Professional Documents

Culture Documents

Gas Metering System-Woodward - Swift

Uploaded by

kats2404Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gas Metering System-Woodward - Swift

Uploaded by

kats2404Copyright:

Available Formats

ProductSpecification

03252(Rev.F)

Swift

GasMeteringSystem

Applications

The Woodward Swift Gas

Metering System (GMS) is

suitable for use on microturbines,

miniturbines, small industrial gas

turbines (up to 2 MW), and highpressure fuel cell applications.

The Swift system has four valve

sizes with maximum fuel flows between 6.3 and 88.9 g/s (50 and 695 lb/hr) of

standard natural gas, depending on system pressures. The system is designed for

installation within the engine enclosure and can operate with gas temperatures up to

121 C (250 F).

Description

The main system components of the

Swift GMS include one or two

metering valves and one electronic

valve driver module.

The development of the Swift GMS

focused on meeting the performance

requirements of emerging distributed

resource applications, including gas

turbines and fuel cells. Both cost and

performance are critical in these

applications. Hence, every element

of the design and production process

has been driven to reduce cost. The

result of this effort is an accurate,

fast, and robust valve at a low price. Turbine and fuel cell manufacturers no longer

have to sacrifice performance to meet their cost targets.

The core component within the GMS is the Swift valve. This valve consists of a sonic

flow metering section (with pressure recovery) and a contoured valve needle which

is positioned by a stepping motor. Woodwards experience with sonic flow metering

valves has produced several product platforms that operate at sonic conditions with

pressure ratios (P2/P1) up to 0.85. The use of the sonic flow valve allows precise

gas flow control without measurement and compensation for gas pressure variations

downstream of the metering device.

In addition, the Swift valve has been designed for gas temperatures up to 121 C

(250 F), reducing the requirement for gas cooling after a gas compressor.

The stepping motor allows for accurate valve positioning and very low power usage.

The flow turndown ratio of the metering valve is better than 20:1, which allows

accurate engine start reliability and consistent performance.

The valve is available in a characterized configuration (Model 200) for the best

accuracy. It is also available in an uncharacterized configuration (Model 600) for

applications requiring excellent repeatability but not absolute accuracy.

High accuracy gas

flow metering

Low cost

Fast response

High flow

turndown ratio

Designed for high

gas temperatures

Contaminant

resistant

Compact, modular

design meets wide

range of

applications

Based on

Woodwards

SonicFlo

platform

No field

adjustments or

rigging

Certified for North

American

Hazardous

Locations

Compliant with

applicable CE

DirectivesATEX,

Machinery, and

EMC

Woodward 03252 p.2

Because the valve needle only contacts the nozzle when fully closed, the unit is very resistant to the effects of

contamination in the gas flow. To provide a robust and reliable system, a Woodward digital electronic valve driver

allows the valve to operate with very fast and accurate transient response.

The Swift valve allows for easy integration into a two-valve configuration. For fuel systems requiring two independently

modulated fuel flows, the primary valve can be integrated with a second independently controlled metering valve. The

primary valve can accommodate this integration without duplicating either electrical or mechanical connections. In

addition, a combined driver is available that controls both valves. This integration results in a low-cost system that can

be applied to staged combustors without increasing cable, piping, and installation costs.

SpecificationforSingleSwiftValve

Inlet Pressure (operating)

Maximum Pressure (non-operating)

Gas Temperature

Ambient Temperature

Slew Rate (9010%)

Power Supply

Max. Power (steady state)

Max. Power (transient)

Input Signal

Shutoff Capability

Envelope (valve)

Envelope (driver)

Weight (single valve)

Weight (dual valve)

Weight (driver)

Electrical Connector (valve)

Electrical Connector (driver)

Overboard Vent Port

Inlet Port

Discharge Port

Technical Manual

02070 kPa / 0300 psia (all models except Swift-65)

01380 kPa / 0200 psia (Swift-65)

3100 kPa / 450 psia

29 to +121 C / 20 to +250 F

29 to +70 C / 20 to +158 F

150 ms

1832 Vdc

37.8 W

48 W

PWM, 420 mA, DeviceNet

ANSI B16.104 Class IV

(0.01% of maximum flow at 50 psia / 345 kPa)

