Professional Documents

Culture Documents

Ge Sitepro 20kva

Uploaded by

Nilson Eduardo TorresCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ge Sitepro 20kva

Uploaded by

Nilson Eduardo TorresCopyright:

Available Formats

Before starting a unit some basic rules should be respected, in order to avoid injury or damage.

After placing the UPS(s) at it's final destination and having it unpacked, remove the side- and protection panels.

With access to all parts, a thorough mechanical inspection should ensure the unit(s) has no damage or loose bolts,

screws, nuts or cables.

Remove transit brackets. Insure that the transit brackets and bolts on all transformers and inductors have been

removed. These brackets and bolts are bright yellow in color.

Connect then all Input / Output cables according the instructions in the operating manual.

Inspect fans, insure that the fans spin freely.

Check all fuses ohmically.

Use the commissioning report, to take note of checked items and measured values during commissioning.Note: If any problems

with this installation are found that pose a threat to persons or equipment, do not proceed until the problem has been

corrected.

Make sure all breakers are open (Q1, Q2, Q3a, Q4) then connect Mains voltage to the UPS (both if separate for

Rectifier andBypass).

Power supply starts a the display shows a selftest, at the end of which should result "Self test ok".

Verify in Parameters for correct Date and Time.

Verify in the Service Alarms for the presence of the code 9D04, which indicates the correct function of important parts

of the control board IM 0007. In case you find codes 9D00, 9D01, 0D02, 9D03 instead, a malfunction on the control

board is present. Change the control board !!

Warning: Main Input Feed CB is closed and thus supplying LETHAL voltages to the system. Caution: It is recommanded

that the load supplied by the UPS remains OFF until commissioning has been completed.

Verify for correct phase rotation on power interface IM 8820 or IM 0035.

Measure and record all Power supply voltages on Power supply board IM 8845 or IM 0076.

Verify correct Power wiring. In a parallel system the outputs of all units must be connected. (Customers load not yet

connected)

Close Q2 on 1st Unit.

Measure on 1st Unit with Voltmeter Phase L1 Mains - Phase L1 Load connection, followed by the phases L2 and L3.

Measure then the same on all other units in case of a parallel system. Should you measure voltage you may have a

miss wired output.

Open Q2.

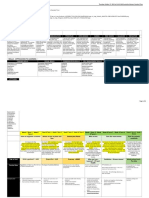

Commisioning report

Subject

Description

Passed

Yes

No

General

Control on positioning the UPS

General conditions: battery and UPS installation area

Visual inspection, check of any transportation damage

Check room ventilation for UPS cooling

Accessibility of UPS sides and/or rear for preventive maintenance

Control delivery completeness. Check Options (LINC, SNMP, Battery Fuse, Filter)

Remove transport protections and fixations

Mechanical inspection of screws and power connections; tighten where needed

Fans Control (running free)

Check internal connections

Verify plugs and flat-cable connections of the different PCB's

Installation

Control before powering the UPS

Check installation: sizing of cables and rating of fuses for Utility and Battery

Check all the external cable connections (utility, battery, load)

Check and tight external connections

Check links for Bypass and Rectifier Utility according to installation

Isolation measurement (with Installer) upon Customer request

Ohmic check of the installation

Control of the batteries positioning and battery connector

Check Battery voltage (value, polarity)

Powering Load from Maintenance Bypass

Check output distribution connections and eventual external manual bypass

Connect external maintenance bypass or UPS Q2 to supply load

Battery

Control of External Battery bank

Check/screw battery connections

Check and eventually provide proper earthing of battery enclosure

Check correct polarity of the blocks

Check voltage and polarity on positive and negative pole of battery bank

Check symmetry of battery voltages to Earth

Subject

System

Description

Controls "on power" of UPS module

All manual switch open (Q1, Q2, Q4, Q3)

Check Input mains voltage Rectifier and By-Pass (Voltage, phase rotation)

Connect Utility and check the functionality of Power Supply board

Check RS232 communication interface running Service Application

Check and eventually adjust Battery parameters (Type, N of cells, Autonomy)

