Professional Documents

Culture Documents

Macromolecules 25 5765 92

Uploaded by

bkprodhCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Macromolecules 25 5765 92

Uploaded by

bkprodhCopyright:

Available Formats

Downloaded from http://polymerphysics.

net

Macromolecules 1992,25, 5765-5768

6766

Normalization of the Temperature Dependence of Segmental

Relaxation Times

C.

M.Roland' and K. L. Ngai

Naval Research Laboratory, Washington, D.C. 20375-5000

Received April 1, 1992; Revised Manuscript Received June 30, 1992

ABSTRACT The validity of Tc-scaled Arrhenius plots of segmental relaxation times for glass-forming

liquids is assessed by comparing the results on polymers differing only in molecular weight. The differences

resultin identicalsegmentalrelaxation dispersions which occur, however, at differenttimes and temperatures.

It is verified herein that the Tc-normalization scheme is a self-consistentmeans to classify and distinguish

segmental relaxation behavior of polymers. Contrarily, changes in glass transition temperature effected by

hydrostatic pressure alter the segmental dynamics in a manner such that the fragility of the polymer is

altered.

Introduction

The time and temperature dependencies of the rheological response of polymers are central issues in the study

of the viscoelasticity of polymers. Over the range of most

experimental measurements, temperature dependencies

are non-Arrhenius; consequently, some normalization

scheme must be invoked to allow comparisons among

different fluids of the effect of temperature on the

measured relaxation times. Recently, a correlation was

demonstratedbetweenthe shape of the relaxation function

of several amorphous polymers and the magnitude of the

time-temperature shift factors.' Specifically, a broader

segmental dispersion was associated with a stronger

temperature dependenceof the segmentalrelaxationtime.

This conclusionwas reached by comparingthe shiftfactors

as a function of inverse temperature normalized by TG,

the glass transition temperature. Although the glass

transition temperature is an obvious normalizing parameter, this specific basis for comparing different materials

is not obviously the correct one.

Angel12t3 has proposed a classification based on the

density of available configurations (corresponding to

minima on a potential energy "hypersurface") for an

N-particle fluid. If the liquid gains access to a high density

of these energeticallypreferred confiiational states when

temperature is raised through TG,the glass to liquid

transition will be accompaniedby a large entropy increase;

consequently,the heat capacity and relaxation time change

markedly with temperature near TG. Such a liquid is

classified as "fragile", an allusion to the loss of short- or

intermediate-range order accompanying the transition

from the glassy state. "Strong" liquids, characterized by

fewer potential energy minima in configuration space,

sufferlittle loss of local"structure" and thus exhibit smaller

incrementain heat capacityat TG. This thermally induced

Structure degradation refers only to the loss of local order;

it is unrelated to chemical stability.

consideration of the heat capacity changeet TGprovides

a meam for comparing the temperature dependencies of

different glasa-forming liquid^.^^^ In the Adam and Gibbs

theory of relaxation' the liquid is comprised of cooperativelyrearrangingregions(CRR's), defined as the smallest

volume element that can relax to a new configuration

independently of neighboring regions. The energy barrier

hindering transition of the CRR to a new configurationis

proportional to the size of the CRR, with the average

transition rate for the CRRs given by

W(T)= A exp(-C/TS,)

(1)

where A is a constant. The parameter C is proportional

to the product of Ap, the energy barrier per molecule, and

8,, the configurational entropy of the smallest CRR

C = AlSJ k

(2)

where k is the Boltzmann constant. The configurational

entropy of the macroscopic sample, S,, can be expressed

in terms of the difference in heat capacity between the

liquid and glassy states2s3

(3)

where TK,identifiable with the K a u " temperature?W

is the temperature at which S,= 0. Assuming a hyperbolic

dependence of heat capacity on temperature, it can be

shown that2a

(4)

where a is a constant. Substituting into eq 1 gives

W = A exp(DTK/T- TK)

