Professional Documents

Culture Documents

Tunnel Failure

Uploaded by

kzxeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tunnel Failure

Uploaded by

kzxeCopyright:

Available Formats

Anju Gopan et al Int.

Journal of Engineering Research and Applications

ISSN : 2248-9622, Vol. 4, Issue 3( Version 1), March 2014, pp.862-865

RESEARCH ARTICLE

www.ijera.com

OPEN ACCESS

A case study on failure of a tunnel intake

Anniamma Chacko**, Akhila Padanattil*, Anju Gopan*,

Chandana Venugopal*, Fasnamol T M*

** (Professor, Department of Civil Engineering, Mar Athanasius College of Engineering, Kothamangalam)

* (Civil Engineering VIII Semester Students, Mar Athanasius College of Engineering, Kothamangalam)

ABSTRACT

This paper deals with the study of causes of failure of a tunnel during excavation and the design of pre-support

system for proceeding the tunneling. The tunnel, 3396m long, driven by full face method, encountered a failure

at the intake during the course of tunneling. Soil tests were carried out to identify the type of soil. The most

probable reason for the failure was identified .A pre-support system known as pipe roofing or umbrella arch

method was suggested to recover from failure and for proceeding the tunneling. It was modelled using Creo

Parametric 1.0 and analysed using ANSYS 12.0 software. This paper concludes that pipe roofing is a practically

feasible pre-supporting technique recommended at the site for carrying out further excavation by means of

conventional method of tunneling.

Keywords Tunnel failure, pre-support system, pipe roofing, Creo Parametric, ANSYS

I.

Introduction

Many cases of tunnel failures have been

reported recently. An engineer who designs or

constructs underground works probably encounters

more uncertainties than those dealing with structures

above the earth surface. It behoves the creator of

underground structures to observe past failures, to

understand their causes and to device precautions

against their recurrence.

A case of tunnel failure occurred in Pallivasal, near

Munnar, Kerala. The history of hydro power

development in Kerala begins with commissioning

of Pallivasal hydroelectric project in 1940.The

Construction of a tunnel as a part of Pallivasal

extension scheme (PES) encountered a failure 550m

ahead of exact intake pool location.

This study deals with engineering analysis of its

cause and establishment of pre-supporting technique

for the collapsed section.

II.

Literature Review

Jerome.C.Neyer[1] reported many cases on

soft ground tunnel failures in Michigan. Failures

were due to ground settlement over tunnel, change

in geological formation, improper preliminary

investigation and ground water overflow.

Schubert W [2] inferred that freezing of the ground

is a pre-support method.

According to R.R Osgoui, A.Poli[3], Hannes

Gamsjager, Marcus Scholz[4], the roof pipe

umbrella is a tunnel pre-support technique

recommended

in case of difficult ground

conditions..

www.ijera.com

M.Pescara[5],Volkmann [6], pipe diameters 200mm

or lower is recommended in most of the ground

conditions.

Harazake[7] presented the result that pipe roofing or

umbrella arch method is an effective method for the

stability of tunnel face and for the improvement of

ground in front of tunnel face by measuring the

surface settlement and stress on steel pipe.

Design criteria for tunnel construction were selected

as per Tunnel design guidelines.

III.

Methodology

Method of tunneling employed at the site

was Full face method which is suitable only for

tunneling through self supporting rock strata. During

the course of tunneling, failure was encountered at

about 550m ahead of the exact intake pool location.

Any type of construction whether underground or

not depends primarily on soil properties. Soil tests

were conducted to identify the soil properties. The

results obtained are given in TABLE 1.

862 | P a g e

Anju Gopan et al Int. Journal of Engineering Research and Applications

ISSN : 2248-9622, Vol. 4, Issue 3( Version 1), March 2014, pp.862-865

www.ijera.com

TABLE 1. SOIL PROPERTIES

PREPROCESSOR

Particle size distribution

Gravel, %

12.2

Sand, %

83.7

Coarse Sand, %

16

Fine sand, %

30

silt, %

4.1

Type of soil

Well graded sand

Specific gravity

2.56

Permeability (cm/s)

8.99x10-4

Angle of internal friction ()

30

POSTPROCESSOR

Due to the presence of unexpected sandy strata in

the course of tunneling, heavy soil inflow resulted

which lead to the failure of tunnel at that region.