Low Voltage Start-up procedure

Perform test procedure and check correct rectifier and inverter functionality

Set correct values on modified parameters

Rectifier Section

Control rectifier soft-start

Check UDC voltage (value, polarity)

Check K3/Battery fuses closure command/indication

Connect Batteries (close fuses)

Passed

Yes

No

Connect and check battery temperature sensor

Inverter Section

Control Inverter soft-start

Check Inverter output voltage (value, phase-rotation, waveform)

Check CP current values

Bypass (SSM) Section

By-Pass static switch activation

Check output voltage (phase rotation)

Control fans (outflow)

Control synchronization between by-pass and inverter

Load transfer

Check bypass voltage readings on UPS display (eventually correct)

Check inverter voltage adaptation and load transfer procedure

Subject

Tuning

Description

Passed

Yes

No

Control and activation of special functions according to Customer requests

Information / activation of automatic battery test

Information / Parameter adjustment for General alarm (delay, etc)

Information / control signals on dry contacts

Information / check / connect LINC-Box / SNMP box/card

Delete alarm memory

Electric

UPS on LOAD

Supply load by UPS Q2

Control Load Current on output distribution (value and waveform)

Switch the load on UPS bypass (SSM)

Control (eventually correct) measurement values on display

Switch the load on inverter

Perform a Manual Battery Test

Check system operation during mains breakdown

Delivery

Delivery to customer

Instruction of the customer (Operation, service-check, alarms)

Delivery of the entire system with option (LINC and SNMP option, ...)

Fill-outs and signing of Acceptance protocol

Low voltage startup

In many occasions it might be useful to test the function of Rectifier and

Inverter with a voltage low enough to avoid damage in case of malfunction, in

particular to the power modules, before running the UPS in nominal voltage.

Find below a description for how to proceed.Important: At the end of Low

voltage startup the UPS must be shutdown completely, including power supply,

to reset some Parameters to their original value.

Open Q1 and Q4, disconnect Battery

Connect Mains (Utility power) to the UPS.

Enter third level Parameters, (see Password) and change the values of the

following 2 Parameters:

- Parameter 217: 21000 (17300 in case of 12 - pulse Rectifier !!!)

(Reduces the Rectifier output voltage)

- Parameter 112: 00050 (Limits the Inverter voltage to 50 Volts)

Connect a Voltmeter to the DC - Link (UDC) and an Oscilloscope to the Inverter

ouput.

Close Q4 to start the Rectifier. The DC Voltage should now gradually increase.

See table below.

Press now the key Inverter ON. As the Inverter starts, the DC Voltage decreases

while the AC Voltage of the Inverter should be a clean sinewave.

If everything looks ok, proceed and increase gradually the DC Voltage by

reducing the value in Parameter 217, until you reach again the previously

installed default value (4000). See in the table below the resulting voltages

(approximate !!!).

Att. Switch Inverter and Rectifier OFF (open Q4) before changing Parameter

217.

An example of the approximately resulting voltages is shown in the table below.

Should at any time of the procedure result a deformation of the Inverter output

sinewave, do not continue, but check first for correct drive pulses of Rectifier

and Inverter. If necessary change the Main control board IM 0007 / 0057 or one

of the driver boards.

Set Parameter 112 for nominal Inverter output voltage. (230V).Important: At

the end of the procedure you must either shut down the UPS completely,

including power supply, or make a reset with PB2 on the main control board IM

0007, always with DC - Capacitors discharged !!!!!!

With 6 - Puls Rectifier and 50Hz !!!

Parameter 217

6 - Puls

UDC with Inverter OFF

UDC with

Inverter ON

U Inverter

21000

Att.: 17000 for 60Hz

80

11

13

20500

120

37

34

20000

150

74

18000

290

230

50

(regulated)

16000

375 (K3 closed)

350

50

15000

408

14000

436

423

50

13000

436

U - floating

50

04000 (Default)

436

U - floating

50

50

The values shown in this table are indicational, in particular the values in

Parameter 217 should be choosen on dependence of an actual existing

problem !!!

