Professional Documents

Culture Documents

MS EMBEDDED Method Statement Rev10 (150131) Final

Uploaded by

Nguyen Dang LongOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MS EMBEDDED Method Statement Rev10 (150131) Final

Uploaded by

Nguyen Dang LongCopyright:

Available Formats

PROJECT: EXCHANGE SQUARE (STREET 106 SITE)

TITLE OF WORK: METHOD STATEMENT FOR

EMBEDDED CONDUITS INSTALLATION

30. JANUARY. 2015

-----------------------------------------------------------------------------------------------------------------------------------

METHOD STATEMENT FOR

EMBEDDED CONDUITS INSTALLATION

Representative

of

Prepare by

Sub contractor

Checked by

POSCO

Signature

NAME

DATE

Page 1

Submission Ref. : PSC-HK-MS-E-0002

Approved by

Consultant

POSCO

PROJECT: EXCHANGE SQUARE (STREET 106 SITE)

TITLE OF WORK: METHOD STATEMENT FOR

EMBEDDED CONDUITS INSTALLATION

30. JANUARY. 2015

----------------------------------------------------------------------------------------------------------------------------------Content

1. Introdution............................3

1.1 Purpose...............................3

1.2 Scope.........................................3

1.3 Exclusions......................................3

2. Generals.............................................3

2.1 Program................................................................................................................................................3

2.2 Location - Address.............................................3

2.3 Approvals..............................................................................................................................................4

2.4 Labor resources....................................................................................................................................4

2.5 Communications...................................................................................................................................4

2.6 Site Resources Required......................................................................................................................4

2.7 Temporary material...............................................................................................................................4

2.8 Protection..............................................................................................................................................4

2.9 Equipment/Tools...................................................................................................................................5

2.10 Hot works............................................................................................................................................6

2.11 Confined space works.........................................................................................................................6

2.12 Emergency & Safety Equipment.........................................................................................................6

2.13 Materials required for installation........................................................................................................6

2.14 Schedule of drawings..........................................................................................................................8

2.15 Schedule of inspection / T&C Form....................................................................................................8

2.16 Attendees............................................................................................................................................9

2.17 Safety Briefing.....................................................................................................................................9

2.18 Mitigation of Risk.................................................................................................................................9

3. Actual Works Method Statement..........................................................................................................9

3.1 Visual Inspection...................................................................................................................................9

3.2 Installation.............................................................................................................................................9

3.2.1 Embedded conduit in concrete walls................................................................................................9

3.2.2 Embedded conduit in floor slab.......................................................................................................13

3.2.3 Embedded conduit in brick wall......................................................................................................16

3.3 Air Tests..............................................................................................................................................18

3.4 Water Tests.........................................................................................................................................18

3.5 Flow Tests...........................................................................................................................................18

3.6 Electrical Tests....................................................................................................................................18

3.7 Setting to work....................................................................................................................................18

3.8 Test Records.......................................................................................................................................18

3.9 T&C Register......................................................................................................................................18

3.10 Reports.............................................................................................................................................19

4. Appendix..........................................21

4.1 Shop Drawing number PSC-HK-SD-ELC-002-Rev2 (Waiting Approval).........................................21

Page 2

PROJECT: EXCHANGE SQUARE (STREET 106 SITE)

TITLE OF WORK: METHOD STATEMENT FOR

EMBEDDED CONDUITS INSTALLATION

30. JANUARY. 2015

----------------------------------------------------------------------------------------------------------------------------------1.Introdution

1.1 Purpose

To describe electrical works associated with installation of embedded conduits for protection of

power cables and preparing for first fix of electrical boxes.

1.2 Scope

This method statement is covering the electrical works related to areas having cables running inside

concrete walls, brick walls, and floor slabs.

Works are carried out basing on construction schedule and detailed shop drawings approved.

