Professional Documents

Culture Documents

Measure kicker septa pulses

Uploaded by

Monal BhoyarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Measure kicker septa pulses

Uploaded by

Monal BhoyarCopyright:

Available Formats

current pulse and store it for an offline

analysis. Another system is installed in the

room of the high voltage pulser to measure

the thyratron voltages.

A measuring system for Kicker

and Septa pulses

J.Hildemann, DESY MIN, 22603 Hamburg

E-Mail: hildeman@min1.desy.de

Hardware

There are two different systems used to

measure the 12 signals. One system consist

of a Hewlett Packard 3488A multiplexer,

two HP 54542A oscilloscopes and a PC

with an National Instrument (NI) PC DIO

24 data acquisition card to get the status of

PETRA and a NI GPIB card to control the

multiplexer and the oscilloscopes. The

HP54542A oscilloscopes can measure with

a sampling rate up to 2Gsamples/s and the

data is read out with the NI GPIB card.

The other system consist of a PC with an

National Instruments AT MIO 16 E-1 data

acquisition card which can measure 4

channels with a sampling rate from 250

ksamples/s for each channel. Both PCs

have a Intel Pentium 133 MHz processor

and they are connected via a LWL-Ethernet

connection to a Novell 3.12 fileserver to

store all the data. For maintenance there is

one additional system, which measures the

voltages of the thyratrons in the high

voltage kicker pulsers and stores it on the

same fileserver as the other systems. Its

one PC with an National Instruments

LPM16 data acquisition card.

Abstract

Since 1994 we are working on a measuring

system for Kicker and Septa pulses. The

system measures the current pulses of the

PETRA ejection and HERA injection

devices for protons and electrons/positrons.

The current pulses are transmitted via

lightwavecable to the electronic room near

the control room. To measure up to 12

signals we use one Hewlett packard 3488

multiplexer and two digital 4-channel

Hewlett Packard oscilloscopes for the fast

kicker pulses (the shortest has a pulse

length of 1 us) and 1 PC with an National

Instruments DAQ card AT-MIO 16 E1 to

measure 4 slower septa pulses.We use 1 PC

to read the 2 oscillocopes and to control

the multiplexer with the GPIB bus. The

data is stored on a Novell 3.12 fileserver.

The software on the 2 measuring PCs and

the controlroom software is made with

LabVIEW, a graphical programming

language. For the controlroom we have

made a program that shows the pulses from

the last ejection and you can load all the

pulses, that are stored on our Novell

Server. This program uses a Novell

connection to our Novell fileerver and is

running on MS Windows 3.11.

For the future we want to read out all the

values of the HERA/PETRA control

system for our devices and store it with our

data for each shot. We are developping a

client/server solution running on Windows

NT using TCP/IP for the control room

program.