(5)

with

D = C/a

(6)

Equation 5 correspondsto the empirical VFTH equation@

with the average transition rate of the CRRs identified

with the inverse relaxation time. Non-Arrhenius temperature dependencydata from glass-formingliquids near

TGcan be represented well using this relation. If both the

energy barrier per molecule and the configurational

entropy of the smallest CRR are constant, then D is

constant, at least to the extent the heat capacity can be

adequately described by a hyperbolic relation. It follows

from eq 5 that two liquids having the same D and A (but

possibly different TK's)will have identical "fragilityplots",

that is, plots of log (W(T))versus TG/T,where TOcan be

operationally defined to be the temperature at which the

transition rate attains a constant (arbitrary) value. Such

plots have been used to depict relaxation times and

viscosities of small-molecule glasses in order to illustrate

the contrasting behavior of strong versus fragile liquids.2*3

An extension of the Adam and Gibbs model to include

This article not eubject to U.S. Copyright. Published 1992 by the American Chemical Society

Macromolecules, Vol. 25,No. 21, I992

6766 Roland and Ngai

dynamic correlations between the CCR's provides a

rationale for the observed correlations between time and

temperature dependencies in small-molecule liquids.1

More recently this approach has been applied to

amorphouspolymers,lJ1although the appellations strong

and fragile may be misleading therein, since there is no

modification of structure at the glass transition. For

polymers the term "cooperativity plot" is more accurate.

From comparisons of segmental relaxation times for

various polymers made on the basis of TG-scaled Arrhenius

plots, correlationshave been adduced.lJ1 These have been

used to draw inferences concerning fundamental relationships between chain structure, intermolecular interactions, and segmental dynamics. Fragility plots have also

been extended to miscible polymer blends to demonstrate

the effect of local compositional variations on segmental

relaxation.12-14

Fragility plots embody the assumptions of constancy of

sc and Ap, the correctness of which cannot be directly

demonstrated. The need to take account of differences

in TG among liquids is apparent, and a simple T/Tc

construct is plausible. However, it is not obvious that

comparisons of different and decidedly non-Arrhenius

temperature dependencies of different liquids are made

meaningful so simply.

To assess this approach to the study of chain dynamics,

it would be useful to demonstrate its validity with liquids

identical in chemical structure but differing in their

dynamics. This is conspicuously impossible for smallmolecule liquids; however, the chain-length dependence

of a polymer's glass transition temperature provides such

an opportunity. Chemically identical materials differing

only in molecular weight will necessarily have the same

energy barrier to conformational transitions, and both sC

and AC, will be essentially equal. While the differences

in Tc confer differences in temperature dependencies,since

the degrees of intermolecular cooperativity of their segmental relaxation are equivalent, the relaxation times

should superimpose when expressed in terms of the

reduced variable T/ TG. We emphasizethat TG-nOrmalized

Arrhenius plots may provide a meaningful basis for

comparing segmental relaxation of different polymers,

aside from the particular model (e.g., the theory of Adam

and Gibbs) from which the approach originated. Accordingly, herein we employ the VFTH expression only to

interpolate experimental measurements of segmental

relaxation. The adequacy of the fragility plot approach

is considered apart from the specific assumptions that

enable one to derive the TITGnormalization scheme.

The glass transition temperature of a given material is

strongly dependent on pressure, reflecting the molecular

crowdinginducedby pres". Isothermalrelaxationtimea

and their temperature dependenceare therefore functions

of pressure. The changes in segmental dynamics engendered by presswe, however, are expectad to alter Ap and

AC,, thus undermining the basis of the fragility plot

approach. Speaking loosely, the "strength" of a liquid

should increase upon densification. It is interesting to

explore the consequences of pressure variations on the

fragility characteristics of glass-forming liquids.

The present study was intended to asm the utility of

fragility plots in accounting for changes in segmental

dynamics of amorphous polymers induced by changes in

TG. The latter were effected by variations in molecular

weight and pressure.