127 x 152 x 102 mm / 5 x 6 x 4 inches

241 x 163 x 58 mm / 9.5 x 6.4 x 2.3 inches

4 kg / 8 lb

5 kg / 10 lb

2 kg / 4 lb

AMP P/N 788158 9-pin connector

Cinch P/N 581-01-30-001S

4 SAE J514

12 SAE J514

10 SAE J514 OR 12 SAE J514

26363

RegulatoryCompliance

European Compliance for CE Marking:

EMC Directive:

Declared to 89/336/EEC COUNCIL DIRECTIVE of 03 May 1989 on the approximation of

the laws of the Member States relating to electromagnetic compatibility.

ATEX Potentially Explosive

Declared to 94/9/EC COUNCIL DIRECTIVE of 23 March 1994 on the approximation of

Atmospheres Directive:

the laws of the Member States concerning equipment and protective systems intended

for use in potentially explosive atmospheres.

Zone 2, Category 3, Group II G, EEx nA II T3

Special Conditions for Safe Use:

Ambient Temperature Range:

29 to +70 C (valves)

40 to +70 C (driver)

Use Supply wires suitable for a maximum ambient temperature of +90 C.

Other European Compliance (Valves only):

Compliance with the following European Directives or standards does not qualify this product for application of the CE Marking:

Machinery Directive:

Compliant as a component with 98/37/EC COUNCIL DIRECTIVE of 23 July 1998 on the

approximation of the laws of the Member States relating to machinery.

Pressure Equipment Directive:

Compliant as SEP per Article 3.3 to Pressure Equipment Directive 97/23/EC of 29 May

1997 on the approximation of the laws of the Member States concerning pressure

equipment.

North American Compliance:

CSA:

CSA Certified for Class I, Division 2, Groups A, B, C, and D, T3C at 70 C Ambient for

use in Canada and the United States

This product is certified as a component for use in other equipment. The final combination is subject to acceptance by the

authority having jurisdiction or local inspection.

Woodward 03252 p.3

ValveSizes

Four valve sizes meet a wide range of applications. The table below provides a breakdown of the maximum rated

flow rates at various pressure conditions. Two-valve systems with any combination of sizes are available.

Inlet Pressure / Discharge Pressure

85/68

200/160

300/240

600/480

1400/1120

2000/1600

psia

psia

psia

kPa

kPa

kPa

Swift-11

50 lb/hr

115 lb/hr

175 lb/hr

6.3 g/s

14.8 g/s

21.1 g/s

Swift-20

90 lb/hr

210 lb/hr

315 lb/hr

11.5 g/s

26.9 g/s

38.4 g/s

Swift-36 160 lb/hr

380 lb/hr

575 lb/hr

21.0 g/s

48.9 g/s

69.8 g/s

Swift-65 295 lb/hr

695 lb/hr

*

38.2 g/s

88.9 g/s

*

* Further development is ongoing to determine performance at higher flows and pressures.

ValveAccuracy

Swift 200 Accuracy

Effective Area Accuracy

Gas Mass Flow Accuracy

Repeatability

Swift 600 Accuracy

Effective Area Accuracy (at 10% flow)

Effective Area Accuracy (at max flow)

Repeatability

2% of point

2.5% of point

< 1% of point

2% of full scale

7% of full scale

< 1% of point

ValveandSystemConfigurations

The valves can be provided in a variety of configurations including:

Configuration

Single Swift Metering Valve

Dual Swift Metering Valve

Single Swift Metering Valve

Position

Command

Engine/

Package

Control

Valve

Driver

Motor

Control

Inlet

Valve

#1

Discharge

Example

Swift 11

Swift 11/36

Dual Swift Metering Valve

Position

Command

Engine/

Package

Control

Valve

Driver

Motor

Control

Inlet

Valve

#1

Valve

#2

Discharge

Woodward 03252 p.4

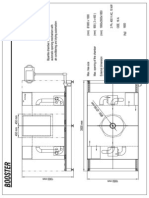

Single Valve Outline Drawing

Dual Valve Outline Drawing (Do not use for construction)

For more information contact:

PO Box 1519, Fort Collins CO, USA 80522-1519

1000 East Drake Road, Fort Collins CO 80525

Tel.: +1 (970) 482-5811 Fax: +1 (970) 498-3058

www.woodward.com

Distributors & Service

Woodward has an international network of distributors and service facilities.