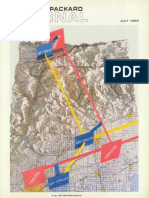

Measuring system for kicker and septa pulses

Trigger

status PETRA

P - E+/-

Petra

Protonen

Eje ktio n

LWL

transmitter

Petra

Elektronen/P ositronen

Eje ktio n

LWL

transmitter

Hera

Protonen

Injektio n

LWL

transmitter

4 channel

Trigger

HP54542A Oszilloskop

4xLWL

5xLWL

LWL receiver

BNC

HP3488A Multiplexer

GPIB

5xLWL

PC with

Labvie w Programm

to measure pulser voltages

BNC

PC with Labview Programm

6xLWL

4 channel

Trigger

HP54542A Oszilloskop

BNC

Hera

Positronen/E le ktronen

Injektio n

LWL

transmitter

connection board

BNC

PC with Labview Program

and

NI AT MIO 16E1 DAQ card

LWL ethernet connection

Repeater BNC / LWL

LWL Ethernet connection

Introduction

Kicker and Septa are used for the in- and

ejection of the particles in the accelarators

and storage rings. To maintain and repair

the kicker and septa pulser it is very

important to get information about their

current status. When particles are stored in

the HERA ring, it is not possible to test our

devices. The only way to get informations

about their work is to measure every

Fileserver MIN2

Figure 1 Hardware

Software

Every program of the measuring system is

made with LabVIEW 4.0 from National

Instruments. LabVIEW is a graphical

programming language (Figure 2), which is

easy to learn and to use. LabVIEW has a

1

lot of device driver for all different kind of

intstruments, controlled with the GPIB bus

or with the serial port of the computer. The

data acquisitions cards from National

Instruments are very good integrated in the

programming language. In LabVIEW the

programs

are

called VI

virtual

instruments. There are some problems to

use the german windows version with

LabVIEW and the device drivers, but its

no problem to modify some parts of the

code, because all subroutines, in LabVIEW

they are called Sub VIs, are delivered by

National Instruments. For LabVIEW you

can get an Application Builder. With this

part of LabVIEW, you can build an

executable program so that you dont need

the whole development program from

LabVIEW on every computer.

On the measuring computers we use

Windows

3.1x,

because

National

Instruments has no plug and play driver for

the AT-MIO 16 E-1 for Windows NT.

When the drivers for Windows NT are

available, we want to convert the PCs to

Windows NT. Currently there are no

problems with the software, Windows 3.11

and LabVIEW are running very stable

together.

table. The program reads the setup by DDE

(dynamic data exchange) from MS Excel.

2 Bit of an SEDAC DIO card are set by the

PETRA control system and give the status

of PETRA. A LabVIEW VI, which is

running seperate, reads this 2 Bits with the

PC DIO 24 card and sets the switches of

the multiplexer ports and sets the

configuration of the oscilloscopes.

The data is stored in different files for the 4

different groups of devices (PETRA

electron/positron ejection, PETRA proton

ejection, HERA electron/positron injection,

HERA proton injection) and the last data is

stored in a single file together with the

status of PETRA.

The second PC has a simple measuring

program. The setup is stored in the same

Excel table. The AT MIO 16 E1 data

acquisition card writes the data with DMA

in the memory of the PC. After the

triggering of the card, the program reads

the data of 512 points and 4 channels and

stores it in a file and in the file of the actual

pulses. This program reads the status of

PETRA out of the file for the actual pulses.

Both programs run without user control.

We got for one shot to HERA ca.

3x8,8kByte of data.

Analysis Software

The Analysis program is running in the

control room of DESY. It shows the 3 sets

of pulses of the last shot (Figure 3). The

program has the option to load stored data

from the fileserver The user can scroll

through all pulses of one day (Figure 4).

Another option for maintenance is to load

more than one pulse (Figure 5). Its easy to

find out timing problems. This program

uses a direct Novell connection (a drive

mapping) to the file server.

Figure 2 Programming example

Measuring Software

On the two measuring PCs the programs

have totally different functions. On the first

PC the program controls the multiplexer

and the oscilloscopes over GPIB bus. The

data is read out by GPIB bus and stored on

the Novell Server. The oscilloscopes

measure for each device 512 points, the

time base is variable and depends on the

devices. The setup is stored in an MS Excel

2

We are developping an analysis software

which uses the TCP/IP protocol. Its an

client/server solution, the serverprogram is

running on Windows NT and needs a

Novell connection to the Novell server with

the data. The clientprogram calls up the

serverprogram and gets the data direct with

the TCP/IP protocol. This helps the Novell

server to save connections, and makes the

client software easier to use on any

computer in the DESY network. The

current versions of the client software are

running under Windows NT, Windows 3.1

and Windows 95 without problems. It is

possible to integrate our pulses into new

versions of the HERA control system,

because the same protocol ist used. This

kind of transmission gives the possibility to

get the data anywhere on the internet, when

the client software is installed on the

computer.

Figure 3 Main screen

References

[1]

National Instruments LabVIEW 4.0

manuals, January 1996

[2]

National Instruments AT-MIO E

Series User Manual, 1995

[3]

Hewlett Packard HP 54542A

Programmers Reference, 1993

[4]

Hewlett Packard HP 3488A Manual

Figure 4 Load screen

Figure 5 Analysis screen

Future

For the future we plan to store all the

values from the in- and ejection devices,

that are available from the HERA and

PETRA control system, because otherwise

its very difficult to analyse, if any changes

on the pulses depend on technical problems

or if someone has changed any values on

the control system. Currently the

mechanism to use DLL of the PKTR

control system with LabVIEW is tested.