Further tunneling requires a suitable pre- supporting

system to avoid the soil inflow during underneath

excavation. Pipe roofing is one such pre supporting

system which was found to be most effective with

regard to the weak ground conditions of the site. In

this system, steel pipes of specific diameters

(ranging from 89mm to 200mm) and length 6m to

9m are installed at the crown of the tunnel. Grouting

is done in the annular gaps of the pipes and between

the ground and pipes.

Considering the structural action, it is a pre-support

system with longitudinal beam action in the

direction of tunnel excavation. Installed steel pipes

are interconnected to form a roof-like structure,

called a pipe roof, above the tunnel excavation. In

soil ground condition, pre reinforcement of the core

which has to be excavated, using longitudinal steel

pipes grouted into the ground, allows the excavation

of tunnels in very difficult ground conditions.

Inorder to suggest a suitable diameter and length for

the pipes to be used in the system, pipes of different

diameters (101.6, 152.4,165.1,193.7,219.1) mm and

length 6m were analysed for the same loading

condition using ANSYS 12.0. As an initial step,

modeling was done using Creo Parametric 1.0. The

modeled figure was imported to the ANSYS 12.0

software, then the analysis was carried out and the

diameter showing minimum deflection on loading

was finalized for using in the system. In ANSYS,

the general process of finite element analysis is

divided into three main phases, preprocessor,

solution, and postprocessor.

www.ijera.com

SOLUTION

1. Preprocessing: Defining the problem; the major

input data given in preprocessing stage are given

below:

Type of analysis (structural)

Element type

Real constants

Material properties

Geometric model

Meshed model

Loadings and boundary conditions

The amount of detail required will depend on the

dimensionality of the analysis. (i.e. 1D, 2D, 3D, axisymmetric).

2. Solution: Assigning loads, constraints and

solving. Here we specify the loads (points or

pressure), constraints (translational and rotational)

and finally solve the resulting set of equations.

Solution phase is completely automatic. The output

from the solution phase (result data files) is in the

numerical form and consists of nodal values of the

field variable and its derivatives.

3. Post processing: Further processing and viewing

of the results; in this stage one may view:

Deflection plots.

Stress contour diagrams

IV.

Results and Discussions

Results obtained in the form of deflection

and stress intensities, on analysing pipes of different

diameters using ANSYS for the same loading

conditions are given in TABLE 2.From the results

obtained, it was observed that pipes of diameter

165.1 mm and length 6 m gave minimum deflection

and uniform stress distribution (stresses within the

permissible limit)without any concentration of stress

at a particular point of the pipe, which means that

pipe section is most effective in resisting the earth

load due to overburden. Figures showing the

deformation and the stress distribution in the case of

863 | P a g e

Anju Gopan et al Int. Journal of Engineering Research and Applications

ISSN : 2248-9622, Vol. 4, Issue 3( Version 1), March 2014, pp.862-865

pipe diameter corresponding to the best section

Sl.No

Pipe

diameter

(mm)

101.6

152.4

165.1

www.ijera.com

(165.1 mm dia) are given below (Fig.1to3).

TABLE 2. RESULTS FROM ANALYSIS

Stress

Length

Deflection intensity

of pipe

Remarks

(mm)

(N/mm2)

(mm)

0.001913

15.094

0.001711

5.059

0.001662

6.425

6000

7.349

193.7

0.002556

219.1

0.003694

13.647

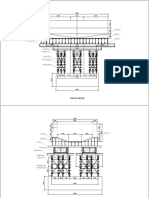

Fig. 1 Pipe roof model in ANSYS

When pipe dia = 165.1mm

Min. deformation and

uniform stress distribution

on the system.

ECONOMICAL SECTION

:

PIPE DIA = 165.1 mm

LENGTH = 6m

Fig.2 Deformed shape

Fig.3 Stress distribution

V.

Conclusions

From the soil tests conducted on the sample

of soil collected from the location of failure, the soil

at the site was found to be well graded sand. As the

tunneling method employed at the site was full face

method which is suitable only for self supporting

www.ijera.com

hard rock, tunnel driving failed when they

encountered sandy strata near the intake region. A

suitable pre-supporting system has to be

implemented at the site for carrying out further

tunnling process. From the detailed study conducted

on various types of pre supporting systems used in

tunnels such as ground freezing, pipe roofing etc.,

864 | P a g e

Anju Gopan et al Int. Journal of Engineering Research and Applications

ISSN : 2248-9622, Vol. 4, Issue 3( Version 1), March 2014, pp.862-865

www.ijera.com

the most feasible method that can be employed

conveniently in the field was found to be pipe

roofing method. The design of pipe roof support

system consists of selecting the diameter and length

of pipes to be used. From the results obtained from

analysis, a section which showed minimum

deformation was selected as the best section.

