Professional Documents

Culture Documents

QCP-0714-11, Rev. A, Field Welded API Std. 650 Tanks' Shop Pre-Fabrication QC Procedure.

Uploaded by

abdul azizOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QCP-0714-11, Rev. A, Field Welded API Std. 650 Tanks' Shop Pre-Fabrication QC Procedure.

Uploaded by

abdul azizCopyright:

Available Formats

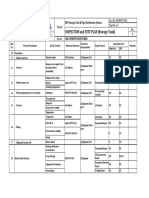

METSCCO Heavy Steel Industries Co. Ltd.

Field Welded API Std. 650 Tanks

Shop Pre-Fabrication Quality Control Procedure.

For

Upgrade Fire Water Protection System at SA GOSPs;

13 No. Fire Water Tanks Project.

BI No.: 00091

Document No.: QCP-0714-11

REVISION HISTORY

Rev.

Date

Description

Prepared by:

QA/QC Dept. Head

Reviewed by:

Project Mgr

Engg. Mgr.

Approved by:

Dy. General Mgr.

METCCO Heavy Steel Industries Co. Ltd.

Project: Upgrade Fire Water Protection System at SA GOSPs 13 No. Fire Water Tanks.

Document Title: Field Welded API Std. 650 Tanks Shop Pre-Fabrication Quality Control Procedure.

A

15th Oct.07

Initial Issue.

R. DSouza

B. Phillip

Cris M. S. Jr.

A. Choghari

Table of Contents

No.

1.0

2.0

3.0

4.0

5.0

5.1

5.2

5.3

5.3.1

5.3.2

5.3.3

5.3.4

5.3.5

5.3.6

5.3.7

5.4

5.5

5.6

5.7

6.0

7.0

Section Title

Scope

Purpose

References

Responsibility

Method Statements (Title only)

Material Control

Pre-Fabrication Control

Fabrication & Dimensional Control (Title only)

Bottom Annular Plates

Bottom Rectangular & Sketch Plates

Shell Plates

Curb Angle

Nozzles/Manholes

Permanent Attachments including Structures

Roof Plates

Welding Control

Painting Control

Final Inspection/Shop Release

Shipping/Delivery

Safety Precautions

Exhibits/Attachments

Page

2 of 6

2 of 6

2 of 6

3 of 6

3 of 6

3 of 6

4 of 6

4 of 6

4 of 6

4 of 6

4 of 6

5 of 6

4 of 6

5 of 6

5 of 6

5 of 6

6 of 6

6 of 6

6 of 6

6 of 6

6 of 6

1.0 Scope.

The scope of this procedure is to provide guidelines for the effective quality control of the shop pre-fabrication of Field

welded storage tanks, as per the requirements of API Std. 650 and 32-SAMMS-005, to be constructed for Upgrade Fire Water

Protection System at SA00 GOSPs Project and shall be applicable for all 13 No. Fire Water Tanks, bearing tag # U52-D-0201

at Ain Dar GOSP-2, U54-D-0101 at Ain Dar GOSP-4, U53-D-0101 at Ain Dar GOSP-3, 268-D-0412 at Ain Dar GOSP-6, U51D-0101 at Ain Dar GOSP-1, U57-D-0541 at Shedgum GOSP-2, U59-D-0201 at Shedgum GOSP-4, D28-D-0425 at Shedgum

GOSP-5, U27-D-0101 at Uthamaniyah GOSP-7, U28-D-0101 at Uthamaniyah GOSP-8, U30-D-0101 at Uthamaniyah

GOSP-10, U31-D-0802 at Uthamaniyah GOSP-11 and U32-D-0802 at Uthamaniyah GOSP-12.

2.0 Purpose.

The purpose of this procedure is to ensure that the above mentioned tanks material is pre-fabricated and examined in a

controlled manner.

3.0 References.

API Std. 650, 10th Edition, Add. 3

32-SAMMS-005

SAES-W-017

Form 175-324900

Document No.: QCP-0714-11, Rev. 0, Dated: 15th Oct. 2007

Welded Steel Tanks for Oil Storage.

Manufacture of Atmospheric Tanks.

Welding requirements for Tanks.

Tanks: Atmospheric, Steel Within the scope of 32-SAMMS-005.

METCCO Heavy Steel Industries Co. Ltd.

