Professional Documents

Culture Documents

PSP Fat Procedure - Template

Uploaded by

Michael HaiseOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PSP Fat Procedure - Template

Uploaded by

Michael HaiseCopyright:

Available Formats

Custom Process Equipment

4727 NW Evangeline Thruway

Carencro, LA 70520

Tel : (337) 896-3815

DPSD DOCUMENT NO.

DPS-2010-1105-Q-KA-0005

FAT PROCEDURE

Abu Qir Thermal Power Plant

Supplier: DPS

Contents

1

Introduction

1.1

1.3

Objective

Supplier Reference Documents

Necessary Material

FAT Overall Planning

Procedures

1.2

3.1

3.1.1

3.1.2

3.1.3

3.1.4

Mechanical Checklist

Package General

Piping

Vessels

Access

3.2

3.2.1

3.2.2

3.2.3

3.2.4

3.2.5

3.2.6

Instrument Checklist

Level Gauges

Level Control Valves

Differential Pressure Transmitters

Pressure Indicators/Pressure Differential Indicator/Temperature Indicators/Flow Indicators

Pressure Relief Valves

Level Switches

3.3

3.3.1

3.3.2

3.3.3

3.3.4

3.3.5

Electrical Checklist

Junction Boxes

General Inspections

Documentation

Conformity

Cable Installation and Tests

3.4

Document Verification

Manufacturer: CPE

Client PO:10-118-26

Custom Process Equipment

DPSD DOCUMENT NO.

DPS-2010-1105-Q-KA-0005

4727 NW Evangeline Thruway

Carencro, LA 70520

Tel : (337) 896-3815

FAT PROCEDURE

Abu Qir Thermal Power Plant

Supplier: DPS

1

1.1

Objective

The Objective of this document is to provide a detailed Factory Acceptance Test Plan for DPS purchase order PO-2010-1105-001, which consist of a Filter

Separator and Drain Tank Skid Assembly. The major components of the package include the following:

1. Filter Separator Skid Assembly

a .Filter Separator Vessel 6-FG-MT001

b. Filter Separator Vessel 7-FG-MT001

c. Drain Tank 9-FG-MT-001

The test procedures containted in Section 3 of this document will be utilized to determine the following:

1. Product compliance with the purchase order document

2. Product compliance with the purchase order specifications

3. Acceptability of workmanship

4. Integrity if components

5. Verification of Functionality

It should be noted that process control is being performed in the Plant Control System. The instruments and valving

associated with these functions will be checked for calibration and functionality using a hand held communicator.

FAT will be considered complete when all items on the checklist have be brought into conformity.

All Equipment from sub-vendors will have been tested and calibrated prior to delivery.

1.2

Client PO:10-118-26

Introduction

Supplier Reference Documents

DPS Document No.

DPSD-2010-1105-I-LA-0001 Rev.H

DPS-2010-1105-TST-001

DPS-2010-1105-TST-002

DPS-2010-1105-R-STD-003

DPS-2010-1105-R-STD-006

DPS-2010-1105-402

DPS-2010-1105-500

DPS-2010-1105-201

DPS-2010-1105-101

DPS-2010-1105-102

DPS-2010-1105-201

2010-D-1105-202

2010-D-1105-203

DSP-2010-1105-400

DSP-2010-1105-401

DPS-2010-1105-I-VD-0001

Client Doc. No.

Document Title

Instrument List Rev H

Manufacturer's Hydrotest Reports

Manufacturer's NDE Reports

Manufacturer's Coating Reports

Material Test Certificates

Cause & Effect Matrix / Logic Function

Pipe & Instrument Diagrams (P&ID)

Piping GA (Plans & Elevations)