Pipe roofing is a practically possible method which

is recommended at the site because of its simplicity

in design and implementation.

VI.

Acknowledgement

We thank the authorities of coastal projects limited

for their help in this work

References

[1]. Jerone.C.Neyer,(2013),Soft ground tunnel

failure in Michigan,First International

Conference

on

case

Histories

on

Geotechnical Engineering.

[2]. Sthubert.W,A contribution(2006) to the

design of tunnel supported by a pipe roof in

Golden Rocks,Collarado

[3]. R.R.Usgoui, A.Poli, Challenging features in

design and execution of a low overburden

underpass-A case history from Malasia and

north south highway.

[4]. HannesGasjager,MarcusScholz, Pipe roofing

features and applications.

[5]. M.Pescara,Challenging features in design and

execution of a low overburden underpass-A

case history from Malasia and north south

highway.

[6]. Volkmann,contribution (2006) to the design

of tunnel supported by a pipe roof in Golden

Rocks,Collarado.

[7]. Harazaki et.al, Field observation of large

tunnel supported by umbrella method, Case

of Miko tunnel in Kobe,Japan. Pro. World

tunnel cong.98, on Tunnel and Metropolises,

Vol.2 Page 1009-1014.

www.ijera.com

Page

865 |

You might also like

- Essentials For A Good Night'S Sleep: Mattresses, Duvets and PillowsDocument4 pagesEssentials For A Good Night'S Sleep: Mattresses, Duvets and PillowselizondomaruNo ratings yet

- Ground Freezing 1980: Selected Papers from the Second International Symposium on Ground Freezing, Trondheim, Norway, 24-26 June 1980From EverandGround Freezing 1980: Selected Papers from the Second International Symposium on Ground Freezing, Trondheim, Norway, 24-26 June 1980No ratings yet

- IS 9120 - Guidelines For Planning Layout and Design of Cavities in Underground Hydroelectric Power Stations PDFDocument22 pagesIS 9120 - Guidelines For Planning Layout and Design of Cavities in Underground Hydroelectric Power Stations PDFthavisiNo ratings yet

- Design of The Metrowest Pressure TunnelDocument19 pagesDesign of The Metrowest Pressure Tunnelelisa02No ratings yet

- Nathpa - Jhakri Hydroelectric ProjectDocument12 pagesNathpa - Jhakri Hydroelectric Projectkulbrsingh4975No ratings yet

- Calculation of Induction Motor Starting Parameters Using MatlabDocument6 pagesCalculation of Induction Motor Starting Parameters Using MatlabДејан ПејовскиNo ratings yet

- No-Dig 2009 Paper B-2-01 Hunt-Del Nero - r5 - FinalDocument11 pagesNo-Dig 2009 Paper B-2-01 Hunt-Del Nero - r5 - FinalswhuntNo ratings yet

- Underground Construction TechonologyDocument107 pagesUnderground Construction TechonologyJose David GarciaNo ratings yet

- Mark-Vi Super Mark-Vi Super: SK200 SK200Document12 pagesMark-Vi Super Mark-Vi Super: SK200 SK200Pavidee100% (1)

- Instrumentation in TunnelsDocument14 pagesInstrumentation in Tunnelssravan_ruby100% (2)

- Karuma Cavern DesignDocument6 pagesKaruma Cavern DesignBinodNo ratings yet

- Fixed Platforms, Walkways, Stairways and Ladders-Design, Construction and InstallationDocument7 pagesFixed Platforms, Walkways, Stairways and Ladders-Design, Construction and InstallationgeofounNo ratings yet

- Guidelines For Operation of Desilting Basins PDFDocument23 pagesGuidelines For Operation of Desilting Basins PDFRajni Sharma100% (2)

- Tunnel Engineering-1Document26 pagesTunnel Engineering-1Ankit PatelNo ratings yet

- Globe Alarm Check Valve Installation and Maintenance GuideDocument36 pagesGlobe Alarm Check Valve Installation and Maintenance GuideAbdul Majeed KottaNo ratings yet

- Trip TicketDocument2 pagesTrip TicketKynth Ochoa100% (2)

