Professional Documents

Culture Documents

Stucturalsteelproject3 150410221010 Conversion Gate01

Uploaded by

Amjad PervazCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stucturalsteelproject3 150410221010 Conversion Gate01

Uploaded by

Amjad PervazCopyright:

Available Formats

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

STRUCTURAL STEEL PROJECT

Member of Group 2:

-

Tutor: TS. Dinh Van Thuat

Trnh c Duyn

Nguyn Hong Tng

Duy Khang.

I. Design data and requirement

1) Design data

- Frame span : L = 30 (m)

- Frame bay : B = 6 (m)

- Number of frames : n = 15

- Height from the ground to the top of rail : H1 = 8(m)

- Crane capacity : Q = 7 (T)

- Number of traveling crane average acting levels : 2

- Wind zone (TCVN 3727:1995) : IIIB

- Topography types of the construction site (TCVN 3727: 1995) : B

- Type of roof cladding : Single- skin trapezoid sheeting system with insulating foam

- Height of crane runway girder : hr = 0,15 (m)

- Height of travelling crane : hdct = 0,65 (m)

- Height of skylight : Hct = 2 (m)

- Skylight bay : Lct = 5 (m)

- Materials : Steel CCT34 ; Concrete B15

- Surrounding covered structure : the height of brick wall from the ground is 1,5 m ; the above is

covered by sheet iron

2. Requirements

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

II. Calculation for design

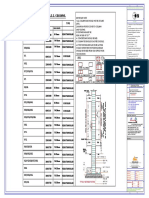

1. Structural diagram of Portal Frame

Portal Frame Consist of solid columns and I- shaped beam, the columns have uniform cross

section and fixed at the foundation. According to requirements of architecture and drainage,

we choose rafter with the slope of 10o (equal to i = 17%). Because a horizontal frame is

mainly subjected to self-weight loads and wind force, the internal force in rafter at its armpit

is much greater than that at the middle of rafter. The component of rafter has a changing

cross-section located at the distance of about 0,35- 0,4 of half of the rafter from column. The

rest of the rafter is constant.

The Skylight run along the length of building for ventilation and lighting. We choose

preliminarily the height of skylight is 2 m and its width is 5 m

Cladding

+14.74

Purlin

Rafter

+9.46

+8.00

wall cladding

Q= 7T

Brick wall

-1.00

Fig.1.1 -Portal Frame

1.1 The size of structural frame in vertical direction

The height of lower column : Hd = H1 (hdct + hr) + hch

With, H1 = 8(m) : the elevation of the top of rail

hdct = 0,65 (m) : the height of the crane girder

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

hr = 0,15 (m) : the height of the rail

hch = 0,5 (m) : embedded depth of the foundation

Hd = 8 ( 0,65+0,15) +1 = 8,2(m)

The height of upper column : Ht = (hdct + hr) + K1 + 0,5

With, K1 = 0,96 : the distance from the top of rail to the highest location of crane car.

This value is taken from the catalog of crane ( it depends on crane capacity Q = 8 (T) and

frame span L = 30 (m)).

0,5 (m) : safe distance from the highest location of crane car to portal frame

Ht = ( 0,65 + 0,15) + 0,96 + 0,5 = 2,26 (m)

So, the height of the column H = Ht + Hd = 8,2 + 2,26 = 10,46 (m)

1.2 Choose preliminary the size in horizontal direction

Frame span (positioning axis is considered at outer edge of column) : L = 30 (m)

, we choose approximately S = 28 (m) from catalog of the crane

safe distance from the axis of rail to inner edge of column : Zmin = 180 (mm)

a. the size of the column cross-section

- the height of the cross-section : h =

1 1

1 1

( ) H ( )10, 46

10 15

10 15

0, 697 1, 046

=

We choose h = 0,8 (m) = 80 (cm)

(0,3 0, 5) h (0,3 0,5).0,8

- The width of the cross-section : b =

(m)

0, 24 0, 4

=

(m)

