Professional Documents

Culture Documents

Lab Complete

Uploaded by

randyooiscribdOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lab Complete

Uploaded by

randyooiscribdCopyright:

Available Formats

Ran Dy Ooi | 8563481

EXPERIMENTAL STUDY OF PITTING CORROSION OF STAINLESS

STEEL SERIES 316 IN 0.1M SODIUM CHLORIDE WITH POLISHED AND

ROUGH SURFACE

Ran Dy Ooi

Abstract Corrosion could badly effects on materials.

Pitting is one of the localized corrosion that will occur on

material surface. Usually, pitting corrosion make a small

holes on the surface material. In this study, a piece of

stainless steel series 304 have been tested in two different

solutions; one is in the sodium chloride with neutral pH

while the other solution is in the sodium chloride with pH 2

solution. The experimental study is performed by scanning

the potential using a sweep generator connected to a

potentiostat. It is found at the end of the study that stainless

steel series 304 in pH2 have lower pitting potential

compared with in neutral solution. Thus, the corrosion rate

is higher.

in pH 2. In the end, the polarization curve is

being plotted after the data is being logged

using data-logger device.

KeywordsCorrosion, pitting, polarization curve, stainless

steel series 304, pH, neutral

INTRODUCTION

Figure 1: Experimental Setup

Corrosion or simply known by people as rust

is a gradually destructive situation usually on

metal. This is because the tendency of metal

reacts with the environment mostly with

atmospheric gases through chemical reaction. In

the most common use of term, this means

chemical reaction whereby oxidation of metal

with oxidant.

The pitting corrosion is one of the localized

corrosion that leads to the formation of small

holes in the metal. The driving power for pitting

corrosion is the depassivation of a small area,

which becomes anodic while an unknown but

potentially vast area becomes cathodic, leading

to localized corrosion. The corrosion penetrates

the mass of the metal, with limited diffusion of

ions.

In this respect, the present work is aimed to

study the corrosion behaviour of the stainless

steel series 304 in sodium chloride solutions,

mainly its pitting corrosion and the morphology

of pits. The effect of the pH of the solutions on

the localised corrosion of the stainless steel 304

series will be considered.

METHODOLOGY

The workflow of study is divided into two

phases. Initially, the condition of electrolyte is

in neutral. Next, the condition of electrolyte is

Figure 2: Experimental Setup. Computer shows the

data logger software interface.

DATA

Graph 1: Graph Applied Potential versus Logarithm

of Current Density for Stainless Steel Series 304 in

Sodium Chloride Neutral Solution.

Ran Dy Ooi | 8563481

Graph 2: Graph Applied Potential versus Logarithm

of Current Density for Stainless Steel Series 304 in

Sodium Chloride pH 2 Solution.

Graph 3: Combine Graph of Applied Potential versus

Logarithm of Current Density for Stainless Steel

Series 304 in Sodium Chloride Neutral Solution and

pH 2 Solution.

RESULTS AND DISCUSSION

Graph 1 shows the polarization curve of

Stainless Steel Series 304 behaviour in Sodium

Chloride neutral solution. It is found that as the

applied potential increase, the curve undergo

passivity first. In the passivity region, it is

shown that noise occurs. This happened because

of disturb from electronic device while

experimental study is being conducted. As the

applied potential reach its pitting potential level,

the curve immediately spike up with constant

value recorded.

As for in pH 2 solution, it is observed from

polarisation curves that the metastable region

behaves moderately compared to neutral

solution. As it reached the pitting potential, it

goes same as well as neutral solution behaviour

whereby the curve immediately spike up with

constant value recorded.

In comparison between neutral solution and

pH solution, it can be seen from the graph that

there is a difference pitting potential value. In

neutral solution, the pitting potential is higher

compared with in pH 2 solution. Nevertheless,

the metastable region for pH 2 solution is

moderate in noise compared with the neutral

solution.

