability was de-

termined before and after immobilization and freeze drying

and throughout 6 months of storage by the agar plate method.

Of the samples, 20 mg was collected from the center and the

periphery of films. These results were averaged for each

sample and then the mean and standard deviation calculated:

low standard deviation reflected little variation between the

center and the periphery of the film. Calcium alginate was

dissolved in sterile sodium citrate solution (1%, pH 6.0) fol-

lowed by serial dilutions made in sterile water and plated in

duplicate on MRS agar.

Antibacterial activity. Micro- and macrodilution broth

methods (7) were used to test the in vitro antibacterial activity

of L. plantarumbefore and after processing into calciumalginate

films and during 6 months of storage. L. plantarum at concen-

trations of 10

8

to 10

2

cfu/ml was co-incubated with P. aeruginosa

(10

5

cfu/ml). Samples were analyzed at 6, 8, 10, and 24 h to

determine the time necessary for the inhibition of P. aeruginosa.

Statistical analysis. Significance of results was found by

performing one-way ANOVA tests followed by a Tukey post

hoc test to the data (Statistical Package for Social Sciences,

SPSS Int. BV, USA, v.17.0).

T

a

b

l

e

I

I

.

P

h

y

s

i

c

a

l

C

h

a

r

a

c

t

e

r

i

s

t

i

c

s

o

f

C

a

l

c

i

u

m

A

l

g

i

n

a

t

e

F

i

l

m

s

(

m

e

a

n

S

D

)

,

A

f

t

e

r

D

r

y

i

n

g

C

a

C

I

2

f

o

r

m

a

t

i

o

n

s

o

l

u

t

i

o

n

[

M

]

F

i

l

m

c

a

l

c

i

u

m

c

o

n

t

e

n

t

(

m

M

)

T

h

i

c

k

n

e

s

s

(

m

m

)

S

w

e

l

l

i

n

g

r

a

t

i

o

C

r

u

s

h

i

n

g

f

o

r

c

e

(

N

)

T

e

n

s

i

l

e

s

t

r

e

n

g

t

h

(

1

0

3

N

/

m

2

)

Y

o

u

n

g

s

m

o

d

u

l

u

s

(

1

0

3

N

/

m

2

)

W

o

r

k

o

f

b

o

i

a

d

h

e

s

i

o

n

(

1

0

2

J

/

m

2

)

P

e

a

k

d

e

t

a

c

h

m

e

n

t

(

1

0

2

N

/

m

2

)

L

a

c

t

o

b

a

c

i

l

l

i

l

o

a

d

e

d

f

i

l

m

s

0

.

8

0

.

9

1

4

.

1

0

.

2

9

1

0

.

0

7

0

.

1

2

0

.

8

4

0

.

0

4

7

2

3

4

8

3

5

3

5

1

5

6

4

5

1

.

6

1

.

6

5

4

.

0

0

.

1

2

8

.

9

6

0

.

5

8

1

.

0

9

0

.

2

8

3

5

1

1

1

5

2

5

5

5

1

4

5

4

5

3

.

2

2

.

3

7

4

.

0

0

.

1

2

8

.

0

6

0

.

6

2

1

.

3

8

0

.

2

4

4

2

7

2

3

1

5

6

5

1

5

5

3

8

B

l

a

n

k

f

i

l

m

s

0

.

8

1

.

5

5

3

.

8

5

0

.

1

1

8

.

9

6

0

.

2

0

1

.

3

3

0

.

2

4

4

4

8

1

8

1

6

7

1

3

8

7

3

1

1

.

6

3

.

2

2

3

.

8

4

0

.

2

0

7

.

0

5

0

.

6

1

1

.

3

5

0

.

2

8

4

5

4

2

0

5

5

0

6

6

5

1

1

3

.

2

4

.

5

5

3

.

8

5

0

.

2

5

3

.

6

2

0

.

2

5

1

.

5

3

0

.

2

5

4

8

1

1

2

4

3

1

1

9

2

8

2

7

0

5

2

359 Delivery of L. Plantarum Immobilized in Films

RESULTS

The production of a film was observed with a minimal

calcium concentration of 0.8 M CaCl

2

. Below this value, films

did not show an adequate structure falling apart. On the other

hand, by increasing the concentration of calcium in the calci-

um chloride solution, the time for films formation decreased

(Table I) together with a smaller volume observed (before

freeze drying, Table I; and after freeze-drying, Table II).

The aqueous solution of CaCl

2

used in a concentration up

to 3.2 M did not affect significantly the L. plantarum viability.

However, high concentrations of CaCl

2

(6.4 M) led to a lack of

uniformity in L. plantarum viability, i.e., L. plantarum cell con-

centration in the periphery of the film (210

7

cfu/ml) was lower

compared to the cell concentration in the central part of the

films (810

8

cfu/ml; higher standard deviation bars; Fig. 1a,

immobilization) and to a viability decrease lower than the limit

of detection noted with 12.8 M CaCl

2

(Fig. 1a, immobilization).