For your nearest representative, call the Fort Collins plant or see the

Worldwide Directory on our website.

This document is distributed for informational purposes only. It is not to be construed as

creating or becoming part of any Woodward Governor Company contractual or warranty

obligation unless expressly stated in a written sales contract.

Woodward 2001, All Rights Reserved

2008/8/Fort Collins

You might also like

- Professor Von Kliptip Explains Constant Speed Propeller SystemsDocument16 pagesProfessor Von Kliptip Explains Constant Speed Propeller Systemskats2404100% (1)

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- Silicone MoldingDocument6 pagesSilicone Moldingkats2404No ratings yet

- Automotive Air Conditioning and Climate Control SystemsFrom EverandAutomotive Air Conditioning and Climate Control SystemsRating: 4 out of 5 stars4/5 (6)

- Class Prophecy 012Document11 pagesClass Prophecy 012Mythical Persues100% (2)

- DMGT403 Accounting For Managers PDFDocument305 pagesDMGT403 Accounting For Managers PDFpooja100% (1)

- A6 VDocument40 pagesA6 VWesame Shnoda100% (1)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Variable Pitch Constant Speed Propellers For Light AircraftDocument72 pagesVariable Pitch Constant Speed Propellers For Light Aircraftkats2404100% (1)

- TH255C Engine CAT PartsDocument134 pagesTH255C Engine CAT PartsKevine KhaledNo ratings yet

- Waukesha L7042 GSI SpécificationsDocument2 pagesWaukesha L7042 GSI SpécificationssuptedNo ratings yet

- Elgi Screw CompressorDocument12 pagesElgi Screw CompressorRAVINDER DHINGRANo ratings yet

- Bettis Valve Actuator GuideDocument12 pagesBettis Valve Actuator Guideprufino2No ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- DeaeratorDocument8 pagesDeaeratorfjoesandiNo ratings yet

- Moog ServovalvesDocument8 pagesMoog Servovalvesdylan_dearing@hotmail.com100% (1)

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Ultrasonic Gas Metering Skid SpecificationDocument38 pagesUltrasonic Gas Metering Skid Specificationer_bhavin3119100% (1)

- Woodward Gs6 Gas ValveDocument4 pagesWoodward Gs6 Gas ValveIsaias Fernandez Calderon100% (1)

- 520L0940 - PVG 100 VLV - DS - Aug-2005 - REVDocument2 pages520L0940 - PVG 100 VLV - DS - Aug-2005 - REVSasko DimitrovNo ratings yet

- D Ape Av1234 - FDocument24 pagesD Ape Av1234 - FAngel FortuneNo ratings yet

- HR E576qDocument12 pagesHR E576qIsanka SathsaraneeNo ratings yet

- Accurately measure oil, water and gas flow without separationDocument4 pagesAccurately measure oil, water and gas flow without separationCristhian Torres0% (1)

- Prime Model: P70 Emergency Model: P76E Diesel Generator Technical SpecificationsDocument4 pagesPrime Model: P70 Emergency Model: P76E Diesel Generator Technical SpecificationsLeonardusHSijabatNo ratings yet

- HYD. PumpDocument40 pagesHYD. Pumprohitbhat2345No ratings yet

- Sensor Systems Broch 09 MedDocument12 pagesSensor Systems Broch 09 MedscribdkhatnNo ratings yet

- AD01166M NUFLO Liquid Turbine Flow Meters Data SheetDocument8 pagesAD01166M NUFLO Liquid Turbine Flow Meters Data SheetdediekosNo ratings yet

- Perkins P200Document4 pagesPerkins P200PaulusIwanNo ratings yet

- Agilent 6890n DatasheetDocument5 pagesAgilent 6890n DatasheetMayar SayedNo ratings yet