- SEM Mined Tunnel PDFDocument3 pagesSEM Mined Tunnel PDFqaisarmehboob82No ratings yet

- Design and Construction of A Segmental LiningDocument9 pagesDesign and Construction of A Segmental LiningLiew Yen Ching100% (1)

- Nathpa - Jhakri Hydroelectric Project Him PDFDocument12 pagesNathpa - Jhakri Hydroelectric Project Him PDFSandeep Kumar Prajapati B.Tech. Mining Engg, IIT(BHU), Varanasi (U.P.), INDIANo ratings yet

- 100-Year Design Life of Rock Bolts and Shotcrete - 5th Ground Support in Mining Underg ConstDocument6 pages100-Year Design Life of Rock Bolts and Shotcrete - 5th Ground Support in Mining Underg Consteep1977No ratings yet

- Underground Cavern DesignDocument6 pagesUnderground Cavern DesignIsaacQuispeAriasNo ratings yet

- Innovation in Bored Tunnel Segmental Lining Design in Singapore - Steel Fiber Reinforced Concrete (SFRC)Document9 pagesInnovation in Bored Tunnel Segmental Lining Design in Singapore - Steel Fiber Reinforced Concrete (SFRC)SeasonNo ratings yet

- IS 4880-1 (1987) Code of Practice For Design of Tunnels Conveying Water, General DesignDocument7 pagesIS 4880-1 (1987) Code of Practice For Design of Tunnels Conveying Water, General DesignAlok Kumar0% (1)

- Barton, N. and E. Grimstad, 2014 Q-System - An Illustrated Guide Following 40 Years in Tunnelling. 43p, 79 FigsDocument44 pagesBarton, N. and E. Grimstad, 2014 Q-System - An Illustrated Guide Following 40 Years in Tunnelling. 43p, 79 FigsGeogeneralNo ratings yet

- Kawasaki EDGE CatalogDocument99 pagesKawasaki EDGE CatalogkzxeNo ratings yet

- Umbrella Arch Method Performance, Structural Behavior and DesignDocument15 pagesUmbrella Arch Method Performance, Structural Behavior and Designzimbazimba75No ratings yet

- Designing Sequential Excavation for Weak Rock TunnelsDocument8 pagesDesigning Sequential Excavation for Weak Rock TunnelstibammNo ratings yet

- Design of Tail Race System of Rampur HEPDocument9 pagesDesign of Tail Race System of Rampur HEPengineerramanNo ratings yet

- Tunnel-1 Support Final Design ReportDocument68 pagesTunnel-1 Support Final Design ReportAishwarya KumarNo ratings yet

- Latest Technology Ofunderground Rock Cavern Excavation in JapanDocument18 pagesLatest Technology Ofunderground Rock Cavern Excavation in JapanpbldzcmsNo ratings yet

- Kutehr-IE Phase1 ReportDocument96 pagesKutehr-IE Phase1 ReportL.C. GOYALNo ratings yet

- Temporary Excavation Support System For A New Railway Bridge and Highway Underpass in Pittsburgh, Pennsylvania by Andrew G. Cushing and Christopher J. LewisDocument8 pagesTemporary Excavation Support System For A New Railway Bridge and Highway Underpass in Pittsburgh, Pennsylvania by Andrew G. Cushing and Christopher J. LewisAndrew CushingNo ratings yet

- Tunnels and Suport SystemsDocument33 pagesTunnels and Suport SystemsShella Marie Nartatez-NiroNo ratings yet

- 17 Rock Lab TestingDocument41 pages17 Rock Lab TestingshnkrvusharmaNo ratings yet

- Zojila and Z-Morh TunnelDocument29 pagesZojila and Z-Morh TunnelJamsheed Monu0% (1)

- Construction of a Cross-Passage for Delhi Metro's Twin Tunnel SystemDocument3 pagesConstruction of a Cross-Passage for Delhi Metro's Twin Tunnel SystemJothimanikkam SomasundaramNo ratings yet

- Tunnelling in Weak Zone - A Case Study of Tunnel Construct Ion at Allain Duhangan Hydroelectric ProjectDocument19 pagesTunnelling in Weak Zone - A Case Study of Tunnel Construct Ion at Allain Duhangan Hydroelectric ProjectAnanda Sen100% (1)

- Economic DispatchDocument37 pagesEconomic DispatchHasan KurniawanNo ratings yet