Freeze drying resulted in a decrease of approximately 1 log unit:

from 4.710

9

to 2.410

8

cfu/ml (p=0.0382), 3.310

9

to 3.0

10

8

cfu/ml (p=0.0012), 1.810

9

to 3.010

8

cfu/ml (p<0.0001)

of L. plantarum viability in films obtained with 0.8, 1.6 and

3.2 M CaCl

2

, respectively. Stable viability of bacteria during

6 months of storage (monitored at 0, 3, and 6 months of

storage) was observed in the same films (4.710

9

to 5.5

10

9

cfu/g (p=0.5648), 5.910

9

to 1.410

9

cfu/g (p=0.1402),

5.910

9

to 2.710

9

cfu/g (p=0.1714); Fig. 1b).

Lactobacilli-loaded films were characterized by smooth

surface morphology, while blank films by rough (Fig. 2) with

no significant differences on their thicknesses. The calcium

content in films (Table II) was well below from the amount

applied in film formation in both blank and lactobacilli-loaded

films. The presence of lactobacilli led to a 1.70- to 1.95-fold

decrease of the calcium concentration compared to blank

films. The percentage of swelling of the lactobacilli-loaded

films (705.7906.6%) was significantly higher (p<0.0001) than

the swelling percentage of blank films (261.6795.6%). The

water absorption capacity increased significantly with the de-

crease of calcium content, i.e., the swelling percentage of the

lactobacilli-loaded films formed with low calcium concentra-

tion (0.8 M) was significantly greater than loaded films formed

with 1.6 M (p=0.0201) or 3.2 M (p=0.0052). By analogy,

significant differences in the swelling percentage were ob-

served among the blank films (p<0.01 to p<0.0001). The

tensile strength values of the lactobacilli-loaded films ranged

from 23 to 4210

3

N/m

2

(p=0.0625), whereas the blank films

showed smaller variations of the tensile strength values (44

4810

3

N/m

2

; p=0.8679). The presence of lactobacilli had a

significant effect on crushing force and tensile strength,

whereas the effect of the calcium content was only significant

when lactobacilli were present. Similarly, Youngs modulus

values in L. plantarum-loaded films ranged from 8 to 23

10

3

N/m

2

(p=0.0119) and showed smaller variation in blank

films (182410

3

N/m

2

; p=0.1751; Table II). The tensile

V

i

a

b

i

l

i

t

y

[

l

o

g

c

f

u

/

m

l

]

2

4

6

8

10

12

Overnight

culture MRS broth

Freeze Drying

2

4

6

8

10

12

Immobilization Incubation in

0 3 6

V

i

a

b

i

l

i

t

y

[

l

o

g

c

f

u

/

g

]

Time of storage [month]

Fig. 1. Viability of L. plantarum (mean and SD, n=3) in calcium alginate films obtained

with 0.8 M CaCl

2

(black bar), 1.6 M CaCl

2

(dashed black bar), 3.2 M CaCl

2

(gray bar), 6.4 M

CaCl

2

(dashed gray bar) and 12.8 M CaCl

2

(striped black bar) before and after processing a

and throughout 6 months of storage at 4C b

360 Brachkova, Duarte and Pinto

strength as well as the Youngs modulus of films obtained with

0.8 M calcium solutions differed significantly from films

obtained with 3.2 M solutions (p=0.0152) and from the

blank films. Thus, the increase of calcium content in films

was reflected by an increase in tensile strength and decrease

of elasticity of films. The films bioadhesion values ranged from

50 to 6710

2

J/m

2

, except with 3.2 M blank patch (119

10

2

J/m

2

) which was significantly different from the other

values (<0.0001; Table II). Significant differences were

observed for the force required to detach the patches.

Differences were dependent particularly on the presence of

lactobacilli.

The lactobacilli released in the first 10 min from 0.8 and

1.6 M films corresponded to 10

8

cfu/g (1.591.88%) vs. 10

7

cfu/g

(0.38%) released from the 3.2 M films. In 2 h, the released

lactobacilli from the three types of patch corresponded to

10

9

cfu/g (35.2%, 23.1%, and 18.1%, respectively). Of the

films, 0.8, 1.6, and 3.2 M released their total number of

lactobacilli as follows: 4, 8, and 10 h, respectively (Fig. 3).

The nonprocessed L. plantarum cultures were active

against P. aeruginosa at a cell concentration of 1.110

7

2.9

10

6

cfu/ml. After the immobilization of L. plantarum into

alginate freeze-dried films, as well as during storage, the

inhibition of P. aeruginosa was obtained by 6.210

7

5.410

7

L. plantarum cells/ml (p=0.1764). Inhibition of P. aeruginosa

was observed 8 h after its co-incubation with nonprocessed or

processed to films L. plantarum cultures.