3

You might also like

- Data LoggingDocument20 pagesData Loggingjass1304No ratings yet

- Mic Project ReportDocument11 pagesMic Project ReportDivya BansodeNo ratings yet

- Gpls Vme Module: A Diagnostic and Display Tool For Nsls Micro SystemsDocument3 pagesGpls Vme Module: A Diagnostic and Display Tool For Nsls Micro SystemsSai KrishnaNo ratings yet

- Project2 PsocDocument10 pagesProject2 PsocKarthik V KalyaniNo ratings yet

- VirtualInstrumentation ArticleDocument22 pagesVirtualInstrumentation ArticleSumit MauryaNo ratings yet

- (IJET-V2I3 - 1P9) Authors: Apurva Ganar, Rachana Borghate, Kumudini Borkute, Nilesh ChideDocument4 pages(IJET-V2I3 - 1P9) Authors: Apurva Ganar, Rachana Borghate, Kumudini Borkute, Nilesh ChideInternational Journal of Engineering and TechniquesNo ratings yet

- lAB MANUAL MIC ROPROCESSORS AND MICROCONTROLLERS LAB, IV b.tECH Eee PDFDocument111 pageslAB MANUAL MIC ROPROCESSORS AND MICROCONTROLLERS LAB, IV b.tECH Eee PDFASDM asdmNo ratings yet

- Mplab 1Document75 pagesMplab 1lingalashanthipriya_No ratings yet

- 1985-07 - HP Journal PapersDocument36 pages1985-07 - HP Journal PapersElizabeth WilliamsNo ratings yet

- PID Analyzer Field Portable PID Logging SoftwareDocument2 pagesPID Analyzer Field Portable PID Logging SoftwareJennifer MaclachlanNo ratings yet

- Virtual Instrumentation Interface For SRRC Control System: The Is AsDocument3 pagesVirtual Instrumentation Interface For SRRC Control System: The Is AsJulio CésarNo ratings yet

- Remote Control Software For Rohde & Schwarz InstrumentsDocument4 pagesRemote Control Software For Rohde & Schwarz InstrumentsTomáš ShejbalNo ratings yet

- Embedded Systems GuideDocument28 pagesEmbedded Systems GuideS.DurgaNo ratings yet

- 1.2 Parts of A DAQ SystemDocument37 pages1.2 Parts of A DAQ SystemMaddipati SumanthNo ratings yet

- BITalino PDFDocument4 pagesBITalino PDFRabab M AlyNo ratings yet

- Pir Sensor Based Energy SaverDocument76 pagesPir Sensor Based Energy Saverk.aparna100% (1)

- Objective and AimDocument6 pagesObjective and AimSaadat ZaidiNo ratings yet

- Hitachi HD44780 LCDDocument2 pagesHitachi HD44780 LCDDamodarBhatNo ratings yet

- MP & DSP Lab ManualDocument122 pagesMP & DSP Lab ManualShiva RamNo ratings yet

- Ementation RF Monito NG System Fo: FA NEWDocument3 pagesEmentation RF Monito NG System Fo: FA NEWakasheieNo ratings yet

- Real Time Systems Lab: Managing A Schedule With A Remote DeviceDocument14 pagesReal Time Systems Lab: Managing A Schedule With A Remote DeviceJ robertsNo ratings yet

- Tutorial Background: Fundamentals of Virtual Instruments Tradtional Instruments Virtual InstrumentsDocument17 pagesTutorial Background: Fundamentals of Virtual Instruments Tradtional Instruments Virtual InstrumentsMohammed JunedNo ratings yet

- Micro HopeDocument48 pagesMicro Hopeviolator100% (1)

- Gpib and Ieee 488Document17 pagesGpib and Ieee 488communicationridersNo ratings yet

- Research Paper Pic MicrocontrollerDocument6 pagesResearch Paper Pic Microcontrollerupvipbqlg100% (1)

- Processor FundamentalDocument15 pagesProcessor Fundamentaldhaylan cuneapenNo ratings yet