Filter Separator GAt Drawing

Drain Tank GA Drawing

Skid Assembly Drawing

Structural Skid Drawing

Filter Separator Platform Drawing

Electrical / Wiring Drawings

Junction Box Layout Drawing

Instrument Calibrations and Certification

Client Reference Documents

Purchaser's Minimum Quality Surveillance Summary Data Sheet

Client Document Number

7929-511-413-03-18

DPS-2010-1105-R-DS-00001

DPS-2010-1105-R-DS-00002

99999-9-3DS-P72-00001

10054-9-3PS-JQ07-00001

DPS-2010-1105-R-K-0002

99999-9-3SS-NX00-00003

Document Title

Purchase Order Number

Fuel Gas Filter Separator Data Sheet

Drain Tank Data Sheet

Design of Piping on skids

Instrumentation & Electrical Requirements for

packaged equipment

ITP Form

Surface Preparation and Painting

Custom Process Equipment

4727 NW Evangeline Thruway

Carencro, LA 70520

Tel : (337) 896-3815

DPSD DOCUMENT NO.

DPS-2010-1105-Q-KA-0005

FAT PROCEDURE

Abu Qir Thermal Power Plant

Supplier: DPS

1.3

Client PO:10-118-26

Necessary Material

HART COMMUNICATOR FOR PDIT

MANOMETER PRESSURE SET FOR PDIT

24VDC POWER SUPPLY

FLUKE MULTIMETER

WATER SOURCE

COMPRESSED AIR SOURCE

FAT Overall Planning

The FAT is intended to cover the following major areas:

1. Documentation Review. A review of the project documentation will be conducted by Supplier personnel as well as the Client

representative. The following are the major areas of review.

a. Manufacturing data review

b. Valve and instrument data review

c. Miscellaneous Equipment data review

2. Equipment Inspection and Testing. The checklists contained in Section 3 of this document will be used to verify their functionality and

conformance with project requirements. Supplier personnel along with the customer representative will proceed through the lists and perform the necessary

evaluation. The checklists are divided into the following major categories:

a. Mechanical

b. Instruments

c. Electrical

Custom Process Equipment

4727 NW Evangeline Thruway

Carencro, LA 70520

Tel : (337) 896-3815

DPSD DOCUMENT NO.

DPS-2010-1105-Q-KA-0005

FAT PROCEDURE

Abu Qir Thermal Power Plant

Supplier: DPS

3

3.1

Client PO:10-118-26

Procedures

Mechanical Checklist

Checklist

3.1.1

3.1.2

3.1.3

3.1.4

Package General

Verify package completed to P&ID: DPS-2010-1105-500

All tagging to be checked in position and correct to P&ID for all items.

Verify package completed to all General Arrangement drawings.

Confirm all TP locations.

Check for any visible signs of damage.

Review project documentattion.

Check for any required actions: Conforming ________X_______ Non-Conforming _______________

SIGN

DATE

TS

TS

TS

TS

TS

TS

TS

3/31/2011

Piping

Confirm that all flanged joints are made up correctly.

Confirm pipe routing, supporting and painting are in accordance to Project Specifications.

Confirm all paintwork is undamaged.

Confirm piping color banding and identification is correct (if applicable).

Review project documentation.

Check for any required actions: Conforming _________X_________ Non-Conforming _______________

TS

TS

TS

TS

TS

TS

3/31/2011

Vessels

Confirm all hold down bolts are correctly fitted.

Confirm vessel nameplates are correct and securely fitted

Confirm vessel hand hole bolts and gaskets are correctly fitted.

Confirm all paintwork is undamaged.

Review project documentation.

Check for any required actions: Conforming ________X_______ Non-Conforming _______________

TS

TS

TS

TS

TS

TS

3/31/2011

Access

Confirm access for operation and maintenance of all valves,and instruments.

Review project documentation.

Check for any required actions: Conforming ________X_______ Non-Conforming _______________

TS

TS

TS

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

Checklist

3.2

3.2.1

3.2.2

Instrument Checklist

SIGN

DATE

Level Gauges

Check mechanical mounting is correct and firm.

Check instrument for any visible sign of damage.

Verify material certification available with instrument

Verify nameplate is correct and securely fitted.

Review project documentattion.

Check for any required actions: Conforming _______X________ Non-Conforming _______________

TS

TS

TS

TS

TS

TS

3/31/2011

Level Control Valves

Check valve failure mode for loss of air supply.

Check wiring termination cable tag is correct and securely fastened

Check mechanical mounting is correct and firm.