Project: Upgrade Fire Water Protection System at SA GOSPs 13 No. Fire Water Tanks.

Document Title: Field Welded API Std. 650 Tanks Shop Pre-Fabrication Quality Control Procedure.

Note: The references mentioned here-in shall provide the required acceptance criteria or references to it. Where specific

item/s are not specified or covered, industrys best practice shall be followed.

4.0 Responsibility.

The primary responsibility for the implementation of this procedure shall be with the QC Inspector assigned at the shop.

He shall ensure that the monitoring, verification and reporting required as per the applicable Std., specifications and ITP are

performed in a consistent manner in line with the guidelines provided by this procedure.

The QC Manager shall monitor & supervise the works performed by the Shop QC Inspector/s is consistent and meeting the

requirements of the applicable Std., specifications and ITP.

The Shop Production Engineer shall ensure that the request for inspection I provided to the QC Inspector appropriately so

as to facilitate smooth flow of the work. And also provide all necessary assistance that is within their scope of responsibility.

5.0 Method Statements:

5.1 Material Control.

The plates (bottom, shell & roof) & other constituent parts material of the tank shall be received at METSCCOs Riyadh

Workshop from the suppliers or used from the existing stock.

The Site Storekeeper shall receive the material at the workshop and inform the QC Inspector by providing him with the

verbal intimation, the Delivery Advice/Packing List and all documents received along with the delivery.

The QC Inspector shall check the material received for the following as a minimum, before forwarding the RFI to the

client:

The material is being ordered from the supplier, from whom it is received.

The material as mentioned in the suppliers Delivery Advice/Packing list is received and that it has not been

damaged during transportation.

All the material is conforming to the dimensional requirements and the corresponding documents required are

received. All material shall be clearly identified and provided with mill test certificates unless otherwise specified.

Review the documents received to be conforming to the applicable specification requirements.

Mark the inspection status, on the item with the help of the permanent paint marker or a suitable means that will

retain the marking, i.e. Accepted or Rejected or Hold. Also mark the material identification on the item, the

required identification, i.e. Job Order No., Specification, Heat No. (Information available on the material may be

encircled to highlight the identification).

Prepare and sign-off the Material Inspection Report (Doc. No.: SF.01). Notify the client for his review and

acceptance.

Any discrepancies in the supply noticed, shall be notified to the Purchasing Dept. to take necessary action.

If any material is received & accepted on conditional basis, the QC Inspector imposing the condition/s shall be

responsible to ensure that the conditions on which basis it is received / accepted is/are cleared prior to any welding

works are started/delivery of the item to the site

While at the workshop, the shop production crew shall assist the Storekeeper in proper & safe handling, storage and

preservation of the material. Material shall be stored in a manner that it shall not be in direct contact with the soil and as much

as possible covered to avoid damage and/or weather effects.

To use the stock material, the Storekeeper shall notify and identify to the QC Inspector the material intended to be used.

The QC shall check the material from the stock as if it is being received from the supplier (as stated above) and similarly follow

all other requirements.

Upon acceptance from the client the QC Inspector shall release the material for production use, by distributing the signed

MIR to all concerned, i.e. Original -to QA/QC Dept. Job Order file, Copies-to Operations, Stores & Purchasing. To the client if

specifically specified in the contract.

Storekeeper shall issue the material to the production crew.

The same procedure shall be followed for the welding consumables and painting consumables.

Note: The QC Inspector may issue all or any non-pressure containing parts material prior to the review and acceptance of the

Saudi Aramco Inspector, provided the material is acceptable and meeting all the specifications requirements.

Document No.: QCP-0714-11, Rev. 0, Dated: 15th Oct. 2007

METCCO Heavy Steel Industries Co. Ltd.

Project: Upgrade Fire Water Protection System at SA GOSPs 13 No. Fire Water Tanks.

Document Title: Field Welded API Std. 650 Tanks Shop Pre-Fabrication Quality Control Procedure.

5.2 Pre-Fabrication Control.

The Shop Production-in-charge shall, on a weekly basis, every Saturday, provide details of the planned production

activities, using Doc. No.: QF-0714-07, for the next two weeks. The QC in-charge shall prepare the Two weeks look-ahead

schedule and forward it to the Project Manager for his review and submittal to the client, every Sunday.