1.3 Exclusions

1.3.1 Installation of the exposed conduits. (GI solid and flexible conduit)

2.General

2.1 Program (Working period: 28.01.2015 ~ 10.03.2016)

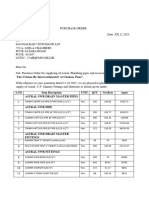

No

Working

time

Task

The

number of

labor

Prepared tools and materials

Check of all boxes installation position

2 person

Assemble the wall and the slab boxes as shown 3.2.1.10 photos

2 person

Locate the boxes(wall and slab), and fix box to position of form work

using nail fixing

Connect the boxes to designated conduits using the connector,

coupling hand tighten with steel wire handle

Self-checking, the fixed boxes, the connected conduits, the boxes,

conduits connection and route, check final installed positions all

conduit boxes, conduit routing and connections

Make sure there is no conflict of works to other subcontractor -

AM 07:30

~PM 05:30

12 person

20 person

5 person

-

2.2 Location - Address

Throughout the Exchange Square 106 street project, the embedded boxes and conduits will be installed

at every floor, concrete wall, brick wall and floor slab

2.3 Approvals

2.3.1 Material of submission : PSC-HK-MAT-ELC-002-Rev1 (Approved, 28-Jan-2015)

Page 3

PROJECT: EXCHANGE SQUARE (STREET 106 SITE)

TITLE OF WORK: METHOD STATEMENT FOR

EMBEDDED CONDUITS INSTALLATION

30. JANUARY. 2015

----------------------------------------------------------------------------------------------------------------------------------2.3.2 Shop drawing : Lighting, small power, cable containment and embedded conduit in B3 column and

ceiling : PSC-HK-SD-ELC-002-Rev2 (Waiting Approval)

2.4 Labor resources

The electrical team coordinates and carries out as below tree.

POSCO

Electric senior

Manager

Park Sang Min

097-806-3610

GS Neotek

Electric Manager

Seo Sung Won

099-580-959

GS Neotek

GS Neotek

GS

Neotek

Electric Engineer

Electric Engineer

Electric Engineer Vandica

Sem Mun

Yan Co 070-240-702

089-225-899

GS Neotek

099-580-959

GS Neotek

GS

Electric

Labor 2.5 Communications

GS Neotek

GS

Electric

Labor

Sopheap

Electric

LaborGS Neotek

Chhouu Dara

Electric Labor

The means of communication between work areas with office

077kunthea

99 03 02

HO

096-307-6566

dara phone or walkie-talkie.

077 99 49 98 Kenmobile

017 92 93 13

2.6 Site Resources Required

Neotek

Electric Labor

2.6.1 Local power supplies

Nop yeang

2.6.2 Area clearance obtained

from other discipline/ main contractor.

087-202-173

Neotek

2.7 Temporary materials

Electric Labor

Heng Srean

Cable leads 20m/2set will be connected

from construction temporary panel for AC 220V power supply

092-329-945

for power tools and lighting.

2.8 Protection

Designated inspectors shall protect materials during rebar working and casting concrete and prepare

spare parts for damaged materials

2.9 Equipment/Tools

2.9.1 Steel wire handle

2.9.2 Steel wire (Pre cut)

Page 4

PROJECT: EXCHANGE SQUARE (STREET 106 SITE)

TITLE OF WORK: METHOD STATEMENT FOR

EMBEDDED CONDUITS INSTALLATION

30. JANUARY. 2015

----------------------------------------------------------------------------------------------------------------------------------2.9.3 Electric drill

2.9.4 Extension cords

2.9.5 Ladder

2.9.6 Spring Bender

2.9.7 Hammer

2.9.10 Nails

Steel wire handle

Steel wire (precut)

Electric drill

Extension cords

A Ladder

Spring bender

Hammer

Nails

Page 5

PROJECT: EXCHANGE SQUARE (STREET 106 SITE)

TITLE OF WORK: METHOD STATEMENT FOR

EMBEDDED CONDUITS INSTALLATION

30. JANUARY. 2015

----------------------------------------------------------------------------------------------------------------------------------2.10 Hot works

Not Applicable

2.11 Confined space works

Not Applicable

2.12 Emergency & Safety Equipment

2.12.1 Safety Helmet 20ea

2.12.2 Safety Shoes 20ea

2.12.3 Safety Vests 10ea

2.12.4 Hand Gloves 2ea

2.12.5 Safety Goggles 2ea

2.13 Materials required for installation

2.13.1 PVC rigid conduit : 20D 1,800m, 25D 5,000m, 32D 2,000m (Including draw wires)

2.13.2 The boxes (steel and PVC) : 5,000 EA

2.13.3 PVC coupling and connector : 20,000 EA

.