Results

Polystyrene. Compliance measurements at temperatures encompassing the glass to liquid transition have

4r-l-----

? I

2-

d-

O-

D -2-

0

rl

-4-

-6-

-EL

2.4

2.6

2.8

3.0

1000/T

'

t

50 . 3 6L

0.96

1.00

L1 . 0L2

TO /T

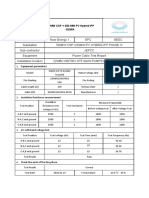

Figure 1. (a) Shift factors determined from compliance measurementson polystyrenes of molecular weights equal to 3.4 X

109(.),1.6Xl(r(O),and1.2X

1o6(+).l6 (b)Segmentalrelaxation

times that become coincident when the temperaturesare scaled

by the respective TG'S(Table I) of each polymer.

Table I

polymer

polystyrene

polystyrene

polystyrene

poly(propy1eneoxide)

poly(propy1ene oxide)

poly(phenylmethylsiioxane)

poly(phenylmethylsiloxane)

Mw

3.4 x 109

1.6 X 10'

1.2 x 106

1.0 x 109

9.5x 106

2.5 X 109

8.3 x 106

TO

3530

36W

372O

202b

205b

235b

245b

Temperature at which compliance i n c r e w by a factor of 10

from the glassy level in 100 B. Temperature at which the segmental

relaxation time equals 18.

(1

J

J

been reported for polystyrenes of various molecular

weight.lS The obtained shift factors (the ratio of the

relaxation time, T , measured at a given temperature to the

relaxationtime at an arbitrary reference temperature) are

displayed in Figure 1 for the three polystyrenes listed in

Table I. It is evident that the differences in molecular

weights give rise to substantial differences in temperature

dependencies for the segmental relaxation. The VFTH

parameters, determined by fitting eq 5 with W taken to

be ~ - lvary

, with molecular weight due to the variation of

TGwith molecular weight. However, no molecular weight

dependence was found for the shape of the segmental

relaxation dispersion (reflecting the degree of intermolecular cooperativity16J7). Thus,these data provide an

opportunity to evaluate the fragility approach to scaling

the results from polystyrenes of different TG.

From the original compliance data,'6 a glass transition

temperature is defiied for each molecular weight as the

temperature at which the compliance increases 10-fold

from the glassy complianceover a 100-stime span. Using

Macromoleculee, Vol. 26, No.21, 1992

Segmental Relaxation Times 5767

0

-6

-e

3.4

0.88

4.2

3.8

0.94

1.00

TQ/ T

Figure 4. (a) Shift factors determined for PPMS of molecular

weightequalto2.5X 108Wand8.3X 106(0).20

(b)Datareplotted

with the abscissa values normalized by the respective To of each

polymer (Table I).

a

a +o

ol

a

-61

+o

00

'O

0.85

0.90

TO

0.95

1.oo

/T

Figure 3. Shift factors determined for amorphous PPO (MW

= 9.5 X 109 at 1 (01, 1000 (+I, and 2000 ( 0 )atmospheres of

pressure.19 The TGwas taken to be the temperatureat which the

relaxation time equaled 1 s at that pressure.

the TG'Sso determined, the shift factors of Figure l a are

replotted in Figure lb, with the temperatures normalized

by the respective TG'Sof each polystyrene. It is seen that

this ecaling unifies the behavior, indicating that at least

for mechanical measurements on these polymers the

disparate characteristicsof the molecular weight dependent TGand molecular weight independent fragility can be

distinguished.

Poly(propy1ene oxide). Dielectric spectroscopy has

been carried out on both low1*and highlBmolecularweight

poly(propy1ene oxide) (PPO) in the vicinity of its glass

transition. The frequency, fp, of the maximum in the

dielectriclose defines a peak relaxation time, T~ = (2rfP)-l.