The inspection schedules involving client witness and/or hold points shall be notified and confirmed by the Shop

Production-in-charge, at least five (5) Saudi Aramco working days in advance to the QC in-charge. The QC in-charge on his

part shall notify the client (Doc. No.: QF-0714-06) and arrange the necessary quality documents

On a day-to day basis, once any fabrication, welding or painting activity is completed and is ready for inspection, the Shop

Production-in-charge or his deputy shall request the QC Inspector to perform the inspection. The QC Inspector shall inspect the

completed activity and prepare the Fabrication (visual & dimensional) Inspection Report (Doc. No.: QF-0714-02), Welding

Inspection Report (Doc. No.: QF-0714-03) or Painting Inspection Report (Doc. No.: QF-0714-04). Also when the item is ready

for delivery, prior to the release of the item for shipment to site, the Shop Production-in-charge shall notify the QC Inspector to

inspect, prepare the Final Inspection Report (Doc. No.: QF-0714-05) and to arrange for client review/verification and release

of the item for delivery/shipment.

A copy of the accepted report shall be provided to the Shop Production-in-charge, for each inspection completed, for his

further action.

5.3 Fabrication & Dimensional Control.

5.3.1. Bottom Annular Plates.

The Bottom Annular plates shall be cut on the CNC profile cutting machine, and then the heat number marking shall

be transferred (required only where it is not part of the plate/item), and the identification marks (J.O. #, Tank #, part/item

number) as required shall be hard punched.

The Shop Production-in-charge or his deputy shall notify Shop QC Inspector, when the plate/s are completed and

ready for inspection. The Shop QC Inspector shall inspect the plate/s, against a template and prepare a Fabrication (visual &

dimensional) Inspection Report (Doc. No.: QF-0714-02) and notify the client, and provide him with the report for his

review/verification.

A copy of the accepted report shall be provided to the Shop Production-in-charge for his further action.

5.3.2. Bottom Rectangular & Sketch Plates.

The rectangular plates shall be kept as mill cut while the sketch plates shall be cut either on the CNC profile cutting

machine or by a pug cutting machine guided with a rail specially fabricated to suit the radius of the bottom plate (the guide

rail shall be examined prior to use).

The Shop Production-in-charge or his deputy shall notify Shop QC Inspector, when the plate/s are completed and

ready for inspection. The Shop QC Inspector shall inspect the plate/s, against a template and prepare a Fabrication (visual &

dimensional) Inspection Report (Doc. No.: QF-0714-02) and notify the client, and provide him with the report for his

review/verification.

A copy of the accepted report shall be provided to the Shop Production-in-charge for his further action.

5.3.3. Shell Plates.

The shell plates shall be cut to square, edge prepared and bent/shaped (rolled) to the curvature of the tank radius.

The Shop Production-in-charge or his deputy shall notify Shop QC Inspector, when the plate/s are completed and

ready for inspection. The Shop QC Inspector shall inspect the plate/s, against a template and prepare a Fabrication (visual &

dimensional) Inspection Report (Doc. No.: QF-0714-02) and notify the client, and provide him with the report for his

review/verification.

A copy of the accepted report shall be provided to the Shop Production-in-charge for his further action.

Document No.: QCP-0714-11, Rev. 0, Dated: 15th Oct. 2007

METCCO Heavy Steel Industries Co. Ltd.

Project: Upgrade Fire Water Protection System at SA GOSPs 13 No. Fire Water Tanks.

Document Title: Field Welded API Std. 650 Tanks Shop Pre-Fabrication Quality Control Procedure.

5.3.4. Curb Angle.

The curb angle shall be in pieces and shall be provided in the overall length basis (may be slightly longer for

adjustment and to be cut on site). Each angle shall be edge prepared and bent/shaped (rolled) to the curvature of the tank

radius.

The Shop Production-in-charge or his deputy shall notify Shop QC Inspector, when the plate/s are completed and

ready for inspection. The Shop QC Inspector shall inspect the plate/s, against a template and prepare a Fabrication (visual &

dimensional) Inspection Report (Doc. No.: QF-0714-02) and notify the client, and provide him with the report for his

review/verification.

A copy of the accepted report shall be provided to the Shop Production-in-charge for his further action.