- Ap B14 02L 01e - Akm - 38750 PDFDocument4 pagesAp B14 02L 01e - Akm - 38750 PDFsamsungloverNo ratings yet

- GAS-Guard 8: Answers For EnergyDocument6 pagesGAS-Guard 8: Answers For Energyeross_saptaNo ratings yet

- 0 Tecjet 180Document4 pages0 Tecjet 180Anonymous yugocxnNo ratings yet

- Ad00489m Barton 7400Document6 pagesAd00489m Barton 7400robercl51No ratings yet

- Perkins Diesel Generator Set - ISO Certified, 50Hz 3-Phase GeneratorDocument4 pagesPerkins Diesel Generator Set - ISO Certified, 50Hz 3-Phase GeneratorConstantyn_FrederikNo ratings yet

- G3520 Lehe2832 02 PDFDocument6 pagesG3520 Lehe2832 02 PDFCostas Aggelidis100% (1)

- Gas EngineDocument6 pagesGas EngineMRizwanSadiq313No ratings yet

- Kohler 14 & 20kW RESADocument4 pagesKohler 14 & 20kW RESADerekMarkleyNo ratings yet

- Compressor L7044GSI-7045 - 1210Document2 pagesCompressor L7044GSI-7045 - 1210Dedy Chasan Aflah MutoharNo ratings yet

- Cummins 250KVA 1Document4 pagesCummins 250KVA 1Pio Roni100% (2)

- Woodward CPC Convertidor de Corriente A Presion EspecificacionesDocument4 pagesWoodward CPC Convertidor de Corriente A Presion EspecificacionesJossi Perez ANo ratings yet

- Sf6 Circuit Breakers Catalog 1Document8 pagesSf6 Circuit Breakers Catalog 1Leonardo HernandesNo ratings yet

- L7044gsi 7045 0710Document2 pagesL7044gsi 7045 0710Martin Alejandro NievaNo ratings yet

- HR E577rDocument6 pagesHR E577rAnton RenaldoNo ratings yet

- K-Gas Metering SystemDocument4 pagesK-Gas Metering SystemmohamadziNo ratings yet

- AA Bard 5.0 TonRDocument12 pagesAA Bard 5.0 TonRCarlos GudiñoNo ratings yet

- Model 215 Wafer Sphere 3"-12" Digital Control Valve: FeaturesDocument4 pagesModel 215 Wafer Sphere 3"-12" Digital Control Valve: FeaturesFaull JackmanNo ratings yet

- SM TM 1.5-4 Guardsman (G) Series02002Document4 pagesSM TM 1.5-4 Guardsman (G) Series02002Paola Arevalo RinconNo ratings yet

- PG GovernorsDocument4 pagesPG GovernorsPj EastonNo ratings yet

- GF Brochure RevL VeriCal RevCDocument6 pagesGF Brochure RevL VeriCal RevCjakkyjeryNo ratings yet

- Diesel Generator Set: Prime Model:LP90P Standby Model:LP100SDocument4 pagesDiesel Generator Set: Prime Model:LP90P Standby Model:LP100SLeonardusHSijabatNo ratings yet

- Sys/Ftbg-100 Series: With Atex EnclosuresDocument2 pagesSys/Ftbg-100 Series: With Atex EnclosuresrezaNo ratings yet

- FEPA Gas-over-oil ActuatorsDocument4 pagesFEPA Gas-over-oil Actuatorstoader56No ratings yet

- 6890 GC Site Preparation ChecklistDocument4 pages6890 GC Site Preparation Checklistigor_239934024No ratings yet

- Cameron Temperature Switches Technical Data SheetDocument28 pagesCameron Temperature Switches Technical Data Sheetvlcmstne04No ratings yet

- 100 0400Document8 pages100 0400Benito.camelasNo ratings yet

- g3520c Im Natural Gas For 1966Document6 pagesg3520c Im Natural Gas For 1966Pankaj KambleNo ratings yet

