Professional Documents

Culture Documents

Impressed Current Anodes Summary

Uploaded by

Lawrence Osuvwe OfuokuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Impressed Current Anodes Summary

Uploaded by

Lawrence Osuvwe OfuokuCopyright:

Available Formats

IMPRESSED CURRENT ANODES

Types of groundbeds and anode applications

Shallow groundbed, horizontal

Anode material

Magnetite anodes

Shallow groundbed, vertical

Silicon iron anodes

Deep groundbed, open hole

Deep groundbed, closed hole

Mixed metal oxide anodes

Pt/Ti-Ta-Nb anodes

Offshore structures

Internal protection

Steel rebars in concrete

IMPRESSED CURRENT ANODES

Magnetite anodes

German Cathodic Protection

Document No.: 04-100-R1

Sheet: 1 of 5

Magnetite (Fe3O4) is a natural mineral with good

conductivity and a high degree of oxidation that

makes it resistant to corrosion even at high

temperatures. Careful alloying with other minerals

can produce anodes with excellent electrochemical

properties and mechanical strength.

The magnetite anode is casted in hollow cylindrical

forms to minimise weight and to facilitate cable-toanode connections at the centre of the anode. This

center cable-to-anode connection allows a uniform

current distribution at the anode surface.

The surface of the anode in the hollow centre is

lined with a layer of lead of optimum thickness and

length to ensure a highly reliable current conduction

between cable connector and anode.

The hollow annular space is filled with a dielectric

compound after the cable connection is made and

the ends of the anode are sealed with anode caps

to prevent ingress of foreign matter.

Special features:

operates at high current densities with extremely

low dissolution

not susceptible to ripple in DC supply

no limit on DC voltage output

light weight and easy to install, removable for

inspection and reinstallment

centre cable-to-anode connection for uniform

current distribution and consumption of anode

surface

Specific gravity

Brinell hardness

Bending strength

Density

Melting point

Consumption rate

Current density 1)

4.7 - 4.8 kg / dm3

344 HB

5 kN / cm2

4.71 g / cm3

1500 C

0.02 kg/A year

0.7 A/dm2

1) depends on environment

Conductive layer

Magnetite

Porous body

Compression sleeve

Centre connected spring

Resin filler

Anode cap

Cable

Highlights:

The magnetite anode performance has been tested for several years. Endusers, technical analysts and

independent research laboratories have regulary confirmed its reliability as an anode.

Quality and value additions:

independent series of examinations and selection of castings for the making of the anodes

experienced-based selection of anode caps and lead materials according to enduser specifications and

environmental conditions

impregnable anode cap connections with corrosion resistant material and special welding process

special electrical resistance and potential tests to confirm uniform current distribution without hot spots

controlled sealing of anode hollow annular space with special dielectric compound

a full range of accessories for easy installation, inspection and replacement according to enduser specified

requirements and environmental conditions

IMPRESSED CURRENT ANODES

Magnetite anodes

Document No.: 04-100-R1

Sheet: 2 of 5

German Cathodic Protection

TYPE: MA-U

Surrounding electrolyte:

Applications:

neutral soil and water without chlorine and sulphate content

shallow groundbeds, deep groundbeds

Diameter

Total length

Effective length

Total weight

Minimum effective mass

Surface area

Max. current load

60

720

670

6.0

4.7

13.4

3.0

mm

mm

mm

kg

kg

dm2

A

Diameter

Total length

Effective length

Total weight

Minimum effective mass

Surface area

Max. current load

60

760

710

6.0

4.7

13.4

6.0

mm

mm

mm

kg

kg

dm2

A

Diameter

Total length

Effective length

Total weight

Minnimum effective mass

Surface area

Max. current load

60

760

710

6.0

4.7

13.4

16.0

mm

mm

mm

kg

kg

dm2

A

60

740

600

6.2

4.7

11.3

6.0

16.0

mm

mm

mm

kg

kg

dm2

A

A

60

740

600

6.2

4.7

11.3

6.0

16.0

mm

mm

mm

kg

kg

dm2

A

A

TYPE: MA-CS

Surrounding electrolyte:

Applications:

chlorine and/or sulphate containing soil or stagnant water

shallow groundbeds, deep groundbeds

TYPE: MA-SEA

Surrounding electrolyte:

Applications:

flowing seawater or brackish water

platforms, jetties, harbours

TYPE: MA-CHAIN-1

Surrounding electrolyte:

Applications:

chlorine containing soil or stagnant water

deep groundbeds open hole, deep groundbeds closed hole, water tanks

Diameter

Total length

Effective length

Total weight

Minimum effective mass

Surface area

Max. current load (groundbeds)

Max. current load (tanks)

TYPE: MA-CHAIN-2

Surrounding electrolyte:

Applications:

chlorine containing soil or stagnant water

deep groundbeds open hole, deep groundbeds closed hole, water tanks

Diameter

Total length

Effective length

Total weight

Minimum effective mass

Surface area

Max. current load (groundbeds)

Max. current load (tanks)

IMPRESSED CURRENT ANODES

Magnetite anodes

Document No.: 04-100-R1

Sheet: 3 of 5

German Cathodic Protection

CANISTER FOR TYPE: MA-U + TYPE: MA-CS

COKE BACKFILL

Minimum carbon content

Maximum moisture content

Maximum resistivity

Density

Maximum particle size (dia.)