- Methods of TunnellingDocument4 pagesMethods of TunnellingVicces P. EstradaNo ratings yet

- Important design aspects of the Railway Tunnel T-74RDocument9 pagesImportant design aspects of the Railway Tunnel T-74RAjay SinghNo ratings yet

- Support System Design of Power House and Transformer Caverns in DDocument5 pagesSupport System Design of Power House and Transformer Caverns in Dvikalp1982No ratings yet

- History of Tunnels in IndiaDocument191 pagesHistory of Tunnels in IndiaSaurabh Singh100% (1)

- Chameliya Hydroelectric Project Underground Excavations Case StudyDocument77 pagesChameliya Hydroelectric Project Underground Excavations Case StudySaphal LamichhaneNo ratings yet

- Design and Construction of The Billy Bishop City Airport Pedestrian Tunnel, Toronto, CanadaDocument8 pagesDesign and Construction of The Billy Bishop City Airport Pedestrian Tunnel, Toronto, CanadaAndrew Cushing100% (1)

- Planning and Design of Underground Hydropower StructuresDocument41 pagesPlanning and Design of Underground Hydropower StructuresshantanusamajdarNo ratings yet

- Empirical Correlation Between RMR and Q Systems For Lesser Himalayan RocksDocument7 pagesEmpirical Correlation Between RMR and Q Systems For Lesser Himalayan Rocksrahul khannaNo ratings yet

- Bill of Quantity For Drilling of Twenty BoreholesDocument1 pageBill of Quantity For Drilling of Twenty BoreholesAnonymous OeoeVBmwNo ratings yet

- Construction of Deep Plastic Concrete Cut-Off Wall in Upstream Coffer Dam of Punatsangchhu-I Hydropower Project, BhutanDocument8 pagesConstruction of Deep Plastic Concrete Cut-Off Wall in Upstream Coffer Dam of Punatsangchhu-I Hydropower Project, BhutanVetriselvan ArumugamNo ratings yet

- SJVNL 76 - 1 - Finalconsolidated - Environmental - RHEP PDFDocument364 pagesSJVNL 76 - 1 - Finalconsolidated - Environmental - RHEP PDFVARUNNo ratings yet

- Damage Profile AnalysisDocument4 pagesDamage Profile AnalysisPalashNo ratings yet

- Influence of Geology on Tunnel Design & ConstructionDocument29 pagesInfluence of Geology on Tunnel Design & ConstructionGEOMAHESHNo ratings yet

- Product Index Working Method and Technique ForepolingDocument3 pagesProduct Index Working Method and Technique Forepolingmypenta2008No ratings yet

- India's Growing Metro Rail SystemsDocument121 pagesIndia's Growing Metro Rail SystemsfidicNo ratings yet

- Indian Standard: Code of Practice For Construction of TunnelsDocument12 pagesIndian Standard: Code of Practice For Construction of Tunnelsvijaykadam_ndaNo ratings yet

- Tunnelling challenges overcome at Tala hydroelectric projectDocument9 pagesTunnelling challenges overcome at Tala hydroelectric projectAnanda SenNo ratings yet

- Pregrouting For Leakage Control and Rock Improvement 2165 784X 1000226Document4 pagesPregrouting For Leakage Control and Rock Improvement 2165 784X 1000226Abhilash UrsNo ratings yet

- The Seepage Control of The Tunnel Excavated in High-Pressure Water Condition Using Multiple Times Grouting Method PDFDocument17 pagesThe Seepage Control of The Tunnel Excavated in High-Pressure Water Condition Using Multiple Times Grouting Method PDFMarsheal FisongaNo ratings yet

- Geological Society, London, Engineering Geology Special Publications, 16, 257-289, 1 January 1999Document33 pagesGeological Society, London, Engineering Geology Special Publications, 16, 257-289, 1 January 1999akhila sNo ratings yet

- Fore PoleDocument4 pagesFore PoleBilal MirNo ratings yet

- 4880 - 6-Tunnel Support PDFDocument12 pages4880 - 6-Tunnel Support PDFGarg TjNo ratings yet

- Clay BlanketDocument2 pagesClay BlanketAhmed Tarek100% (1)

- Rockfall Mitigation NH-22 Case StudyDocument4 pagesRockfall Mitigation NH-22 Case StudyRaghavNo ratings yet