- Weishaupt WG10 and WG20 Gas Burners Technical SpecificationsDocument8 pagesWeishaupt WG10 and WG20 Gas Burners Technical SpecificationsbatazivoNo ratings yet

- MassflowmetersandcontrollersDocument19 pagesMassflowmetersandcontrollersMilectron Ion100% (1)

- Tecjet 50plus PDFDocument6 pagesTecjet 50plus PDFZaheer MehmoodNo ratings yet

- Gas Turbine Fuel Valve Model 8402Document6 pagesGas Turbine Fuel Valve Model 8402giopetrizzoNo ratings yet

- P40PB (1004G) GensetDocument4 pagesP40PB (1004G) GensetBudi WaskitoNo ratings yet

- 2 and 3 Genesis Series PD Meter SpecificationsDocument6 pages2 and 3 Genesis Series PD Meter Specificationsjimbo2032No ratings yet

- Inert Gas System (IGG)Document3 pagesInert Gas System (IGG)Fadzil NorNo ratings yet

- LAND FGA 900 Series EnglishDocument6 pagesLAND FGA 900 Series EnglishRaymundo CorderoNo ratings yet

- Us 5890441Document21 pagesUs 5890441kats2404100% (1)

- Dillon Aero M-240 Mount Quick Change 500 Round MagazineDocument2 pagesDillon Aero M-240 Mount Quick Change 500 Round Magazinekats2404No ratings yet

- Us 7249732Document42 pagesUs 7249732kats2404No ratings yet

- Helio ServicesDocument68 pagesHelio Serviceskats2404No ratings yet

- Lift Calculations: FT LBF FT LBF A F PDocument3 pagesLift Calculations: FT LBF FT LBF A F Psabzg89No ratings yet

- Comparison of 10s, 12s, and 14s Lipo Power Systems for RC JetsDocument1 pageComparison of 10s, 12s, and 14s Lipo Power Systems for RC Jetskats2404No ratings yet

- Thin Gap Brochure 2015 WebDocument12 pagesThin Gap Brochure 2015 Webkats2404No ratings yet

- Heat ExchangersDocument8 pagesHeat Exchangerskats2404No ratings yet

- Von Klip Tip Cs PropellerDocument12 pagesVon Klip Tip Cs PropellergerezairNo ratings yet

- CB-8491 Heat Recovery BrochureDocument8 pagesCB-8491 Heat Recovery Brochurekats2404No ratings yet

- F135 Engine SpecificationDocument2 pagesF135 Engine Specificationkats2404100% (1)

- Computer Controlled Air Isolation SystemDocument2 pagesComputer Controlled Air Isolation Systemkats2404No ratings yet

- StackEconomizer CRE-CCE Boiler BookDocument22 pagesStackEconomizer CRE-CCE Boiler BookBorisvukic89No ratings yet

- Cabin Boom Noise DampingDocument1 pageCabin Boom Noise Dampingmanzoni1No ratings yet

- IC 900 IC 910 Ignition ControllerDocument50 pagesIC 900 IC 910 Ignition Controllerkats2404No ratings yet

- Combined GearboxDocument8 pagesCombined Gearboxkats2404No ratings yet

- Q A About Infrared 1Document2 pagesQ A About Infrared 1kats2404No ratings yet

- Mil HDBK 1783b Notice 1Document1 pageMil HDBK 1783b Notice 1kats2404No ratings yet

- Mil HDBK 1783bDocument171 pagesMil HDBK 1783bkats2404No ratings yet

- Rotary and Conveyorized OvensDocument2 pagesRotary and Conveyorized Ovenskats2404No ratings yet

- BOOSTER - EnglishDocument1 pageBOOSTER - Englishkats2404No ratings yet

- IC 900 IC 910 Ignition ControllerDocument50 pagesIC 900 IC 910 Ignition Controllerkats2404No ratings yet

- Besander TD English 02Document1 pageBesander TD English 02kats2404No ratings yet

- Adjustable OvenDocument3 pagesAdjustable Ovenkats2404No ratings yet

- Powder Coating IR CuringDocument4 pagesPowder Coating IR Curingkats2404No ratings yet