Standard canister

CAN 10

CAN 15

CAN 20

CAN 21

Diameter

160 mm

300 mm

300 mm

160 mm

Length

1000 mm

1500 mm

2000 mm

2100 mm

%

90

%

5

m

1

700-950 kg/m3

mm

20

Total weight

22 kg

85 kg

110 kg

46 kg

IMPRESSED CURRENT ANODES

Magnetite anodes

Document No.: 04-100-R1

Sheet: 4 of 5

German Cathodic Protection

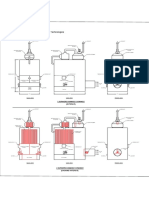

Type: MA-CHAIN-1

Maximum carrying load of fixing device up to 1.10 kN

Special type magnetite anode chains that can be used for

either open or closed hole deep well anode groundbeds.

Anode cable PVDF 1 x 10 mm2

to junction box

DETAIL -ATitanium wire

Heat shrinked cable

pulling grip

Heat shrinked tube

Anode cap: PVDF

As open hole anode groundbed they, can be used in

conjunction with non-conductive slotted casing without

backfill but they can also be used in close hole groundbeds

with coke backfill material in case of unstable or nonexisting static water level.

All parts of anodes, anode chains and suspension devices

are made of material resistant against low pH values,

high chloride content of water and high concentrations

of chlorine gas.

Each anode is centre connected to the cable using a

copper compression clamp and a bronze connection

spring. The internal space is filled with a two component

mixture of polyurethane and polyester.

Each anode chain has one individual lead cable connection

and is suspended by one heat shrinked cable pulling grip,

fixed to a titanium wire, ready for fixing on suspension

device inside groundbed head structure.

PVDF sintering

Magnetite anode

Head structure

Crash barrier

Anode junction box

Concrete foundation

Soil layer

Soil layer

Non-conductive casing

Water level

Perforated non-conductive

casing (Anode section)

DETAIL -AAnode cable,

termnated inside anode

junction box

Titanium wire wound twice

around the fixing device inside

groundbed head structure

Magnetite anode chain

IMPRESSED CURRENT ANODES

Magnetite anodes

German Cathodic Protection

Document No.: 04-100-R1

Sheet: 5 of 5

Type: MA-CHAIN-2

For carrying load of fixing device > 1.10 kN

Special type magnetite anode chains that can be used for

either open or closed hole deep well anode groundbeds.

Anode cable PVDF 1 x 10 mm2

to junction box

Anode chain suspension device

inside head structure

DETAIL -A-

Steel rope: PVDF insulated

As open hole anode groundbed, they can be used in

conjunction with non-conductive slotted casing without

backfill but they can also be used in close hole groundbeds

with coke backfill material in case of unstable or non

-existing static water level.

All parts of anodes, anode chains and suspension devices

are made of material resistant against low pH values,

high chloride content of water and high concentrations

of chlorine gas.

Each anode is centre connected to the cable using a

copper compression clamp and a bronze connection

spring. The internal space is filled with a two component

mixture of polyurethane and polyester.

Heat shrinked tube

Suspension clamp: PVDF

Anode cap: PVDF

Each anode chain has one individual lead cable connection

ready for fixing on suspension device inside groundbed

head structure.

PVDF sintering

Magnetite anode

Head structure

Crash barrier

Anode junction box

Concrete foundation

Soil layer

Soil layer

Non-conductive casing

DETAIL -A-

Water level

Perforated non-conductive

casing (Anode section)

Anode cables, terminated

inside anode junction box

Anode chain suspension

device

Magnetite anode chain

IMPRESSED CURRENT ANODES

Open hole replaceable deep groundbeds

German Cathodic Protection

Document No.: 04-500-R1

Sheet: 1 of 1

Accessories

uPVC Casing

Centraliser

for centralisation of casings in the

borehole during installation

Hoisting device with steel insert

for lifting and lowering the pipe sections

These casings withstand external pressure loading which is caused by

geological formation, the depth of the groundbed, the ratio of borehole

diameter to casing diameter and the position of dynamic water levels.

Perforated casings are provided with slots which run perpendicular to

the pipe axis for higher collapse resistance as compared to pipes having

longitudinal slots.

The perforated (open) casings have a minimum of 20 % slotted surface

for a low resistance increase factor.

Microfine PP wire mesh is durably fixed over the perforated area of

the casings to prevent entry by silt or foreign particles after installation.

Steel clamp

for fixing casing segments during

installation

Sealing plug

for the bottom end of the casing or

sump pipe

Both perforated and unperforated casing sections are supplied with

threaded joints which allow quick assembly on site.

Rigid uPVC is chemically resistant against all types of groundwater,

seawater, brines, diluted acids and alkalines.

Physical Material Properties

Properties

Elasticity Modulus

CHARPY-Impact Strength

at 20 C for uPVC;

normal toughness

Density

Tensile Strength

Impact Resistance

Value

2500 to 3000

Unit

N/mm2

Test method

DIN EN ISO 178

approx. 3 to 5

approx. 1.4

approx. 45 to 55

max.

10 % breakage

kJ/m2

g/cm3

N/mm2

DIN EN ISO 179

DIN 53479

DIN EN ISO 527-2

Following

DIN EN ISO 179

80

DIN EN ISO 306

Vicat Softening Point,

Temperature

Dimensions

Casing type

Nominal diameter ND (mm)

Outer diameter (mm)

Wall thickness (mm)

Outer diameter over socket (mm)

Collapse resistance (N/mm2)

Weight (kg/m)

Delivery length (m)

Thread (trapezoidal), DIN 4925

K

150

165

7.5

176

0.7

5.5

5.78

T

K

175

195

8.5

205

0.6

7.4

5.78

T

KV

175

195

11.5

211

1.6

9.8

5.78

T

K

200

225

10.0

241

0.7

10.0

5.78

T

KV

200

225

13.0

247

1.5

12.8

5.78

T

Wooden clamp

for fixing the casing to the top

foundation

IMPRESSED CURRENT ANODES

Open hole replaceable deep groundbeds

Document No.: 04-603-R1

Sheet: 1 of 1

Head structure, typical

German Cathodic Protection

Head structure with crash barrier for deep

groundbeds

The wellhead structure is designed for use in

combination with deep well anode groundbeds.