Confirm that instrument is installed in correct position

Test with increasing and decreasing signal 0%, 25%, 50%, 75%, 100%, 75%, 50%, 25%, 0%

Check instrument for any visible sign of damage.

Verify material certification available

Verify nameplate is correct and securely fitted.

Review project documentattion.

Check for any required actions: Conforming _______X_______ Non-Conforming _______________

TS

TS

TS

TS

TS

TS

TS

TS

TS

TS

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

Custom Process Equipment

4727 NW Evangeline Thruway

Carencro, LA 70520

Tel : (337) 896-3815

DPSD DOCUMENT NO.

DPS-2010-1105-Q-KA-0005

FAT PROCEDURE

Abu Qir Thermal Power Plant

Supplier: DPS

3.2.3

3.2.4

3.2.5

3.2.6

Client PO:10-118-26

Differential Pressure Transmitters

Will be powered and checked at ambient pressure.

Check wiring termination cable tag is correct and securely fastened

Confirm that instrument is installed in correct postion

Check wiring termination cable tag is correct and securely fastened

Confirm that instrument is installed in correct postion

Check mechanical mounting is correct and firm.

Check instrument installed in correct position.

Check instrument for any visible sign of damage.

Verify nameplate is correct and securely fitted.

Review project documentattion.

Check for any required actions: Conforming _______X________ Non-Conforming _______________

TS

TS

TS

TS

TS

TS

TS

TS

TS

TS

TS

3/31/2011

Pressure Indicators/Pressure Differential Indicator/Temperature Indicators/Flow Indicators

Check mechanical mounting is correct and firm.

Check instrument installed in correct position.

Check indicator is reading correct ambient conditions.

Check instrument for any visible sign of damage.

Verify that instrument is installed with correct accessories

Verify nameplate is correct and securely fitted.

Review project documentattion.

Check for any required actions: Conforming ________X_______ Non-Conforming _______________

TS

TS

TS

TS

TS

TS

TS

TS

3/31/2011

Pressure Relief Valves

Check mechanical mounting is correct and firm.

Check instrument installed in correct position.

Check for any visible sign of damage.

Verify nameplate is correct and securely fitted.

Review manufacturers set pressure certification.

Review project documentattion.

Check for any required actions: Conforming ________X_______ Non-Conforming _______________

TS

TS

TS

TS

TS

TS

TS

3/31/2011

Level Switches

Check mechanical mounting is correct and firm.

Check instrument installed in correct position.

Check for any visible sign of damage.

Verify nameplate is correct and securely fitted.

Review manufacturers set pressure certification.

Review project documentattion.

Check for any required actions: Conforming _______X________ Non-Conforming _______________

TS

TS

TS

TS

TS

TS

TS

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

Checklist

3.3

3.3.1

3.3.2

3.3.3

3.3.4

Electrical Checklist

SIGN

DATE

Junction Box Installation and Tests

Confirm junction box and wiring installation is complete and in accordance with project approved documents and contract specifications.

TS

Confirm all junction boxes are adequately supported and the installation does not foul operators access.

Verify junction box is tagged as per the cable schedule.

Confirm all items are correctly earth bonded.

TS

TS

TS

Confirm all electrical equipment is certified for the hazardous environment and that correct certification is available for review.

TS

Confirm that all spare entries are plugged with certified plugs

Review project documentattion.

Check for any required actions: Conforming ______X_________ Non-Conforming _______________

TS

TS

TS

3/31/2011

General Inspections

Verify materials agree with Bill of Material

Verify dimensions agree with Assembly

Verify component layout agrees with Assembly

Verify fuses are installed and ratings

Verify equipment grounding connections to chassis and instrument ground busses

TS

TS

TS

TS

TS

3/31/2011

Documentation

Junction Box Layout drawing number DSP-2010-1105-401

Junction Box Wiring drawing number DSP-2010-1105-402

TS

TS

3/31/2011

Conformity

Check for any required actions: Conforming _______X________ Non-Conforming _______________

TS

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

Custom Process Equipment

4727 NW Evangeline Thruway

Carencro, LA 70520

Tel : (337) 896-3815

DPSD DOCUMENT NO.