The reason of difference pitting potential

value between neutral solution and pH 2

solution is because the reaction takes place in

the solution itself. As the pH decrease, the

passive current increase, and it goes the same

with the pitting potential. In the end, the

corrosion rate increase.

Figure 3: Morphological View for Sample of Stainless

Steel Series 304 in Sodium Chloride Neutral Solution

#1

Figure 4: Morphological View for Sample of Stainless

Steel Series 304 in Sodium Chloride Neutral Solution

#2

Ran Dy Ooi | 8563481

and 7 is the condition of stainless steel series

304 in sodium chloride pH 2 solution.

It can be deduce that when stainless steel

series 304 in sodium chloride neutral solution, it

is more severe compared to the pH 2 solution.

The corrosion behaviour in pH 2 is less severe

compared to in the neutral solution. In figure 6

and 7, the hole or pit is being visualised

clearly while in figure 3, 4 and 5, the pit not

severe as in figure 6 and 7.

Figure 5: Morphological View for Sample of Stainless

Steel Series 304 in Sodium Chloride Neutral Solution

#3

Figure 6: Morphological View for Sample of Stainless

Steel Series 304 in Sodium Chloride pH 2 Solution #1

I.

CONCLUSION

AND

RECOMMENDATION

In conclusion, it is found that as the pH value

decrease, the passive current increase and the

general corrosion rate increase. But, the value

of pitting potential is decrease. As for the

neutral condition, the passive current decrease

and the general corrosion rate lower compared

with in the pH 2 solution. The pitting potential

for neutral solution is higher compared with the

pH 2 solution.

Based on the sample morphology observed

via microscope, the stainless steel series 304 in

sodium chloride neutral solution has severe

pitting on the metal. In contrary, the stainless

steel series 304 in sodium chloride pH 2

solution act oppositely whereby it more and less

like general corrosion on the metal.

II.

ACKNNOWLEDGEMENT

The author would like to thanks Corrosion

Protection Centre, Dr Stuart Lyon, Dr Drik

Engelberg, Dr Peter Skeldon, Dr Fabio Scenini

and Mr Paul Jordan, the faculty members and

classmates in order completing the experimental

study.

Figure 7: Morphological View for Sample of Stainless

Steel Series 304 in Sodium Chloride pH 2 Solution #2

Based on the sample shown on figure 3, 4 and

5 using microscope, it is found that the

corrosion is less severe compared to sample

shown on figure 6 and 7. Figure 3, 4 and 5 is

the condition of stainless steel series 304 in

sodium chloride neutral solution while figure 6

III.

REFERENCES

Abbaspour, M., Chapman, K. S., & Glasgow, L.

A. (2010). Transient modeling of nonisothermal, dispersed two-phase flow in natural

gas pipelines. Applied Mathematical Modelling,

495507.

Ran Dy Ooi | 8563481

De waard, C., Miliam, D.E. 1975. Carbonic

Acid Corrosion of Steel. Corrosion 31:177-181

P. Marcus and J. Oudar (eds), Corrosion

Mechanisms in Theory and Practice, Marcel

Dekker, 1995

Localized Corrosion, NACE, Houston, Texas

1986

Uhligs Corrosion Handbook, 2-Ed, John Wiley

and Sons, 2000

You might also like

- Career AdvicesDocument1 pageCareer AdvicesrandyooiscribdNo ratings yet

- Demands and Needs StatementDocument34 pagesDemands and Needs StatementrandyooiscribdNo ratings yet

- LudoxDocument1 pageLudoxrandyooiscribdNo ratings yet

- ReportDocument3 pagesReportrandyooiscribdNo ratings yet

- Applying Titanium Alloys in Drilling and Offshore Production SystemsDocument3 pagesApplying Titanium Alloys in Drilling and Offshore Production SystemsrandyooiscribdNo ratings yet

- NDT inspection plugs provide reusable access for pipe inspectionsDocument2 pagesNDT inspection plugs provide reusable access for pipe inspectionsURIELNo ratings yet