DISCUSSION

When the cellalginate suspension was added to CaCl

2

solutions, calcium alginate films were formed. These gel sys-

tems evolved slowly with time because of cross-linking

reactions, taking place during the gel formation, proceeding

progressively from the surface to the interior (11). The in-

crease of calcium content reduced the time of film formation

and allowed the building of a stronger and more compacted

network (Table I). The observed decrease in film volume

could be due to network formation, characterized by higher

complexing between the carboxylate groups of the guluronate

monomers of alginate and the calcium cations, resulting in

reduced space occupied by alginate and therefore decreased

film volume (11).

Figure 1 shows the viability of L. plantarum during film

production and storage. The amount of calcium added to the

film was critical to both film formation and lactobacilli viability.

The higher the amounts of calcium, the higher the tensile

strength of the film but lower the number of viable bacteria.

Figure 1a shows that immobilization with high concentrated

Fig. 2. Photo of loaded film a and scanning electron photomicrographs of internal surface b

and L. plantarum loaded external c and internal d surface alginate films produced with 1.6M

CaCl

2

0

10

20

30

40

50

60

70

80

90

100

0 100 200 300 400 500 600

Time [minute]

L

.

p

l

a

n

t

a

r

u

m

r

e

l

e

a

s

e

(

%

)

Fig. 3. Release of lactobacilli from films (formed with 0.8 M;

1.6M; 3.2M CaCl

2

), represented as % as a function of time

361 Delivery of L. Plantarum Immobilized in Films

calciumsolutions (6.4 and 12.8 M) was reflected by a decrease in

the number of bacteria. The intracellular concentration of calci-

um in bacteria is tightly regulated ranging from 100 to 300 nM

(15), whereas the calcium concentration in bacterial growth

media can be approximately 20 M (16). Generally, extracellu-

lar calcium concentration higher than 10 mM is considered to be

toxic to cells (17). In the present study, the millimolar range of

calcium measured in the films (Table II), when higher than

4.55 mM, resulted in a decreased L. plantarum viability. The

hypertonic calcium solutions used in the film formation could

have provoked plasmolysis with the cytoplasmshrinking and the

plasma membrane contracting from the cell wall as a result of

internal water loss. Consequently, cells may survive and resume

growth if favorable conditions are found, as observed during

incubation in MRS broth of films formed with high concentrated

calcium solutions (6.4 and 12.8 M; Fig. 1a; 18).

Beside the influence on lactobacilli, the calcium concen-

tration may affect the proliferation of fibroblasts (19). It is

known that when applied to wounds, the calcium ions from the

calcium alginate fibers rapidly exchange with sodium ions

from the exudate and the release of free calcium ions provides

one of the essential factors in the clotting cascade. However,

the elevated release of calcium ions (6.712.8 mM) by wound

alginate dressings was found to inhibit the proliferation of

fibroblasts and to be partly responsible for a cytotoxic effect

on fibroblasts and epidermal cells in culture (19). The same

authors showed that alginate dressings with calcium content

up to 4 mM had the least cytotoxic effect andencouraged

quicker wound closure (19). The calcium content in the lacto-

bacilli loaded (0.912.37 mM) was in the recommended range.

The preservation of the films by freeze drying has shown a

decrease in L. plantarum viability of about 1 log unit. It must be

pointed out that films formed with calcium concentrations up to

3.2 M have shown the smallest decrease in numbers (1 order of

magnitude), whereas for higher calcium contents a significant

decrease was observed. Different survival rates in films during

freeze drying might be due to the different initial lactobacilli

concentration in films. In general, surviving fraction of the

microorganisms increases with the increasing biomass concen-

tration before freeze-drying, and this is attributed to the mutual

shielding effect of the microorganisms against the severe con-

ditions of the external medium (20). Furthermore, cellular dam-

age induced by the hypertonic calcium solutions could have

accumulated through the freezing and drying processes (21).

Once immobilization was carried out in the best con-

ditions, films were stable overtime (Fig. 1b). It means that

the process of drying was adequate to preserve the bacteria

and the calcium alginate with nutrients from the MRS

broth left after incubation provided a proper protection

to the lactobacilli.

The morphology of the films with and without lactobacilli

was quite different. Figure 2 shows the surfaces of blank and

loaded films. It might be due to the interaction between the

lactobacilli cells and the calcium alginate matrix. The rough

internal and external surfaces of films were transformed into

smooth surfaces during the proliferation of lactobacilli in cal-

cium alginate films. The proliferation of lactobacilli resulted in

a decrease of the calcium content in the films, which could be

due to production of lactic acid by the bacteria during incuba-

tion of films in MRS broth, which competes with the alginate

for calcium (22).

Measurement of calcium content in the films has shown

that a large part of calcium was not used in film formation

(amount applied versus amount quantified). A possible expla-

nation could be that the upper layers of the films (the first to

be formed) prevented calcium chloride to go underneath.

Velings and Mestdagh (11) described a parabolic distribution

in the calcium concentration in the calcium alginate gels,

which is higher on the surface of the gel that is in contact with

the formation solution than in the center of the gels.