The variation with temperature of T~ is found to be well

described by the VTHF equation. The temperature at

which rp = 1s is determined and identified as TG. A l-s

time scaleis employedsince the dielectricdata are available

only over a limited range of frequencies. TOis arbitrary

as far as dynamics are concerned, so that any convenient

operational definition suffices. Using the TG so determined, shift factors are calculated as shown in Figure 2a.

Since the glass transition temperatures are different for

the two molecular weights,nonparallelcurvesare obtained.

Similarly as for PS above, we normalize the temperatures

by the respective TGof each species and replot the data

(Figure 2b). The plots for the two molecular weights are

~

~

~

coincident, supporting

the normalization

scheme.

The TGof a polymer can be altered by the application

of hydrostaticpressure. Dielectricloss measurements have

in fact been reported for the higher molecular weight PPO

at high pressure.lS From this data we determine the

pressure dependence of TGand thereby construct fragility

curves (Figure 3). However, it is seen that the changes in

temperature dependence brought about by changing

pressure cannot be accounted for simply by scaling the

temperatures by the TG-'. The change in TGwith pressure

can be attributed to changes in the intramolecularly

correlated conformational transition rates, similar to the

effect of changing molecular weight. However, whereas

the increase in TGwith increasing molecular weight has

no effect on the normalized temperature dependence,the

TGincrease brought about by higher pressure is accompanied by a reduction in the fragility of the liquid.

Poly(phenylmethylsiloxane). Dielectric and photon

correlation spectroscopy results have been obtained on

poly(phenylmethylsi1oxane) (PPMS)of molecular weight

= 8.3 X 106,20921

and both techniques yielded equivalent

Macromolecules, Vol. 25, No. 21, 1992

6768 Roland and Ngai

ration of the fragility plot approach (Figureslb, 2b,and

4b) is not taken as confirmation of any connectionbetween

temperature dependenciesand the heat capacitydifference

of the liquid and glassy states. In fact, for polymers no

such relationship is expected. Correlations have been

demonstrated previously between the degree of intermolecular cooperativity of a polymeric liquid and the temperature dependence of segmental relaxation.lJl The

present assessmentof the T c - n o d e d scalingprocedure

is made possible because of the equivalence of this

cooperativity(and thus the shape of segmental relaxation

dispersions) for polymers differing only in molecular

weight.

I-

rl

/

I

0.92

0.95

0.96

1.01

To / T

Figure 6. Shift factors determined for low molecular weights

PPMSatl(-),450(-- -),and900(-..)ba~hydrostaticpressure.~

TGwas taken to be the temperature at which the relaxation time

equaled 1 s, with temperature and pressure dependencies for the

latter obtained from eq 7.

temperature dependencies for segmental relaxation. In

Figure 4a the shift factors for the dielectric loss maximum

are displayed for this PPMS, along with shift factors

determined for a low molecular weight (=2.5 X lo3)

PPMS.20 When a glass transition temperature is defined

as the temperature at which the relaxation time equals 1

s, the data are replotted in the TG-normalizedArrhenius

form (Figure 4b). Superpositioning of the data is again

observed.

The pressure dependence of the relaxation time was

determined for the low molecular weight PPMS to bem

r = 7.94 X lo-'' exp((1659 0.813P)/(T - 207)j (7)

where P is in unita of bar. Using eq 7, the pressure

dependenceof the 7 vs TITGrelation was calculated,where

TGis again the temperature at which the relaxation time

equals 1a. The reeulta (shownin Figure 5) are in agreement

with the data in Figure 3 for PPO; that is, the fragility

curves diverge at different pressures, with increasing

pressure reducing the temperature sensitivity when the

latter is normalized by TG.

Summary

The log r vs TGIT form has been tested herein and

verified to be a rational means to classify and distinguish

the segmentalrelaxation characteristics of polymers. The

original derivation of this normalization relied on several

assumptions as discussed above; however, the corrobo-

Acknowledgment. We thank D. J. Plazekfor the creep

compliance data on polystyrenes and E. Schlosser and A.

