Professional Documents

Culture Documents

PS 10.02 General Requirement For Pipe Tube Plate Shapes Structural Steel

Uploaded by

Sreenubabu KandruOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PS 10.02 General Requirement For Pipe Tube Plate Shapes Structural Steel

Uploaded by

Sreenubabu KandruCopyright:

Available Formats

QUALITY ASSURANCE SPECIFICATIONS MANUAL

Category:

QAS:

Rev.:

Date:

Title:

10 - Material and Services Control

PS-10.02

9

2/11/03

GENERAL REQUIREMENTS FOR PIPE, TUBING, PLATE, SHAPES AND STRUCTURAL

STEEL

Approved:

DATE: 06/23/03

1.0 Purpose

The purpose of this specification is to establish general quality assurance

requirements for ordering pipe, pipe nipples, instrumentation tubing,

pressure vessel plate, stainless steel plate and shapes and structural

steel.

2.0 Scope

This specification shall apply to non-fabricated pipe, pipe nipples,

instrumentation tubing, pressure vessel plate, stainless steel plate and

shapes or structural steel ordered for ASME and AWS Code work.

3.0 Definitions

3.1 ASTM - American Society for Testing & Material

3.2 ASME - American Society for Mechanical Engineers

3.3 ANSI - American National Standards Institute

3.4 AWS -

American Welding Society

3.5 ISO system

International Standards Organization - A registered quality

4.0 References

4.1 ASTM/ASME Material Specifications

4.2 ASME Boiler & Pressure Vessel Code Section I, II, & IX

4.3 ASME B1.20.1

5.0 Responsibility

5.1 The vendor shall be responsible for fulfilling the requirements as

set forth in this specification.

5.2 The requisition shall be responsible for completing all essential

ordering information in Section 6.0.

QAS No.: PS-10.02

Dated 02/11/03

Page 2 of 2

5.3 Materials for ASME Sections I or VIII and Boiler External Piping

applications shall be specified as ASME (SA or SB) grade.

6.0 Instructions

6.1 The attachment listed in Section 7.0 shall be included with the

procurement documents (specification, purchase order, requisition, or

bill of material), and shall be considered as part of that document.

6.2 Purchase order for pipe, tubing, plate, shapes and structural steel

(including boiler membrane material)

6.2.1

Description of the product

6.2.2

ASTM/ASME material specification number and grade

6.2.3

Size

6.2.4

Schedule number or minimum wall thickness

6.2.5

Quantity

6.2.6

Certified material test report, if required

6.2.7

Supplementary requirements, if any (such as: ultrasonic

examination of plate in accordance with specification no.

A435/A435M)

7.0 Attachments

7.1 General Requirements for Pipe, Tubing, Plate, Shapes & Structural

Steel

Category: 10 -

Material and Services Control

Attachment No.: 7.1

QAS No.: PS-10.02

Dated 02/11/03

Page 1 of 5

GENERAL REQUIREMENTS FOR PIPE, TUBING, PLATE, SHAPES AND STRUCTURAL STEEL

1.0 All pipe, instrumentation tubing, plate, shapes or structural steel,

(including boiler membrane material) shall comply with the requirements of

the specified ASTM/ASME Standard.

2.0 Substitute material is prohibited.

2.1 Materials purchased under this specification must be manufactured in

the United States or Canada. However, non-domestic material will be

acceptable if the material is from a registered quality system in

accordance with ISO 9001 or ISO 9002.

2.2 If non-domestic material, the manufacturer/supplier must supply a

certificate or registration of ISO 9001 or ISO 9002 and material test

report in English units only. In the event that a material test report

is in metric units, conversion must be made into English and both

documents submitted with delivery of material, from the non-domestic

material manufacture or the material supplier.

3.0 Pipe shall comply with the following.

3.1 Pipe shall be seamless unless otherwise specified.

3.2 ASTM/ASME A530/A530M "General Requirements for Specialized Carbon and

Alloy Steel Pipe" shall be followed.

3.3 Material identification markings shall be stenciled on the pipe once

every 3 to 4 feet.