Once the Rectifier is running at floating voltage, stop the Inverter and change

Parameter 112 for the Inverter output voltage, back to it's nominal value.

You might also like

- Refer DX 300 X-Ray Control With Anode Breaking CCT - SL No Si-0236-3345A & AboveDocument4 pagesRefer DX 300 X-Ray Control With Anode Breaking CCT - SL No Si-0236-3345A & AboveKarthick BalakrishnanNo ratings yet

- X-Ray Flat Panel Detectors Careview 750Cw/ Careview 750C Operation ManualDocument58 pagesX-Ray Flat Panel Detectors Careview 750Cw/ Careview 750C Operation ManualEric Valery TAHOUE NOUMSINo ratings yet

- 555 Timer Waveform Generator Circuit GuideDocument40 pages555 Timer Waveform Generator Circuit GuidesaravananNo ratings yet

- Iom Lp33 40k 120k SeriesDocument94 pagesIom Lp33 40k 120k SeriesMike MendozaNo ratings yet

- Troubleshooting PDFDocument8 pagesTroubleshooting PDFAswanth tkNo ratings yet

- Aplio MXDocument259 pagesAplio MXudara badusenaNo ratings yet

- No. 2Y314-009E: Toshiba Corporation 2002 All Rights ReservedDocument30 pagesNo. 2Y314-009E: Toshiba Corporation 2002 All Rights ReservedRashid Kh100% (3)

- PLX112 Mobile C-arm Service GuideDocument7 pagesPLX112 Mobile C-arm Service GuideEvaruz SangNo ratings yet

- Specification TECHNIX Mobile C Arm TCA 6S With RTP 500Document2 pagesSpecification TECHNIX Mobile C Arm TCA 6S With RTP 500Ahmed AhmedNo ratings yet

- Brivo XR 115 - DataSheetDocument8 pagesBrivo XR 115 - DataSheetCarlos R. Sanchez100% (1)

- OmnixDocument1 pageOmnixKania LouisNo ratings yet

- Service Engineer training for DEXXUM T bone densitometry deviceDocument36 pagesService Engineer training for DEXXUM T bone densitometry deviceEdinson Salguero67% (3)

- Tank Side Monitor NRF590 PDFDocument96 pagesTank Side Monitor NRF590 PDFTani BakuNo ratings yet

- Sedecal Standard X-RayDocument2 pagesSedecal Standard X-RayFlmedservicesNo ratings yet

- 100ma MobileDocument3 pages100ma MobileYASHPREET SINGHNo ratings yet

- Operating Instructions for DGC-11 Digital Genset ControllerDocument15 pagesOperating Instructions for DGC-11 Digital Genset Controllergigo_dreamNo ratings yet

- DCARE Series Dental Autoclave: Operation ManualDocument14 pagesDCARE Series Dental Autoclave: Operation ManualPolyclinique MahdiaNo ratings yet

- CMP200DR Service - 2016.02.16Document301 pagesCMP200DR Service - 2016.02.16Jayson LopezNo ratings yet

- Calibration Manual DIG SeriesDocument83 pagesCalibration Manual DIG SeriesGerardo S. Millena100% (1)

- CS-2/CS-2000 Production Manual: Regius ConsoleDocument32 pagesCS-2/CS-2000 Production Manual: Regius ConsoleJanet WaldeNo ratings yet

- ProteusXRaSM21 PDFDocument562 pagesProteusXRaSM21 PDFРухулла АгакеримовNo ratings yet

- Pc-1000 Panoramic X-Ray Service ManualDocument4 pagesPc-1000 Panoramic X-Ray Service ManualJosé Luís Cheo Barrios CristóbalNo ratings yet

- Best-In-Class Compact Multi-Purpose UltrasoundDocument8 pagesBest-In-Class Compact Multi-Purpose UltrasoundAhmed FawzyNo ratings yet

- Skan Mobile XRAYDocument2 pagesSkan Mobile XRAYJC ZorrovskiNo ratings yet

- Mark 7 Arterion Injection System Training MaterialDocument22 pagesMark 7 Arterion Injection System Training MaterialSyamsul PutraNo ratings yet