DPS-2010-1105-Q-KA-0005

FAT PROCEDURE

Abu Qir Thermal Power Plant

Supplier: DPS

3.3.5

Client PO:10-118-26

Cable Installation and Tests

Confirm the instrument wiring installation is complete and in accordance with project approved documents and contract specifications.

Confirm all cable and cable tray is adequately supported and the installation does not foul operators access.

Confirm all cable tray edges are smooth and protected.

Verify all cables are tagged as per the cable schedule.

Confirm all items are correctly earth bonded.

Confirm all electrical equipment is certified for the hazardous environment and that correct certification is available for review.

Review project documentattion.

Check for any required actions: Conforming ________X_______ Non-Conforming _______________

TS

TS

TS

TS

TS

TS

TS

TS

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

Checklist

3.4

Documentation Verification

Verify completion of hydrotest record and stamp from customer inspector.

Verify completion of NDE record and stamp from customer inspector..

Verify completion of coating record and stamp from customer inspector..

Verify availability of Material Test Record and stamp from customer inspector..

Verify availability of instrument calibrations and verification, and stamp from customer inspector..

Verify all instruments' data against the instrument list.

Verify Cause & Effect is approved with no customer comments.

Verify P&ID is approved with no customer comments.

Verify Junction Box Diagram is approved with no customer comments.

Verify Instrument Calibrations and Certification is approved with no customer comments.

Verify on-skid cable routing and earthing is approved with no customer comments.

CPE Representative:

Date:

Client Representative:

Date:

SIGN

DATE

DD

3/31/2011

DD

3/31/2011

DD

3/31/2011

DD

3/31/2011

DD

3/31/2011

TS

TS

TS

TS

TS

TS

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

3/31/2011

You might also like

- 01$GC Cable-Install Manual PowerControl Cables-7 14Document102 pages01$GC Cable-Install Manual PowerControl Cables-7 14galdreyNo ratings yet

- Mercury Capsule No. 14, Configuration Specification (Mercury-Little Joe No. 5 (A)Document87 pagesMercury Capsule No. 14, Configuration Specification (Mercury-Little Joe No. 5 (A)Bob AndrepontNo ratings yet

- Robway SLI ManualDocument135 pagesRobway SLI ManualBatagor H. Isan100% (1)

- Pump Suction ArrangementsDocument24 pagesPump Suction ArrangementskidseismicNo ratings yet

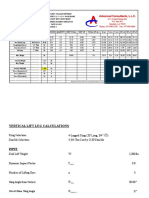

- Saddle CalculationDocument7 pagesSaddle CalculationMichael HaiseNo ratings yet

- BMW-Bus Systems PDFDocument76 pagesBMW-Bus Systems PDFNasiri6594% (17)

- VSD Manual GDocument125 pagesVSD Manual GMohamedMansourNo ratings yet

- VENDOR DOCUMENT REVIEW OF PRESSURE RELIEF VALVE DATA SHEETSDocument8 pagesVENDOR DOCUMENT REVIEW OF PRESSURE RELIEF VALVE DATA SHEETSMichael HaiseNo ratings yet

- Cost EstimationDocument28 pagesCost Estimationmayur1980100% (1)

- Control Valve IPF Function Test1Document5 pagesControl Valve IPF Function Test1btjajadiNo ratings yet

- Nec 2017 Article690Document130 pagesNec 2017 Article690Director PQR CON18-74EC100% (2)

- J1525-HW1-010 SAT Procedure - Rev ADocument16 pagesJ1525-HW1-010 SAT Procedure - Rev Aluis HernandezNo ratings yet

- Saleh Muhammad Durrani CVDocument4 pagesSaleh Muhammad Durrani CVJamshaid SultanNo ratings yet

- Oil and Gas Offshore Pipeline Leak Detection System: A Feasibility StudyDocument8 pagesOil and Gas Offshore Pipeline Leak Detection System: A Feasibility StudycbqucbquNo ratings yet

- Building Fire Alarm SystemDocument16 pagesBuilding Fire Alarm Systemsuhailfarhaan100% (1)