- Low Cost Data Acquisition From Digital Caliper To PCDocument6 pagesLow Cost Data Acquisition From Digital Caliper To PCInternational Journal of Research in Engineering and TechnologyNo ratings yet

- DB-51 User's GuideDocument21 pagesDB-51 User's GuideyogeshmgaidhaneNo ratings yet

- Development of Monitoring Unit For Data Acquisition From Avionic BusDocument9 pagesDevelopment of Monitoring Unit For Data Acquisition From Avionic Busiwc2008007No ratings yet

- Nanodac AN 030817U001 1Document6 pagesNanodac AN 030817U001 1aca85No ratings yet

- Parallel CommunicationDocument47 pagesParallel CommunicationBituNo ratings yet

- BME 438 Digital Logic Design and Computer Architecture LabDocument73 pagesBME 438 Digital Logic Design and Computer Architecture LabHafiz Muhammad Ahmad RazaNo ratings yet

- Max DnaDocument17 pagesMax DnaAdil ButtNo ratings yet

- Distributed Control Systems: Prof - Dr. Joyanta Kumar RoyDocument27 pagesDistributed Control Systems: Prof - Dr. Joyanta Kumar Royramu308No ratings yet

- Program Controlled I/ODocument7 pagesProgram Controlled I/ODavid RenzoNo ratings yet

- 8085 Microprocessor Trainer GuideDocument73 pages8085 Microprocessor Trainer GuideKuldeep Saini0% (1)

- TCP IP Lan ThermometerDocument12 pagesTCP IP Lan ThermometerBranislav BusovskyNo ratings yet

- 8 TemparatureDocument31 pages8 TemparatureDemonfox NarutoUzumakiNo ratings yet

- CoDocument80 pagesCogdayanand4uNo ratings yet

- SCADA Data Gateway Fact SheetDocument3 pagesSCADA Data Gateway Fact SheetAswanth Kumar KurellaNo ratings yet

- Microprocessor ProjectDocument7 pagesMicroprocessor ProjectNewton Scientist100% (1)

- FPGA-based multi-protocol data acquisition system with high-speed USBDocument4 pagesFPGA-based multi-protocol data acquisition system with high-speed USBksajjNo ratings yet

- Overall Description: Advantage of Proposed SystemDocument34 pagesOverall Description: Advantage of Proposed Systemletter2lalNo ratings yet

- Distributed Control Systems: Prof - Dr. Joyanta Kumar RoyDocument27 pagesDistributed Control Systems: Prof - Dr. Joyanta Kumar RoyShyamNo ratings yet

- ESP-WROOM-02: What Is The "Internet of Things"?Document7 pagesESP-WROOM-02: What Is The "Internet of Things"?KOKONo ratings yet

- Res 2 DinvDocument133 pagesRes 2 DinvAfifah Nur'aghnia KusumadewiNo ratings yet

- FPGA-based multi-protocol data acquisition systemDocument4 pagesFPGA-based multi-protocol data acquisition systemVibin MammenNo ratings yet

- Electronics Project Automatic Bike Controller Using Infrared RaysDocument16 pagesElectronics Project Automatic Bike Controller Using Infrared RaysragajeevaNo ratings yet

- Patient GSM NewDocument39 pagesPatient GSM Newpiyushji125No ratings yet

- Cold Storage Temperature MonitoringDocument24 pagesCold Storage Temperature Monitoringpashupathyiyer100% (1)

- 8085 Microprocessor Programming Modes and Instruction SetDocument16 pages8085 Microprocessor Programming Modes and Instruction SetUiNo ratings yet

- Annexure For Beeprog+Document4 pagesAnnexure For Beeprog+Mdd Papis0% (1)

- Converter Ethernet TCP/IP 10/100 Mbps RJ45 to Serial RS-232 DB9 with Client - Server - Mode User ManualDocument49 pagesConverter Ethernet TCP/IP 10/100 Mbps RJ45 to Serial RS-232 DB9 with Client - Server - Mode User ManualsunrayNo ratings yet

- Example ReportDocument26 pagesExample ReportSofi FaizalNo ratings yet

- Digital Assignment-1Document6 pagesDigital Assignment-1shivaNo ratings yet

- Practical Data Acquisition for Instrumentation and Control SystemsFrom EverandPractical Data Acquisition for Instrumentation and Control SystemsNo ratings yet