- System WiringDocument65 pagesSystem WiringEduardo Saul MendozaNo ratings yet

- Allengers 325 RF - Installation and Service Manual PDF Relay Series and Parallel CircuitsDocument1 pageAllengers 325 RF - Installation and Service Manual PDF Relay Series and Parallel CircuitsAung Kyaw LinnNo ratings yet

- General TroubleshootingDocument37 pagesGeneral TroubleshootingDante NuevoNo ratings yet

- 295 PDFDocument132 pages295 PDFAlbion PllanaNo ratings yet

- Reliable C-arm with Configurations and MemoriesDocument1 pageReliable C-arm with Configurations and Memoriesahmed_galal_waly1056No ratings yet

- Digital Panoramic X-Ray SystemDocument32 pagesDigital Panoramic X-Ray SystemNeamtu2No ratings yet

- Operating Instructions CS 3000 - Pausch LLCDocument33 pagesOperating Instructions CS 3000 - Pausch LLCEdgar DauzonNo ratings yet

- 03 - Alinhamentodxap2001Document10 pages03 - Alinhamentodxap2001Omar Stalin Lucio RonNo ratings yet

- Parker-Hannifin Spindleblok Troubleshooting GuideDocument1 pageParker-Hannifin Spindleblok Troubleshooting GuideAndreyNo ratings yet

- Aquilion3264 Spellman2 MergedDocument79 pagesAquilion3264 Spellman2 MergedPabloNo ratings yet

- 1.1. OSTEOPro DEXA User's Manual - V3.0 - 20120202Document94 pages1.1. OSTEOPro DEXA User's Manual - V3.0 - 20120202Sergio Alejandro Castro100% (1)

- Insulating The High Voltage ConnectionsDocument6 pagesInsulating The High Voltage ConnectionsKo Phyo Wai100% (1)

- Spare Part List: 7600 SystemsDocument41 pagesSpare Part List: 7600 SystemsmrscribdNo ratings yet

- EDS1000 Manual Podesenje PDFDocument199 pagesEDS1000 Manual Podesenje PDFKmnzmnNo ratings yet

- PLX5100Installation Manual KDocument8 pagesPLX5100Installation Manual KAla'a Ismail100% (1)

- Cmp200dr ServiceDocument295 pagesCmp200dr Serviceeduardo100% (1)

- XC-131 Instruction Manual Covers Precision Instrument StartupDocument186 pagesXC-131 Instruction Manual Covers Precision Instrument StartupLuis Albarracin100% (1)

- Service Manual Td850 (Te698883-10 - E-Sm40)Document72 pagesService Manual Td850 (Te698883-10 - E-Sm40)Bio-Scientific GroupNo ratings yet

- Xd3-3.5/100 And Xd3A-3.5/100: 杭州亿龙电子有限公司 Hangzhou Yilong Electronic Co., LtdDocument3 pagesXd3-3.5/100 And Xd3A-3.5/100: 杭州亿龙电子有限公司 Hangzhou Yilong Electronic Co., LtdEng-Mohamed SaadaNo ratings yet

- Multimobil 25Document12 pagesMultimobil 25dody100% (1)

- Kodak 101-102 SDocument20 pagesKodak 101-102 Sspaske_No ratings yet

- M516-E011l Wha-200 Pleno Om PDFDocument218 pagesM516-E011l Wha-200 Pleno Om PDFbozza85No ratings yet

- Multimobil 2.5: Your Local PartnersDocument4 pagesMultimobil 2.5: Your Local Partnersاحمد زغارى100% (1)

- Siemens Imaging Parts - January 2013 PDFDocument10 pagesSiemens Imaging Parts - January 2013 PDFfelipe pinedoNo ratings yet

- Main Controller Tech Manual 04Document28 pagesMain Controller Tech Manual 04Khalil Issaad100% (3)

