Professional Documents

Culture Documents

TMG Stressing Equipments

Uploaded by

sujay13780Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TMG Stressing Equipments

Uploaded by

sujay13780Copyright:

Available Formats

TMG Stressing Equipments

TMG Stressing Equipments

TMG has a range of stressing equipments which includes Mono Jacks, Stressing Jacks, and accessories, to economically and efficiently stress its tendons. Our equipments are designed to inter-match

different pumps and jacks to achieve maximum efficiency.

TMG Mono Jack

Mono Jack is designed to stress a single strands (bare or epoxy coated) and PC Wire. It has an automatic grip-and-release build-in system that allows faster stressing. Our Mono Jacks are popular with

operators for Slab On Grade, building slab and pre-cast yards stressing.

Mono Jack

Mono Jack with chrome coating

Mono Jack Accessories

Technical Drawing for TMG Mono Jack

Cylinder

Piston

Centre Tube

Gripper Wedge

Wedge Seat

Nose

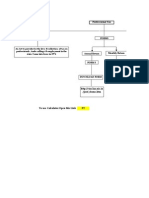

TMG Mono Jack Structural Diagram

TMG Mono Jack Block-Out Dimensions

Technical Data for TMG Mono Jack

Part Number

PC Wire Diameter

Strand Diameter

MJ10

4.00 - 9.00

mm

12.70

mm

15.24

mm

MJ26

Capacity

kN

100

260

Maximum Operating Pressure

MPa

45

58

Stroke

Centre-Hole Diameter

Piston Area

Reverse Piston Area

Maximum Return Pressure

mm

mm

120

17

200

18

m2

m2

MPa

2.21 x 10-3

0.86 x 10-3

4.417 x 10-3

1.256 x 10-3

mm

80

200

mm

mm

mm

mm

kg

700

60

75

380

10

900

100

105

440

19

Block-Out

Dimensions

A (Necessary Strands

Protrusion)

B

C

D

L

Dimension

Weight

Scenes of Production

(Copper Plated Piston for Stressing Jack)

< 25

Scenes of Production

TMG Stressing Equipments

TMG Stressing Jack

TMG Stressing Jack is small, compact and highly efficient. Our Stressing Jacks are 35% - 40% lighter

than many other makers. These advantages are crucial to many operators as it will lessen the work

load on the users. And with its compact size, it can work in smaller confined places and also reduce

the usage of strands.

VLM Mono stressing jack

Stressing Jack

Technical Drawing for TMG Stressing Jack

Lock Nut

Plug

Cylinder

Piston

Centre Tube

Handle

TMG Stressing Jack Structural Diagram

TMG Stressing Jack Block-Out Dimensions

Technical Data for TMG Stressing Jack

Part Number

SJ60

SJ100

SJ150

SJ200

SJ250

SJ300

SJ400

SJ500

SJ650

SJ900

Capacity

kN

600

1000

1500

2000

2500

3000

4000

5000

6500

6500

Maximum Operating pressure

MPa

50

52

51

53

54

52

53

50

50

55

Stroke

mm

200

200

200

200

200

200

200

200

200

200

Centre-Hole Diameter

mm

55

78

97

110

138

145

175

195

215

280

Piston Area

m2

12.08 x 10-3

19.09 x 10-3

29.37 x 10-3

37.79 x 10-3

45.94 x 10-3

57.73 x 10-3

76.11 x 10-3

100.5 x 10-3

131.90 x 10-3 165.87 x 10-3

Reverse Piston Area

m2

4.08 x 10-3

5.34 x 10-3

8.35 x 10-3

13.05 x 10-3

28.03 x 10-3

18.85 x 10-3

45.95 x 10-3

47.75 x 10-3

79.20 x 10-3

87.26 x 10-3

Maximum Return Pressure

MPa

Block-Out

Dimensions

A (Necessary Strand

Protrusion)