- Vessel Sizing Calculation Data Sheets: Customer Name: Project Title: Cpe Job #: Document #Document13 pagesVessel Sizing Calculation Data Sheets: Customer Name: Project Title: Cpe Job #: Document #Michael HaiseNo ratings yet

- Technical Doc 1 - Technical Scope of Work Drs Eac181Document25 pagesTechnical Doc 1 - Technical Scope of Work Drs Eac181bhargavpansuria09No ratings yet

- 01-01-1865-D ELDS Technical Manual Iss13Document221 pages01-01-1865-D ELDS Technical Manual Iss13Alberyt099No ratings yet

- Bms Design Guide PDFDocument95 pagesBms Design Guide PDFalmig200100% (2)

- Vessel Data Sheet: Design CriteriaDocument8 pagesVessel Data Sheet: Design CriteriaMichael HaiseNo ratings yet

- Vessel Data Sheet: Design CriteriaDocument8 pagesVessel Data Sheet: Design CriteriaMichael HaiseNo ratings yet

- Process Operator Gas ExperienceDocument3 pagesProcess Operator Gas Experiencejohn MNo ratings yet

- Mechanical Completion Check Sheet Electrical: Lighting & Power CircuitDocument2 pagesMechanical Completion Check Sheet Electrical: Lighting & Power CircuitYadira Centanaro GutierrezNo ratings yet

- Instrument Installation ChecklistDocument1 pageInstrument Installation ChecklistAli AkbarNo ratings yet

- PT ANSI MEGA Factory Acceptance TestDocument56 pagesPT ANSI MEGA Factory Acceptance Testana erika Menendez SalvatierraNo ratings yet

- Mellitah Oil & Gas BV: Wafa Gathering ProcedureDocument19 pagesMellitah Oil & Gas BV: Wafa Gathering ProcedureThirukkumaranBalasubramanianNo ratings yet

- KLM - PROJECT - STANDARD - AND - SPECIFICATIONS - Plant - Operating - Manuals - Rev01 PDFDocument10 pagesKLM - PROJECT - STANDARD - AND - SPECIFICATIONS - Plant - Operating - Manuals - Rev01 PDFLenaldy Nuari GarnokoNo ratings yet

- Request for Inspection & TestDocument3 pagesRequest for Inspection & TestYusufNo ratings yet

- Functional Test: FT-Packaged Boiler and Boiler System Including HW Pumps 1 & 2Document7 pagesFunctional Test: FT-Packaged Boiler and Boiler System Including HW Pumps 1 & 2vin ssNo ratings yet

- HKJFTCC 1 DKK 1B M GPT 99 05654 PDFDocument18 pagesHKJFTCC 1 DKK 1B M GPT 99 05654 PDFIBIKUNLENo ratings yet

- Ce-Const2-132kv-Cb-Siemens-2012.pdf Wiring PMT PDFDocument12 pagesCe-Const2-132kv-Cb-Siemens-2012.pdf Wiring PMT PDFLatief BobNo ratings yet

- Tightness Control SystemDocument4 pagesTightness Control SystemYetkin Erdoğan100% (1)

- PC - EXHAUST FANS ID #'SDocument3 pagesPC - EXHAUST FANS ID #'SAbdul Mohid SheikhNo ratings yet

- Kidde FM-200 Fire Suppression System SpecificationDocument6 pagesKidde FM-200 Fire Suppression System SpecificationFi NDNo ratings yet

- PROJECT STANDARD AND SPECIFICATIONS Instrumentation Specifications Rev01web PDFDocument8 pagesPROJECT STANDARD AND SPECIFICATIONS Instrumentation Specifications Rev01web PDFMohsin AliNo ratings yet

- Dzb200 SeriesDocument54 pagesDzb200 SeriesAkos Pocik100% (1)

- PEL-TP-00-INS-SP-002 - Rev 0Document40 pagesPEL-TP-00-INS-SP-002 - Rev 0sswahyudi100% (1)

- General Service Type Vertical Inline PumpsDocument22 pagesGeneral Service Type Vertical Inline Pumpssas999333No ratings yet