We choose b = 0,34 (m) = 34 (cm)

(

-The thickness of the web tw

t w 6(cm)

resistance and

1

1

)h

70 100

in order to satisfy the condition of corrosion

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

tw (

NATIONAL UNIVERSITY OF

1

1

1

1

)h (

)80 1,14 0,8

70 100

70 100

(cm)

So , we choose tw = 1,0 (cm)

(

-The thickness of flange tf : tf =

1 1

1 1

)b ( )34 1, 21 0,97

28 35

28 35

(cm)

So, we choose tf = 1,4 (cm)

Recheck safe distance from the axis of rail to the inner edge of column

1

( L 2.h S )

2

Z=

With, L : frame span ; S : crane span ; h: the height of the column cross-section

Z=

1

(30 2.0,8 28)

2

0,2 (m) > Zmin = 0,18

Satisfy the condition of safety

b. The size of rafter cross-section

-The height of the cross-section at the armpit of the frame : h1

1

1

L 30

40

40

= 0,75 (m)

we choose h1 = 0,8 (m)

1 1

h1

2 5

-The width of the cross-section at the armpit of the frame : b =

usually choose the width of the flange equaling to that of column

1 1

1 1

h1

.80 15 37,5

2 5

2 5

(cm)

and

b 180mm

. We

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

we choose b = 34 (cm)

(1,5 2)b

-The height of the constant cross-section of rafter h2 =

h2 (1,5 2)b (1,5 2).34 51 68

(cm)

we choose h2 = 50 (cm)

(

- The thickness of the web tw

1

1

) h1

70 100

in order to satisfy the condition of corrosion

t w 6(cm)

resistance and

tw (

1

1

1

1

)h1 (

)80 1,14 0,8

70 100

70 100

(cm)

So , we choose tw = 1,0 (cm)

(

-The thickness of flange tf : tf =

1 1

1 1

)b ( )34 1, 21 1,36

28 35

28 35

(cm)

So, we choose tf = 1,2 (cm)

-The location, has changing cross-section, be at the distance of about 0,35- 0,4 of half of the

(0,35 0, 4).15 5, 25 6

portal frame from column : Ltd =

(m)

So, we choose Ltd = 5,5 (m)

c. The size of console cross-section

The size of console cross-section depends on crane loading ( concentrated forces made by

vertical pressure of overhead crane , self-weight of crane girder, rail , braking girder and live

load on overhead crane) and the span of console (the distance from the point put on by

concentrated force to the edge of the column). We choose preliminarily the size of console

cross-section as following:

-The distance from positioning axis to the axis of rail:

=(L-S)/2=(30-28)/2 = 1 (m)

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

- The length of console (from the inner edge of the column to the outer edge of console)

LV = - hc + 0,15 = 1- 0,8 +0,15 = 0,35 (m)

( We choose the distance from the axis of rail to the outer edge of console is 150 mm

-Choose

-Choose the inclined angle between the bottom flange of console and horizontal direction is 15o

- We choose the height of a cross-section at fixed end : hdv= 60 (cm) ( Z = 25)

We have: the height of console at the point put Dmax :

h = 60-20tan15o= 54,6(cm) cm)=> we choose: h = 55 (cm)

-The width of console cross-section : bf = 34 cm

-The thickness of console web : tw = 0,8 cm

-The thickness of console flange: tf = 1,2 cm

d. The size of skylight cross-section

-The height of the cross-section of skylight column : hc-ct = 20 cm

-The width of the cross-section of skylight column : bc-ct = 10 cm

- The thickness of web skylight column : tw = 0,6 cm

-The thickness of flange skylight column : tf = 1,0 cm

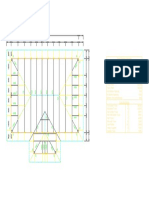

1.3 Bracing system

Bracing system is part of the building to connect horizontal frames together in order to form

space structural system leading to some following effect :

+ make sure geometrical stability in the direction of building length and space stiffness of

building

+ resist some loadings in the direction of building length and perpendicular to frame plan such

as wind load, seismic or braking forces from overhead crane

+ ensure stability of some compressive members such as : truss, column ....