A decrease of calcium in the network affected the phys-

ical properties of the films (Table II). For the same surfaces

(3.22.2 cm), the film strips have shown different thicknesses

showing clearly an increase in thickness when lactobacilli are

present. This suggests that the network is not so compact, as

for the blanks, derived from lower calcium content, as dis-

cussed. Furthermore, the creation of networks between lacto-

bacilli during their proliferation to the films surface could have

contributed to decreasing the films shrinkage during freeze

drying (7).The smaller compaction as a consequence increases

the absorption of water by the films: the blank films show a

larger range of swelling percentage (261.6795.6%) than load-

ed films (705.7906.6%). Results of the force at crush and the

tensile strength emphasize the effect of the presence of lacto-

bacilli. Whereas the blank strips show closer range of results

(not significantly different), for the loaded strips the largest

tensile strength almost doubles the smallest one. Still with the

mechanical properties of strips, the Youngs modulus shows

that blank strips are less elastic than the loaded ones. This

suggests that the network formed by the calcium alginate was

stronger and less elastic in the absence of lactobacilli. The

calcium content did also affect the release of lactobacilli from

films. Increased cross-linking density with calcium and the

consequent decrease of porosity (17) resulted in slower re-

lease of bacteria (Fig. 3). The lactobacilli were at both the

surface of strips and within the network (Fig. 2c, d). The

presence of surface lactobacilli explained the observed burst

effect: 0.32.5% of the total bacterial load was released im-

mediately after contact with PBS.

The adhesion between the loaded film and chicken skin

was reflected by the work of adhesion which was quite con-

stant for loaded strips whereas for blank strips it varied con-

siderably. The explanation must be formed at the surface of

the strips. Figure 2 clearly shows differences at the surface of

strips: loaded strips have a smooth surface covered with bac-

teria whereas the blank strips have rough surface. The asper-

ities observed might have increased the surface of contact

between the strip and the chickens skin in a non-anticipating

pattern. The force at detachment showed that loaded strips

required generally a larger force than blank strips. However,

the work of adhesion was smaller for loaded strips. It shows

that bacteria promoted an easier detachment of films under

tension, decreasing the adhesion work.

The inhibitory effect of L. plantarum ATCC 8040

against a VIM-2-metalo--lactamase producing P. aerugi-

nosa was studied in vitro. The results have shown that L.

plantarum cultures at high cell concentrations of 10

7

10

8

cfu/

ml before and after immobilization into calcium alginate

films were effective against the multiresistant P. aeruginosa.

The results showed that alginate films could be a suitable

matrix preserving both viability and antibacterial activity of

lactobacilli.

362 Brachkova, Duarte and Pinto

CONCLUSIONS

The study has confirmed the possibility of immobilization

of L. plantarum in calcium alginate films preserving the viability

and antibacterial activity of L. plantarum.

The study has demonstrated interference between L.

plantarum and the alginate films resulting in improved water

absorption capacity and film elasticity, quicker lactobacilli

release, and lower adherence. These properties could be ad-

vantageous in wound management, protecting the wound

from trauma, absorbing excessive exudate, promoting the de-

livery of lactobacilli to compete with pathogens, and prevent

infection.

Finally, films could be considered solid dosage forms

which are easier to handle and deliver to patients than the

starting cell cultures or other liquid dosage forms.

ACKNOWLEDGMENTS

This work was supported by a research grant fromFundao

para a Cincia e a Tecnologia, Portugal (SFRH/BD/17193/2004

and PEst-OE/SAU/UI4013/2011) and ADEIM.

REFERENCES

1. Singh S, Goswami P, Singh R, Heller KJ. Application of molec-

ular identification tools for Lactobacillus, with a focus on discrim-

ination between closely related species: a review. LWT-Food Sci

& Tech. 2009;42:44857.

2. FAO/WHO (Food and Agriculture Organization/World Health Or-

ganisation). Joint FAO/WHO Working Group Guidelines for the

Evaluation of Probiotics in Food. London, Ontario, Canada: 2002.

3. Falagas ME, Makris GC. Probiotic bacteria and biosurfactants

for nosocomial infection control: a hypothesis. J Hosp Infection.

2009;71:3016.

4. Valdez JC, Peral MC, Rachid M, Santana M, Perdigon G. Inter-

ference of Lactobacillus plantarum with Pseudomonas aeruginosa

in vitro and in infected burns: the potential use of probiotics in

wound treatment. Clin Microbiol Infect. 2005;11:4729.

5. Peral MC, Martinez MA, Valdez JC. Bacteriotherapy with Lac-

tobacillus plantarum in burns. Int Wound J. 2009;6:7381.

6. Brachkova M, Marques P, Rocha J, Sepodes B, Duarte MA,

Pinto JF. Alginate films containing Lactobacillus plantarum as

wound dressing for prevention of burn infection. J Hosp Infection.

2011;79:3757.

7. Brachkova MI, Duarte A, Pinto JF. Preservation of the viability

and antibacterial activity of Lactobacillus spp in calcium alginate

beads. Eur J Pharm Sci. 2010;41:58996.