The square hollow steel structure is internally

coated with a special coating of PVDF to be

resistant against chlorine gas.

The wellhead structure consists of vent pipes, an

anode chain fixing device and a special conduit

connection between the wellhead and the anode

junction box (AJB) to prevent gas entering the

AJB.

The optional crash barrier protects the wellhead

structure against physical damage caused by

vehicles.

Crash barriers, cables, wooden clamps, steel surface

casing, uPVC casing and concrete foundations are

not as standard in of well head structure.

Structure specially designed for use in oilfields, etc.

Anode cables to junction box

Cable and conduit glands

Vent pipe, variable design depending on site conditions

Support axle carrier

Support steel axle inside PVDF pipe

as anode chain fixing device

Square hollow steel section with screwed steel plate

Vent pipe, variable design depending on site conditions

Profile steel 100 x 65 x 9 mm

Dowel

Wooden clamp for casing support

Concrete foundation

uPVC-casing

Steel surface casing

IMPRESSED CURRENT ANODES

Silicon iron anodes

German Cathodic Protection

Document No.: 04-200-R1

Sheet: 1 of 2

Silicon Iron anodes (Fe/Si) (Fe/Si/CR) (Fe/Si/Mo)

High Silicon Cast Iron anodes supplied with chemical

compositions according to ASTM A518 or BS 1591.

Applications

High Silicon Cast Iron anodes are widely used in

underground applications in shallow groundbeds.

Their performance can improved with coke backfill

breeze.

Standard type Fe/Si-anode

for use in neutral soil and freshwater environments.

Fe/Si/Cr and Fe/Si/Mo-anodes

for use in aggressive acidic or alkaline soil and

seawater environments.

Effectiveness of cast iron`s performance as an anode

depends upon the formation of a thin layer silicon

oxide on its surface. this protective film is formed

by oxidation.

Silicon-chromium cast iron is highly resistant to acid

solutions but has a better performance in alkaline

environments or in the presence of sulphate ions.

Fabrication

Each cast iron anode is normally provided with an

individual cable of varying length. Cast iron anodes

are provided in both end-connected and centreconnected configurations.

Following the anode-to-cable connection, the annular

space around the cable is filled with a high quality

electrical sealant. Heat shrinkable anode caps are

commonly used for additional protection. Cast iron

anodes can be prepacked in steel canisters with

carbonaceous backfill.

Chemical Compositions of Fe/Si/Cr-Anodes

Standard

Elements

Silicon

Chromium

Carbon

Manganese

Molybdenum

Copper

Phosphorus

Sulphur

ASTM A518 Gr3

Minimum

Maximum

14.20 %

3.25 %

0.70 %

14.75 %

5.00 %

1.10 %

1.50 %

0.20 %

0.50 %

BS 1591 SiCr 14 4

Minimum

Maximum

14.25 %

4.00 %

15.25 %

5.00 %

1.40 %

1.00 %

0.25 %

0.10 %

Characteristics

Tensile strength

103

N/mm2

Compressive strength

689

N/mm2

Brinell hardness

520

HB

Density

7.0

g/cm3

Melting point

1300

C

-5

Coefficient of linear expansion 1.86 x 10 1/C (0-100C)

Environment

Freshwater

Saltwater

Soil

Current

Density

A/m2

Consumption

Rate

kg/A year

Efficiency

10 - 30

10 - 50

10 - 30

0.15

0.50

0.30

90

90

90

The following cable types are available

as anode lead cables:

PVC

PE

XLPE

HDPE

CSP

EPR

PVDF

Polyvinylchloride

Polyethylene

Cross linked Polyethylene

High density Polyethylene

Chlorosulphonated Polyethylene

Ethylene Propylene Rubber

Polyvinylidenfluoride

Armourured cables are also available on request.

IMPRESSED CURRENT ANODES

Silicon iron anodes

German Cathodic Protection

Document No.: 04-200-R1

Sheet: 2 of 2

TYPE: 915

Total length -XDiameter -ADiameter -BSurface area

Total weight

915 mm

25 mm

50 mm

0.08 m2

3.2 kg

915

38

63

0.12

7.1

mm

mm

mm

m2

kg

915

50

76

0.16

14.5

mm

mm

mm

m2

kg

915

63

89

0.20

21.0

mm

mm

mm

m2

kg

915

76

101

0.23

31.4

mm

mm

mm

m2

kg

1220 mm

25 mm

50 mm

0.11 m2

4.5 kg

1220

38

63

0.16

10.0

mm

mm

mm

m2

kg

1220

50

76

0.20

19.0

mm

mm

mm

m2

kg

1220

63

89

0.25

28.6

mm

mm

mm

m2

kg

1220

76

101

0.30

38.2

mm

mm

mm

m2

kg

TYPE: 1220

Total length -XDiameter -ADiameter -BSurface area

Total weight

Tubular Anodes

Silicon iron tubular anodes with a specially designed low resistance

centre connection.

