Professional Documents

Culture Documents

FTS004 Deep Fat Fryers

Uploaded by

Wissam JarmakCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FTS004 Deep Fat Fryers

Uploaded by

Wissam JarmakCopyright:

Available Formats

Fire Test Summary #004/DFF/MAR01

Page 1 of 3

HI-FOG systems for protection of Deep Fat Fryers

HI-FOG

Product KAU/SPU

18 Apr 2002

Fire test summary HI-FOG systems for protection of deep fat fryers.

Test standard

ISO 15371:2000 Ships and marine technology - Fire-extinguishing systems for protection of

galley deep-fat cooking equipment Fire tests

Summary

Twelve fire tests were conducted to evaluate the fire extinguishing capability of two different

HI-FOG systems for the fire protection of galley deep fat fryers. Both configurations, the selfcontained accumulator system and the pumped system, quickly extinguished the fires

without causing any splashing of oil, and hence met all the fire performance requirements of

the test standard.

Conclusions

The HI-FOG fire extinguishing systems, with the installation criteria below, were shown to

comply with the fire performance requirements set out in the ISO 15371 for fire-fighting

equipment for galley deep fat fryers.

Spray head OR

Sprinkler

4S 1FA 4FA/4FB 1000

2B 1MA 4FA/4FB 100E

Max vertical distance from fryer

1.35 m

Min vertical distance from fryer

1.0 m (spray head) / 1.2 m (sprinkler)

Spray head / sprinkler location

Centred between 2 vats, projecting vertically down

Water supply options:

1. Selfcontained system: Kitchen Accumulator Unit (KAU) with one 20 litre water

cylinder and one 10 or 20 litre nitrogen cylinder (nominally 200 bar), pipe size 12/

1.2 mm, pipe length 4 12 m

2. Pumped system: Fixed pressure pump, minimum 60 bar, maximum 140 bar at the

spray head or sprinkler

Marioff Corporation Oy reserves the right to revise and improve its products and recommended system configurations as it deems necessary without notification. The information contained herein is

intended to describe the state of Hi-fog products and system configurations at the time of its publication and may not reflect the product and/or system configurations at all times in the future.

HI-FOG

Fire Test Summary #004/DFF/MAR01

Page 2 of 3

1. Introduction

International Maritime Organisation (IMO) requires that galley deep fat cooking equipment on ships complying

with the SOLAS convention must be protected by a fire extinguishing system. The system requirements are specified

in MSC/Circ.800 that contains a draft new paragraph 9 to be added in SOLAS II-2/18. The fire-extinguishing systems

must be tested to an appropriate standard, like the ISO 15371. Systems meeting the requirements of this standard

are also suitable for protection of similar fryers in land-based installations.

Twelve fire extinguishing tests in accordance with ISO 15371 were conducted for two HI-FOG systems: for a selfcontained accumulator system and for a pumped system that may be a part of a larger fire protection system onboard

a ship.

2. Test arrangement

The tests were carried out in gesta, Sweden,

at a training facility of the Stockholm Fire Brigade.

The deep fat fryer used in the tests was representative of those encountered in shipboard

galley areas. The test fryer had two separate

vats about 4cm apart, each having a 240 mm

x 370 mm cooking surface area and a depth of

250mm. One vat was filled with oil in each test;

the other vat was filled with water up to the

same level. Figure 1 shows the test arrangement for an accumulator system.

Three tests were conducted for each system

as required by the standard:

- two extinguishing tests (at min and max nozzle distances, minimum discharge rate condition)

- one splash test (at the minimum nozzle distance, maximum discharge rate condition).

In total, four sets of tests were conducted. Prior

to each test, the fryer was cleaned and filled

with fresh oil. The oil was heated up to 363C

by which point it caught fire due to auto-ignition.

In the extinguishing tests, the ignited oil was

allowed to burn freely for 1 min with the heating source on. Then the heating source was

turned off and the extinguishing system was

manually activated. To pass the tests, the extinguishing system must (i) extinguish the fire

and (ii) prevent re-ignition for 20 minutes or

until the oil temperature is at least 34 C below

the observed auto-ignition temperature.