8. Brachkova MI, Duarte A, Pinto JF. Evaluation of the viability of

Lactobacillus spp. after the production of different solid dosage

forms. J Pharm Sci. 2009;98:332939.

9. Estahbanati HK, Kashani PP, Ghanaatpisheh F. Frequency of

Pseudomonas aeruginosa serotypes in burn wound infections

and their resistance to antibiotics. Burns. 2002;28:3408.

10. Kneafsey B, O'Shaughnessy M, Condon KC. The use of calcium

alginate dressings in deep hand burns. Burns. 1996;22:403.

11. Velings NM, Mestdagh MM. Physico-chemical properties of algi-

nate gel beads. Polymer Gels and Networks. 1995;3:31130.

12. Davies PN, Newton JM. Mechanical strength. In: Alderborn

G, Nystrom C, editors. Pharmaceutical powder technology.

vol. 71. New York: Drugs and the Pharmaceutical Sciences;

1995. p. 16591.

13. Rowe RC, Roberts RJ. Mechanical properties. In: Alderborn G,

Nystrom C, editors. Pharmaceutical powder technology, vol. 71.

New York: Drugs and the Pharmaceutical Sciences; 1995. p. 283

322.

14. Sezer AD, Hatipolu F, Cevher E, Ourtan Z, Ba AL, Akbua

J. Chitosan film containing fucoidan as a wound dressing for

dermal burn healing: preparation and in vitro/in vivo evaluation.

AAPS Pharm Sci Tech. 2007;8(2):39. Article.

15. Dominguez DC. Calcium signalling in bacteria. Mol Microbiol.

2004;54:2917.

16. Rosch JZ, Sublett J, Gao G, Wang YD, Tuomanen EI. Calcium

efflux is essential for bacterial survival in the eukaryotic host. Mol

Microbiol. 2008;70:43544.

17. Wan LQ, Jiang J, Arnold DE, Guo E, Lu HH, Mow VC. Calcium

concentration effects on the mechanical and biochemical proper-

ties of chondrocyte-alginate constructs. Cell Mol Bioeng.

2008;1:95102.

18. Korber DR, Choi A, Wolfaardt GM, Caldwell DE. Bacterial

plasmolysis as a physical indicator of viability. Appl Environ

Microbiol. 1996;96:393947.

19. Suzuki Y, Nishimura Y, Tanihara M, Suzuki K, Kitahara AK,

Yamawaki Y, et al. development of alginate gel dressings. J Artif

Organs. 1998;1:2832.

20. Bozoglu TF, Ozilgen M, Bakir U. Survival kinetics of lactic acid

starter cultures during and after freeze drying. Enzyme Microbial

Technol. 1987;9:5317.

21. Souzu H. Basic aspects and industrial strategies for the preservation

of microorganisms by freezing and drying. In: Rey L, May JC,

editors. Freeze-drying/lyophilisation of pharmaceutical and biolog-

ical products, Vol. 137. New York: Drugs and the Pharmaceutical

Sciences; 2004. p. 23165.

22. Morin N, Bernier-Cardou M, Champagne CP. Production of

concentrated Lactococcus lactis subsp. cremoris suspensions

in cal cium al gi nate beads. Appl Environ Mi crobi ol.

1992;58:54550.

363 Delivery of L. Plantarum Immobilized in Films

You might also like

- 10.1007/s11947 014 1379 6Document9 pages10.1007/s11947 014 1379 6Mari Fei LagmayNo ratings yet

- A Novel Multiparameter in Vitro ModelDocument9 pagesA Novel Multiparameter in Vitro ModelthyNo ratings yet

- Chitosan and Guar Gum Composite FilmDocument5 pagesChitosan and Guar Gum Composite FilmMutiara Putri Utami SusantoNo ratings yet

- Silva 2013Document4 pagesSilva 2013capau87No ratings yet

- Setting Time Affects in Vitro Biological Properties of Root Canal SealersDocument4 pagesSetting Time Affects in Vitro Biological Properties of Root Canal SealersNunoGonçalvesNo ratings yet

- Microencap Lacto BileDocument10 pagesMicroencap Lacto BileNatalia Valentina Toledo AguilarNo ratings yet

- 10 3390@foods9091303Document12 pages10 3390@foods9091303aruna prasadNo ratings yet

- Cryopreservation of in Vitro-Grown Shoot Tips of Clinopodium Odorum Using Aluminium Cryo-PlatesDocument7 pagesCryopreservation of in Vitro-Grown Shoot Tips of Clinopodium Odorum Using Aluminium Cryo-PlatesRoger Barboza CastroNo ratings yet

- Plasticization of Zein Protein Studied Using Thermomechanical and Spectroscopy MethodsDocument5 pagesPlasticization of Zein Protein Studied Using Thermomechanical and Spectroscopy MethodsSabina BancilaNo ratings yet