Total length

Diameter (outside)

Diameter (inside)

Approx. area

Total weight

1067 mm

68.0 mm

45.7 mm

0.2 m2

14.1 kg

2134

56.0

38.0

0.4

20.9

mm

mm

mm

m2

kg

2134

68.0

45.7

0.5

28.6

mm

mm

mm

m2

kg

2134

96.0

73.7

0.6

38.6

mm 2134 mm

mm 122.0 mm

mm 99.0 mm

m2

0.8 m2

kg

59.9 kg

CANISTER FOR TYPE: 915 + TYPE: 1220

COKE BACKFILL

Minimum carbon content

Maximum moisture content

Maximum resistivity

Density

Maximum particle size (dia.)

Standard canister

CAN 10

CAN 15

CAN 20

Diameter

160 mm

300 mm

300 mm

Length

1000 mm

1500 mm

2000 mm

90

%

5

%

1

m

700-950 kg/m3

20

mm

Total weight

22 kg

85 kg

110 kg

IMPRESSED CURRENT ANODES

Mixed metal oxide (MMO)

German Cathodic Protection

Document No.: 04-300-R1

Sheet: 1 of 1

Mixed metal oxide (MMO) anodes

This material consists of a high purity titanium substrate

with an applied mixed metal oxide coating consisting

of a mixture of oxides. The titanium serves as a support

for the oxide coating. The titanium functions as a

valve metal by forming thin, self-healing, adherent

oxide film which is acid resistant does not conduct

anodic current. The oxidefilm is formed on the titanium

substrate by thermal decomposition of precious

metal salts that have been applied the substrate.

Mesh anodes

Mesh anodes are used for the protection of steel

reeinforced concrete structures.

Technical data

Base metal

MMO coating,standard

MMO layer thickness

Max. phase/interphase voltage

Max. current density

Consumption rate

Titanium

12

approx. 5.0

8.0

11

approx. 0.01

g/m2

m

V

A/dm2

g/A year

Rod anodes

Screw-in type rod anodes with pressure resistant

head structure are widely used for the internal

protection of pipes, tanks, condensers and other

process equipment.

Dimensions

Rod length

Rod diameter

150 up to 2500 mm

4 / 6 / 8 / 10 / 12 / 16 / 20 / 25 mm

Max. current density

Coating

Substrate (Grade 1/ASTM B265)

Width per coil

Length

Weight

Mesh size

Resistivity, longitudinal direction

Current distributor wire,diameter

Length (uncoated)

or

Current distributor flat profile

Thickness

Width

Length (uncoated)

18.0 mA/m2

27.5 mA/m2

33.0 mA/m2

Mixed precious

metal oxide

Mixed precious

metal oxide

Mixed precious

metal oxide

Titanium

1m

10 m

120 to 130 kg

76 x 35 mm

0.120 /m

3 mm

100 m

Titanium

1m

10 m

220 to 230 kg

76 x 35 mm

0.060 /m

3 mm

100 m

Titanium

1m

10 m

220 kg

62 x 20 mm

0.060 /m

3 mm

100 m

1 - 1.5 mm

5 - 10 mm

1m

1 - 1.5 mm

5 - 10 mm

1m

1 - 1.5 mm

5 - 10 mm

1m

Tubular anodes

Tubular anodes are assembled as anode chain for

deep groundbed installations. The centre connected

cable ensures that current can pass from the centre

of one tube to the next. The materials used for the

different parts of anodes and anode chains are suitable for

satisfactory performance in areas with low pH-value

and high chloride/chloride concentrations.

Plate anodes

Plate anode structure consists of anode plate assembled

and sealed inside a support frame made of impact

resistant plastic material.

Plate anodes are used for offshore structures and

sluices.

Dimensions

Plate length

Plate width

Plate thickness

max. 800 mm

max. 800 mm

0.5 - 10 mm

Dimensions

Tube length

Tube diameter

1000 - 2500 mm

25.4 / 32.0 / 40.0 / 45.0 / 50.8 mm

IMPRESSED CURRENT ANODES

Platinised Titanium/Niobium/Tantalum

Document No.: 04-400-R1

Sheet: 1 of 1

Platinised Titanium/Niobium/Tantalum

(Pt/Ti-Nb-Ta) anodes

Platinium is an excellent anode material due to its

high conductivity and low consumption rate. Because

of its high cost, it is not economical to use platinium

by itself. Platinium can be made practical for use by

cladding or electroplating a thin layer of platinium

over a lower cost substrate. This also increases the

effective anode surface area. The substrate must

also be able to form an insulating oxide film under

anodic conditions. The substrate materials most

commonly used are titanium, niobium and tantalum.

Of these, titanium is least expensive but it has a much

lower breakdown potential than niobium or tantalum.

Titanium oxide breaks down at anodic potentials in

the 12 V range.

(Pt/Ti-Nb-Ta) Rod anodes

Screw-in type Pt/Ti-Nb-Ta rod anodes with pressure

resistant head structure are widely used for internal

protection of condensers and other process equipment.

German Cathodic Protection

(Pt/Ti-Nb-Ta) Wire anodes

Pt/Ti-Nb-Ta wire anodes are used for the internal

protection of water tanks and pipelines.

Technical data

Base metal

Max. allowable operating voltage

Wire length

Wire diameter

Pt coating thickness

Consumption rate

Max. current density

Titanium Niobium Tantalum

12 V

40 V

80 V

100 m

50 m

50 m

1 / 2 / 3 / 4 mm

5 / 7.5 / 10 m

approx. 0.08 g / A year

10 A / dm2

(Pt/Ti-Nb-Ta) Mesh anodes

Pt/Ti-Nb-Ta mesh anodes are used for the protection

of reinforced concrete structures.