Dimension

Weight

mm

< 25

500

550

550

580

600

650

700

800

850

900

1300

mm

900

900

950

1000

1050

1100

1150

1150

1200

mm

120

150

180

200

220

240

260

290

350

380

mm

168

214

270

305

344

376

432

495

570

660

mm

345

340

346

360

361

367

379

445

450

583

kg

38

55

90

132

154

190

243

425

616

1205

Scences of Production

TMG Stressing Equipments

TMG Lifting Jack

Lifting Jacks are widely used in the lifting of bridge girders, formworks, structures, etc. It is also

popular with precision relocation work where heavy structures needed to be moved and joined.

Lifting Jack

Technical Drawing for TMG Lifting Jack

Support Plate

Lock Nut

Centre Tube

Piston

Cylinder

Pedestal

TMG Lifting Jack Structural Diagram

TMG Lifting Jack Block-Out Dimensions

Technical Data for TMG Lifting Jack

Part Number

LJ250

LJ300

LJ400

Capacity

kN

2500

3000

4000

Maximum Operating Pressure

MPa

49

45

50

Stroke

mm

1000

800

1000

Piston Area

m2

51.07 x 10-3

66.02 x 10-3

80.42 x 10-3

Maximum Return Pressure

MPa

Block-Out Dimensions

Dimension

Weight

mm

< 25

620

550

580

mm

1505

1265

1495

mm

310

344

376

mm

1487

1243

1470

kg

700

800

1140

TMG Lifting Jack under Load Test

Customised Lifting Jacks

TMG Stressing Equipments

TMG Compression Fitting Machine

Compression Fitting Machine is the equipment designed for forming Fixed Anchors (also common

known as Dead Anchors). By installing the Compression Fitting onto one end of the Strands, the

machine will compress the fitting onto the Strands and lock onto it permanently, thus forming a

secure Fixed Anchors.

Compression Fitting Machine

Compression Fitting

Strands with Compression Fitting

10

Technical Drawing for TMG Compression Fitting Machine

Cylinder

Piston

Lock-Off Head

Lock-Off Head Mould

TMG Compression Fitting Machine Structural Diagram

Technical Data for TMG Compression Fitting Machine

12.70

15.24

mm

mm

kN

Maximum

Operating

Pressure

MPa

565

50

Strands Diameter

Part

Number

CF60

Capacity

Scenes of Production

mm

Maximum

Return

Pressure

MPa

150

< 25

Stroke

Dimension

Length Width Height

Weight

mm

mm

mm

kg

626

195

195

41

Scenes of Production (Stay Cable)

11

TMG Stressing Equipments

TMG Bond Head Machine

Bond Head Machine is designed for forming bond heads (also commonly known as pear / onion

shape heads) which are used for Fixed Anchors (Dead Anchors).

Bond Head Machine

Bond Head

12

Technical Drawing for TMG Bond Head Machine

Grip Wedge

Strand

Lock-Off Head

Frame

Piston

Cylinder

TMG Bond Head Machine Structural Diagram

Technical Data for TMG Bond Head Machine

Part

number

BH30

Capacity

kN

30

Maximum

Operating

Pressure

MPa

50

Stroke

mm

70

Maximum

Return

Pressure

MPa

< 25

Dimension

Length Width Height

mm

535

mm

150

mm

230

Weight

kg

15

Scenes of Production

13

TMG Global Pte Ltd

8 Jalan Kukoh #01-33 Singapore 162008

Tel

: +65 6315 4615 / +65 9684 8728

Fax

: +65 6887 5273

: sales@tmgglobals.com

Website

: www.tmgglobals.com

The information set forth in this website including technical drawing and

engineering data is presented for general information and as a reference only.