In the splash tests, the ignited oil was allowed

to burn freely for about 4 min till it stabilised,

after which the system was manually activated.

To pass the test, the extinguishing system must

(i) extinguish the fire and (ii) cause no splashing of grease.

Exit

to G

alley

Duct

s

Hoo

d

ryer

Fat F

Deep

4Pipe

Actu

ation

Valv

Pres

e

sure

Gau

ge

Shut

-off V

al

Wate

r

Cylin

12 m

ve

der

Gas

Cylin

der

Figure 1. A schematic presentation of the test arrangement.

HI-FOG

Fire Test Summary #004/DFF/MAR01

Page 3 of 3

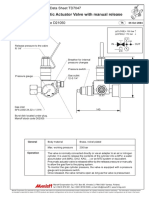

3. HI-FOG system

Two different HI-FOG systems, each with two slightly differing parameters, were tested. In each case a spray head

of type 4S 1FA 4FA/4FB 1000 was applied. Alternatively, a sprinkler head of type 2B 1MA 4FA/4FB 100D may be

used, as was verified in a worst-case test. The spray head was placed centrally above the fryer and projecting

vertically down.

Water was supplied to the spray head by the following systems:

1. Self-contained system:

Accumulator unit consisting of one 20 litre water cylinder and one 10 litre (System A) or 20 litre (System B) pressurised N2 cylinder (nominally 200 bar). Discharge pressure at the spray head is shown in figure

2. Pumped system:

Constant pressure pump supplying a pressure between 60 bar (System C) and 140 bar (System D) at the spray

head.

Pressure at spray

head (bar)

200

150

100

50

8

Time (min)

Figure 2. Self-contained system: Discharge pressure

4. Results

All the tests were passed: the fires were extinguished in less than 20 seconds, and the oil temperature decreased to

the required 34 C below the observed auto-ignition temperature in less than two minutes. No splashing was observed in the splash tests.

NOTE: The tests described form the basis for the relevant type approvals.

A complete description of the tests and their results are given in the

Test Report No. RTE1280/01, VTT Building and Transport, April 2001

Marioff Corporation Oy, P.O. Box 86, Virnatie 3, FIN-01301 Vantaa, Finland,

tel +358 9 870 851, fax +358 9 8708 5399, e-mail info@marioff.fi, www.hi-fog.com

You might also like

- Air Release Vacuum Breaker ValveDocument16 pagesAir Release Vacuum Breaker ValveLao Zhu100% (1)

- Hi Fog For HotelsDocument8 pagesHi Fog For HotelsJose ArroyoNo ratings yet

- Aksa Master Pricelist 2014Document1 pageAksa Master Pricelist 2014Wissam JarmakNo ratings yet

- 81 Co2man 001 - Print PDFDocument324 pages81 Co2man 001 - Print PDFLupiNo ratings yet

- Waterspray MistextinguishingsystemDocument10 pagesWaterspray MistextinguishingsystemSalley BukhariNo ratings yet

- Overhead Munck Cranes - Crane and Trolleys Own WeightDocument8 pagesOverhead Munck Cranes - Crane and Trolleys Own WeightWissam JarmakNo ratings yet

- Fts012 Gpu Us Light Hazard (FM)Document3 pagesFts012 Gpu Us Light Hazard (FM)Wissam JarmakNo ratings yet

- Tyco Water Curtain NozzleDocument2 pagesTyco Water Curtain NozzlejonejackrousseauNo ratings yet

- Hi-Fog For Buildings: Technical IntroductionDocument16 pagesHi-Fog For Buildings: Technical IntroductionEsther TapiaNo ratings yet

- ANSUL High Pressure Carbon Dioxide Systems ManualDocument248 pagesANSUL High Pressure Carbon Dioxide Systems ManualPablo SotoNo ratings yet

- Smoke Control in Malls PDFDocument4 pagesSmoke Control in Malls PDFmukeshsinghtomarNo ratings yet