5.3.5. Nozzles & Manholes.

The manhole neck shall be cut to size, edge prepared and rolled to the curvature of the manhole radius, the joint

between both the ends of the fitted together for welding. Also the manhole flange shall be fabricated from the plate and fitted

to the neck, once the neck longitudinal seam is welded. The nozzles shall be fabricated from standard pipe and fittings, and

the fabrication shall involve cutting to size, edge preparation and the joint fit-up. The reinforcing pad plates shall be cut to

shape and size, rolled to the curvature of the tank outside radius.

The Shop Production-in-charge or his deputy shall notify Shop QC Inspector, when the activity is completed and ready

for inspection. The Shop QC Inspector shall inspect the item/s, and prepare a Fabrication (visual & dimensional) Inspection

Report (Doc. No.: QF-0714-02) and notify the client, and provide him with the report for his review/verification.

A copy of the accepted report shall be provided to the Shop Production-in-charge for his further action.

5.3.6. Permanent Attachments including Structures.

The permanent attachments and structures shall include but not be limited to spiral stairway and its component parts,

internal ladders, brackets, support cleats, center drum/column, rafters, etc.

The Shop Production-in-charge or his deputy shall notify Shop QC Inspector, when the activity is completed and ready

for inspection. The Shop QC Inspector shall inspect the item/s, and prepare a Fabrication (visual & dimensional) Inspection

Report (Doc. No.: QF-0714-02) and notify the client, and provide him with the report for his review/verification.

A copy of the accepted report shall be provided to the Shop Production-in-charge for his further action.

5.3.7. Roof Plates.

The rectangular plates shall be kept as mill cut while the sketch plates shall be cut either on the CNC profile cutting

machine or by a pug cutting machine guided with a rail specially fabricated to suit the radius of the bottom plate (the guide

rail shall be examined prior to use).

The Shop Production-in-charge or his deputy shall notify Shop QC Inspector, when the plate/s are completed and

ready for inspection. The Shop QC Inspector shall inspect the plate/s, against a template and prepare a Fabrication (visual &

dimensional) Inspection Report (Doc. No.: QF-0714-02) and notify the client, and provide him with the report for his

review/verification.

A copy of the accepted report shall be provided to the Shop Production-in-charge for his further action.

5.4.

Welding Control.

All the welding production and inspection shall be performed, examined and controlled as per the requirements of

SAES-W-017, including the conditioning, storage and exposure of electrodes.

The welding production works involved at the shop shall include manholes assembly fabrication, nozzles flange to

neck assembly fabrication, spiral stairway- landing platforms, stair treads, brackets, supports assembly fabrication, internal

ladders assembly fabrication, roof support structure including rafters, cleats, supports fabrication.

The acceptance criteria for visual weld examination shall be as per the reference code/Std. specified in the section 3,

unless otherwise stated.

No NDE: PT/MT/RT shall be performed at the Shop.

After the welds are ready for welding and after completion of the welds and are ready for inspection, the Shop

Production-in-charge or his deputy shall notify Shop QC Inspector. The Shop QC Inspector shall inspect the welds and

Document No.: QCP-0714-11, Rev. 0, Dated: 15th Oct. 2007

METCCO Heavy Steel Industries Co. Ltd.

Project: Upgrade Fire Water Protection System at SA GOSPs 13 No. Fire Water Tanks.

Document Title: Field Welded API Std. 650 Tanks Shop Pre-Fabrication Quality Control Procedure.

welding against the requirements and prepare a Welding Inspection Report (Doc. No.: QF-0714-03) and notify the client,

and provide him with the report for his review/verification.

A copy of the accepted report shall be provided to the Shop Production-in-charge for his further action.

5.5.

Painting Control.

All the painting production and inspection shall be performed, examined and controlled as per the requirements with

the project requirements and the Saudi Aramco standards particularly SAES-H-100.

The painting works to be undertaken at the shop shall include the application of the complete paint system to the

bottom plate underside surface (APCS-3). All other painting shall be performed on-site, after the completion of the erection

of the tank.

The acceptance criteria for visual paint examination shall be as per the reference code/Std. specified in the section 3,

unless otherwise stated.

After each coat of paint is ready for application and after completion of each coat application and after drying, when it

is ready for inspection, the Shop Production-in-charge or his deputy shall notify Shop QC Inspector. The Shop QC Inspector

shall inspect the paint, weather conditions, equipment and the coating against the requirements and prepare a Painting

Inspection Report (Doc. No.: QF-0714-04) and notify the client (if client witness is required, client shall be appropriately

informed in advance), and provide him with the report for his review/verification.