While every effort has been made to insure its accuracy, this information should

not be used or relied upon for any specific application without independent

professional examination and verification of its accuracy, suitability and

applicability. Anyone using this material assumes any and all liability resulting

from such use. TMG disclaims any and all express or implied warranties of

merchantability fitness for any general or particular purpose or freedom from

infringement of any patent, trademark, or copyright in regard to the information or products contained or referred to herein. Nothing herein contained shall

be construed as granting a license, express or implied under any patents.

You might also like

- INKOMA - Shaft-Hub Connections - Polygonaxlar Enligt DIN 32711 Och DIN 32712Document18 pagesINKOMA - Shaft-Hub Connections - Polygonaxlar Enligt DIN 32711 Och DIN 32712kristoffer_mossheden100% (1)

- MK4 Posttensioning SpecificationsDocument28 pagesMK4 Posttensioning SpecificationsshashireshNo ratings yet

- Brake ChamberDocument6 pagesBrake ChamberEder AcasieteNo ratings yet

- Magna T Injection Moulding MachineDocument7 pagesMagna T Injection Moulding MachinenitinmuthaNo ratings yet

- Dywidag High Strength BarsDocument4 pagesDywidag High Strength Barsnishchint100% (1)

- Grundfos MTS Screw Spindle PumpDocument68 pagesGrundfos MTS Screw Spindle PumpAnonymous lswzqlo100% (1)

- Group Crushers Cone GCDocument8 pagesGroup Crushers Cone GCOrlando MelipillanNo ratings yet

- YCM GT SeriesDocument30 pagesYCM GT SeriesCNC SYSTEMSNo ratings yet

- PHNCDocument6 pagesPHNCAmit MangaonkarNo ratings yet

- PEM Self Clinching Self Locking FastenersDocument4 pagesPEM Self Clinching Self Locking FastenersAce Industrial SuppliesNo ratings yet

- Approved Source List Pneumatics Content: 3 4 X X 3 7 X XDocument98 pagesApproved Source List Pneumatics Content: 3 4 X X 3 7 X XWilson Silva SousaNo ratings yet

- JKV-2300 Series Hydraulic Cylinders Technical SpecificationsDocument44 pagesJKV-2300 Series Hydraulic Cylinders Technical Specificationsmedi38No ratings yet

- Catálogo Renold-TyreflexDocument4 pagesCatálogo Renold-TyreflexLuis ValenzuelaNo ratings yet

- Post TensionDocument56 pagesPost TensionanoopsurendranNo ratings yet

- Brochure - 14.458 DC Spring Apllied BrakesDocument2 pagesBrochure - 14.458 DC Spring Apllied Brakeskpr_02161371No ratings yet

- No.8 DTS Components 02 UK PDFDocument19 pagesNo.8 DTS Components 02 UK PDFhepcomotionNo ratings yet

- Front Mount HF TechdataDocument14 pagesFront Mount HF TechdataAlexandru NicuNo ratings yet

- Hydraulic Cylinders CHDocument8 pagesHydraulic Cylinders CHStoianovici CristianNo ratings yet

- TTM Post TensioningDocument103 pagesTTM Post Tensioninghorea67100% (2)

- Spare Parts ListDocument188 pagesSpare Parts ListhanhccidNo ratings yet

- StraubClamp NEU (E)Document4 pagesStraubClamp NEU (E)paulpopNo ratings yet

- CMC Brushless Servo Motor 2011 CatalogDocument4 pagesCMC Brushless Servo Motor 2011 CatalogElectromateNo ratings yet

- Caracteristicas Motores PDFDocument60 pagesCaracteristicas Motores PDF0ZKRCITHONo ratings yet

- Gls 150 SeriesDocument20 pagesGls 150 SeriesHâlid ŞenNo ratings yet

- Catlog of QMCS and QDC For Injection Molding Machine From Mico, Korea by Semyung India, ChennaiDocument19 pagesCatlog of QMCS and QDC For Injection Molding Machine From Mico, Korea by Semyung India, ChennaiMuthu KumaranNo ratings yet