Technical data

Base metal

Titanium Niobium Tantalum

Max. allowable operating voltage

40 V

80 V

12 V

Rod length

150 - 2500 mm

Rod diameter

4 / 6 / 8 / 10/ 12 / 16 / 20 / 25 mm

Pt-coating thickness

5 / 7.5 / 10 m

Consumption rate

approx. 0.08 g / A year

Max. current density

10 A / dm2

Technical data

Base metal

Max. allowable operating voltage

Mesh length

Mesh width

Pt coating thickness

Consumption rate

Max. current density

Titanium

12 V

Niobium Tantalum

40 V

80 V

max. 2500 mm

max. 800 mm

5 / 7.5 / 10 m

approx. 0.08 g / A year

10 A / dm2

IMPRESSED CURRENT ANODES

Accessories: LORESCO SC-2

Document No.: 04-601-R1

Sheet: 1 of 1

Super conducting earth contact backfill

Loresco type SC-2 is designed specifically for deep

anode systems.

German Cathodic Protection

Loresco SC-2 is designed to be used in impressed

current cathodic protection systems, deep or shallow.

Specify Loresco SC-2 Super-Conducting Premium

Earth Contact Backfill. For high current installations,

Loresco SC-3 is recommended.

Installation

Loresco SC-2 has excellent pumping qualities and

when agitated in water, takes on the characteristics

of heavy mud. A recommended mix is seven gallons

of water per one hundred pounds. After installing

SC-2, allow twenty-four hours settling time before

energising. The modified surface of the carbon

particles in SC-2 will achieve positive electrical

contact by settling. Vibrating or compacting is not

necessary.

Loresco type SC-2 is a dust-free product and,

according to EPA extraction tests, is extremely pure

and complies with regulations governing buried

products. SC-2 mixes easily with water and may be

pumped into deep anode systems. Loresco SC-2

is designed to promote electronic flow between the

anode surface and itself.

Loresco SC-2 is produced specifically for cathodic

protection applications using an exclusive multistep process. First, a high quality base carbon with

desired characteristics is selected. Next, this carbon

is calcined to a minimum temperature of 1250 C

under exacting and controlled standards. This step

results in semi-graphitised carbon particles with

excellent conductivity.

Then, to further improve bulk conductivity, the surfaces

of the individual particles are half-modified to enhance

the contact con-ductance. This breakthrough in

surface alteration ensures maximum electronic

current transfer with positive anode contact. The

surface alteration on the particle surfaces is not easily

removed and stands up to the vigorous application

methods in all field requirements.

Loresco SC-2 has a bulk density of 74 lbs. per cubic

foot. The fixed carbon content is greater than 99.35%

by weight. The bulk density and high fixed carbon

content coupled with the assured low resistivity

medium allows for longer groundbed life at a lower

operating cost.

Material Description

Loresco SC-2 is a surface modified, blended, and

sized carbon backfill.

Specification

Bulk Density: 74 lbs. per cubic foot

Predominantly round particles

All particles surface modified for maximum electrical conductivity

Particle sizing: To be dust free with a maximum particle size of 1 mm

Minimum calcination temperature of base materials is 1250 C

Base materials are calcined under ISO 9002 quality control

No de-dusting oils are used during the manufacture of base particles

Shipping Data

Loresco SC-2 is shipped in fifty (50) pound (22.7 kg)

coated, woven polypropylene bags. SC-2 may be

stored outside for limited periods (not to exceed four

hundred hours of sunlight). Pallets are available with

fifty bags per pallet. Proven export packaging is also

available.

IMPRESSED CURRENT ANODES

Accessories: Carbonaceous backfills

Document No.: 04-602-R1

Sheet: 1 of 1

German Cathodic Protection

Carbonaceous backfills

Impressed current anodes are usually surrounded

by a carbonaceous backfill. Types of materials use

include metallurgical coke and calcined petroleum

coke.

The dual purpose of the carbonaceous backfill is to

reduce the groundbed resistance by increasing the

effective size of the anode and to provide a surface

on which oxidation reactions could occur. The

latter function prolongs anode life. To ensure good

electrical contact, the backfill must be tamped around

the anode. Resistivity of carbonaceous backfills are

in the range of 10 - 50 cm.

Particle size and shape are also important when

specifying a backfill. Both parameters determine the

contact area between anode and surrounding soil

whilst influencing the porosity of the column which

is important for gas ventilation. A general purpose

coke breeze is for use in shallow horizontal and

vertical groundbeds. It has a resistivity of approx. 35

cm. For deep well applications a special calcined

petroleum coke breeze is available. It has a resistivity

of approx. 15 cm and can be pumped.

Metallurgical coke of high quality that gives optimum

performance at a low cost is available in various size

ranges..

Coke backfill, prepared from calcinated petroleum

coke, has been properly developed to meet all the

basic requirements for an earth contact backfill. The

carbon content, very high in calcined coke assures

a low consumption rate of the backfill material and

therefore a longer system life.

The low resistivity of calcined coke and the small

particle size allow the best possible contact between

the anode surface and the surrounding soil. As a

consequence, this increases the anode size and

allow the majority of the current to be discharged

electrolytically at the backfill to soil interface.

Shipping Data

Coke backfill is shipped in bags, each bag weighing

20 kg, 25 kg or 50 kg. Pallets are available with 20

bags, 40 bags or 50 bags. Other bag sizes are available on request.