- 08 AkibaiyoDocument5 pages08 AkibaiyoDeepak RajendranNo ratings yet

- Developmento of An Active Biodegradable Film Containing Tocopherol and Avocado Peel Extract-with-cover-page-V2Document9 pagesDevelopmento of An Active Biodegradable Film Containing Tocopherol and Avocado Peel Extract-with-cover-page-V2CESIA RAQUEL AVITIA CANONo ratings yet

- Binding and Uptake of Wheat Germ Agglutinin-Grafted PLGA-Nanospheres by Caco-2 MonolayersDocument7 pagesBinding and Uptake of Wheat Germ Agglutinin-Grafted PLGA-Nanospheres by Caco-2 MonolayerszeminkNo ratings yet

- Bone Reconstruction: Au Nanocomposite Bioglasses With Antibacterial PropertiesDocument9 pagesBone Reconstruction: Au Nanocomposite Bioglasses With Antibacterial PropertiesMaya HidiNo ratings yet

- Journal of Dental Research: Validation of An in Vitro Biofilm Model of Supragingival PlaqueDocument9 pagesJournal of Dental Research: Validation of An in Vitro Biofilm Model of Supragingival PlaqueJorge SaenzNo ratings yet

- Antimicrobial Properties of CMC Films on Mycotoxigenic AspergillusDocument6 pagesAntimicrobial Properties of CMC Films on Mycotoxigenic AspergillusSurya NegaraNo ratings yet

- 123Document6 pages123necboowatonNo ratings yet

- Biocompatibility of Graphene OxideDocument8 pagesBiocompatibility of Graphene OxidelpuresearchNo ratings yet

- Role of Plasmid in Production of Acetobacter Xylinum BiofilmsDocument4 pagesRole of Plasmid in Production of Acetobacter Xylinum BiofilmsShofiaNo ratings yet

- 2007mi 1Document2 pages2007mi 1KAKAWNo ratings yet

- Bacteriocin Production by Lactic Acid Bacteria Encapsulated in Calcium Alginate BeadsDocument8 pagesBacteriocin Production by Lactic Acid Bacteria Encapsulated in Calcium Alginate BeadsangelicaaragonNo ratings yet

- 2 Biological Properties of 3 Calcium Silicate-Based SealersDocument11 pages2 Biological Properties of 3 Calcium Silicate-Based SealersAndre ChangNo ratings yet

- Acidophilus ParticulaDocument6 pagesAcidophilus ParticulaMay MolinaNo ratings yet

- Effect of Minimal Processing On The Textural and Structural Properties of Fresh-Cut PearsDocument7 pagesEffect of Minimal Processing On The Textural and Structural Properties of Fresh-Cut PearsNeida SanabriaNo ratings yet

- Research Article: Biological Safety of Fish (Tilapia) CollagenDocument10 pagesResearch Article: Biological Safety of Fish (Tilapia) CollagenRadenSiwi Bagus HadhiningratNo ratings yet

- 1-S2.0-S0257897221002607-Main Ref. Chitosan+AuNpDocument7 pages1-S2.0-S0257897221002607-Main Ref. Chitosan+AuNplinuspaulingNo ratings yet

- 2021 Oct 14 STT47 Paper p.664-670Document7 pages2021 Oct 14 STT47 Paper p.664-670Pheeraphong BunroekNo ratings yet

- Application Note 360 DASboxDocument8 pagesApplication Note 360 DASboxWilliam Sousa SalvadorNo ratings yet

- Effect of Calcium on Guava StructureDocument5 pagesEffect of Calcium on Guava StructureTrang LêNo ratings yet

- Physico-Mechanical Properties of Chemically-Treated Bacterial Cellulose Membrane - George Et Al., 2005Document5 pagesPhysico-Mechanical Properties of Chemically-Treated Bacterial Cellulose Membrane - George Et Al., 2005Carinna SaldanaNo ratings yet

- Ultrafiltration of Aqueous Solutions Containing DextranDocument11 pagesUltrafiltration of Aqueous Solutions Containing DextranJulio TovarNo ratings yet

- البحث الأولDocument8 pagesالبحث الأولMostafa Shaker El AasserNo ratings yet

- Assessment of Cytotoxicity of Giomer On Human Gingival FibroblastsDocument6 pagesAssessment of Cytotoxicity of Giomer On Human Gingival FibroblastsRetta Gabriella PakpahanNo ratings yet

- Micro-encapsulation of Bifidobacterium lactis for soft foods and beveragesDocument6 pagesMicro-encapsulation of Bifidobacterium lactis for soft foods and beveragesArisbet SantisNo ratings yet

- Llama Palacios2019Document10 pagesLlama Palacios2019collin samuelNo ratings yet

- Research ArticleDocument8 pagesResearch ArticleGabriela SolanoNo ratings yet

- Sensors 09 00378Document8 pagesSensors 09 00378gpaivNo ratings yet

- Quality changes during frozen storage of blue shrimp (Litopenaeus stylirostris) with antioxidant, α-tocopherol, under different conditionsDocument7 pagesQuality changes during frozen storage of blue shrimp (Litopenaeus stylirostris) with antioxidant, α-tocopherol, under different conditionsRamzi SaeedNo ratings yet