- MANUAL IOMFES-iflow REV01 PDFDocument139 pagesMANUAL IOMFES-iflow REV01 PDFambition1340cnNo ratings yet

- Goulds Pump Selection GuideDocument24 pagesGoulds Pump Selection GuidecladonellNo ratings yet

- Technical Journal Fire PumpDocument7 pagesTechnical Journal Fire PumpIzallmachineNo ratings yet

- GUYER 2012 Introduction To Pumping Stations For Water Supply Systems PDFDocument42 pagesGUYER 2012 Introduction To Pumping Stations For Water Supply Systems PDFKaniz PriyangkaNo ratings yet

- FTS020 MT4 3300m3 Machinery SpacesDocument3 pagesFTS020 MT4 3300m3 Machinery SpacesWissam JarmakNo ratings yet

- Compressed Air Foam Outperforms Foam-Water SprinklersDocument34 pagesCompressed Air Foam Outperforms Foam-Water SprinklersDayanne MartinsNo ratings yet

- Review of Water Mist Tech for Fire SuppressionDocument93 pagesReview of Water Mist Tech for Fire Suppressiongambin888No ratings yet

- Gorbel PDFDocument42 pagesGorbel PDFWissam JarmakNo ratings yet

- Forward Osmosis - Principles, Applications, and Recent DevelopmentsDocument18 pagesForward Osmosis - Principles, Applications, and Recent DevelopmentsYuMdzaNo ratings yet

- 800291pricelist PDFDocument48 pages800291pricelist PDFWissam Jarmak100% (1)

- 800291pricelist PDFDocument48 pages800291pricelist PDFWissam Jarmak100% (1)

- Role of The Consulting Engineer in The Application of Water Mist SystemsDocument23 pagesRole of The Consulting Engineer in The Application of Water Mist Systemsershad7404No ratings yet

- FM200 Fire Suppression System: 1-1/2" BS 336 MaleDocument18 pagesFM200 Fire Suppression System: 1-1/2" BS 336 MaleSofiqNo ratings yet

- HI FOG For BuildingsDocument33 pagesHI FOG For BuildingsNuno RosaNo ratings yet

- Minimax BrochureDocument20 pagesMinimax BrochureDevieAgungNo ratings yet

- Firewater SystemDocument69 pagesFirewater SystemSyed HameedNo ratings yet

- R-FIR-DIOMM INEREX-GB-2015 02 UL 2015 05 17 KomprimiertDocument128 pagesR-FIR-DIOMM INEREX-GB-2015 02 UL 2015 05 17 Komprimiertthuan100% (1)

- PyroSim User Manual - Thunderhead Support PDFDocument138 pagesPyroSim User Manual - Thunderhead Support PDFJohnson ChuaNo ratings yet

- Pneumatic Actuator Valve With Manual Release: Hi-FogDocument1 pagePneumatic Actuator Valve With Manual Release: Hi-FogGutsavoNo ratings yet

- FTS001 Galley DuctsDocument3 pagesFTS001 Galley DuctsWissam JarmakNo ratings yet

- Fts042 Hi-Fog 2000 Hotel Rooms (CNPP)Document5 pagesFts042 Hi-Fog 2000 Hotel Rooms (CNPP)Wissam JarmakNo ratings yet

- NBR12313 (Inglês)Document27 pagesNBR12313 (Inglês)Marcos Dos Santos Vieira67% (3)

- Guidance Fuel Storage May08 PDFDocument35 pagesGuidance Fuel Storage May08 PDFWissam JarmakNo ratings yet

- DampersDocument7 pagesDampersPrasath SivaNo ratings yet

- Bermad Fire ProtectionDocument48 pagesBermad Fire ProtectionJay JayNo ratings yet

- PotterSprinkler CatalogDocument36 pagesPotterSprinkler CatalogSaleh Mohamed100% (1)

- Fire ProDocument104 pagesFire ProMaiger100% (2)