Page 6

PROJECT: EXCHANGE SQUARE (STREET 106 SITE)

TITLE OF WORK: METHOD STATEMENT FOR

EMBEDDED CONDUITS INSTALLATION

30. JANUARY. 2015

-----------------------------------------------------------------------------------------------------------------------------------

2.14 Schedule of drawings

2.14.1 Basement structure work : ~ 21. 07. 2015

2.14.2 Podium structure work : 28. 08. 2015 ~ 23. 11. 2015

2.14.2 Tower structure work : 28. 08. 2015 ~ 26. 04. 2016

Page 7

PROJECT: EXCHANGE SQUARE (STREET 106 SITE)

TITLE OF WORK: METHOD STATEMENT FOR

EMBEDDED CONDUITS INSTALLATION

30. JANUARY. 2015

-----------------------------------------------------------------------------------------------------------------------------------

2.15 Schedule of inspections/T&C form

Refer to ITP number ITP-E-0004 attached (3.10)

2.16 Attendees

2.16.1 Sub-contractor manager : Seo Sung Won (099-580-959)

Page 8

PROJECT: EXCHANGE SQUARE (STREET 106 SITE)

TITLE OF WORK: METHOD STATEMENT FOR

EMBEDDED CONDUITS INSTALLATION

30. JANUARY. 2015

----------------------------------------------------------------------------------------------------------------------------------2.16.2 Sub-contractor site manager : Su Mun (089-225-899)

2.16.3 Contractor manager : Park Sang Min (097-806-3610)

2.16.4. HKL M&E manager : Tran Huu Phuoc (012-833-209)

2.17 Safety Briefing

The contents of this method statement shall form the basis of a toolbox talk for all operatives before the

commencement of such works.

2.18 Mitigation of Risk

2.18.1 Risk Assessment

2.18.1.1 Theft, ensure security staffs are aware steel materials installed and maintain surveillance while

Exposed to eliminate risk of theft.

.

2.18.1.2 Incorrect connections or materials, ensure the final installation and connections are inspected

and signed off with photographic records by senior on site M&E staff from contractor, architect,

client.

2.18.1.3 Damage of conduits during rebar installation and concrete casting mitigated by full time

designated inspectors observing builders works

3. Actual Works Method Statement

3.1 Visual Inspection

Supervisor to carry out a visual inspection of the work areas, materials, tools, safety equipment and

confirm ready to commence works.

3.2 Installation

3.2.1 Embedded conduit in concrete walls

3.2.1.1 Prepare tools and materials such as PVC rigid conduit, embedded box, box connector, coupling

accessories, hand tools etc.

3.2.1.2 PVC rigid conduits shall conform to BS EN 61386-21 and BS767-2008 standard.

3.2.1.3 Conduit boxes will be installed at the positions as defined on the shop drawing to accommodate

all the light switches, power outlets, lighting points and ELV equipment. Conduit boxes will be

connected with appropriate sized conduits secured within the rebar matrix. Intermediate draw

boxes will be installed to long conduit runs (15m) and at acute changes in direction (2bends)

3.2.1.4 Embedded conduits shall be firmly tightened with a steel wire to prevent movement during casting

concrete. Distance between the steel wire for holding conduits shall be minimum 0.6m.

3.2.1.5 The embedded boxes shall be filled with polystyrene and masking tape to prevent concrete

Page 9

PROJECT: EXCHANGE SQUARE (STREET 106 SITE)

TITLE OF WORK: METHOD STATEMENT FOR

EMBEDDED CONDUITS INSTALLATION

30. JANUARY. 2015

----------------------------------------------------------------------------------------------------------------------------------ingression to the boxes.

3.2.1.6 The conduit boxes for lighting switches, socket outlets, ELV equipment etc. shall be fixed into

position with a nail fix to the form work and steel wire to the rebar

.

3.2.1.7 All conduits shall be installed in proper routing with a minimum bending radius as shown Deatil-5

3.2.1.8 Check all the embedded conduit works are in proper order before the commencement of casting

works.