Specification Metallurgical Coke

Ash

Volatile

Sulfur

Moisture

Fixed carbon

10.0 %

1.4 %

0.6 %

0.6 %

89.0 %

max.

max.

max.

max.

min.

12.0 %

1.8 %

1.0 %

1.0 %

86.0 %

Grading:

0-1 mm / 1-5 mm / 2-7 mm / 3-10 mm

Resistivity: 50 cm

Bulk density: approx. 700 kg/m3 (compacted)

Specification Calcined Petroleum Coke

Ash

Volatile

Moisture

Fixed carbon

0.1 %

0.6 %

0.1 %

99.0 %

max.

max.

max.

min.

0.8 %

0.8 %

0.5 %

98.0 %

Grading:

2 mm up to 8 mm

Resistivity: 10 cm

Bulk density: approx. 800-900 kg/m3 (compacted)

You might also like

- CP PresentationDocument24 pagesCP PresentationCương Lê VănNo ratings yet

- Cathodic Protection AssessmentDocument122 pagesCathodic Protection AssessmentАртурNo ratings yet

- Stray Current MagazineDocument13 pagesStray Current MagazineRoberto ArmentaNo ratings yet

- AAN - SRP Procedure - TCP - BPCL - RUPNAGAR1 18.08.2020Document15 pagesAAN - SRP Procedure - TCP - BPCL - RUPNAGAR1 18.08.2020Aashish MoyalNo ratings yet

- SP60 18 Rev3 Cathodic Protection PDFDocument138 pagesSP60 18 Rev3 Cathodic Protection PDFsouheil boussaidNo ratings yet

- Primary Thermal BatteriesDocument4 pagesPrimary Thermal BatteriesPavan KumarNo ratings yet

- CATHODIC PROTECTION FOR BURIED PIPELINEDocument22 pagesCATHODIC PROTECTION FOR BURIED PIPELINEdevanbongiriNo ratings yet

- Anodic ProtectionDocument50 pagesAnodic ProtectionEngr Arfan Ali DhamrahoNo ratings yet

- CVTDocument9 pagesCVTaanouar77No ratings yet

- Souvik Ghosh - (Uni. No.34)Document24 pagesSouvik Ghosh - (Uni. No.34)bishuNo ratings yet

- BY: Afifah BT Abdul RashidDocument37 pagesBY: Afifah BT Abdul Rashidsuzilamatsalleh100% (3)

- Intermetallics PDFDocument4 pagesIntermetallics PDFgurudev001No ratings yet

- Meccoct18 12573Document9 pagesMeccoct18 12573Malik Ansar HayatNo ratings yet

- Tensile TesterDocument12 pagesTensile Testerlhanx2No ratings yet

- CH 06 - Corrosion & ErosionDocument22 pagesCH 06 - Corrosion & ErosionvegaronNo ratings yet

- Membranes For Hydrogen Separation 2007 PDFDocument33 pagesMembranes For Hydrogen Separation 2007 PDFRavi Mohan Prasad100% (1)

- Chapter 5 Motorola R56!09!01 05 Internal Grounding & BondingDocument72 pagesChapter 5 Motorola R56!09!01 05 Internal Grounding & BondingAnonymous V6y1QL6hn100% (1)

- API 934 Minutes Fluor ATT CDocument28 pagesAPI 934 Minutes Fluor ATT CAnonymous rUs4PjYo5No ratings yet

- Site Test Record: VT - Secondary Injection: TDocument5 pagesSite Test Record: VT - Secondary Injection: Tsiva2001eeeNo ratings yet

- Shielding MaterialsDocument7 pagesShielding MaterialsEduardo SaavedraNo ratings yet

- OPERATION MANUAL v1.1 - Orbital PDFDocument63 pagesOPERATION MANUAL v1.1 - Orbital PDFRubens AndradeNo ratings yet

- Repair Procedure F - 23202 NewDocument5 pagesRepair Procedure F - 23202 NewMohd Shafuaaz KassimNo ratings yet

- Mil DTL 24211CDocument8 pagesMil DTL 24211CmurphygtNo ratings yet

- JM IND InsulationIntel Ebook ExploringtheMechanismandLongevityofCorrosionInhibitorsinInsulationDocument11 pagesJM IND InsulationIntel Ebook ExploringtheMechanismandLongevityofCorrosionInhibitorsinInsulationSerge PossikNo ratings yet

- Coating Grade System For Prevention of Corrosion Under Insulation (CUI)Document2 pagesCoating Grade System For Prevention of Corrosion Under Insulation (CUI)Bobby SatheesanNo ratings yet

- Ador BookletDocument22 pagesAdor Bookletgssrraju0% (1)

- 6 Cathodic Protection Final RedactedDocument175 pages6 Cathodic Protection Final Redactedzaheer ahamedNo ratings yet

- RTRDocument3 pagesRTRRaziKhanNo ratings yet

- 01 Samss 045 PDFDocument22 pages01 Samss 045 PDFCarlos MondragomNo ratings yet

- CP System DesignDocument8 pagesCP System Designvchui34No ratings yet

- MOTS-08 Squirrel Cage Induction Motors - Rev 4.0Document17 pagesMOTS-08 Squirrel Cage Induction Motors - Rev 4.0Kingston RivingtonNo ratings yet

- Tubular Vent BinderDocument12 pagesTubular Vent BinderbayuNo ratings yet

- Zaclon Galvanizing HandbookDocument127 pagesZaclon Galvanizing HandbookMohammed Abdallah100% (2)

- Incoloy & Monel CorrosionDocument3 pagesIncoloy & Monel CorrosionAbbasNo ratings yet