- Project Proposal On Hydraulic Transient. Case Study Rubavu HPTDocument8 pagesProject Proposal On Hydraulic Transient. Case Study Rubavu HPTEng Bagaragaza RomualdNo ratings yet

- Rock TunnelDocument28 pagesRock TunnelPrachiti ShingadeNo ratings yet

- Desain Metode Pier Head Lebar 10m REV01Document3 pagesDesain Metode Pier Head Lebar 10m REV01kzxeNo ratings yet

- Zener DiodeDocument6 pagesZener DiodePhani SingamaneniNo ratings yet

- Zener DiodeDocument6 pagesZener DiodePhani SingamaneniNo ratings yet

- Tempe Mendoan in Bhs JawaDocument1 pageTempe Mendoan in Bhs JawakzxeNo ratings yet

- Price List Kaze Series As Dated 08-08-2011Document49 pagesPrice List Kaze Series As Dated 08-08-2011kzxe100% (2)

- Diccionario de Urbanismo Geografia Urbana y Ordenacion Del TerritorioDocument10 pagesDiccionario de Urbanismo Geografia Urbana y Ordenacion Del TerritorioGpe. MercadoNo ratings yet

- Refrigeration Cycles and Systems: A Review: ArticleDocument18 pagesRefrigeration Cycles and Systems: A Review: ArticleSuneel KallaNo ratings yet

- CIECO PPC1000R Installation Manual V3.3Document61 pagesCIECO PPC1000R Installation Manual V3.3TomNo ratings yet

- Dmr-Es10Eb Dmr-Es10Ec Dmr-Es10Eg Dmr-Es10Ep Dmr-Es10Ebl: DVD Video RecorderDocument71 pagesDmr-Es10Eb Dmr-Es10Ec Dmr-Es10Eg Dmr-Es10Ep Dmr-Es10Ebl: DVD Video RecorderWILIAM RODRIGUEZNo ratings yet

- Narrative Report 2BDocument14 pagesNarrative Report 2BMarc Edson CastroNo ratings yet

- IV-series-fieldnetwork Field Network Um 442gb GB WW 1086-2Document114 pagesIV-series-fieldnetwork Field Network Um 442gb GB WW 1086-2azzszoNo ratings yet

- NLPDocument20 pagesNLPAvishek01No ratings yet

- Hi Tech ApplicatorDocument13 pagesHi Tech ApplicatorSantosh JayasavalNo ratings yet

- Medium Voltage Surge Arresters Catalog HG 31.1 2017 Low Resolution PDFDocument79 pagesMedium Voltage Surge Arresters Catalog HG 31.1 2017 Low Resolution PDFAnkur_soniNo ratings yet

- Cisco Mobility Express Command Reference, Release 8.3Document1,158 pagesCisco Mobility Express Command Reference, Release 8.3Ion Vasilescu100% (1)

- Analyzing Kernel Crash On Red HatDocument9 pagesAnalyzing Kernel Crash On Red Hatalexms10No ratings yet

- Southwire Mining Product CatalogDocument32 pagesSouthwire Mining Product Catalogvcontrerasj72No ratings yet

- Polyken Pipeline #1027,: Primers #1019Document3 pagesPolyken Pipeline #1027,: Primers #1019Azmi SyariefNo ratings yet

- Example Problem Solutions - Chapter 8Document18 pagesExample Problem Solutions - Chapter 8Nguyen Tien DungNo ratings yet

- Nitin FicoDocument3 pagesNitin Ficoapi-3806547100% (1)

- WarpriestDocument8 pagesWarpriestBenguin Oliver MasonNo ratings yet

- MBA Final ProjectDocument108 pagesMBA Final ProjectMindy Thomas67% (3)

- AUC-Knowledge QuestionsDocument68 pagesAUC-Knowledge QuestionsFarhan SethNo ratings yet

- Database ScriptsDocument111 pagesDatabase ScriptsVikas GaurNo ratings yet

- GAZT E-invoice Data DictionaryDocument119 pagesGAZT E-invoice Data Dictionarysahira TejadaNo ratings yet

- Olympus Industrial Endoscopes Offer Reliable InspectionsDocument16 pagesOlympus Industrial Endoscopes Offer Reliable InspectionsYeremia HamonanganNo ratings yet

- Modules Test ReportDocument4 pagesModules Test ReportprojectsNo ratings yet

- Anshul BhelDocument96 pagesAnshul BhelMessieurs Avinash PurohitNo ratings yet