- PLC: Programmable Logic Controller – Arktika.: EXPERIMENTAL PRODUCT BASED ON CPLD.From EverandPLC: Programmable Logic Controller – Arktika.: EXPERIMENTAL PRODUCT BASED ON CPLD.No ratings yet

- Preliminary Specifications: Programmed Data Processor Model Three (PDP-3) October, 1960From EverandPreliminary Specifications: Programmed Data Processor Model Three (PDP-3) October, 1960No ratings yet

- Japan Covering LetterDocument1 pageJapan Covering LetterMonal Bhoyar0% (1)

- Japan - Schedule of Stay4Document2 pagesJapan - Schedule of Stay4Monal BhoyarNo ratings yet

- ARTICLE - Oral History of Captain Grace Hopper (Computer History) PDFDocument54 pagesARTICLE - Oral History of Captain Grace Hopper (Computer History) PDFMonal BhoyarNo ratings yet

- SsDocument3 pagesSsMonal BhoyarNo ratings yet

- File SetDocument1 pageFile SetMonal BhoyarNo ratings yet

- Google MapsDocument3 pagesGoogle MapsMonal BhoyarNo ratings yet

- BoardingPass ReturnDocument2 pagesBoardingPass ReturnMonal BhoyarNo ratings yet

- TEST - Labview BasicsDocument12 pagesTEST - Labview BasicsMonal BhoyarNo ratings yet

- Cumulative Test: Labview BasicsDocument4 pagesCumulative Test: Labview BasicsAnirban Mitra0% (1)

- Issues On 26112016Document1 pageIssues On 26112016Monal BhoyarNo ratings yet

- Certification FAQDocument5 pagesCertification FAQMonal BhoyarNo ratings yet

- README - Finding CH01 ExamplesDocument1 pageREADME - Finding CH01 ExamplesMonal BhoyarNo ratings yet

- ActionsDocument2 pagesActionsMonal BhoyarNo ratings yet

- Test Program Naming StandardDocument3 pagesTest Program Naming StandardMonal BhoyarNo ratings yet

- Header For GrrstudyDocument1 pageHeader For GrrstudyMonal BhoyarNo ratings yet

- An Introduction To Labview Exercise PDFDocument4 pagesAn Introduction To Labview Exercise PDFMonal BhoyarNo ratings yet

- Experiment GuideDocument12 pagesExperiment GuideMonal BhoyarNo ratings yet

- Introduction To Labview Two-Part ExerciseDocument6 pagesIntroduction To Labview Two-Part ExerciseMonal BhoyarNo ratings yet

- Introduction To Labview Two-Part ExerciseDocument6 pagesIntroduction To Labview Two-Part ExerciseMonal BhoyarNo ratings yet

- Using Pivot Tables in Excel 2003Document4 pagesUsing Pivot Tables in Excel 2003Monal BhoyarNo ratings yet

- Fpga PinoutDocument3 pagesFpga Pinoutsureshchattu100% (1)

- Logiclock MakefileDocument2 pagesLogiclock MakefileMonal BhoyarNo ratings yet

- S 5Document5 pagesS 5Monal BhoyarNo ratings yet

- Importing HSM Datalog FilesDocument2 pagesImporting HSM Datalog FilesMonal BhoyarNo ratings yet

- Article - Who Were Upagupta and His AshokaDocument24 pagesArticle - Who Were Upagupta and His AshokaMonal BhoyarNo ratings yet

- Teaching Tip: Practice Integration On Problem Triplets: ReferencesDocument1 pageTeaching Tip: Practice Integration On Problem Triplets: ReferencesMonal BhoyarNo ratings yet

- S 3Document8 pagesS 3Monal BhoyarNo ratings yet

- S 4Document10 pagesS 4Monal BhoyarNo ratings yet

- VISHAY VjcommercialseriesDocument15 pagesVISHAY VjcommercialseriesMonal BhoyarNo ratings yet

- Operation Manual of HE173 USB Data Loggers - PDFDocument12 pagesOperation Manual of HE173 USB Data Loggers - PDFEmilis Campo OchoaNo ratings yet