- Factory and Site Acceptance Testing Dave Lawrence TCT ConsultancyDocument17 pagesFactory and Site Acceptance Testing Dave Lawrence TCT ConsultancySuguna DeviNo ratings yet

- Condensate Line SizingDocument2 pagesCondensate Line Sizingemmanuilmoulos6339100% (1)

- Insulation Thickness Heat Transfer Pipe CalculationsDocument2 pagesInsulation Thickness Heat Transfer Pipe Calculationsrajpal14667% (6)

- Pump (English) TemplateDocument1 pagePump (English) TemplateMichael HaiseNo ratings yet

- Boiler Comm SequenceDocument30 pagesBoiler Comm SequenceDian PriengadiNo ratings yet

- Hazid WorksheetDocument2 pagesHazid WorksheetHarry SiswajiNo ratings yet

- Section 01 91 00 - General Commissioning Requirements Part 1 - GeneralDocument20 pagesSection 01 91 00 - General Commissioning Requirements Part 1 - GeneralJim WoodNo ratings yet

- Water Specialist WS2H and WS3 Control Valve Programming and Wiring ManualDocument36 pagesWater Specialist WS2H and WS3 Control Valve Programming and Wiring Manualpepepepito100% (1)

- 2-Test Pack Cover SheetDocument1 page2-Test Pack Cover SheetPintu KumarNo ratings yet

- FAT & SAT For Electrical System in Utility EndDocument16 pagesFAT & SAT For Electrical System in Utility EndBabuNo ratings yet

- JSA Blank FormDocument6 pagesJSA Blank FormRuppee EdwardNo ratings yet

- Site Acceptance Test Contract No.: 537856: 863013-VPS-PQM-E-DS-0002Document16 pagesSite Acceptance Test Contract No.: 537856: 863013-VPS-PQM-E-DS-0002Andry YanuarNo ratings yet

- Mechanical Completion Certificate for Export PumpsDocument1 pageMechanical Completion Certificate for Export PumpsDeonNo ratings yet

- KhairulDocument244 pagesKhairulAyie KhairiNo ratings yet

- DCI JK5 Fire Protection Site Acceptance TestDocument14 pagesDCI JK5 Fire Protection Site Acceptance TestAwaludin Angga WNo ratings yet

- Commisisoning Procedure of Air Compressor System (Rev.3) PDFDocument27 pagesCommisisoning Procedure of Air Compressor System (Rev.3) PDFfairelNo ratings yet

- 60.35-001 - 1994 Pressure GuagesDocument3 pages60.35-001 - 1994 Pressure GuagespradeepNo ratings yet

- Calibrate Fire & Gas Detection SystemsDocument5 pagesCalibrate Fire & Gas Detection Systemskirandevi1981No ratings yet

- Instrumentation Cables: Multipair Individual and Overall Screen, Armoured and Lead SheathedDocument1 pageInstrumentation Cables: Multipair Individual and Overall Screen, Armoured and Lead SheathedHuythuong NguyenNo ratings yet

- Doha North Sewerage Treatment & Associated WorksDocument67 pagesDoha North Sewerage Treatment & Associated WorksLito MendozaNo ratings yet

- MSDS for Sodium Hypochlorite, 5% SolutionDocument19 pagesMSDS for Sodium Hypochlorite, 5% SolutionMuhammadPurnamaSugiriNo ratings yet

- Honeywell Prover PDFDocument12 pagesHoneywell Prover PDFMelina SbhNo ratings yet

- MC20005-WHP-WI-P-0118 Corrosion PR & Erosion PR Datasheet WI - Rev.D1Document18 pagesMC20005-WHP-WI-P-0118 Corrosion PR & Erosion PR Datasheet WI - Rev.D1nguyenmainamNo ratings yet

- Commissioning Requirements SummaryDocument20 pagesCommissioning Requirements SummaryVenkataramanan SNo ratings yet

- Factors Contributing To Foarming Crude OilDocument11 pagesFactors Contributing To Foarming Crude OilSang Duong Van100% (1)