- 98685-Article Text-259121-1-10-20131213Document8 pages98685-Article Text-259121-1-10-20131213Svetlana Khyn SeseNo ratings yet

- Bacillus PolyfermenticusDocument6 pagesBacillus Polyfermenticussi275No ratings yet

- ADocument11 pagesARichie JuNo ratings yet

- Antioxidant Potential of Gynura procumbens LeavesDocument11 pagesAntioxidant Potential of Gynura procumbens LeavesAbdul Rachman CholikNo ratings yet

- Conventional Scanning Electron Microscopy of Bacteria: Miloslav Kaláb, Ann-Fook Yang, Denise ChabotDocument20 pagesConventional Scanning Electron Microscopy of Bacteria: Miloslav Kaláb, Ann-Fook Yang, Denise ChabotpolychaetaNo ratings yet

- Articulo CientificoDocument7 pagesArticulo CientificoSalocinNo ratings yet

- Antiscalants Influence on RO Membrane BiofoulingDocument10 pagesAntiscalants Influence on RO Membrane BiofoulingCristina Pablos CarroNo ratings yet

- Gingger EdibleDocument6 pagesGingger EdibleIndah Nur FadhilahNo ratings yet

- FDA Advanced Oxidation Technology With PhotohydroionizationDocument6 pagesFDA Advanced Oxidation Technology With Photohydroionizationpattysaborio520No ratings yet

- Anti-Inflammatory and Osteogenic Effects of Calcium Silicate-Based Root Canal SealersDocument6 pagesAnti-Inflammatory and Osteogenic Effects of Calcium Silicate-Based Root Canal SealersÁbilson FabianiNo ratings yet

- 1 s2.0 S1991790220302324 MainDocument9 pages1 s2.0 S1991790220302324 MainBryan RamirezNo ratings yet

- Var WWW HTML CCT HTML Authors 3 3749 3749 2023-09-28 3 1695908592Document13 pagesVar WWW HTML CCT HTML Authors 3 3749 3749 2023-09-28 3 1695908592wjohn6182No ratings yet

- 2016 Aparece en 2018Document9 pages2016 Aparece en 2018Fy ChsNo ratings yet

- Valencia-Perez 2015 Con DOIDocument7 pagesValencia-Perez 2015 Con DOIImelevenNo ratings yet

- Thomasjohnson 1993Document11 pagesThomasjohnson 1993Anonymous PIlHE6tOENo ratings yet

- 41 Antimicrobial Effect of OzonatedDocument11 pages41 Antimicrobial Effect of OzonatedGabriel BrandiniNo ratings yet

- Cytotoxicity of GuttaFlow Bioseal, GuttaFlow2, MTA Fillapex, and AH Plus On Human Periodontal Ligament Stem CellsDocument7 pagesCytotoxicity of GuttaFlow Bioseal, GuttaFlow2, MTA Fillapex, and AH Plus On Human Periodontal Ligament Stem CellschristianNo ratings yet

- Isolation Characterization and Molecular Weight Determination of Collagen From Marine Sponge Spirastrella Inconstans (Dendy)Document8 pagesIsolation Characterization and Molecular Weight Determination of Collagen From Marine Sponge Spirastrella Inconstans (Dendy)Paulo JuniorNo ratings yet

- Food Control PDFDocument10 pagesFood Control PDFAtna AzaNo ratings yet

- Effect of Cryopreservation Protocols On The Phenotypic Stability of YeastDocument7 pagesEffect of Cryopreservation Protocols On The Phenotypic Stability of Yeastandrea galibay perezNo ratings yet

- Abstract 2Document8 pagesAbstract 2Beni PrasetyoNo ratings yet

- Packaging for Nonthermal Processing of FoodFrom EverandPackaging for Nonthermal Processing of FoodMelvin A. PascallNo ratings yet

- Aquaculture Ecosystems: Adaptability and SustainabilityFrom EverandAquaculture Ecosystems: Adaptability and SustainabilitySaleem MustafaNo ratings yet

- Propriedades Da Embalagem e Controle de L. Monocytogenes em Mortadela Por Filmes Celulósicos Incorporados Com PediocinaDocument10 pagesPropriedades Da Embalagem e Controle de L. Monocytogenes em Mortadela Por Filmes Celulósicos Incorporados Com PediocinaBoorin DbtNo ratings yet

- Kamile Nazan TurhanDocument5 pagesKamile Nazan TurhanBoorin DbtNo ratings yet

- Kamile Nazan TurhanDocument5 pagesKamile Nazan TurhanBoorin DbtNo ratings yet

- 16 21Document6 pages16 21Boorin DbtNo ratings yet

- 15 Chapter 4Document54 pages15 Chapter 4Boorin DbtNo ratings yet

- Microbial Cellulose As Support Material For The Immobilization of Denitrifying BacteriaDocument6 pagesMicrobial Cellulose As Support Material For The Immobilization of Denitrifying BacteriaBoorin DbtNo ratings yet