+ Create favorable condition for construction as fabrication, erection and transportation

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

Bracing system consist of roof bracing system and column bracing system

Column bracing system

Column bracing system ensure geometrical stability and stiffness of entire building in the

direction of the length of building. Its subjected to the loading applying in the direction of the

length of building and make sure that the column is stable. Along the length of building, column

bracing system is placed at the middle and the two side of the block in order to transmit wind

loading rapidly. The bracing system has two layers. One is arranged from braking gird to the top

of column, the other is from the ground to the console. According to the cross-section of the

column , the bracing system is placed at the middle of column flange . Because crane capacity

Q<10(T) , we choose the cross-section of bracing members made by rebar with diameter of

25mm .We layout shores along the building . The height of the column H = 10,46 (m) > 8m, so

we layout shores along the building at the locations where have elevation of +4.00m. We need

max 200

choose the cross-section of the shores satisfied the condition of slenderness :

choose 2C20

, we

Longitudinal bracing

Column bracing

+9.46

+8.00

Crane runway girder

+4.00

0.00

-1.00

500

5500

6000

6000

6000

6000

6000

6000

6000

6000

6000

6000

6000

6000

5500

500

84000

10

11

12

13

Fig.1.2 Column bracing system

Roof bracing system

Roof bracing system is layout at the location where have column bracing system. The

bracing system includes diagonal members and shores. We need to meet demand about

max 200

slenderness of shores

. Diagonal members is made from rebar with 25, we

choose 2C20 for shores. According to the cross-section of portal frame, roof brace is

layout up (in order to make portal frame stable when they are subjected loadings the

top flange of portal frame is subjected to compressive loads). When the frame is

subjected to wind loading , its bottom flange suffer compressive loadings , so we need to

strengthen by adding diagonal shores (connected to purlin) . They are spaced 3-bay

purlin distance centre . We choose the cross-section of shores L50X5. The location

14

15

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

connected to portal frame is at the distance of 800mm from portal frame. Besides, we

need to layout shores run along the ridge with cross-section of 2C20 in order to create

favourable condition for construction

Roof bracing

30000

Longitudinal Bar

500

5500

6000

6000

6000

6000

6000

6000

6000

6000

6000

6000

6000

6000

5500

500

84000

10

11

12

13

Fig.1.3 Roof bracing system

2. Determine the loading applying on the frame

* 2.1 Continuous loadings

- Continuous loading caused by iron sheet , bracing system, purlin, skylight : gtc = 15 (daN/m2)

(distributed according to the slope of roof)

-The load factors ng = 1,1:

qtc = gtc . B = 6.15 = 90 (daN/m)

qtt = ng. qtc = 90.1,1 = 99 (daN/m)

-The loading caused by surrounding covered structure : gtc = 12 (daN/m2)

qtt = ng.gtc. B = 1,1.12.6= 79,2 (daN/m)

- Self-weight loading of crane bridge :

dct L2dct

Gdct =

= 30.62 = 1080 (daN)

cdt

With

= 30 : factor of self-weight

- Self-weight loading of braking girder: Gdh = 500 (daN) ( according to experience)

Table 1.1-Roof dead load

14

15

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

STT

Types of

loading

Characteristic

load

(daN/m2)

Load

factor

1

2

3

Iron sheet

purlin

8

7

1,1

1,1

Factored

load

(daN/m2)

The bay of

frame (m)

Loadings

(daN/m)

6

6

52,8

46,2

99

8,8

7,7

-The load factors ng = 0,9:

qtc = gtc . B = 6.15 = 90 (daN/m)

qtt = ng. qtc = 90.0,9 = 81 (daN/m)

-The loading caused by surrounding covered structure : gtc = 12 (daN/m2)

qtt = ng.gtc. B = 0.9.12.6= 64,8 (daN/m)