- Torque Systems MDM-5000 Product GuideDocument4 pagesTorque Systems MDM-5000 Product GuideElectromateNo ratings yet

- Chapter 5 Technical Specs & DimensionsDocument6 pagesChapter 5 Technical Specs & DimensionsSenophoeNo ratings yet

- Post-tensioning steel strands technical dataDocument28 pagesPost-tensioning steel strands technical datanovakno1No ratings yet

- Rubber Sandwich Mounts From GMTDocument2 pagesRubber Sandwich Mounts From GMTGMT Rubber-Metal-TechnicNo ratings yet

- DAEMO FULL LINEUP Catalogue 2012 PDFDocument12 pagesDAEMO FULL LINEUP Catalogue 2012 PDFnaya 2014No ratings yet

- T101 Drilling MachineDocument4 pagesT101 Drilling MachineFranklin Avendaño ArapaNo ratings yet

- T101 Drilling Machine BrochureDocument4 pagesT101 Drilling Machine BrochureRicardo OrtegaNo ratings yet

- CP6120 PaselDocument3 pagesCP6120 PaselZeckNo ratings yet

- CMC Brushless Servo Motor 2011 CatalogDocument4 pagesCMC Brushless Servo Motor 2011 CatalogServo2GoNo ratings yet

- NOVA Servo CatalogueDocument7 pagesNOVA Servo CatalogueDip Narayan BiswasNo ratings yet

- TSGE - TLGE - TTGE - Reduce Moment High Performance CouplingDocument6 pagesTSGE - TLGE - TTGE - Reduce Moment High Performance CouplingazayfathirNo ratings yet

- Post Tension MultistrandDocument15 pagesPost Tension MultistrandStephanie K ChanNo ratings yet

- Hydraulic Cylinders CH: - Big Bore Sizes To Iso 6020-3 - Nominal Pressure 16 Mpa (160 Bar) - Max 25 Mpa (250 Bar)Document6 pagesHydraulic Cylinders CH: - Big Bore Sizes To Iso 6020-3 - Nominal Pressure 16 Mpa (160 Bar) - Max 25 Mpa (250 Bar)Stoianovici CristianNo ratings yet

- Disc Brake Units Be 100, Be 125, and Be 200: Technical InformationDocument6 pagesDisc Brake Units Be 100, Be 125, and Be 200: Technical InformationJose Maria Castro PazosNo ratings yet

- Api 23 02Document4 pagesApi 23 02montsegranNo ratings yet

- Dywidag DSI Baranchor enDocument8 pagesDywidag DSI Baranchor enwalitedisonNo ratings yet

- Bolt StandardDocument42 pagesBolt StandardSHIVASHANKARNo ratings yet

- Formwork Tie Rods & Accessories GuideDocument14 pagesFormwork Tie Rods & Accessories Guideparag_358No ratings yet

- Piston Ring Groove Gauges To Quickly and Accurately Determine Reusability of Pistons (1214,0763)Document3 pagesPiston Ring Groove Gauges To Quickly and Accurately Determine Reusability of Pistons (1214,0763)TASHKEELNo ratings yet

- Maintenance Arpex enDocument39 pagesMaintenance Arpex enPatrick BaridonNo ratings yet

- Lintech Ball Screw Option SpecsheetDocument6 pagesLintech Ball Screw Option SpecsheetElectromateNo ratings yet

- Specification Cop 1838 MeDocument2 pagesSpecification Cop 1838 MeVeljko Lapcevic50% (4)

- Cr6 Geomat DetailsDocument27 pagesCr6 Geomat DetailsfastenersworldNo ratings yet

- F79UDocument4 pagesF79URezi SyahputraNo ratings yet

- AV Industrial Products LTD Catalogue Anti Vibration MountsDocument52 pagesAV Industrial Products LTD Catalogue Anti Vibration MountsAV Industrial Products LtdNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Performance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallFrom EverandPerformance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallRating: 4 out of 5 stars4/5 (8)