3.3.1 Markings shall include the following as a minimum:

a.

b.

c.

d.

e.

Specification No. and Grade

Pipe Size and Schedule

Heat Number

P.O. Number

Six digit material number (when provided on the P.O.)

3.4 Each pipe is required to be marked with size (O.D.; schedule)

or length. However tagging of pipe size 1/8 thru 3/8 is acceptable.

3.5 Material Test Reports are required for all seamless pipe, however for

continues welded pipe, Certificate of Compliance is acceptable.

3.6 All ferrous piping shall be supplied with a protective external coating

applied to prevent corrosion. Oil dipped pipe will not be accepted.

Attachment No.: 7.1

QAS No.: PS-10.02

Dated 02/11/03

Page 2 of 5

3.7 All pipe shall be internally clean and free of dirt, rust, oil or other

foreign matter.

4.0 Pipe nipples shall comply with the following:

4.1 Pipe nipples shall be seamless, threaded and extra strong (SCH80)

minimum

4.2 ASTM/ASME A530/A530M "General Requirements for Specialized Carbon and

Alloy Steel Pipe" shall be followed.

4.3 Threads shall be in accordance with ASME B1.20.1

4.4 Traceable material identification markings shall be stenciled or tagged

on the pipe nipple.

4.4.1 Markings shall include the following as a minimum:

a.

b.

c.

d.

e.

Specification No. and Grade

Pipe Size and Schedule

Heat Number

P.O. Number (on box only)

Six digit material no. (when provided on the P.O., on box only)

4.4.2 Each pipe nipple is required to be marked regardless of size

(O.D.; schedule). Stenciling of the pipe nipple is preferred.

However, if this is not possible due to physical size or

threading, boxing or individual tagging will be acceptable. Each

box or tag must be marked as in 4.4.1 above.

4.5 Material test reports are NOT required for pipe nipples as long as

Supplier can provide traceability.

5.0 Instrumentation tubing shall comply with the following:

5.1 Tubing shall ASTM A213/A213M Grade TP 316.

5.2 Fully annealed high quality tubing with Rockwell hardness HRB 90 or

less.

5.3 Tubing shall be seamless unless otherwise specified.

5.4 A 100% ultrasonic or eddy current test or Owner approved equivalent is

required for all tubing.

5.5 ASTM A450/A450M General Requirements for Carbon, Ferritic Alloy, and

Austenitic Alloy Steel Tubes for ASTM A213/A213M Gr. TP316

instrumentation tubing shall be followed.

5.6 Material identification markings shall be stenciled on the tubing once

every 3 to 4 feet with ASTM/ASME Spec. No., Grade, Tube OD, Minimum wall

and Heat Number.

Attachment No.: 7.1

QAS No.: PS-10.02

Dated 02/11/03

Page 3 of 5

5.7 Certified Material Test Reports are required.

5.8 All instrumentation tubing shall be internally clean and free of dirt,

rust, oil or other foreign matter.

6.0 Pressure Vessel plate shall comply with the following.

6.1 100% ultrasonic examination shall be conducted on all plate over 1" in

thickness.

6.2 ASTM/ASME A20/A20M "General Requirements for Steel Plates for Pressure

Vessels" shall be followed.

6.3 Identification of plate.

6.3.1 Manufacture, the heat number, plate identifier, and slab number,

and specification number, grade, class and type, when indicated in the

material specification shall be legibly die stamped in two

places on each plate.

6.3.2 For plates under 1/4 in thickness, the marking specified in

paragraph 6.3.1 shall be legibly stenciled instead of stamped.

6.3.3 Marking of Purchase Order Number

6.4 Certified Material Test Reports are required for all pressure vessel

plate.

7.0 Structural steel (including Boiler membrane material) shall comply with the

following:

7.1 ASTM/ASME A6 "General Requirements for Rolled Steel Plates, Shapes,

Sheet Piling, and Bars for Structural Use" shall be followed.

7.1.1 Purchasing must include all ordering information called out in

Section 4.1 (4.1.1 through 4.1.7) of ASTM A6/A6M.