- Fans in Fire SafetyDocument58 pagesFans in Fire SafetyMohammed Majeed Ali100% (1)

- Performance-based smoke management system design for shopping mall atriumDocument12 pagesPerformance-based smoke management system design for shopping mall atriumShiva CivilenggNo ratings yet

- BurnerManagementSystems PresDocument12 pagesBurnerManagementSystems Presgisaelsa100% (1)

- Overview of Smoke Control System DesignDocument7 pagesOverview of Smoke Control System DesignTony GallacherNo ratings yet

- Guidance - Pressure Relief and Post Discharge Venting of Enclosures Protected by Gaseous Fire Fighting SystemsDocument25 pagesGuidance - Pressure Relief and Post Discharge Venting of Enclosures Protected by Gaseous Fire Fighting Systemsbetterone100% (1)

- Wet Chemical Deep Fat FryerDocument64 pagesWet Chemical Deep Fat FryerSergei KurpishNo ratings yet

- Portable Fire Extinguishers - : Part 7: Characteristics, Performance Requirements and Test MethodsDocument56 pagesPortable Fire Extinguishers - : Part 7: Characteristics, Performance Requirements and Test MethodsManan ChadhaNo ratings yet

- 6special Protection SystemDocument59 pages6special Protection SystemGurusumiNo ratings yet

- Fts034 Hi-Fog 2000 Us Light Hazard (FM)Document3 pagesFts034 Hi-Fog 2000 Us Light Hazard (FM)Wissam Jarmak100% (1)

- 2 FM200 ComponentsDocument40 pages2 FM200 ComponentsJose Antonio Lara0% (1)

- Nordtest Method NT Fire 049Document16 pagesNordtest Method NT Fire 049mail2021No ratings yet

- ANSUL R-102 Restaurant Fire Suppression System ManualDocument186 pagesANSUL R-102 Restaurant Fire Suppression System ManualGary AtenNo ratings yet

- Microsoft PowerPoint - 2. Design Inert Gas System - HDocument54 pagesMicrosoft PowerPoint - 2. Design Inert Gas System - HBidang KK3L Unit PLTP Gunung Salak100% (1)

- Mechanical Plan Review GuideDocument11 pagesMechanical Plan Review GuideEngelbert CasanovaNo ratings yet

- Online Enclosure Integrity Training PDFDocument6 pagesOnline Enclosure Integrity Training PDFsujiNo ratings yet

- LPCO2Document15 pagesLPCO2don timoNo ratings yet

- Vortex Inhibitor VortibreakDocument1 pageVortex Inhibitor VortibreakNabil RamehNo ratings yet

- 'Protecting Escape Routes - Smoke Shafts V Pressurisation' - Means of Escape - Fire Safety MagazineDocument6 pages'Protecting Escape Routes - Smoke Shafts V Pressurisation' - Means of Escape - Fire Safety MagazineAnonymous NGXdt2BxNo ratings yet

- Ansul R-102Document4 pagesAnsul R-102heliopintoNo ratings yet

- Fire Hydrant Equipment NAFFCODocument6 pagesFire Hydrant Equipment NAFFCOStanisclaus Kostka Rheyno ANo ratings yet

- Inbal - Deluge Valve Pressure Control 03 - 13 CR01Document4 pagesInbal - Deluge Valve Pressure Control 03 - 13 CR01gustavosalvatoNo ratings yet

- Clean Agent Suppression System Method of Statement PDFDocument3 pagesClean Agent Suppression System Method of Statement PDFKo ZayNo ratings yet

- Fike - Water Mist Design Machinery SpacesDocument6 pagesFike - Water Mist Design Machinery SpacesminiongskyNo ratings yet

- HydraulicDocument8 pagesHydraulicOsama OmayerNo ratings yet

- Sprinkcad (N1) Sprinkcad (Pro Ii) Sprinkcalc Sprinkcode Sprinkslic SprinkfdtDocument51 pagesSprinkcad (N1) Sprinkcad (Pro Ii) Sprinkcalc Sprinkcode Sprinkslic SprinkfdtJhoNo ratings yet