- Sogec - CP Cathodic Protection Training Manual-Module 6Document10 pagesSogec - CP Cathodic Protection Training Manual-Module 6Emre ErdemNo ratings yet

- Stainless Steel Material PropertiesDocument4 pagesStainless Steel Material PropertiesMohammed RiyazNo ratings yet

- Thermo-Mechanical Processing and Forming of SteelsDocument14 pagesThermo-Mechanical Processing and Forming of SteelsParth AshokNo ratings yet

- Vendor Print For Generator Step-Up TransformerDocument416 pagesVendor Print For Generator Step-Up TransformerSinulingga YanNo ratings yet

- Cathodic Protection: Current Drainage Tank Base PerformanceDocument6 pagesCathodic Protection: Current Drainage Tank Base PerformancebookbumNo ratings yet

- Ad CDZZZZ MT Spe 0020 000Document31 pagesAd CDZZZZ MT Spe 0020 000Mehman NasibovNo ratings yet

- BEP3.0 Operating Manual GuideDocument9 pagesBEP3.0 Operating Manual GuideDamiano FuschiNo ratings yet

- Casing PresentationDocument33 pagesCasing PresentationJua RulerNo ratings yet

- Tribology Coupled With Condition MonitoringDocument5 pagesTribology Coupled With Condition MonitoringRaj RajendranNo ratings yet

- Instruction Manual: Portable Spot GunDocument15 pagesInstruction Manual: Portable Spot GunMustafa SabryNo ratings yet

- New Guidance For Wind TurbineDocument10 pagesNew Guidance For Wind TurbineSuraj MoodNo ratings yet

- Platformless DC Collection and Transmission For Offshore Wind FarmsDocument6 pagesPlatformless DC Collection and Transmission For Offshore Wind FarmsLesleyAnne RowandNo ratings yet

- Are Wind Turbine Step Up Transformers The Weak Link in The Wind Energy Supply ChainDocument3 pagesAre Wind Turbine Step Up Transformers The Weak Link in The Wind Energy Supply ChainpctinformationNo ratings yet

- Technical Specification-ZTT Subsea CableDocument9 pagesTechnical Specification-ZTT Subsea Cableabhi1648665No ratings yet

- W P SD 010 Rev2 Gate ValvesDocument3 pagesW P SD 010 Rev2 Gate ValvesBasanth VadlamudiNo ratings yet

- Corrosion - by DR - Kallol Mondal, Department of Metallurgy and Material Science, IIT KanpurDocument3 pagesCorrosion - by DR - Kallol Mondal, Department of Metallurgy and Material Science, IIT KanpurEddie TaiNo ratings yet

- EXTRACTING PLATINUMDocument16 pagesEXTRACTING PLATINUMCesar Mera LlinasNo ratings yet

- Introduction to Welding Processes and Their ApplicationsDocument4 pagesIntroduction to Welding Processes and Their ApplicationsSreejith MenonNo ratings yet

- Electric Motor Manual: Intermediate GuideDocument95 pagesElectric Motor Manual: Intermediate Guidetapiwa phiriNo ratings yet

- Crystalline Silicon Terrestrial Photovoltaic Cells - : Solar America Board For Codes and StandardsDocument22 pagesCrystalline Silicon Terrestrial Photovoltaic Cells - : Solar America Board For Codes and Standardsmihai_faur88No ratings yet

- Comparison of Nepal DTA 20181011Document39 pagesComparison of Nepal DTA 20181011Bhava Nath DahalNo ratings yet

- Iecex FMG 12.0022XDocument6 pagesIecex FMG 12.0022XFrancesco_CNo ratings yet

- Mechanics of Offshore Pipelines: Volume I: Buckling and CollapseFrom EverandMechanics of Offshore Pipelines: Volume I: Buckling and CollapseNo ratings yet

- 07-Permanent Reference Electrodes-Datasheets SummaryDocument6 pages07-Permanent Reference Electrodes-Datasheets SummaryMauro HorstNo ratings yet

- Mixed Metal Anodes Data Sheet: Pipeline Maintenance LimitedDocument5 pagesMixed Metal Anodes Data Sheet: Pipeline Maintenance LimitedDotty RoseNo ratings yet

- MAWP Calculation SpreadsheetDocument9 pagesMAWP Calculation SpreadsheetLawrence Osuvwe OfuokuNo ratings yet

- UW-10 Postweld Heat Treatment: ASME BPVC - VIII.1-2019 UW-9 - UW-11Document1 pageUW-10 Postweld Heat Treatment: ASME BPVC - VIII.1-2019 UW-9 - UW-11Lawrence Osuvwe OfuokuNo ratings yet

- 2 Burner Biomass Furnance SketchDocument1 page2 Burner Biomass Furnance SketchLawrence Osuvwe OfuokuNo ratings yet

- G3508 - 600kvaDocument7 pagesG3508 - 600kvaJim Patrick ChombaNo ratings yet

- Flare Thermal Radiation Study - Work Execution Plan Rev 1 PDFDocument1 pageFlare Thermal Radiation Study - Work Execution Plan Rev 1 PDFLawrence Osuvwe OfuokuNo ratings yet

- Buckingham's Pi TheoremDocument8 pagesBuckingham's Pi TheoremJOPAKNo ratings yet

- 3406 350kva Cat GeneratorDocument6 pages3406 350kva Cat GeneratorLawrence Osuvwe OfuokuNo ratings yet