7.1.2 Identification of Material shall conform to Section 5 of

ASTM/ASME A6.

Attachment No.: 7.1

QAS No.: PS-10.02

Dated 02/11/03

Page 4 of 5

7.1.2.1 Plates - Each plate shall be steel die stamped, marked or

stenciled in one place with heat number, manufacturer's

name, brand or trademark, size and thickness (per ASTM/ASME

A6/A6M).

7.1.2.2 Shapes shall be marked with the heat number, size of

section, length and mill identification marks on each

piece. Small shapes with the greatest cross-sectional

dimension not greater than 6" may be bundled for shipment

with each lift marked or tagged showing previously listed

identification (per ASTM/ASME A6/A6M).

7.1.2.3 Bars in secured lifts shall be identified with a tag

showing purchase order number, grade or specification,

size, length, weight of lift and heat number (per ASTM/ASME

A6/A6M).

7.1.2.4 All structural grades shall be color coded per section 5

with colors corresponding to those specified under

paragraph 5.6 of ASTM/ASME A6/A6M..

7.2 Identification of all plate shall be by stenciling.

7.3 ASTM A700 "Packaging, Marking, and Loading Methods for Steel Products

for Domestic Shipping" shall be followed.

7.3.1 Material, bundle or lift identification per paragraph 3.6. Tags

must be able to withstand shipping and exposure to the elements;

paper tags especially must be the quality to resist exposure to

rain, snow, sleet and wind.

7.4 Material Test Reports are required for all structural steel except that

a certificate of compliance will be accepted for ASTM A36 steel.

8.0 Stainless steel plate shall comply with the following:

8.1 ASTM/ASME A480/A480M "General Requirements for Flat-Rolled Stainless and

Heat-Resisting Steel Plate, Sheet, and Strip" shall be followed.

8.1.1 Purchasing must include all ordering information called out in

Section 4 (4.1.1 thru 4.11) of ASTM/ASME A480/A480M.

8.1.2 Identification of material shall conform to Section 25 of

ASTM/ASME A480/A480M.

8.1.2.1 Each Plate shall be steel die stamped, marked or stenciled

in one place with heat number, material specification and

grade, manufacturers name, brand or trademark, size and

thickness.

Attachment No.: 7.1

QAS No.: PS-10.02

Dated 02/11/03

Page 5 of 5

8.2 ASTM A700 "Packaging, Marking and Loading methods for Steel Products

for Domestic Shipping" shall be followed.

8.3 Material test reports are required for all stainless steel plate.

9.0 Stainless steel bars and shapes shall comply with the following:

9.1 ASTM/ASME A484/A484M "General Requirements for Stainless and Heat

Resisting Wrought Steel Products"

9.1.1 Purchasing must include all ordering information called out in the

appropriate ASME/ASTM specification.

9.1.2 Identification of material shall conform to Section 4 of ASTM/ASME

A484/A484M.

9.1.2.1 Bars and shapes shall be marked (stenciled) or tagged with

the name or brand of manufacturer, material specification

number, grade or type, heat number and size, length, and

weight (where applicable).

9.2 ASTM A700 "Packing, Marking and Loading Methods for Steel Products for

Domestic Shipping" shall be followed.

9.2.1 Material, bundle or lift identification per Paragraph 3.0 tags

must be able to withstand shipping and exposure to the elements.

9.3 Material test reports are required for all stainless bars and shapes.

NOTE: This specification does not cover general machining stock (i.e.

bars, sounds), steel sheet, steel flats and shafting materials.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Complete Spoken EnglishDocument543 pagesComplete Spoken Englishjastisrinivasulu86% (64)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Pressure Reducing ValveDocument28 pagesPressure Reducing ValveSreenubabu Kandru50% (2)

- Telugu Books SiteDocument19 pagesTelugu Books SiteSreenubabu Kandru67% (3)

- Worksheets Electropneumatics Basic LevelDocument128 pagesWorksheets Electropneumatics Basic LevelNur SyimahNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Complete Spoken English - 011 - 24212027 Complete Spoken English - 301Document90 pagesComplete Spoken English - 011 - 24212027 Complete Spoken English - 301Sreenubabu Kandru100% (2)