- Instrumentation FormsDocument7 pagesInstrumentation FormsMark TrussellNo ratings yet

- Inspection and Test Plan for Mars CS PackageDocument17 pagesInspection and Test Plan for Mars CS PackageMariah PearsonNo ratings yet

- Materials ManagementDocument17 pagesMaterials ManagementAkash SahaNo ratings yet

- Fat - Functional Factory Acceptance Test Procedure For Flare and Burn Pit Packages 2600-PK-001 / 2600-PK-002 / 2600-PK-003Document8 pagesFat - Functional Factory Acceptance Test Procedure For Flare and Burn Pit Packages 2600-PK-001 / 2600-PK-002 / 2600-PK-003kami safaviNo ratings yet

- Comment Resolution Sheet 19009 Welding DossierDocument1 pageComment Resolution Sheet 19009 Welding DossierDheeraj E MohananNo ratings yet

- FAT Protocol PDFDocument2 pagesFAT Protocol PDFvinodNo ratings yet

- Pre-Commissioning Procedure - Air Blowing of Fuel Gas System 1Document3 pagesPre-Commissioning Procedure - Air Blowing of Fuel Gas System 1AdelNo ratings yet

- Air conditioned EnclosureDocument5 pagesAir conditioned EnclosureSakeer PeringodanNo ratings yet

- Danalyzer GC MAN 3 9000 744 700XA PDFDocument204 pagesDanalyzer GC MAN 3 9000 744 700XA PDFFercho MNo ratings yet

- ITR-C (Instrument) 16cDocument1 pageITR-C (Instrument) 16cMomo ItachiNo ratings yet

- 2014-0192 QTN r.0 - Technical QuotationDocument8 pages2014-0192 QTN r.0 - Technical QuotationShibin SahadevanNo ratings yet

- Leak TestingDocument5 pagesLeak Testingogie_0513No ratings yet

- Acid Rinsing FRP TankDocument2 pagesAcid Rinsing FRP Tankkasvikraj0% (1)

- Lco Tank Relief Valve (2016.04.11.) - For ApprovalDocument87 pagesLco Tank Relief Valve (2016.04.11.) - For ApprovalEnoch TwumasiNo ratings yet

- CommissioningDocument4 pagesCommissioningowaise007No ratings yet

- COMMISSIONING AND TRIAL OPERATION Rev01Document2 pagesCOMMISSIONING AND TRIAL OPERATION Rev01Ricardo Escudero VinasNo ratings yet

- Structured What If Technique A Complete Guide - 2020 EditionFrom EverandStructured What If Technique A Complete Guide - 2020 EditionNo ratings yet

- 3623-DAL-F-J-112-R1 DP Txs (Flow)Document6 pages3623-DAL-F-J-112-R1 DP Txs (Flow)Roshin99No ratings yet

- CalculationsDocument6 pagesCalculationsMichael Haise100% (1)

- Hydrotest Questionnaire & ResourcesDocument2 pagesHydrotest Questionnaire & ResourcesMichael HaiseNo ratings yet

- Air Inclusion Report PDFDocument1 pageAir Inclusion Report PDFMichael HaiseNo ratings yet

- Fired Furnace Excess Air CalculationDocument3 pagesFired Furnace Excess Air CalculationAtul kumar KushwahaNo ratings yet

- 1st Stage in Frac Water Reuse System - Rev1Document2 pages1st Stage in Frac Water Reuse System - Rev1Michael HaiseNo ratings yet

- Desuperheater Boiler Feed Water RequirementDocument2 pagesDesuperheater Boiler Feed Water RequirementMichael HaiseNo ratings yet

- Project Design, Build Manage Flow ChartDocument2 pagesProject Design, Build Manage Flow ChartMichael HaiseNo ratings yet

- Karman DPDocument4 pagesKarman DPFrancisco RenteriaNo ratings yet

- Reuse of Flowback Produced Water For Hydraulic FracturingDocument34 pagesReuse of Flowback Produced Water For Hydraulic FracturingAnonymous 3nevEoNo ratings yet