A copy of the accepted report shall be provided to the Shop Production-in-charge for his further action.

5.6.

Final (Shop Release) Inspection.

After all activities including inspection and testing, as required by the shop ITP and applicable Std./specifications is

completed and the item/s is ready for final (shop release) inspection, the Shop Production-in-charge or his deputy shall notify

Shop QC Inspector. The Shop QC Inspector shall inspect the item/s against the requirements and prepare a Final Inspection

Report (Doc. No.: QF-0714-05) and notify the client (if client witness is required, client shall be appropriately informed in

advance), and provide him with the report for his review/verification.

A copy of the accepted report shall be provided to the Shop Production-in-charge for his further action.

5.7.

Shipping & Delivery.

Upon completion of shop inspection & testing and release of the item/s for delivery by the Shop QC Inspector, the

Shop Production-in-charge or his deputy shall make arrangements for the transportation of the item/s to erection site. The

Production crew shall pack and load the item/s in such a manner that it shall not be damaged or lost during transportation. In

general, the plates (bottom, shell and roof) shall be transported in saddles specially fabricated for the purpose or adequately

supported to avoid deformation of the formed edges & shape. The smaller parts shall be transported in boxes to avoid any

loss during transportation, while bigger and bulky structural parts shall be transported by directly placing them and fastening

with belt/chain sling, on the trailer/truck bed.

6.0.

Safety Precautions.

The inspectors- Client or In-House, shall be provided with safe and free access to perform the desired inspection and

testing, in compliance with the Saudi Aramco Construction Safety Manual.

7.0.

Exhibits/Attachments.

Applicable forms are attached along with the Inspection & Test Plans.

Document No.: QCP-0714-11, Rev. 0, Dated: 15th Oct. 2007

You might also like

- 24.tank Oil Chalk TestDocument3 pages24.tank Oil Chalk TestShubham ShuklaNo ratings yet

- Tank Procedure by Conventional MethodDocument8 pagesTank Procedure by Conventional Methodsatish04No ratings yet

- Shell Plate Dimension CheckDocument7 pagesShell Plate Dimension Checksetak0% (1)

- Contractor Quality Control Plan For Storage Tank ErectionDocument2 pagesContractor Quality Control Plan For Storage Tank ErectionHamid Alilou100% (4)

- Tank Fabrication SpecsDocument21 pagesTank Fabrication Specsjlcheefei9258100% (1)

- Tank Inspection NotesDocument5 pagesTank Inspection Notesaneeshjose013No ratings yet

- Inspection & Test Plan TankDocument3 pagesInspection & Test Plan TankJOSHUA SULLEGUE100% (1)

- STS Co. storage tank fabrication methodologyDocument15 pagesSTS Co. storage tank fabrication methodologypurshottam GHNo ratings yet

- AST Nozzle Repair Req.Document10 pagesAST Nozzle Repair Req.Irvansyah RazadinNo ratings yet

- Tank Erection Method Statement For Mot Oil Storage TanksDocument13 pagesTank Erection Method Statement For Mot Oil Storage TanksErmal RulaNo ratings yet

- 10) Itp - Tank Fabrication PDFDocument6 pages10) Itp - Tank Fabrication PDFAndy Chong100% (5)

- Tank Erection Procedure GuideDocument5 pagesTank Erection Procedure Guidegeorge israelNo ratings yet

- Erection Procedure For Floating Roof TankDocument10 pagesErection Procedure For Floating Roof Tankabdul1207100% (2)

- Annular Plate RemovalDocument2 pagesAnnular Plate RemovalVishvjeet Prakash TiwariNo ratings yet

- Scope of Work for Pipeline InstallationDocument10 pagesScope of Work for Pipeline InstallationAsongwe HansNo ratings yet

- SOP Tank ConstructionDocument24 pagesSOP Tank ConstructionSuci YatiningtiyasNo ratings yet

- TDI41 Tank Inspection Repair & Alteration API 653 Sec 9Document13 pagesTDI41 Tank Inspection Repair & Alteration API 653 Sec 9Faizal Sattu100% (2)

- Example of Tank Field ErectionDocument12 pagesExample of Tank Field Erectionfazeel mohammedNo ratings yet