Sch6nhalsfor providing prior to publication their data on

the dielectric relaxationof PPO. This work was supported

by the Office of Naval Research (toK.L.N. under Contract

NOQO1491WX24019).

References and Notes

(1) Plazek, D. J.; Ngai, K. L. Macromolecules 1991,24,1222.

(2) Angell, C. A. In Relaxations in Complelc Systems; Ngai, K.L.,

Wright, G. B., Eds.; Government Printing Office: Washingon,

DC, 1985;p 3;Proceedings of the Materials Research Society

Symposium on the Physical Aging of Glasses; Baton, 1990.

(3) Angell, C. A. J. Non-Cryst. Solids 1991,131-133,13.

(4)Adam, G.;Gibbs, J. H. J. Chem. Phys. 1966,43,139.

(5) Birge, N.;Nagel, S. Phys. Rev. Lett. 198S,54,2674.

(6)Dixon, P.; Nagel, S. Phys. Rev. Lett. 1988,61,341.

( 7 ) Richet, P. Geochim. Cosmochim. Acta 1984,48,417.

( 8 ) Tweer, H.;Laberge, N.; Macedo, P. B. J.Am. Ceram. SOC.1971,

54,122.

(9)Ferry, J. D. Viscoelastic Properties ofPolymers; Wiley: New

York, 1980.

(10) Ngai, K. L.; Rendell, R. W.; Plazek, J. J. Chem. Phys. 1991,94,

3018.

(11)Roland, C. M.; Ngai, K. L. Macromolecules 1991,24,5315.

(12)Roland, C. M.; Ngai, K. L. Macromolecules 1991,24,2261.

(13)Roland, C. M.; Ngai, K. L.; OReilly, J. M.; Sedita, J. S.

Macromolecules 1992,25,3906.

(14)Roland, C. M.; Ngai, K. L. J. Rheol., in press.

(15) Plazek, D. J.; ORourke, V. M. J. Polym. Sci., Polym. Phys. Ed.

1971,9,209.

(16)Ngai, K.L.;Rendell, R. W.; Rajagopal, A. K.; Teitler, S. Ann.

N.Y. Acad. Sci. 1986,484,150.

(17) Ngai, K. L.; Rendell, R. W. J. Non-Cryst.Solids 1991,131-133,

942.

(18) Schonhals, A.; Schloeser,E. Presented at the 27th Europhysics

Conference on Macromolecular Physics, Heraklion, Crete,

Greece, 1991. Colloid Polym. Sci., in press.

(19) Williams, G. Trans. Faraday SOC.1966,61,1564.

(20) Fytas, G.; Dorfmuller,Th.; Chu, B. J.Polym. Sci.,Polym.Phys.

Ed. 1984,22,1471.

(21) Boese, D.; Momper, B.; Meier, G.; Kremer, F.; Hagenah, J.4.;

Fischer, E. W. Macromolecules 1989,22,4416.

You might also like

- FE410WWA - Equivalent Steel Grades QualitiesDocument6 pagesFE410WWA - Equivalent Steel Grades QualitiesbkprodhNo ratings yet

- Soporte UboltDocument2 pagesSoporte UboltJames HansonNo ratings yet

- J 33Document2 pagesJ 33bkprodhNo ratings yet

- X GR Grating Fastening System Product Data 330924Document14 pagesX GR Grating Fastening System Product Data 330924bkprodhNo ratings yet

- Cong Truc Hai Dam PDFDocument3 pagesCong Truc Hai Dam PDFbkprodhNo ratings yet

- J 32Document2 pagesJ 32bkprodhNo ratings yet

- J 31Document2 pagesJ 31bkprodhNo ratings yet

- Mobile Crane 250T - Liebherr LTM - 1250Document12 pagesMobile Crane 250T - Liebherr LTM - 1250bkprodhNo ratings yet