Detail-1

Typical detail of embedded conduit in concrete wall & column

Note: The box mounting levels shall be complied with construction working the inking line floor D-wall

3.2.1.10 Wall box assembling

Page 10

PROJECT: EXCHANGE SQUARE (STREET 106 SITE)

TITLE OF WORK: METHOD STATEMENT FOR

EMBEDDED CONDUITS INSTALLATION

30. JANUARY. 2015

-----------------------------------------------------------------------------------------------------------------------------------

3.2.1.11 Box Installation

- Wall box Installation

Page 11

PROJECT: EXCHANGE SQUARE (STREET 106 SITE)

TITLE OF WORK: METHOD STATEMENT FOR

EMBEDDED CONDUITS INSTALLATION

30. JANUARY. 2015

-----------------------------------------------------------------------------------------------------------------------------------

- Column box Installation

Page 12

PROJECT: EXCHANGE SQUARE (STREET 106 SITE)

TITLE OF WORK: METHOD STATEMENT FOR

EMBEDDED CONDUITS INSTALLATION

30. JANUARY. 2015

-----------------------------------------------------------------------------------------------------------------------------------

3.2.2 Embedded conduit in floor slab

3.2.2.1 Prepare tools and materials such as PVC rigid conduit, embedded box, box connector, coupling

accessories, hand tools etc.

3.2.2.2 PVC rigid conduits shall conform to BS EN 61386-21 and BS767-2008 standard.

3.2.2.3 Conduit boxes will be installed at the positions as defined on the shop drawing to accommodate

all the light switches, power outlets, lighting points and ELV equipment. Conduit boxes will be

connected with appropriate sized conduits secured within the rebar matrix. Intermediate draw

boxes will be installed to long conduit runs (15m) and at acute changes in direction (2bends)

3.2.2.4 The routing of the embedded conduits shall be laid minimum 50mm depth from face of slab.

3.2.2.5 After the bottom layer of rebar has been set up, the conduit shall be laid into position the upper

rebar layer is then installed, taking care not to damage conduit.

3.2.2.6 Embedded conduit shall be firmly fixed to upper layer of rebar with the steel wire or any means to

prevent movement before casting concrete. Distance between steel wires shall be at least 0.6m

and in case of joint area shall be at least 0.3m. Refer to detail-3

3.2.2.7 The embedded boxes shall be filled with polystyrene and masking tape to prevent concrete

ingression to the boxes.

3.2.2.8 All conduits shall be installed in proper routing following bending radius as shown Deatil-5

3.2.2.8 Check all conduit works are in order before the commencement of casting concrete.

Page 13

PROJECT: EXCHANGE SQUARE (STREET 106 SITE)

TITLE OF WORK: METHOD STATEMENT FOR

EMBEDDED CONDUITS INSTALLATION

30. JANUARY. 2015

-----------------------------------------------------------------------------------------------------------------------------------

Detail-2

Typical detail of embedded conduit installation in floor slab

Page 14

PROJECT: EXCHANGE SQUARE (STREET 106 SITE)

TITLE OF WORK: METHOD STATEMENT FOR

EMBEDDED CONDUITS INSTALLATION

30. JANUARY. 2015

-----------------------------------------------------------------------------------------------------------------------------------

Detail-3

Typical detail of embedded conduit installation in floor slab

Note: The conduits shall be fixed with the upper rebar, to prevent damage from anchors by builder.

Anchoring is avoid near-by 200mm from embedded boxes that shall be informed of construction

Builder

Detail-4

Typical detail of embedded conduit installation in floor slab

Note: The conduits passing from conditioned to non conditioned space and all conduits in plenum plant

rooms, must be sealed with mastic tape sealent after wiring to prevent humid air movement and

Page 15

PROJECT: EXCHANGE SQUARE (STREET 106 SITE)

TITLE OF WORK: METHOD STATEMENT FOR

EMBEDDED CONDUITS INSTALLATION

30. JANUARY. 2015

----------------------------------------------------------------------------------------------------------------------------------water condensation occurring inside conduits.

Detail-5

Typical detail of embedded conduit installation in floor slab

3.2.3 Embedded conduit in brick/block wall

3.2.3.1 Prepare materials and tools such as PVC rigid conduit, embedded box, accessories, drilling

machine, steel wire, etc.