- Procedure For Tin - inDocument13 pagesProcedure For Tin - inAdil IjazNo ratings yet

- Tank Erection ProcedureDocument15 pagesTank Erection Procedurejohney294% (16)

- Iqwq-ce1092-Mpere-00-0001 - 1 Static Equipement Installation Plan (Tank)Document17 pagesIqwq-ce1092-Mpere-00-0001 - 1 Static Equipement Installation Plan (Tank)Ali MajeedNo ratings yet

- Tank ErectionDocument13 pagesTank Erectionsajay2010No ratings yet

- Storage Tank DetailDocument22 pagesStorage Tank DetailRamu NallathambiNo ratings yet

- UG PIPING COATINGDocument10 pagesUG PIPING COATINGcloud23No ratings yet

- Erection 009 CTP Storage TankDocument44 pagesErection 009 CTP Storage Tankgst ajah100% (1)

- Storage Tank Erection Procedure PDFDocument6 pagesStorage Tank Erection Procedure PDFEko Kurniawan89% (19)

- Tank Erection ProcedureDocument29 pagesTank Erection ProcedureVisas Siva100% (3)

- Reconstruction of Pakistan Refinery Tank T-53Document16 pagesReconstruction of Pakistan Refinery Tank T-53javaidahmedshaikh100% (1)

- Vaccum Test MethodDocument4 pagesVaccum Test MethodMahmud AlamNo ratings yet

- Tank Fabrication ProcedureDocument11 pagesTank Fabrication ProcedureNurul100% (2)

- Inspection and Test Plan: ITP NO: 7979-ITP-ME-031-1 Title: Bolt Tightening WorksDocument9 pagesInspection and Test Plan: ITP NO: 7979-ITP-ME-031-1 Title: Bolt Tightening WorksDelta akathehuskyNo ratings yet

- Tank Erection Procedure OverviewDocument16 pagesTank Erection Procedure OverviewKing王No ratings yet

- Tank Erection ProcedureDocument5 pagesTank Erection Procedureeng_elhedabyNo ratings yet

- Cone Roof Tank Erection ProcedureDocument8 pagesCone Roof Tank Erection ProcedureBoby Thomas100% (1)

- Itp - Tanks - 01Document10 pagesItp - Tanks - 01ravigurajapuNo ratings yet

- Itp TankDocument4 pagesItp TankAmber Chavez100% (2)

- Job Procedure For Eriction of TankDocument13 pagesJob Procedure For Eriction of TankAnonymous i3lI9M100% (2)

- Niigata - Replacing Bottom Plates of Oil Storage TanksDocument7 pagesNiigata - Replacing Bottom Plates of Oil Storage TanksJohnson Olarewaju100% (2)

- New Bottom PlateDocument9 pagesNew Bottom PlateEmmanuel kusimo100% (1)

- Job Procedure For PWHT of Storage Tanks: 10 of Ramadan City, Industrial Area A1, EgyptDocument5 pagesJob Procedure For PWHT of Storage Tanks: 10 of Ramadan City, Industrial Area A1, EgyptShubham ShuklaNo ratings yet

- Tank Erection Itp & Org ChartDocument34 pagesTank Erection Itp & Org Charthasan_676489616100% (2)

- Site Erected Atmospheric Pressure Storage TankDocument16 pagesSite Erected Atmospheric Pressure Storage TankRakesh RanjanNo ratings yet

- Storage Tank Inspection Check ListDocument2 pagesStorage Tank Inspection Check Listparthasarathy281267% (6)

- Tank 7 Repair Procedure Rev1Document6 pagesTank 7 Repair Procedure Rev1Mohd Shafuaaz Kassim33% (3)

- Procedure For Product IdentificationDocument5 pagesProcedure For Product IdentificationAjay RanganathanNo ratings yet

- Job Procedure for Incoming Material Checking & WarehousingDocument6 pagesJob Procedure for Incoming Material Checking & WarehousingShubham ShuklaNo ratings yet

- Pipe Fabrication and Installation Work Procedure Rev-01Document21 pagesPipe Fabrication and Installation Work Procedure Rev-01Dilshad Ahemad50% (4)

- 80 Marketing - QC-HSE Installtion Procedure Q-051-07-YMN Betara Rev ADocument9 pages80 Marketing - QC-HSE Installtion Procedure Q-051-07-YMN Betara Rev Agstketut100% (1)