- Cla-Val: Fire Protection Pressure Relief ValveDocument2 pagesCla-Val: Fire Protection Pressure Relief ValveShoaib AhmedNo ratings yet

- FirePro Xtinguish V1.03Document99 pagesFirePro Xtinguish V1.03احمد الجزار2007100% (1)

- Fire Pump Compliance MatrixDocument5 pagesFire Pump Compliance Matrixshakil612No ratings yet

- TFP-315 Rociadores PDFDocument4 pagesTFP-315 Rociadores PDFJosue' GonzalezNo ratings yet

- Supplementary Specification To NFPA 750 Water Mist Fire Protection SystemsDocument25 pagesSupplementary Specification To NFPA 750 Water Mist Fire Protection SystemsMohamed MansourNo ratings yet

- Disel Pump Acceptance ReportDocument4 pagesDisel Pump Acceptance ReportNOMAN100% (1)

- Nfs2-8 Instal Manual WebDocument0 pagesNfs2-8 Instal Manual WebDota NgNo ratings yet

- Smoke Control: in Malls With Atria & RestaurantsDocument4 pagesSmoke Control: in Malls With Atria & RestaurantsRinaldyNo ratings yet

- Fees For ChildbirthDocument1 pageFees For ChildbirthWissam JarmakNo ratings yet

- PricelistDocument184 pagesPricelistWissam JarmakNo ratings yet

- 2016 WiloUSA ListPricing BuildingServices 0216Document52 pages2016 WiloUSA ListPricing BuildingServices 0216Wissam JarmakNo ratings yet

- FEM 2012 Price List Effective 1 Oct 2012 Version 10 With Service LevelsDocument21 pagesFEM 2012 Price List Effective 1 Oct 2012 Version 10 With Service LevelsWissam JarmakNo ratings yet

- Under Running Single Girder PDFDocument8 pagesUnder Running Single Girder PDFWissam JarmakNo ratings yet

- 1500 GPMDocument5 pages1500 GPMWissam JarmakNo ratings yet

- Kito Crane: End Carriage, Geared Motor, Peripheral EquipmentDocument40 pagesKito Crane: End Carriage, Geared Motor, Peripheral EquipmentVenu GopalNo ratings yet

- Sound AttenuatorsDocument10 pagesSound AttenuatorsArumugam MurugesanNo ratings yet

- Sound AttenuatorsDocument10 pagesSound AttenuatorsArumugam MurugesanNo ratings yet

- Regulators PDFDocument2 pagesRegulators PDFWissam JarmakNo ratings yet

- BAC MaintenanceVL MVLv10EN PDFDocument16 pagesBAC MaintenanceVL MVLv10EN PDFWissam JarmakNo ratings yet

- Crane Components: Technical CatalogueDocument30 pagesCrane Components: Technical CatalogueWissam JarmakNo ratings yet

- Crane Components: Technical CatalogueDocument30 pagesCrane Components: Technical CatalogueWissam JarmakNo ratings yet

- FIRE KiddeHoseReelsandCabinets PDFDocument48 pagesFIRE KiddeHoseReelsandCabinets PDFVaidya PanditNo ratings yet

- Leila Delivery MenuDocument5 pagesLeila Delivery MenuWissam JarmakNo ratings yet

- ABUS Overhead Cranes Design GuideDocument12 pagesABUS Overhead Cranes Design GuideCelestino LucioNo ratings yet

- Water Air Valve Lynx 3F RFPDocument4 pagesWater Air Valve Lynx 3F RFPWissam JarmakNo ratings yet

- Nominal Capacity Data: M100 RangeDocument1 pageNominal Capacity Data: M100 RangeWissam JarmakNo ratings yet

- 2 Session 1opening Speech by ITA COSUF Chairman Final2 CompatibiliteitsmodusDocument20 pages2 Session 1opening Speech by ITA COSUF Chairman Final2 CompatibiliteitsmodusWissam JarmakNo ratings yet