3.2.3.2 PVC rigid conduits shall conform to BS EN 61386-21 and BS767-2008 standard.

3.2.3.3 Mark location of switches and outlet boxes on brick walls according to approved shop drawings.

3.2.3.4 The routing of embedded conduits shall be placed at the exact location of lighting switches,

outlet boxes, floor/ceiling slab and according to approved shop drawings.

3.2.3.5 Use diamond saw cutter to cut brick wall accurately to create a channel, maximum depth 25mm.

3.2.3.6 The chisel and hammer shall be used to hack and remove the brick in space between the two

lines to form the conduit recess. (channel)

3.2.3.7 The channels will generate support a maximum of 6 conduits.

3.2.3.8 The embedded box shall be filled with polystyrene and masking tape to prevent mortar plaster

entering the boxes, and fixed into the wall with screws.

3.2.3.9 Embedded conduit shall be secured by conduit clamps not more than 1.5m apart, the channel

should be covered with a plaster mesh to allow adhesion of mortar fill.

3.2.3.10 Mortar shall be used to plaster back a portion of conduit chases to ensure the conduit is properly

buried into the brick wall.

Page 16

PROJECT: EXCHANGE SQUARE (STREET 106 SITE)

TITLE OF WORK: METHOD STATEMENT FOR

EMBEDDED CONDUITS INSTALLATION

30. JANUARY. 2015

----------------------------------------------------------------------------------------------------------------------------------3.2.3.11 After installing embedded conduits boxes and as mortar is dry, plaster work has to be applied on

brick wall by plastering workers.

Detail-6

Typical detail of embedded conduit in brick wall

Detail-7

Typical detail of embedded conduit in brick wall

Page 17

PROJECT: EXCHANGE SQUARE (STREET 106 SITE)

TITLE OF WORK: METHOD STATEMENT FOR

EMBEDDED CONDUITS INSTALLATION

30. JANUARY. 2015

----------------------------------------------------------------------------------------------------------------------------------3.3 Air Tests

Not Applicable

3.4 Water Tests

Not Applicable

3.5 Flow Tests

Not Applicable

3.6 Electrical Tests

Not Applicable

3.7 Setting to work

Not Applicable

3.8 Test Records

Not Applicable

3.9 T&C Register

Not Applicable

Page 18

PROJECT: EXCHANGE SQUARE (STREET 106 SITE)

TITLE OF WORK: METHOD STATEMENT FOR

EMBEDDED CONDUITS INSTALLATION

30. JANUARY. 2015

----------------------------------------------------------------------------------------------------------------------------------3.10 Reports

Page 19

PROJECT: EXCHANGE SQUARE (STREET 106 SITE)

TITLE OF WORK: METHOD STATEMENT FOR

EMBEDDED CONDUITS INSTALLATION

30. JANUARY. 2015

-----------------------------------------------------------------------------------------------------------------------------------

Page 20

PROJECT: EXCHANGE SQUARE (STREET 106 SITE)

TITLE OF WORK: METHOD STATEMENT FOR

EMBEDDED CONDUITS INSTALLATION

30. JANUARY. 2015

----------------------------------------------------------------------------------------------------------------------------------4. Appendix

4.1 Shop Drawing number PSC-HK-SD-ELC-002-Rev2 (Waiting Approval)

Page 21

You might also like

- Method Statement For Exposed Conduits InstallationDocument24 pagesMethod Statement For Exposed Conduits InstallationNguyen Dang LongNo ratings yet

- PSC-HK-MS-MVAC-0007 Rev.2 - Method Statement For MVAC FCU InstallationDocument20 pagesPSC-HK-MS-MVAC-0007 Rev.2 - Method Statement For MVAC FCU Installationchinitn100% (1)

- MD1 0 T 052 05 00114 CDocument20 pagesMD1 0 T 052 05 00114 Chunkenx01100% (1)

- EXW-P006-0000-CD-SHC-MT-00093 Method Statement For Waterproofing System Rev 1Document43 pagesEXW-P006-0000-CD-SHC-MT-00093 Method Statement For Waterproofing System Rev 1Syed Umair HashmiNo ratings yet