- High-Performance GM LS-Series Cylinder Head GuideFrom EverandHigh-Performance GM LS-Series Cylinder Head GuideRating: 4.5 out of 5 stars4.5/5 (2)

- Brochure - For ReferenceDocument4 pagesBrochure - For Referencesujay13780No ratings yet

- 004 Star BurnDocument14 pages004 Star BurnAneek KumarNo ratings yet

- 2015 MeetupsDocument17 pages2015 Meetupssujay13780No ratings yet

- Industry DataDocument74 pagesIndustry Datasujay13780No ratings yet

- Fluid BedsDocument6 pagesFluid Bedssujay13780No ratings yet

- Bank of America - Online Banking - Transfer SubmittedDocument2 pagesBank of America - Online Banking - Transfer Submittedsujay13780No ratings yet

- ScriptDocument10 pagesScriptA'KumarNo ratings yet

- Biotech and Tics Companies in BangaloreDocument35 pagesBiotech and Tics Companies in Bangaloresivagodai100% (14)

- HR ContactsDocument70 pagesHR Contactssujay1378080% (5)

- DocumentDocument1 pageDocumentsujay13780No ratings yet

- Tie Rod CylindersDocument4 pagesTie Rod Cylinderssujay13780No ratings yet

- Opening ChecklistDocument75 pagesOpening Checklistsujay13780100% (1)

- States With CapitalsDocument13 pagesStates With Capitalssujay13780No ratings yet

- Unit 2Document10 pagesUnit 2sujay13780No ratings yet

- Gear CouplingDocument78 pagesGear CouplingchikoopandaNo ratings yet

- 46 - Complete Compliance Need For The Financial YearDocument48 pages46 - Complete Compliance Need For The Financial Yearsujay13780No ratings yet

- Casting 1 Casting 2 Casting 3Document2 pagesCasting 1 Casting 2 Casting 3sujay13780No ratings yet

- 21 Free Excelgestion v1b EnglishDocument2 pages21 Free Excelgestion v1b Englishsujay13780No ratings yet

- Casting Supplier QuestionaireDocument1 pageCasting Supplier Questionairesujay13780No ratings yet

- T-6 Heat Treat: T-6 30% Increase in StrengthDocument2 pagesT-6 Heat Treat: T-6 30% Increase in Strengthsujay13780No ratings yet

- Equivalent Grades of Gray IronDocument2 pagesEquivalent Grades of Gray Ironsujay13780100% (1)

- F02 Project Status Purchased Parts QR83 2011 Version 1-0-01Document3 pagesF02 Project Status Purchased Parts QR83 2011 Version 1-0-01sujay13780No ratings yet

- Valve Manufacturers in USADocument24 pagesValve Manufacturers in USAsujay13780No ratings yet

- Useful Articles: What To Consider When Buying CastingsDocument5 pagesUseful Articles: What To Consider When Buying Castingssujay13780No ratings yet

- Steel Weight CalculatorDocument4 pagesSteel Weight CalculatorMujjo Sahb0% (1)

- Calculation CNCDocument2 pagesCalculation CNCsujay13780No ratings yet

- Hot Dip Galvanizing, A Guide ToDocument14 pagesHot Dip Galvanizing, A Guide Topbharadwaj545No ratings yet

- ISO 9001 Clauses Simply ExplainedDocument26 pagesISO 9001 Clauses Simply Explainedpooja.dayal3930No ratings yet

- Financial Plan For Starting Up The RestaurantDocument11 pagesFinancial Plan For Starting Up The Restaurantsujay13780No ratings yet

- Advanced Part 2012Document356 pagesAdvanced Part 2012leokareyxoxoers100% (2)

- Scriptoresorigi 00 UnkngoogDocument168 pagesScriptoresorigi 00 UnkngoogAlfredo BizantinoNo ratings yet