- Schedule LevelsDocument7 pagesSchedule LevelsbkprodhNo ratings yet

- Piping-Progress-Measurement - (In Dia and in Meter)Document6 pagesPiping-Progress-Measurement - (In Dia and in Meter)bhardwaj_rahul7937100% (2)

- Rules of Thumb Chapter 8: VesselsDocument4 pagesRules of Thumb Chapter 8: VesselsAri KurniawanNo ratings yet

- BNBM Rock Wool PDFDocument4 pagesBNBM Rock Wool PDFbkprodhNo ratings yet

- Manhole D430: Fitting DetailsDocument1 pageManhole D430: Fitting DetailsbkprodhNo ratings yet

- Steel StructuralsDocument10 pagesSteel Structuralsdchz_62No ratings yet

- ASGEpg187 PDFDocument3 pagesASGEpg187 PDFbkprodhNo ratings yet

- Tadano TL 300 Truck CraneDocument1 pageTadano TL 300 Truck CranebkprodhNo ratings yet

- STT Lincoln Electric PDFDocument30 pagesSTT Lincoln Electric PDFbkprodhNo ratings yet

- PTQ q4 2016 Designing Storage TanksDocument4 pagesPTQ q4 2016 Designing Storage TanksJonathan RangelNo ratings yet

- TL-250M 2 PDFDocument12 pagesTL-250M 2 PDFbkprodhNo ratings yet

- X GR Grating Fastening System Product Data 330924Document14 pagesX GR Grating Fastening System Product Data 330924bkprodhNo ratings yet

- TongHeer Brouchure)Document10 pagesTongHeer Brouchure)bkprodhNo ratings yet

- TemJournalFebruary2016 76 79Document4 pagesTemJournalFebruary2016 76 79bkprodhNo ratings yet

- ETA-Danmark Technical Assessment SWE01 Sinto ST-EE Bonded AnchorDocument23 pagesETA-Danmark Technical Assessment SWE01 Sinto ST-EE Bonded AnchorbkprodhNo ratings yet

- DP StraightDocument22 pagesDP StraightbkprodhNo ratings yet

- ETA-Danmark Technical Assessment SWE01 Sinto ST-EE Bonded AnchorDocument23 pagesETA-Danmark Technical Assessment SWE01 Sinto ST-EE Bonded AnchorbkprodhNo ratings yet

- Air Filters and Filtration Equipment WebDocument100 pagesAir Filters and Filtration Equipment WebbkprodhNo ratings yet

- PROCEDURE FOR TANK FABRICATION & ERECTIONDocument15 pagesPROCEDURE FOR TANK FABRICATION & ERECTIONsenthilkumarsk88% (8)

- ANZ Anchoring CatWEBDocument92 pagesANZ Anchoring CatWEBbkprodhNo ratings yet

- Ks FP M6-F9: Compact FiltersDocument1 pageKs FP M6-F9: Compact FiltersbkprodhNo ratings yet

- Weight Breaking Load PDFDocument1 pageWeight Breaking Load PDFbkprodhNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Solution - Tutorial 3Document11 pagesSolution - Tutorial 3zgalionoooNo ratings yet

- Lecture # 05Document14 pagesLecture # 05Rahil BalochNo ratings yet

- General Physics 2: Quarter 4 - Module 5Document26 pagesGeneral Physics 2: Quarter 4 - Module 5Lorilie100% (1)

- Assignment I - Spring 2021 - PHY101 - 03Document2 pagesAssignment I - Spring 2021 - PHY101 - 03Nasif KamalNo ratings yet

- Model: THG1365YLS: Technical Data SheetDocument3 pagesModel: THG1365YLS: Technical Data SheetAndres VargazNo ratings yet