- 1 Technical ProposalDocument64 pages1 Technical ProposalNana BarimaNo ratings yet

- JPK-056-07-Q-0794 - Rev 1Document84 pagesJPK-056-07-Q-0794 - Rev 1aibekNo ratings yet

- Method Statement - Upvc Piping - Rev 01Document10 pagesMethod Statement - Upvc Piping - Rev 01Tamil Da RasckalzNo ratings yet

- For Approval: Bac Mien Trung Consultancy Investment Construction and Trading Joint Stock CompanyDocument11 pagesFor Approval: Bac Mien Trung Consultancy Investment Construction and Trading Joint Stock CompanyBui Van DiepNo ratings yet

- Method Statement For General HVAC WorkDocument19 pagesMethod Statement For General HVAC WorkĐặng Quang HuyNo ratings yet

- Method Statement For Tank Jack LiftingDocument20 pagesMethod Statement For Tank Jack Liftingvpsimbu8680% (5)

- JPK-056-07-L-1754 - Rev 0Document245 pagesJPK-056-07-L-1754 - Rev 0aibek100% (1)

- 1 Method Statement For Barapullah Post Tensioning Rev-CDocument20 pages1 Method Statement For Barapullah Post Tensioning Rev-CJkkhyhNo ratings yet

- Bottom Slab Method StatementDocument22 pagesBottom Slab Method Statementfehmi-fjr4696No ratings yet

- Installation & Termination of Wiring Devices Method Statement KSA ProjectDocument13 pagesInstallation & Termination of Wiring Devices Method Statement KSA ProjectehteshamNo ratings yet

- Method Statement For Execution of Jet Grout Columns Works - 2nd CommentDocument3 pagesMethod Statement For Execution of Jet Grout Columns Works - 2nd Commenthessian123100% (1)

- ITP&ProcedureDocument38 pagesITP&ProcedurerajkbhatiaNo ratings yet

- 2014-4800-1L-0008 Rev D Piping Design BasisDocument49 pages2014-4800-1L-0008 Rev D Piping Design BasisKev Tra100% (1)

- method-statement-for-installation-of-hume-pipeDocument26 pagesmethod-statement-for-installation-of-hume-pipemanishsinghqcmccNo ratings yet

- HSTD-PTSCMC-TS-Q-PR-0001 Dimension Control Procedure For TOPSIDE FabricationDocument19 pagesHSTD-PTSCMC-TS-Q-PR-0001 Dimension Control Procedure For TOPSIDE Fabricationngtchung100% (2)

- MOS-Construction of 132kv OHTL From Ad Darb To Looping PointDocument27 pagesMOS-Construction of 132kv OHTL From Ad Darb To Looping PointEngr Muhammad Azam ThaheemNo ratings yet

- Modern Fastening Systems in Tunnel ConstructionDocument12 pagesModern Fastening Systems in Tunnel ConstructionfreezefreezeNo ratings yet

- Mackintosh Probe TestDocument9 pagesMackintosh Probe Testmyke_0101100% (2)

- PointsDocument2 pagesPointsGaneshNo ratings yet

- Work Procedure For HVAC CONTROL SystemDocument20 pagesWork Procedure For HVAC CONTROL SystemResearcher50% (2)

- For Information For Review For Approval For Construction As-BuiltDocument10 pagesFor Information For Review For Approval For Construction As-BuiltUtku Can KılıçNo ratings yet

- Volume 3Document116 pagesVolume 3Nazmul HasanNo ratings yet

- Electrical Conduit Installation MethodDocument8 pagesElectrical Conduit Installation MethodUtku Can KılıçNo ratings yet

- 132kV Switchyard Circuit Breaker InstallationDocument27 pages132kV Switchyard Circuit Breaker InstallationUtku Can Kılıç100% (1)

- HVAC Works for Intermediate School Type 2000Document54 pagesHVAC Works for Intermediate School Type 2000oth369No ratings yet

- Technical SpecificationsDocument135 pagesTechnical SpecificationsSrinivasan RajenderanNo ratings yet

- 2 500 - 1 S JPK 10002Document27 pages2 500 - 1 S JPK 10002aibekNo ratings yet

- SWMS Surface Condenser WeldingDocument11 pagesSWMS Surface Condenser WeldingPeter AntonyNo ratings yet