- Kencana Infrastructure Quality Assurance ProcedureDocument22 pagesKencana Infrastructure Quality Assurance Procedurenaseema1100% (9)

- QWI-155 Receiving Rev 0Document8 pagesQWI-155 Receiving Rev 0kbldamNo ratings yet

- MS For Welding Consumable ControlDocument10 pagesMS For Welding Consumable Controlmansih457100% (1)

- Receiving InspectionDocument5 pagesReceiving InspectionUmair AwanNo ratings yet

- Material Control Procedure SAMPLEDocument24 pagesMaterial Control Procedure SAMPLEJanardhan Surya82% (17)

- QC Inpector Material ReceivingDocument4 pagesQC Inpector Material ReceivingGaneshNo ratings yet

- Technical Delivery Condition - GTU & SRUDocument6 pagesTechnical Delivery Condition - GTU & SRUpratikbhardwajNo ratings yet

- Rotating Equipment Installation ProcedureDocument2 pagesRotating Equipment Installation ProcedureathithancapeNo ratings yet

- WPPDC-QMD-001-Material Control and Werehousing ProcedureDocument4 pagesWPPDC-QMD-001-Material Control and Werehousing ProcedureSimbu ArasanNo ratings yet

- METHOD STATEMENT For Roll-Up Doors InstallationDocument16 pagesMETHOD STATEMENT For Roll-Up Doors Installationmoytabura96100% (2)

- Inspection Test Procedure TemplateDocument8 pagesInspection Test Procedure TemplateMahesh SuthaNo ratings yet

- SAIC-J-6401 - Rev 0Document4 pagesSAIC-J-6401 - Rev 0Adel KlkNo ratings yet

- Check List ElectricalDocument40 pagesCheck List Electricalabdul azizNo ratings yet

- Carbon Monoxide Co Gas Detectors GcoDocument7 pagesCarbon Monoxide Co Gas Detectors Gcoabdul azizNo ratings yet

- LANDYS-GYR Catalog Sheet T550 UH50 enDocument21 pagesLANDYS-GYR Catalog Sheet T550 UH50 enabdul azizNo ratings yet

- Oman Electric RulesDocument83 pagesOman Electric RulesAyoo PcpNo ratings yet

- Autocad ShortcutsDocument13 pagesAutocad ShortcutsKriscel CaraanNo ratings yet

- Substation 3Document1 pageSubstation 3abdul azizNo ratings yet

- Heat LoadDocument53 pagesHeat Loadabdul azizNo ratings yet

- R22 Wall Split Unit 1.5 TR Nominal Model MS GF 18 VC + MU GF 18 VCDocument2 pagesR22 Wall Split Unit 1.5 TR Nominal Model MS GF 18 VC + MU GF 18 VCabdul azizNo ratings yet

- Material Index - LGDocument37 pagesMaterial Index - LGabdul azizNo ratings yet

- CHW Method Statement of FlushingDocument5 pagesCHW Method Statement of FlushingNaiyer Karimi100% (1)

- Rotating Itp 1Document4 pagesRotating Itp 1abdul aziz100% (1)

- Heat Exchanger InspectionDocument43 pagesHeat Exchanger Inspectionabdul aziz100% (6)

- Candidate Nebosh PaperreportDocument14 pagesCandidate Nebosh Paperreportabdul azizNo ratings yet

- Heat Exchanger InspectionDocument43 pagesHeat Exchanger Inspectionabdul aziz100% (6)

- RT Procedure 200-004 Rev. 07Document33 pagesRT Procedure 200-004 Rev. 07abdul aziz67% (6)

- Compressor Train PDFDocument1 pageCompressor Train PDFabdul azizNo ratings yet

- Inspection & Test Plans 1 of 50Document49 pagesInspection & Test Plans 1 of 50abdul azizNo ratings yet

- Spectral Analysis of The ECG SignalDocument2 pagesSpectral Analysis of The ECG SignalCamilo BenitezNo ratings yet

- Otago:Polytechnic: National Diploma in Drinking Water AssessmentDocument33 pagesOtago:Polytechnic: National Diploma in Drinking Water AssessmentThomas CollinsNo ratings yet