- Self-weigh loading of crane bridge :

dct L2dct

Gdct =

= 30.62 = 1080 (daN)

cdt

With

= 30 : factor of self-weight

- Self-weight loading of braking grider : Gdh = 500 (daN) ( according to experience)

Table 1.2-Roof dead load

STT

Types of

loading

Characteristic

load

(daN/m2)

Load

factor

1

2

3

Iron sheet

purlin

8

7

0,9

0,9

Factored

load

(daN/m2)

7,2

6,3

The bay of

frame (m)

Loadings

(daN/m)

6

6

43,2

37,8

81

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

* 2.2 Live loads of repairing roof

- Load factor of the live load : np = 1,3

- According to TCVN 2737 1995 , we have the magnitude of live loads caused by repairing

roof : 30 (daN/m2) distributed on the plan of the building, so the live load distributed on portal

frame is determined as following : p = 30.B

- we need to refer to the loading distributed on the portal frame as following :

ptc = 30.B.

cos

= 30.6.

cos100

= 177,26 (daN/m)

ptt = np.ptc = 1,3.177,26 = 230,45 (daN/m)

* 2.3 Wind loads

Wind pressure acting on the frame is determined according to TCVN 2737-1995

q = n.W0.k.C.B (daN)

With, q: wind pressure distributed along the frame

W0 : characteristic wind pressure ; wind zone IIIB : W0 = 125 (daN/m2)

n = 1,2 : wind load factor

k : the factor considering the wind pressure varying along the height of structure

C : the wind dynamic coefficient depends on the shape of structure

B : the distance between in-plan frame structure of the building

a) In case of wind direction blowing in horizontal direction of the building

* Determine the wind dynamic coefficient Ce

NATIONAL UNIVERSITY OF

490

670

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

800

Fig.1.4Dimension of diagram:

Frame span :Lo= 30 (m),

Height of column :Hce = 10,46+0,67-0,5=10,63 (m) , Hm1= (Lo/2).tan10-(Lct/2)tan10=2,2(m),

Hm2= 2(m),

Hm3=(Lct/2)tan10 =0,44(m)

Follow the table 8 of TCVN 2737-1995 which is depends on

B/ L

,and H/L => Ce

We have : Ce1=-0,8; Ce2=-0,8 ; Ce3=-0,5; Ce4=-0,324

- Determine k-factor:

K depends on height construction and topography type, Construction site is topography type B.

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

Fig.1.5- the wind dynamic coefficient Ce

Table 1.3 Win load in transverse direction

ordinal

Load type

Wind

load

(daN/

m)

125

125

125

Z

(m)

10,63

12,83

14,83

1,009

1,045

1,077

0,8

-0,324

0,7

1,2

1,2

1,2

6

6

6

Total

wind

load

(daN/m)

726,48

-304,72

678,51

1

2

3

Ct n gi

Mi n gi

Ct ca tri

n gi

mi ca tri

n gi

Mi ca tri

ht gi

Ct ca tri

ht gi

Mi ht gi

125

15,27

1,082

-0,8

1,2

-779,04

125

15,27

1,082

-0,8

1,2

-779,04

125

14,83

1,077

-0,6

1,2

-581,58

125

12,83

1,045

-0,5

1,2

-469,65

8

Ct ht gi

125

10,63

1,009

-0,5

Minus (-) show wind load direction outside of the frame

1,2

-454,05

4

5

6

7

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

b) In case of wind direction blowing in longitudinal direction of the building

Fig.1.6- the wind dynamic coefficient Ce

* Determine the wind dynamic coefficient Ce

NATIONAL UNIVERSITY OF

490

670

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

800

Fig.1.7

In this the win dynamic coefficient both two side of the building roof and both side of the roof

light window, Ce =-0,7.