- ID LegendDocument12 pagesID LegendrandyooiscribdNo ratings yet

- A New Approach Corrosion Monitoring ChemEngJune07Document8 pagesA New Approach Corrosion Monitoring ChemEngJune07piolinwallsNo ratings yet

- Attachment #1-Blank Cover Sheet - Rev.BDocument5 pagesAttachment #1-Blank Cover Sheet - Rev.BrandyooiscribdNo ratings yet

- Refining Corrosion TechnologistDocument1 pageRefining Corrosion TechnologistrandyooiscribdNo ratings yet

- Iceland ItineraryDocument1 pageIceland ItineraryrandyooiscribdNo ratings yet

- Control Phase - Lean Six Sigma Tollgate TemplateDocument37 pagesControl Phase - Lean Six Sigma Tollgate TemplateSteven BonacorsiNo ratings yet

- GlossaryDocument1 pageGlossaryrandyooiscribdNo ratings yet

- Daily ActivityDocument4 pagesDaily ActivityrandyooiscribdNo ratings yet

- JobAdvertisement 103653Document1 pageJobAdvertisement 103653randyooiscribdNo ratings yet

- GlossaryDocument1 pageGlossaryrandyooiscribdNo ratings yet

- Assessed CourseworkDocument4 pagesAssessed CourseworkrandyooiscribdNo ratings yet

- XOM Strategy For Preventing CUIDocument6 pagesXOM Strategy For Preventing CUIrandyooiscribdNo ratings yet

- Template NORSOK EngDocument9 pagesTemplate NORSOK EngPatrick PazNo ratings yet

- Assignment 2Document3 pagesAssignment 2randyooiscribdNo ratings yet

- Companion Study Guide TO Short Course On Geothermal Corrosion and Mitigation in Low Temperature Geothermal Heating SystemsDocument34 pagesCompanion Study Guide TO Short Course On Geothermal Corrosion and Mitigation in Low Temperature Geothermal Heating SystemsrandyooiscribdNo ratings yet

- Analysis of The Integrity of A Single Stud Assembly With Externally Corroded NutsDocument19 pagesAnalysis of The Integrity of A Single Stud Assembly With Externally Corroded NutsrandyooiscribdNo ratings yet

- R P RP O501 E W P S: Ecommended RacticeDocument43 pagesR P RP O501 E W P S: Ecommended RacticerandyooiscribdNo ratings yet

- Surface Engineering Techniques Compared for Coating AdhesionDocument5 pagesSurface Engineering Techniques Compared for Coating AdhesionrandyooiscribdNo ratings yet

- Guidance Note - Potentiodynamic SweepDocument3 pagesGuidance Note - Potentiodynamic SweeprandyooiscribdNo ratings yet

- Chap 3Document17 pagesChap 3randyooiscribdNo ratings yet

- Guidance Note - Potential StepDocument3 pagesGuidance Note - Potential SteprandyooiscribdNo ratings yet

- Austenitic Stainless SteelsDocument1 pageAustenitic Stainless SteelsrandyooiscribdNo ratings yet

- Guidance Note - Current Step (DLE)Document3 pagesGuidance Note - Current Step (DLE)randyooiscribdNo ratings yet

- Coursework - Pitting Questions 2011Document1 pageCoursework - Pitting Questions 2011randyooiscribdNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- ASME - Middle-East-Training-Brochure PDFDocument32 pagesASME - Middle-East-Training-Brochure PDFMohamed F MorsyNo ratings yet

- AP TSS General Safety Course For 2019cycleDocument141 pagesAP TSS General Safety Course For 2019cycleFebry Dwi TranspuriNo ratings yet

- EPL 0006898 ArticleDocument28 pagesEPL 0006898 ArticleGuillermo IdarragaNo ratings yet

- Assignment-Research 2-MJD-MALLARIDocument9 pagesAssignment-Research 2-MJD-MALLARIMark MallariNo ratings yet

- Macroeconomic Modeling for SDGs in Least Developing EconomiesDocument25 pagesMacroeconomic Modeling for SDGs in Least Developing EconomiesAM operationNo ratings yet