- A Rope of Mass 0.65 KG Is Stretched Between Two Supports 30 M Apart. If The Tension in The Rope Is 120 N, How Long Will It Take A Pulse To Travel From One Support To The Other?Document6 pagesA Rope of Mass 0.65 KG Is Stretched Between Two Supports 30 M Apart. If The Tension in The Rope Is 120 N, How Long Will It Take A Pulse To Travel From One Support To The Other?peyying12No ratings yet

- BDOs SheetsDocument25 pagesBDOs Sheets3J Solutions BDNo ratings yet

- T REC K.Sup16 201905 I!!PDF E PDFDocument24 pagesT REC K.Sup16 201905 I!!PDF E PDFMark LionNo ratings yet

- Jeepney Demand and Supply in Baguio CityDocument19 pagesJeepney Demand and Supply in Baguio CityJanna CrowNo ratings yet

- Sectional Results: Sofistik 2020Document28 pagesSectional Results: Sofistik 2020ec05226No ratings yet

- Oracle E-Business Suite Release 11i Upgrade To R12.1Document60 pagesOracle E-Business Suite Release 11i Upgrade To R12.1Vladimir PacotaipeNo ratings yet

- PL-BRICK HP 2850 740 2X6: Product DatasheetDocument4 pagesPL-BRICK HP 2850 740 2X6: Product DatasheetAbhilash ThomasNo ratings yet

- 59-Form and Plot Frame Editor PDFDocument70 pages59-Form and Plot Frame Editor PDFAries TsaiNo ratings yet

- Desizing of CottonDocument16 pagesDesizing of CottonDeepali RastogiNo ratings yet

- Scallops Are Cut Outs in Weld Corners Which Are Used in Many Structures As in BridgesDocument3 pagesScallops Are Cut Outs in Weld Corners Which Are Used in Many Structures As in BridgesJanuel BorelaNo ratings yet

- Infiltration Ventilation LeakageDocument42 pagesInfiltration Ventilation LeakageBulut YildizNo ratings yet

- FST DFS Ge-EgdDocument5 pagesFST DFS Ge-EgdEric DunnNo ratings yet

- Ricoh 2090Document832 pagesRicoh 2090cosmin176100% (1)

- 1329804769qno 5,6,7Document94 pages1329804769qno 5,6,7Aman MishraNo ratings yet

- 70005144e 1314001 PDFDocument501 pages70005144e 1314001 PDFLuis FernandoNo ratings yet

- PalindromeDocument7 pagesPalindromeZy AdrianneNo ratings yet

- M-III (II ECE-B, 1st SEM)Document63 pagesM-III (II ECE-B, 1st SEM)venkatesh sripadNo ratings yet

- Bots and Automation Over Twitter During The U.S. Election: CompropDocument5 pagesBots and Automation Over Twitter During The U.S. Election: CompropRaninha MoraisNo ratings yet

- How To Sputter Thin Films of Metal Onto GlassDocument5 pagesHow To Sputter Thin Films of Metal Onto Glassfred_m_48601No ratings yet

- SHINI Hopper-Loader - SAL-400 SERIES MANUALDocument38 pagesSHINI Hopper-Loader - SAL-400 SERIES MANUALRick ChenNo ratings yet

- RTJ Dimension ASME B16.5/B16.47Document1 pageRTJ Dimension ASME B16.5/B16.47parayilomer0% (1)

- CP 05 - Determine The Young S Modulus of A MaterialDocument2 pagesCP 05 - Determine The Young S Modulus of A MaterialABBIE ROSENo ratings yet

- Online Quiz System DocumentationDocument92 pagesOnline Quiz System DocumentationSultan Aiman100% (1)

- XXXXXXX XXXXXXX: Pour Exemple: Pour Exemple: ArteorDocument5 pagesXXXXXXX XXXXXXX: Pour Exemple: Pour Exemple: ArteorGilbert MartinezNo ratings yet

- Maxxi Report FinalDocument7 pagesMaxxi Report FinalDepanshu Gola100% (1)

- Product Catalog: Ipe ProfilesDocument2 pagesProduct Catalog: Ipe ProfilesGokul royalveritasNo ratings yet

- Tractor 2017 Catalogue WebDocument36 pagesTractor 2017 Catalogue WebAnonymous 1XBCMXNo ratings yet

- Green Aviation SeminarDocument19 pagesGreen Aviation SeminarAromalSPillaiNo ratings yet