- Heat Exchanger Specification Sheet: Performance of One Unit Shell Side Tube SideDocument1 pageHeat Exchanger Specification Sheet: Performance of One Unit Shell Side Tube SideMichael HaiseNo ratings yet

- Beam ConverterDocument13 pagesBeam ConvertervindyavNo ratings yet

- Karman DPDocument4 pagesKarman DPFrancisco RenteriaNo ratings yet

- Basic Pipe AnalysisDocument29 pagesBasic Pipe AnalysisMichael HaiseNo ratings yet

- Wrench SizesDocument6 pagesWrench SizesMichael HaiseNo ratings yet

- Inputs Inputs: Top TriangleDocument4 pagesInputs Inputs: Top TriangleMichael HaiseNo ratings yet

- Mechanical Calcualtions: Date: 3/28/2006 By: MH Checked: ApprovedDocument1 pageMechanical Calcualtions: Date: 3/28/2006 By: MH Checked: ApprovedMichael HaiseNo ratings yet

- Wind LoadDocument2 pagesWind LoadMichael Haise100% (1)

- Firetube FrameDocument1 pageFiretube FrameMichael HaiseNo ratings yet

- Structural Steel SkidsDocument2 pagesStructural Steel SkidsMichael HaiseNo ratings yet

- Column Base Connections Baniotopoulos CCDocument16 pagesColumn Base Connections Baniotopoulos CCmutlu_seçerNo ratings yet

- What Is Electrical Wiring.: Joint Box System or Tree System Loop or Ring SystemDocument3 pagesWhat Is Electrical Wiring.: Joint Box System or Tree System Loop or Ring SystemCharles Ghati100% (1)

- Rosemount 752 Remote IndicatorDocument60 pagesRosemount 752 Remote IndicatorChunli FonsecaNo ratings yet

- M85001 0297 Input ModulesDocument4 pagesM85001 0297 Input Modulesafie pio pioNo ratings yet

- RE-25AR Agent Release Panel OverviewDocument3 pagesRE-25AR Agent Release Panel OverviewHarshith KunjathurNo ratings yet

- Cost Per KM - TCAS & ABS - Version 2Document3 pagesCost Per KM - TCAS & ABS - Version 2SSE PLANNINGNo ratings yet

- 1756 Controllogix and Guardlogix Controllers: Technical DataDocument48 pages1756 Controllogix and Guardlogix Controllers: Technical DataPawan BhattaNo ratings yet

- AMS43Document24 pagesAMS43Cristian OsorioNo ratings yet

- 13 MAN IM IND560x MLDocument541 pages13 MAN IM IND560x MLHebert FirmoNo ratings yet

- EFIS-D10A Installation GuideDocument45 pagesEFIS-D10A Installation GuideBruce BNo ratings yet

- K85005-0132 - VS Series Submittal GuideDocument51 pagesK85005-0132 - VS Series Submittal GuideEliudNo ratings yet

- BA O2 Transmitter 4100e e 52121114 Oct03Document53 pagesBA O2 Transmitter 4100e e 52121114 Oct03kicsnerNo ratings yet

- Backgrounder Flood Damage 130911 FINALDocument3 pagesBackgrounder Flood Damage 130911 FINALBarangay DitumaboNo ratings yet

- EAC OpinionDocument4 pagesEAC OpinionPraveen KumarNo ratings yet

- ST25TechSPECIFICATION JAN2021Document11 pagesST25TechSPECIFICATION JAN2021DHINAKARAN KumarNo ratings yet

- Command Center - As Built 7 AUG 2018Document34 pagesCommand Center - As Built 7 AUG 2018Vignesh WaranNo ratings yet

- Firestop: B-Line Series Cable Tray Systems EatonDocument6 pagesFirestop: B-Line Series Cable Tray Systems EatonibharNo ratings yet

- Ml7984a4009 HoneywellDocument40 pagesMl7984a4009 HoneywellFrancisco Javier BurgosNo ratings yet

- SavijanjeDocument76 pagesSavijanjeSamira Adnan HalilovićNo ratings yet

- Panduit Modular Plug Installation InstructionsDocument2 pagesPanduit Modular Plug Installation InstructionszigbaddyNo ratings yet