- Swedy Doha CablesDocument174 pagesSwedy Doha CablesengmswilamNo ratings yet

- EE-101 (Unit 4)Document46 pagesEE-101 (Unit 4)Chauhan AyushmaanNo ratings yet

- Principles of Communications 7th Edition Ziemer Solutions ManualDocument25 pagesPrinciples of Communications 7th Edition Ziemer Solutions ManualVanessaGriffinmrik86% (42)

- Electricity MarketDocument27 pagesElectricity MarketcakesandfinancesNo ratings yet

- Sy Ee 321 Emw MicroprojectDocument12 pagesSy Ee 321 Emw MicroprojectPari PatilNo ratings yet

- EMT Short NotesDocument11 pagesEMT Short Notesshahswat mallickNo ratings yet

- Das Consultants: Design of 1000KL Capacity OHTDocument19 pagesDas Consultants: Design of 1000KL Capacity OHTPrashant GargNo ratings yet

- Answers To Saqs: Cambridge International A Level PhysicsDocument1 pageAnswers To Saqs: Cambridge International A Level PhysicsharshanauocNo ratings yet

- TVR LX 4TVD Media Presión DC Fan - Manual de Características Técnicas (Inglés)Document27 pagesTVR LX 4TVD Media Presión DC Fan - Manual de Características Técnicas (Inglés)Molnar LeventeNo ratings yet

- Electrical Troubleshooting VespaDocument19 pagesElectrical Troubleshooting VespaMuch Abdulah NurhidayatNo ratings yet

- Fick’s Law for Binary Systems Flux CalculationDocument11 pagesFick’s Law for Binary Systems Flux CalculationDianaNo ratings yet

- 기초회로이론 챕터6 과제Document118 pages기초회로이론 챕터6 과제lostdream0515No ratings yet

- Description: Beijing Estek Electronics Co.,LtdDocument3 pagesDescription: Beijing Estek Electronics Co.,LtdDiego OliveiraNo ratings yet

- ElectrostaticsDocument16 pagesElectrostaticsSuparnaNo ratings yet

- Ambipolar Transport Equation Describes Excess CarriersDocument30 pagesAmbipolar Transport Equation Describes Excess CarriersVikas PsNo ratings yet

- Design of Adaptive Sliding Mode Controller For Single-Phase Grid-Tied PV SystemDocument6 pagesDesign of Adaptive Sliding Mode Controller For Single-Phase Grid-Tied PV SystemEngnr Kami ZebNo ratings yet

- THE Pulsejet Engine A Review Development Potential: OF ITSDocument246 pagesTHE Pulsejet Engine A Review Development Potential: OF ITSPhyuphwaykyaw PhyuphwayNo ratings yet

- HTF Buildigng Cable Hippot Test From VFD To MotorDocument20 pagesHTF Buildigng Cable Hippot Test From VFD To Motorمحمد ابن علیNo ratings yet

- Mechanics For Systems of Particles and Extended BodiesDocument19 pagesMechanics For Systems of Particles and Extended Bodiesraghib83No ratings yet

- 5 General Relativity With Tetrads: 5.1 Concept QuestionsDocument69 pages5 General Relativity With Tetrads: 5.1 Concept QuestionsdheerajkmishraNo ratings yet

- Manual Basler Avr Decs200 NDocument192 pagesManual Basler Avr Decs200 NSandro Muniz SouzaNo ratings yet

- Math Paper-1 0 PDFDocument6 pagesMath Paper-1 0 PDFHimanshu sharmaNo ratings yet

- Thermal Chemistry Calorimeter Problem AnswersDocument3 pagesThermal Chemistry Calorimeter Problem AnswersrkvermNo ratings yet

- Resnick Halliday S Physics For Iit Jee Vol 1Document2 pagesResnick Halliday S Physics For Iit Jee Vol 1vv0% (4)

- Hydrometer Calibration by Hydrostatic Weighing With Automated Liquid Surface PositioningDocument15 pagesHydrometer Calibration by Hydrostatic Weighing With Automated Liquid Surface PositioningSebastián MorgadoNo ratings yet