- Drawing Submittal FormDocument3,989 pagesDrawing Submittal FormAhamed MinverNo ratings yet

- 4 KL Reactor Data SheetDocument4 pages4 KL Reactor Data Sheetpankil patelNo ratings yet

- 4B3.9G2 So10737Document72 pages4B3.9G2 So10737Alexis SanchezNo ratings yet

- Is 2403 1991Document20 pagesIs 2403 1991Naresh JangraNo ratings yet

- Slewing Bearing Catalogue - 06115 2 en TCM 12-182061Document120 pagesSlewing Bearing Catalogue - 06115 2 en TCM 12-182061Alvaro100% (1)

- AS+1349-1986-Bourdon Tube and Pressure GaugeDocument27 pagesAS+1349-1986-Bourdon Tube and Pressure GaugeDenzil D'SouzaNo ratings yet

- Pipes. Wall Thickness Calculation According ASME B31.3Document125 pagesPipes. Wall Thickness Calculation According ASME B31.3musaveerNo ratings yet

- 140-710 BIMG 11 - 2012 - TCM - 12-114679Document146 pages140-710 BIMG 11 - 2012 - TCM - 12-114679Milos BubanjaNo ratings yet

- Pressure VesselDocument31 pagesPressure VesselCkaal74No ratings yet

- English Grammar TensesDocument38 pagesEnglish Grammar Tensesapi-283719185No ratings yet

- Instrument Testing Procedure SummaryDocument13 pagesInstrument Testing Procedure SummaryDaengkulle Firmansyah PuteraNo ratings yet

- Coiled Tubing EquipmentDocument33 pagesCoiled Tubing EquipmentHua Tien DungNo ratings yet

- Is 3224 2002Document47 pagesIs 3224 2002suresh kumar100% (1)

- Is 3224 2002Document47 pagesIs 3224 2002suresh kumar100% (1)

- PVC-Injectors 0.5 - 4.0 KG/H: Installation and Operating InstructionsDocument16 pagesPVC-Injectors 0.5 - 4.0 KG/H: Installation and Operating InstructionsSreenubabu KandruNo ratings yet

- Chlorine .Kit.b.2009Document24 pagesChlorine .Kit.b.2009Sreenubabu KandruNo ratings yet

- Drives & DrivesDocument66 pagesDrives & DrivesSreenubabu KandruNo ratings yet

- HDPE Chemical Resistance ChartDocument3 pagesHDPE Chemical Resistance ChartSarvesh Parmanand SeebundhunNo ratings yet

- Grundfosliterature 1665254Document36 pagesGrundfosliterature 1665254nawajhaNo ratings yet

- Is 4894 1987Document18 pagesIs 4894 1987sajay2010No ratings yet

- Chlorine Evaporator PDFDocument34 pagesChlorine Evaporator PDFSreenubabu Kandru100% (1)

- Product Specification Sheet BELZONA 5811Document3 pagesProduct Specification Sheet BELZONA 5811Sreenubabu KandruNo ratings yet

- Protective Coating For Surfaces Operating Under ImmersionDocument2 pagesProtective Coating For Surfaces Operating Under ImmersionSreenubabu KandruNo ratings yet

- Rolling Bearings - 17000 EN - TCM - 12-121486Document1,152 pagesRolling Bearings - 17000 EN - TCM - 12-121486Abhinav SaiNo ratings yet

- Belzona 5811: Instructions For UseDocument2 pagesBelzona 5811: Instructions For UseSreenubabu KandruNo ratings yet

- Eenadu PrathibaDocument16 pagesEenadu PrathibaNarsimMudirajNo ratings yet

- 0901d196807026e8-100-700 SKF Bearings and Mounted Products 2018 TCM 12-314117Document587 pages0901d196807026e8-100-700 SKF Bearings and Mounted Products 2018 TCM 12-314117ShiepietNo ratings yet