- Optcl System in Orissa 400kv Bid DocumentDocument223 pagesOptcl System in Orissa 400kv Bid Documentranjish_007100% (1)

- Method Statement For Conduit Installation - Cast in Situ of PVC / Gi / Ms Conduit Pipe For Electrical WorksDocument6 pagesMethod Statement For Conduit Installation - Cast in Situ of PVC / Gi / Ms Conduit Pipe For Electrical WorksRahul BharadwajNo ratings yet

- Zee-Method Statement For Construction Steel Platform ErectionDocument8 pagesZee-Method Statement For Construction Steel Platform Erectionzeeshansheikh7No ratings yet

- Method Statement For Road and Paving WorkDocument32 pagesMethod Statement For Road and Paving WorkĐặng Quang Huy100% (7)

- 1797-R0 - Devprayag (BR - No.01)Document29 pages1797-R0 - Devprayag (BR - No.01)V P GUPTANo ratings yet

- Report Pipe RackDocument16 pagesReport Pipe RackMochammad ShokehNo ratings yet

- Kerja Tambah & Kurang 4Document13 pagesKerja Tambah & Kurang 4uki12345No ratings yet

- Sample WorkpackDocument9 pagesSample WorkpackKhairun Mohamad IshakNo ratings yet

- Khabat PP 132kV Switchyard CT InstallationDocument27 pagesKhabat PP 132kV Switchyard CT InstallationUtku Can KılıçNo ratings yet

- 009-Civil-Ms Concrete Works PDFDocument27 pages009-Civil-Ms Concrete Works PDFKöksal PatanNo ratings yet

- Airport Underground Electrical Duct Banks and ConduitsDocument8 pagesAirport Underground Electrical Duct Banks and ConduitsDevrim Gürsel0% (1)

- Job List 01-11-2023Document27 pagesJob List 01-11-2023Thanh DoNo ratings yet

- 26071-100-VSC-CV5-00014 - 00A Construction Method Statement For MH & CBDocument82 pages26071-100-VSC-CV5-00014 - 00A Construction Method Statement For MH & CBRezky BaskoroNo ratings yet

- KOM - Kick Off MeetingDocument9 pagesKOM - Kick Off Meetingkashifshah123No ratings yet

- For Information For Review For Approval For Construction As-BuiltDocument27 pagesFor Information For Review For Approval For Construction As-BuiltUtku Can KılıçNo ratings yet

- USOR - CG - Water Supply - 2015Document377 pagesUSOR - CG - Water Supply - 2015UGD AMRUT HOSPETNo ratings yet

- Formwork Calculation Report - Rev.Document49 pagesFormwork Calculation Report - Rev.Nishant Gaur0% (1)

- Chimney Specification DraftDocument157 pagesChimney Specification DraftKrm Chari100% (1)

- Break DownDocument67 pagesBreak DownSenthilnathan NagarajanNo ratings yet

- Shotcrete Slope StabilizationDocument7 pagesShotcrete Slope StabilizationJ. Kumar Infraprojects Ltd100% (1)

- QCS 2010 Section 28 Part 2Document38 pagesQCS 2010 Section 28 Part 2Saif Abdulla0% (1)

- Tkr-Pro-Epc-Plg-010 - 5Document25 pagesTkr-Pro-Epc-Plg-010 - 5Kaan TektaNo ratings yet

- HVAC - CP BuildingDocument3 pagesHVAC - CP BuildingajaykgNo ratings yet

- PICA TRACKINGDocument38 pagesPICA TRACKINGnicoNo ratings yet

- Recuperación de infraestructura eléctrica escuela inicialDocument31 pagesRecuperación de infraestructura eléctrica escuela inicialPedro LtcNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- MANKO Low-E Cross Reference GlassDocument2 pagesMANKO Low-E Cross Reference GlassbatteekhNo ratings yet

- Fabrication and Development of Vacuum Assisted Resin Infusion MachineDocument9 pagesFabrication and Development of Vacuum Assisted Resin Infusion MachineImrul Kayesh AruNo ratings yet

- Catalogo Yz65 2023Document55 pagesCatalogo Yz65 2023diego vazNo ratings yet

- Civil MallDocument32 pagesCivil MallBigyan Adhikari75% (4)