- Kxo 80 XM RepairDocument21 pagesKxo 80 XM RepairAdeel AbbasNo ratings yet

- Service Manual: X-Ray Beam Limiting Device UgDocument30 pagesService Manual: X-Ray Beam Limiting Device UgmikeNo ratings yet

- Allengers FP4336RW FPD Callibration ProcedureDocument16 pagesAllengers FP4336RW FPD Callibration ProcedureMohammed NahelNo ratings yet

- Sun BladeDocument578 pagesSun BladeEduardo Saul MendozaNo ratings yet

- 90312400b Cpi Digital OptionDocument7 pages90312400b Cpi Digital OptionSwami MeeraNo ratings yet

- 12-GOLDBERG Series Steam Sterilizer - Operation and Installation ManualDocument57 pages12-GOLDBERG Series Steam Sterilizer - Operation and Installation ManualYounes ODM100% (1)

- Juno I General Preset 11-15Document21 pagesJuno I General Preset 11-15lorisaszigiNo ratings yet

- CVT9K-120-208-R Power System Quick Installation and Operation InstructionsDocument13 pagesCVT9K-120-208-R Power System Quick Installation and Operation InstructionsLacides PadillaNo ratings yet

- Babelan - UPS Training - 29Document29 pagesBabelan - UPS Training - 29dimasrimantiktoNo ratings yet

- Testing and Commissioning of UPS System Method StatementDocument3 pagesTesting and Commissioning of UPS System Method StatementHumaid Shaikh100% (1)

- Access IP Information of Logix Ethernet Modules With MSG InstructionDocument4 pagesAccess IP Information of Logix Ethernet Modules With MSG InstructionNilson Eduardo TorresNo ratings yet

- Cip StatusDocument4 pagesCip StatusNilson Eduardo TorresNo ratings yet

- Baker Hughes HPump Operation and Maintenance Manual PDFDocument144 pagesBaker Hughes HPump Operation and Maintenance Manual PDFluis_seczonNo ratings yet

- Isa 84.00.03 PDFDocument222 pagesIsa 84.00.03 PDFNilson Eduardo TorresNo ratings yet

- Oimlr117 2 2CDDocument181 pagesOimlr117 2 2CDNilson Eduardo TorresNo ratings yet

- VNC 7775 BestPractice BP Variable Speed Pump Systems-SCP DIGIDocument12 pagesVNC 7775 BestPractice BP Variable Speed Pump Systems-SCP DIGINilson Eduardo TorresNo ratings yet

- AddendumDocument6 pagesAddendumyogitatanavadeNo ratings yet

- 1000w Inverter PURE SINE WAVE Schematic DiagramDocument84 pages1000w Inverter PURE SINE WAVE Schematic DiagramPERWANA100% (3)

- OIML R117 1 E07Document127 pagesOIML R117 1 E07Nilson Eduardo TorresNo ratings yet

- 842e In001 - en PDocument4 pages842e In001 - en PNilson Eduardo TorresNo ratings yet

- Chemical Process Control A First Course With Matlab - P.C. Chau PDFDocument255 pagesChemical Process Control A First Course With Matlab - P.C. Chau PDFAli NassarNo ratings yet

- InTech-Robust Model Predictive Control DesignDocument24 pagesInTech-Robust Model Predictive Control DesignNilson Eduardo TorresNo ratings yet

- Maciejowski - Predictive Control With ConstraintsDocument346 pagesMaciejowski - Predictive Control With ConstraintsRafael Gonçalves de Lima100% (2)

- Indicator Valve Maintenance GuideDocument15 pagesIndicator Valve Maintenance GuideJonoAlexisDang-awanQuiban100% (1)

- Convert Tank to Wash Service Hazards ReviewDocument74 pagesConvert Tank to Wash Service Hazards ReviewMatthew Adeyinka0% (1)

- 01 Introduction To Programming ConceptsDocument34 pages01 Introduction To Programming ConceptsPoolparty LuluNo ratings yet

- Detailed Statement: Transactions List - Squaircle Energy and Constructions Private Limited (Inr) - 677605600669Document3 pagesDetailed Statement: Transactions List - Squaircle Energy and Constructions Private Limited (Inr) - 677605600669ankit008dixitNo ratings yet