- Horizontal and Vertical OvensDocument2 pagesHorizontal and Vertical Ovenskats2404No ratings yet

- JMC250Document2 pagesJMC250abhijit99541623974426No ratings yet

- Food Sub Inspector Question PaperDocument12 pagesFood Sub Inspector Question PaperGoutam shitNo ratings yet

- Chapter 27 Protists I. Evolution of EukaryotesDocument7 pagesChapter 27 Protists I. Evolution of EukaryotesNadeem IqbalNo ratings yet

- Sonochemical Synthesis of NanomaterialsDocument13 pagesSonochemical Synthesis of NanomaterialsMarcos LoredoNo ratings yet

- Mediclaim - ChecklistDocument4 pagesMediclaim - ChecklistKarthi KeyanNo ratings yet

- Move Over G7, It's Time For A New and Improved G11: Long ShadowDocument16 pagesMove Over G7, It's Time For A New and Improved G11: Long ShadowVidhi SharmaNo ratings yet

- CHEMOREMEDIATIONDocument8 pagesCHEMOREMEDIATIONdeltababsNo ratings yet

- DesignWS P1 PDFDocument673 pagesDesignWS P1 PDFcaubehamchoi6328No ratings yet

- HandoutDocument4 pagesHandoutZack CullenNo ratings yet

- Report On Indian Airlines Industry On Social Media, Mar 2015Document9 pagesReport On Indian Airlines Industry On Social Media, Mar 2015Vang LianNo ratings yet

- M and S Code of ConductDocument43 pagesM and S Code of ConductpeachdramaNo ratings yet

- EMB 690-1 SM Course Outline Spring 21Document8 pagesEMB 690-1 SM Course Outline Spring 21HasanNo ratings yet

- Job Interview CV TipsDocument2 pagesJob Interview CV TipsCarlos Moraga Copier100% (1)

- Affidavit of 2 Disinterested Persons (Haidee Gullodo)Document1 pageAffidavit of 2 Disinterested Persons (Haidee Gullodo)GersonGamasNo ratings yet

- CONTACT DETAILS HC JUDGES LIBRARIESDocument4 pagesCONTACT DETAILS HC JUDGES LIBRARIESSHIVAM BHATTACHARYANo ratings yet

- Test Engleza 8Document6 pagesTest Engleza 8Adriana SanduNo ratings yet

- Unit 4 AE Scan OCRed PDFDocument44 pagesUnit 4 AE Scan OCRed PDFZia AhmedNo ratings yet

- List of Psychotropic Drugs Under International ControlDocument32 pagesList of Psychotropic Drugs Under International ControlRadhakrishana DuddellaNo ratings yet

- The English Center Articulation AgreementDocument9 pagesThe English Center Articulation AgreementJose CabreraNo ratings yet

- Long Standoff Demolition Warheads For Armor, Masonry and Concrete TargetsDocument27 pagesLong Standoff Demolition Warheads For Armor, Masonry and Concrete Targetsahky7No ratings yet

- UMC Florida Annual Conference Filed ComplaintDocument36 pagesUMC Florida Annual Conference Filed ComplaintCasey Feindt100% (1)

- New Pacific Timber v. Señeris, 101 SCRA 686Document5 pagesNew Pacific Timber v. Señeris, 101 SCRA 686Ishmael AbrahamNo ratings yet

- Declarative and Procedural Knowledge (Lêda's Final Paper) 2010 01Document13 pagesDeclarative and Procedural Knowledge (Lêda's Final Paper) 2010 01Jair Luiz S. FilhoNo ratings yet

- Living in a digital age unit review and digital toolsDocument1 pageLiving in a digital age unit review and digital toolsLulaNo ratings yet

- Personality, Movie Preferences, and RecommendationsDocument2 pagesPersonality, Movie Preferences, and RecommendationsAA0809No ratings yet

- Environmental ScienceDocument5 pagesEnvironmental Sciencearijit_ghosh_18No ratings yet

- Raj Priya Civil Court Clerk FinalDocument1 pageRaj Priya Civil Court Clerk FinalRaj KamalNo ratings yet