- TRAFFIC SIGNS, MARKINGS & OTHER ROAD APPURTENANCESDocument2 pagesTRAFFIC SIGNS, MARKINGS & OTHER ROAD APPURTENANCESRajkumar Sagar100% (1)

- Seismic Load CalculationDocument7 pagesSeismic Load CalculationSuraj OjhaNo ratings yet

- Efficiency Vermont BBD Utilizing Insulated Concrete FormsDocument59 pagesEfficiency Vermont BBD Utilizing Insulated Concrete FormsEd Carlo Rosa PaivaNo ratings yet

- Chapter5 - Shear and Diagonal Tension in BeamsDocument9 pagesChapter5 - Shear and Diagonal Tension in BeamsYo FangirlsNo ratings yet

- JNF AcessoriosDocument76 pagesJNF AcessoriosPedro CoutinhoNo ratings yet

- York-Shipley 4 Series Boiler IOMDocument33 pagesYork-Shipley 4 Series Boiler IOMjosebaldesNo ratings yet

- Bazam Company ProfileDocument30 pagesBazam Company ProfileIbrahimrashid Billow HusseinNo ratings yet

- Concrete and asphalt aggregate element chartDocument4 pagesConcrete and asphalt aggregate element chartsaber2s22ahmadNo ratings yet

- Code of Practice Central HeatingDocument8 pagesCode of Practice Central HeatingJohnNo ratings yet

- Analysis of A Building Under Composite Structural System - A ReviewDocument10 pagesAnalysis of A Building Under Composite Structural System - A ReviewRenieNo ratings yet

- JPL Tower John Jacob JPL CorporationDocument4 pagesJPL Tower John Jacob JPL CorporationAlvin AbilleNo ratings yet

- M031565 00de - en 12v183te93Document292 pagesM031565 00de - en 12v183te93fatma kuruNo ratings yet

- Importance of geology in civil engineering fieldsDocument3 pagesImportance of geology in civil engineering fieldsRuby Anne LiwanagNo ratings yet

- 2 HKSDocument2 pages2 HKSBianca Genel Bacalso BedioNo ratings yet

- Department of Labor and Employment RULE 1160 RULE 1170: Gimarangan Saldo Loquinario Pobreza Sano IndinoDocument43 pagesDepartment of Labor and Employment RULE 1160 RULE 1170: Gimarangan Saldo Loquinario Pobreza Sano IndinoJinky Mae PobrezaNo ratings yet

- ME222 Lab Report Experiment 5 - A9Document10 pagesME222 Lab Report Experiment 5 - A9Vasu BansalNo ratings yet

- MADE EASY Editorial Board - SSC JE (Objective) - Civil Engineering-MADE EASY Publications (2018)Document433 pagesMADE EASY Editorial Board - SSC JE (Objective) - Civil Engineering-MADE EASY Publications (2018)Sourabh Raj DesaiNo ratings yet

- Architectural Services for 4318 Gallatin St ArcadeDocument25 pagesArchitectural Services for 4318 Gallatin St ArcadetinieNo ratings yet

- Valtra S353Document610 pagesValtra S353Luis AndersonNo ratings yet

- Seismic Upgrading of Bridges in South-East Europe by Innovative TechnologiesDocument28 pagesSeismic Upgrading of Bridges in South-East Europe by Innovative TechnologiesmilosbosNo ratings yet

- Metal Siding Deflection LimitDocument1 pageMetal Siding Deflection Limitwaweng22No ratings yet

- Seismic DampingDocument5 pagesSeismic DampingFahadmeyoNo ratings yet

- PO - ASTRAL PlumbingDocument3 pagesPO - ASTRAL PlumbingShubhajit ChakrabortyNo ratings yet

- 2 AggregatesDocument45 pages2 AggregatesAshley CanlasNo ratings yet

- AHE ECO-ZEN Wood Composite Catalog - 09-07-2019Document21 pagesAHE ECO-ZEN Wood Composite Catalog - 09-07-2019Ronald WongNo ratings yet

- Flygt 3153 50 LDocument42 pagesFlygt 3153 50 LNguyễn Văn KiênNo ratings yet