- IZOMBE FLOWSTATION FIRE AND GAS SYSTEM ASSESSMENTDocument26 pagesIZOMBE FLOWSTATION FIRE AND GAS SYSTEM ASSESSMENTLawrence Osuvwe OfuokuNo ratings yet

- Energia Precommissioning Upgrade Project: HP Flare Thermal Radiation Analysis - Shell Fred ReportDocument46 pagesEnergia Precommissioning Upgrade Project: HP Flare Thermal Radiation Analysis - Shell Fred ReportLawrence Osuvwe OfuokuNo ratings yet

- Statement of Work-Tuneup1.27104048Document13 pagesStatement of Work-Tuneup1.27104048Lawrence Osuvwe OfuokuNo ratings yet

- 2009 31 Summer Wiring Matters Cables For Temporary InstallationsDocument5 pages2009 31 Summer Wiring Matters Cables For Temporary InstallationsLawrence Osuvwe OfuokuNo ratings yet

- Pdms 12.0 TutorialDocument136 pagesPdms 12.0 Tutorialferozbabu0% (1)

- Belzona 1321 (Ceramic S-Metal) - Product FlyerDocument2 pagesBelzona 1321 (Ceramic S-Metal) - Product Flyervangeliskyriakos8998No ratings yet

- Electrical Heat Tracing - Master PDFDocument49 pagesElectrical Heat Tracing - Master PDFmihai085No ratings yet

- Cov Fast Stainless Steel Cat - 3rd Ed - Jun 09Document116 pagesCov Fast Stainless Steel Cat - 3rd Ed - Jun 09jaffliangNo ratings yet

- Life-Cycle Cost and Performance of Civil Infrastructure Systems PDFDocument332 pagesLife-Cycle Cost and Performance of Civil Infrastructure Systems PDFAnas100% (1)

- HDPE Pipe Delivers 100+ Years of Corrosion-Resistant Service for Oil & Gas ApplicationsDocument40 pagesHDPE Pipe Delivers 100+ Years of Corrosion-Resistant Service for Oil & Gas ApplicationsvijayanmksNo ratings yet

- Reviewing Lay-Up Procedures for Piping SystemsDocument12 pagesReviewing Lay-Up Procedures for Piping Systemsimrankhan22No ratings yet

- Daily Points To Recall (Day 5) : API 653 PreparatoryDocument2 pagesDaily Points To Recall (Day 5) : API 653 PreparatoryMohammed ShakilNo ratings yet

- Cooling Tower Project ReportDocument35 pagesCooling Tower Project Reportdilliprout.caplet2016No ratings yet

- Kingspan Spectrum™: Premium Organic Coating SystemDocument4 pagesKingspan Spectrum™: Premium Organic Coating SystemNikolaNo ratings yet

- DNV RP B401 2010Document28 pagesDNV RP B401 2010Robert Putney100% (3)

- Detect corrosion under pipes with CHIME & CUPSDocument1 pageDetect corrosion under pipes with CHIME & CUPSGistek MarcoNo ratings yet

- Esab DublexDocument8 pagesEsab DublexSuphi YükselNo ratings yet

- JENKA System Technical ManualDocument20 pagesJENKA System Technical ManuallutcusNo ratings yet

- Test Panel Preparation Method No. 1: SSPC: The Society For Protective CoatingsDocument2 pagesTest Panel Preparation Method No. 1: SSPC: The Society For Protective CoatingsRinush SinagaNo ratings yet

- Corrosion and Hydrogen Permeation in H2SDocument10 pagesCorrosion and Hydrogen Permeation in H2SZenon KociubaNo ratings yet

- G 179 - 04 - Rze3oq - PDFDocument5 pagesG 179 - 04 - Rze3oq - PDFcaressaNo ratings yet

- Grounding and Lightning Protection Technical Reference in English M211786EN BDocument66 pagesGrounding and Lightning Protection Technical Reference in English M211786EN BukarthikbhelNo ratings yet

- Revista MP Diciembre 2022Document68 pagesRevista MP Diciembre 2022María Vaquero TxapartegiNo ratings yet

- Bellow Design GuideDocument14 pagesBellow Design Guidelokeshraja007100% (2)

- CE518Document2 pagesCE518Akhilesh B.MNo ratings yet

- Copper and Its AlloysDocument4 pagesCopper and Its AlloysneilNo ratings yet

- TB 100 Basics of Aluminium CareDocument4 pagesTB 100 Basics of Aluminium CareFabio ChiavaroliNo ratings yet

- Chem Paper 1sDocument217 pagesChem Paper 1sJustin SmithNo ratings yet

- VIR 826 FORM AA v0 PDFDocument16 pagesVIR 826 FORM AA v0 PDFArnab SenNo ratings yet

- Environmentally-Friendly Surface TreatmentsDocument13 pagesEnvironmentally-Friendly Surface TreatmentsSeema NadigNo ratings yet

- ASTM DL Content 2016 PDFDocument53 pagesASTM DL Content 2016 PDFdinesh panchalNo ratings yet

- Concrete Reinforcement Degradation and Rehabilitation Damages, CorrosionDocument176 pagesConcrete Reinforcement Degradation and Rehabilitation Damages, CorrosionWilmer PradoNo ratings yet

- Corrosion MonitoringDocument22 pagesCorrosion MonitoringJai Patel100% (2)

- Method Statement - Painting - R01Document40 pagesMethod Statement - Painting - R01Rawoofuddin Chand100% (1)

- ESA SME Initiative Course D:MaterialsDocument64 pagesESA SME Initiative Course D:MaterialsJoseph JonathanNo ratings yet