- Daily Quiz: Register Free LoginDocument27 pagesDaily Quiz: Register Free LoginSreenubabu KandruNo ratings yet

- Nov 05Document13 pagesNov 05khajacheNo ratings yet

- Phrase Books: Kolami & GondiDocument20 pagesPhrase Books: Kolami & GondiSreenubabu KandruNo ratings yet

- Eenadu Pratibha 1 10Document10 pagesEenadu Pratibha 1 10sv swamy100% (6)

- Daily Quiz: Register Free LoginDocument27 pagesDaily Quiz: Register Free LoginSreenubabu KandruNo ratings yet

- D ËA Hùxß, "Œ/÷ Òh Ø Í ¡°óä O O.: Verbs Three FormsDocument42 pagesD ËA Hùxß, "Œ/÷ Òh Ø Í ¡°óä O O.: Verbs Three FormsSreenubabu KandruNo ratings yet

- AL 6XN SourceBookDocument56 pagesAL 6XN SourceBookdrbeyerNo ratings yet

- Rice Dip StandDocument10 pagesRice Dip StandjpmummeyNo ratings yet

- Brosur ITU - FCU Aug-2016Document4 pagesBrosur ITU - FCU Aug-2016Yudhi YudadmokoNo ratings yet

- MONOGRAPH MILLENNIUM CUTTER II Mi0556aDocument90 pagesMONOGRAPH MILLENNIUM CUTTER II Mi0556aAlexander Meza PereyraNo ratings yet

- Iron Balancing Valves IOM For Hattersley ColourDocument8 pagesIron Balancing Valves IOM For Hattersley ColourMuhammad ElbarbaryNo ratings yet

- How To Design and Make A Boost BottleDocument32 pagesHow To Design and Make A Boost BottleAmpDestroyer bose (EVILLSMEUDIESMEU)No ratings yet

- Nordson PumpDocument47 pagesNordson PumpVini LoNo ratings yet

- Mz-000-Ccx-Pi-Req-00040-Mat - Req. For Pipes SMLS and WLDD Api 5L X65 PSL2 For Pipeline Application RevaDocument13 pagesMz-000-Ccx-Pi-Req-00040-Mat - Req. For Pipes SMLS and WLDD Api 5L X65 PSL2 For Pipeline Application RevaPaul NieNo ratings yet

- Bawana BOQDocument28 pagesBawana BOQSasi Kiran VundamatlaNo ratings yet

- Chapter 8 - Miscellaneous Practices: Bht-All-SpmDocument58 pagesChapter 8 - Miscellaneous Practices: Bht-All-SpmAnwar HossainNo ratings yet

- NDT of helically welded pipesDocument13 pagesNDT of helically welded pipes_ARCUL_No ratings yet

- Cotco - 1 PDFDocument2 pagesCotco - 1 PDFAung ZinNo ratings yet

- Fire Sprinkler Design-Part2Document2 pagesFire Sprinkler Design-Part2Henry SuarezNo ratings yet

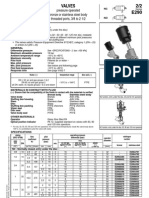

- Valves 2/2 E290: Pressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2Document4 pagesValves 2/2 E290: Pressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2Velpuri RameshBabuNo ratings yet

- s32x s36x BrochureDocument6 pagess32x s36x Brochurebeto pagoadaNo ratings yet

- Acabado Bridas PDFDocument5 pagesAcabado Bridas PDFjast111No ratings yet

- How To Use A Pipe Flaring ToolDocument8 pagesHow To Use A Pipe Flaring Toolmark darrelNo ratings yet

- Eaton Walform Machine Hire v2Document3 pagesEaton Walform Machine Hire v2Manuel CarvalloNo ratings yet

- For EntingDocument5 pagesFor EntingVicente TanNo ratings yet

- Instruction Manual: Deckma Hamburg GMBHDocument25 pagesInstruction Manual: Deckma Hamburg GMBHabuzer1981No ratings yet

- LMI Pumps General ManualDocument36 pagesLMI Pumps General ManualRoberto MejiaNo ratings yet