- Microbial Cellulose As Support Material For The Immobilization of Denitrifying BacteriaDocument6 pagesMicrobial Cellulose As Support Material For The Immobilization of Denitrifying BacteriaBoorin DbtNo ratings yet

- 066 LW Tensile Tester v2.0 PDFDocument4 pages066 LW Tensile Tester v2.0 PDFMarkusNo ratings yet

- IOM Paquetes DX Precedent RT-SVX22U-EN - 03072018Document82 pagesIOM Paquetes DX Precedent RT-SVX22U-EN - 03072018Mario Lozano100% (1)

- Oral Hygiene: Presented By: Anis Anis Andreas KyriakidisDocument60 pagesOral Hygiene: Presented By: Anis Anis Andreas Kyriakidislenami_91No ratings yet

- English Terms 1 Major Assessment Worksheet Answer KeyDocument29 pagesEnglish Terms 1 Major Assessment Worksheet Answer KeySamiNo ratings yet

- Is This Normal or ADHDDocument52 pagesIs This Normal or ADHDDianaNo ratings yet

- Chemistry PropertiesDocument14 pagesChemistry PropertiesconchoNo ratings yet

- Alimak AustraliancontractminingDocument5 pagesAlimak AustraliancontractminingmanudemNo ratings yet

- BCTG Guide-Love in The Time of CholeraDocument21 pagesBCTG Guide-Love in The Time of CholeraBernard MasiphaNo ratings yet

- Renal Cortical CystDocument2 pagesRenal Cortical Cystra222j239No ratings yet

- Section 09 - Traction Electrification SystemDocument47 pagesSection 09 - Traction Electrification SystemAbu Monsur Ali100% (1)

- Outotec: Managing Talent Globally With Successfactors® SolutionsDocument3 pagesOutotec: Managing Talent Globally With Successfactors® SolutionsxandaniNo ratings yet

- Land Rover Range Rover Owners Manual 2007Document358 pagesLand Rover Range Rover Owners Manual 2007PetreCaracaleanu0% (1)

- University of Toronto Astronomy 101 Midterm Test QuestionsDocument6 pagesUniversity of Toronto Astronomy 101 Midterm Test QuestionsTrash RowzanNo ratings yet

- Environmental Law Handbook ExampleDocument20 pagesEnvironmental Law Handbook ExampleThomson Reuters Australia100% (5)

- Solving Problems Involving Kinds of Propotion StudentDocument18 pagesSolving Problems Involving Kinds of Propotion StudentJohn Daniel BerdosNo ratings yet

- Price List Grand I10 Nios DT 01.05.2022Document1 pagePrice List Grand I10 Nios DT 01.05.2022VijayNo ratings yet

- 74HCT259D 8-Bit Addressable Latch DATA SHEETDocument11 pages74HCT259D 8-Bit Addressable Latch DATA SHEETMarc BengtssonNo ratings yet

- 2G - 4G Network Module - Data Sheet - EnglishDocument8 pages2G - 4G Network Module - Data Sheet - EnglishbbwroNo ratings yet

- 2G Call FlowDocument71 pages2G Call Flowm191084No ratings yet

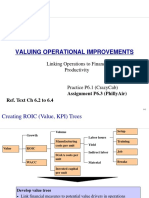

- 2 Linking Operations To Finance and ProductivityDocument14 pages2 Linking Operations To Finance and ProductivityAidan HonnoldNo ratings yet

- Curriculum Vitae of Masilo ModibaDocument11 pagesCurriculum Vitae of Masilo Modibalevy2011No ratings yet

- Estudio CarmenaDocument11 pagesEstudio CarmenaAlfredo BalcázarNo ratings yet

- TDS - RheoFIT 762Document2 pagesTDS - RheoFIT 762Alexi ALfred H. TagoNo ratings yet

- Water Demand Fire Flow Calculation Hydraulic ModelingDocument110 pagesWater Demand Fire Flow Calculation Hydraulic ModelingArthur DeiparineNo ratings yet

- Steam TurbineDocument25 pagesSteam TurbineIshan JunejaNo ratings yet

- Actividad 3.1B-Xport-Model-Exercises-SCMDocument5 pagesActividad 3.1B-Xport-Model-Exercises-SCMDante Rivera SalinasNo ratings yet

- IMG - 0092 PSME Code 2012 90Document1 pageIMG - 0092 PSME Code 2012 90Bugoy2023No ratings yet

- Lab 7 Activities Sheet Winter 2020Document7 pagesLab 7 Activities Sheet Winter 2020Mareline MendietaNo ratings yet

- TOEFL Module 1 - ReadingDocument65 pagesTOEFL Module 1 - ReadingImam NurviyantoNo ratings yet

- X Wing - Quick.referenceDocument6 pagesX Wing - Quick.referenceatilaT0RNo ratings yet