- THE PASSION AND GLOBAL APPROACH DRIVING HONDA MOTORCYCLES TO SUCCESSDocument11 pagesTHE PASSION AND GLOBAL APPROACH DRIVING HONDA MOTORCYCLES TO SUCCESSjatinag990No ratings yet

- LRP I Approved ProjectsDocument1 pageLRP I Approved ProjectsTheReviewNo ratings yet

- Food Safety ChecklistDocument5 pagesFood Safety ChecklistDenver Palingit Rimas100% (3)

- Stresses, Loads, and Factors of Safety in Structural ElementsDocument6 pagesStresses, Loads, and Factors of Safety in Structural ElementsMark Louies Mago VillarosaNo ratings yet

- ZQYM Diesel Cummins Series Injector 2023.07Document13 pagesZQYM Diesel Cummins Series Injector 2023.07harbh9355No ratings yet

- Enprep - 110 EC Steel Cu BrassDocument3 pagesEnprep - 110 EC Steel Cu BrassLựuLiềuLìNo ratings yet

- Download Descargar libro de geometria analitica de ricardo figueroa bookDocument3 pagesDownload Descargar libro de geometria analitica de ricardo figueroa bookJuniorNo ratings yet

- Chap4 Student VersionDocument39 pagesChap4 Student VersionAzrif MoskamNo ratings yet

- 199408Document93 pages199408denis alvarezNo ratings yet

- Mikom Remote Unit Software ManualDocument35 pagesMikom Remote Unit Software ManualealforaNo ratings yet

- Icest 2013 02 PDFDocument424 pagesIcest 2013 02 PDFphanduy1310No ratings yet

- Flow Chart Fixed Column BasesDocument4 pagesFlow Chart Fixed Column BasesstycnikNo ratings yet

- What Is A Project in Project ManagementDocument3 pagesWhat Is A Project in Project ManagementSamuel AntobamNo ratings yet

- Tensile TestDocument15 pagesTensile Testdwimukh360No ratings yet

- Wet Scrapper Equipment SpecificationDocument1 pageWet Scrapper Equipment Specificationprashant mishraNo ratings yet

- OSN 6800 Electronic DocumentDocument159 pagesOSN 6800 Electronic DocumentRashid Mahmood SajidNo ratings yet

- AC - ADENIYI MARUF OPEYEMI - FEBRUARY, 2023 - 2148745001 - FullStmtDocument6 pagesAC - ADENIYI MARUF OPEYEMI - FEBRUARY, 2023 - 2148745001 - FullStmtmophadmophadNo ratings yet

- DTMF Proximity DetectorDocument1 pageDTMF Proximity DetectorAlagappan ArunachalamNo ratings yet

- Bs1030 BrochureDocument2 pagesBs1030 BrochuremgvuleNo ratings yet

- 2018 PAPER 1 Communication Studies PDFDocument14 pages2018 PAPER 1 Communication Studies PDFKimNo ratings yet

- Cable Diagram: Technical Data SheetDocument1 pageCable Diagram: Technical Data SheetCharlie MendozaNo ratings yet

- KTS Quotation Meidan Building Plumbing Works PDFDocument1 pageKTS Quotation Meidan Building Plumbing Works PDFShakeel Ahmad100% (1)

- Environmental Management Plan - MatrixDocument6 pagesEnvironmental Management Plan - Matrixplokhande47100% (1)

- 16BBG - Sec17 - NPR NPRHD NQR NRR Diesel Cab Chassis Electrical Revision 3 100115 FinalDocument34 pages16BBG - Sec17 - NPR NPRHD NQR NRR Diesel Cab Chassis Electrical Revision 3 100115 FinalJou Power50% (2)

- 2019 Planning OverviewDocument7 pages2019 Planning Overviewapi-323922022No ratings yet

- Plan for Inspection and Testing of LV Power CablesDocument1 pagePlan for Inspection and Testing of LV Power CablesRami KsidaNo ratings yet