- Carter Auto Water Pump Components 072420Document2 pagesCarter Auto Water Pump Components 072420geniusNo ratings yet

- Presentation FatigueDocument22 pagesPresentation FatigueRavi Kiran MeesalaNo ratings yet

- Evading Thermal Imaging and Radar Detection-1Document8 pagesEvading Thermal Imaging and Radar Detection-1kokiskoNo ratings yet

- PPR Techincal Data SheetDocument0 pagesPPR Techincal Data SheetKrish ChennaiNo ratings yet

- Green Building Rating Systems ExplainedDocument42 pagesGreen Building Rating Systems ExplainedJake CerezoNo ratings yet

- Product Specifications Product Specifications: CNT CNT - 600 600Document2 pagesProduct Specifications Product Specifications: CNT CNT - 600 600Antonio CorreiaNo ratings yet

- 7.MMCR JuliDocument5,281 pages7.MMCR JuliAngga StwnNo ratings yet

- Nissan Skyline R34 Workshop Manual EnglishDocument401 pagesNissan Skyline R34 Workshop Manual Englishrecklessone0% (2)

- The Sun As The AxisDocument20 pagesThe Sun As The AxisNeb Nyansapo Noopooh100% (2)

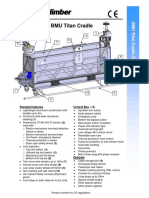

- BMU Titan Cradle: Standard Features Control BoxDocument2 pagesBMU Titan Cradle: Standard Features Control BoxKashyapNo ratings yet

- Plantilla WPS (GMAW-MIG) Junta VDocument1 pagePlantilla WPS (GMAW-MIG) Junta Vjhojan garciaNo ratings yet

- Group 2 Financial Brick Case StudyDocument9 pagesGroup 2 Financial Brick Case StudyMDNo ratings yet

- Accurate Power Demand Forecasting MethodsDocument15 pagesAccurate Power Demand Forecasting MethodsRathinaKumarNo ratings yet

- Quiet Ducted Exhaust Ventilation Fans for Homes and Commercial SpacesDocument2 pagesQuiet Ducted Exhaust Ventilation Fans for Homes and Commercial SpacesKyaw ZawNo ratings yet

- Ingersoll Rand VR-843CDocument2 pagesIngersoll Rand VR-843CMontSB100% (1)

- Work and PowerDocument26 pagesWork and Powernicka castilloNo ratings yet

- Lecture 30 - Enamine and Iminium OrganocatalysisDocument22 pagesLecture 30 - Enamine and Iminium OrganocatalysisDênisPiresdeLimaNo ratings yet

- Axera 5-126 - 6232sd PDFDocument4 pagesAxera 5-126 - 6232sd PDFOscar Acevedo MirandaNo ratings yet

- Steam Turbines Basic Information - Power Generation in PakistanDocument12 pagesSteam Turbines Basic Information - Power Generation in Pakistannomi607No ratings yet

- PIPENET VISION SPRAY MODULE TRAINING MANUALDocument48 pagesPIPENET VISION SPRAY MODULE TRAINING MANUALElton Situmeang50% (2)

- Especificaciones de valvulasDIDocument4 pagesEspecificaciones de valvulasDIAlejandro ValenzuelaNo ratings yet

- Information Sheets 6.1.4Document12 pagesInformation Sheets 6.1.4api-196541959No ratings yet

- IB Physics Climate ModellingDocument11 pagesIB Physics Climate ModellingAnara Noelle Chiongbian100% (1)

- Dual Ingecon Sun U B Series Family at 1500vdcDocument4 pagesDual Ingecon Sun U B Series Family at 1500vdcRoberto SNo ratings yet

- ADIABATIC FLOW IN A DUCT WITH FRICTION (FANNO FLOWDocument30 pagesADIABATIC FLOW IN A DUCT WITH FRICTION (FANNO FLOWHamza AshrafNo ratings yet