- KGSSDocument20 pagesKGSSSrinivasan RajenderanNo ratings yet

- Math4 Q4 Mod2Document42 pagesMath4 Q4 Mod2Geoff ReyNo ratings yet

- Test Taker Score Report: February 28, 2020 Test Date Scores ScoresDocument2 pagesTest Taker Score Report: February 28, 2020 Test Date Scores ScoresLuciano Nicolas Camaño100% (1)

- Schedule IA - Indian Stamp Act (As Applicable To Delhi)Document32 pagesSchedule IA - Indian Stamp Act (As Applicable To Delhi)Rashi JainNo ratings yet

- 2022 Global Law and Order ReportDocument20 pages2022 Global Law and Order Reportpuja sumantriNo ratings yet

- Might and Magic VIIDocument66 pagesMight and Magic VIIfuckyouNo ratings yet

- DisperbyDocument4 pagesDisperbyaragorn26No ratings yet

- Brand PositioningDocument6 pagesBrand PositioningMaryam SafdarNo ratings yet

- BSBPMG531 Project Portfolio 1 UpdatedDocument20 pagesBSBPMG531 Project Portfolio 1 UpdatedAniqa ZafiraNo ratings yet

- Women of American Revolution m01 - w01Document8 pagesWomen of American Revolution m01 - w01AlenJonotaCaldeoNo ratings yet

- 2011 ISEE Blasting Seismograph StdsDocument17 pages2011 ISEE Blasting Seismograph StdsGregory BakasNo ratings yet

- Circuitpro PM 2.3 Ba v1.0 EngDocument386 pagesCircuitpro PM 2.3 Ba v1.0 Engnuit_claire002No ratings yet

- Pronunciation Ed GAMEDocument7 pagesPronunciation Ed GAMEElena MartínNo ratings yet

- DCC - Free RPG Day 2013Document26 pagesDCC - Free RPG Day 2013TheMorteal0% (1)

- Martian V.F.W. by Vandenburg, G.L.Document13 pagesMartian V.F.W. by Vandenburg, G.L.Gutenberg.orgNo ratings yet

- Beauty and The Beast by Anonymous PDFDocument48 pagesBeauty and The Beast by Anonymous PDFLlomelloNo ratings yet

- Mechvib SM Ch03Document118 pagesMechvib SM Ch03Khairul YahyahNo ratings yet

- MSCR Test ASTM D7405 2015Document4 pagesMSCR Test ASTM D7405 2015intanmizwarNo ratings yet

- Lapbook TemplatesDocument38 pagesLapbook TemplatesCristina Mihu100% (1)

- IEEE STD 634-2004 CablesDocument28 pagesIEEE STD 634-2004 CablesAmi ChNo ratings yet

- Drew Technologies v. Robert BoschDocument7 pagesDrew Technologies v. Robert BoschPriorSmartNo ratings yet

- A Mexican Festival: by Rita Cruz Illustrated by Joanne FriarDocument14 pagesA Mexican Festival: by Rita Cruz Illustrated by Joanne FriarprotoginaNo ratings yet

- BS en 10250-3Document16 pagesBS en 10250-3butterflyhuahuaNo ratings yet

- What's New: Flame 2012 Extension 1Document98 pagesWhat's New: Flame 2012 Extension 1gamela999No ratings yet

- Iso 14585 2011Document9 pagesIso 14585 2011Luiz MunariNo ratings yet

- UT Dallas Syllabus For Soc4396.501.11s Taught by Malinda Hicks (Meh033000)Document9 pagesUT Dallas Syllabus For Soc4396.501.11s Taught by Malinda Hicks (Meh033000)UT Dallas Provost's Technology GroupNo ratings yet

- Location Release WrapbookDocument4 pagesLocation Release WrapbookAura JadeNo ratings yet

- NDA AgreementDocument4 pagesNDA AgreementPictionary Arts0% (1)