- ICT Skills Full Book PDFDocument411 pagesICT Skills Full Book PDFTGrey02783% (47)

- UNIT 1: Formal Writing: Chapter 1Document14 pagesUNIT 1: Formal Writing: Chapter 1Ian CampbellNo ratings yet

- Michelle Lagura OutputDocument4 pagesMichelle Lagura Outputmichelle laguraNo ratings yet

- E-Ball - The Smallest ComputerDocument6 pagesE-Ball - The Smallest ComputerKing MakerNo ratings yet

- Digital Prepress PDFDocument16 pagesDigital Prepress PDFstevenNo ratings yet

- Electrical and Computer Engineering: Masc / Meng / PHDDocument3 pagesElectrical and Computer Engineering: Masc / Meng / PHDEmdadul Hoq RakibNo ratings yet

- Ii Unit OsDocument25 pagesIi Unit OsNareshkumarSettiNo ratings yet

- Optiplex 745Document428 pagesOptiplex 745albertoNo ratings yet

- PM Textbook 2008syllabusDocument408 pagesPM Textbook 2008syllabusSaChibvuri Jeremiah100% (1)

- Manual FPX PDFDocument584 pagesManual FPX PDFCyber PhoenixNo ratings yet

- Advanced KM DevelopmentDocument287 pagesAdvanced KM Developmentalmas00No ratings yet

- Comp Worksheet Uploaded Max 5 10Document403 pagesComp Worksheet Uploaded Max 5 10Ahmed Rasheed AliNo ratings yet

- CD5291 Computer Aided Tools for Manufacturing Detailed SyllabusDocument2 pagesCD5291 Computer Aided Tools for Manufacturing Detailed SyllabusKamalakkannan RadhakrishnanNo ratings yet

- Ieee Paper On Arduino Based Hand Gesture ControlDocument6 pagesIeee Paper On Arduino Based Hand Gesture ControlSRUTHI M SREEKUMARNo ratings yet

- Cat Ele IngDocument12 pagesCat Ele Ingkaniappan sakthivelNo ratings yet

- 90210-1221DEA Voice RecorderDocument16 pages90210-1221DEA Voice RecorderqwertyNo ratings yet

- Eng XIDocument214 pagesEng XIThilakRaj ChittibabuNo ratings yet

- Online Hotel Reservation ofDocument69 pagesOnline Hotel Reservation ofc_s_vignesh27100% (2)

- Match The Words in The Box To The Pictures Below.: Power SupplyDocument1 pageMatch The Words in The Box To The Pictures Below.: Power SupplyyuliaNo ratings yet

- Combined EngilishDocument198 pagesCombined EngilishRajkumar MathurNo ratings yet

- Lecture Notes: ON Advance Manufacturing &Cad/CamDocument23 pagesLecture Notes: ON Advance Manufacturing &Cad/CamDr.R.Pugazhenthi Associate Prof.No ratings yet

- Booklet - Present Perfect - MAGDADocument11 pagesBooklet - Present Perfect - MAGDAKarla FreitasNo ratings yet

- 2022 Jan Bcs 011Document8 pages2022 Jan Bcs 011Kashish Kanojia100% (2)

- TECHNOLOGY FOR TEACHING AND LEARNING 1 AnswerDocument19 pagesTECHNOLOGY FOR TEACHING AND LEARNING 1 AnswerRezel SyquiaNo ratings yet

- All Tenses (1) Exercuse 5.Document16 pagesAll Tenses (1) Exercuse 5.Daniela ParradoNo ratings yet

- Computer-Based Test: Simeon Ayoade AdedokunDocument31 pagesComputer-Based Test: Simeon Ayoade AdedokunRajput RishavNo ratings yet

- Australian International School, Dhaka MYP 3 Math AssessmentDocument12 pagesAustralian International School, Dhaka MYP 3 Math AssessmentMohammad AliNo ratings yet

- Your Interactive Guide To The Digital WorldDocument52 pagesYour Interactive Guide To The Digital WorldNisa HassanNo ratings yet

- Ict ModuleDocument26 pagesIct ModuleSai GuyoNo ratings yet