Ce3 depends on both L/

L

Building has :

and

H/

30 0, 75

0, 35

14.6

<1

H

10, 45 2, 2 2 0, 44

0,18

14.6

B

< 0,5

=>Ce3=-0,4

Table 1.4 Win load in along direction

ordinal

Load

type

Column

Wind

load

(daN/m)

125

Total wind

load(daN/m)

10,45

1,007

-0,4

1,2

-362.52

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

2

3

Roof

Column

of roof

window

Roof

window

NATIONAL UNIVERSITY OF

125

125

12,65

14,65

1,042

1,074

-0,7

-0,4

1,2

1,2

6

6

-656,46

-386,64

125

15,09

1,081

-0,7

1,2

-681,03

*2.4 Crane loads

a, Vertical loads

ZLK double girder crane , Load capacity 8 tons, Crane span 28 meters

=> The width of girder crane Bct=5,3m

The distance between two wheels : R=4,6m

Pmcax

The maximum pressure under each wheel :

7020daN

c

Pmin

The minimum pressure under each wheel :

2950daN

b, Vertical load on Console

Dmax n.nc .Pmax . yi

Dmin n.nc .Pmin . yi

Where:

n : is load factor n=1,1

nc =0,85 combination factor ( when 2 girder cranes work in normal not hard)

Total of ordinate of influence line

y1=1 ; y2=0,233 ; y3= 0,883 ; y4= 0,117

=>

2, 233

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

STT

Loads

Ptc

1

2

Dmax

Dmin

7020

2950

2,233

2,233

350

4600

Pmax

1,1

1,1

350350

nc

0,85

0,85

4600

Pmax Pmax

Y4

Y3

6000

350

Pmax

Y2

Y1

Total

(daN)

14657

6159

6000

Fig.1.8

c, Horizontal loadsWhen the hoist trolley brakes, this acts generate horizontal inertial force. The

inertial force transmits through the wheels of hoist trolley to the column ( T forces).Calculating T

forces also bases on influence line. Transverse force T is applied to one column( on the right or

left side of the frame structure in both right and left directions and it is located at the top level of

the crane runway girder.

The total characteristic transverse force of the crane :

T1c

0, 05.(Q Goverhead )

n0

In which :

Q is the maximum load of overhead crane

Goverhead 800daN

is the total self weight of the overhead crane

n0 =2 is the number of wheels on one side of the traveling crane

T1c

0,05.(7000 800)

195daN

2

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

T n.nc .T1c . yi

In which :

n =1,1 ( load factor)

nc = 0,85 ( conbination factor)

2, 233

T n.nc .T1c . yi 407,132daN

3.Design purlin

3.1 Design hot rolled purlin

C12 shape purlin

Purlin and bracing layout

Properties of C12 purlin

Type of

section

C12

hxg

(mm)

120

bxg

(mm)

52

Ix

(cm4)

340

Iy

(cm4)

31,2

Wx

(cm3)

50,6

Wy

(cm3)

8,52

G

(daN/m)

10,4

a, The load distribute on purlins cause by dead load , live load and selfweight of purlins.

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

q ( p .n p

c

c

g cladding

.n

cos

NATIONAL UNIVERSITY OF

).d g cpurlin .ng

Where

g = 8(daN/m ) : is the self weight of roof elements;

pc = 30 (daN/m2): is the roof live load;

d: is the spacing between purlin centers projected in the ground plan

d = 1,5cos = 1,5cos10 = 1.477(m)

ng; np is the load factors, ng = 1.1 v np = 1.3

g cpurlin 10, 4(daN / m)

: is the self weight of purlin

q c (30

Un-factored load (standard load)

q (30.1,3

Factored load( design load)

8

).1, 477 10, 4 66, 72( daN / m)

cos100

8.1,1

).1, 477 10, 4.1,1 82, 25(daN / m)

cos100

Un-factored load in the x direction and the y direction

qxc q c .sin 11,585daN / m

q cy q c .cos 65, 703daN / m

Factored load in the x direction and the y direction

qx q .sin 14, 283daN / m

q y q .cos 81, 002daN / m

Using wire ropes 18 brace at midspan position purlins.

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

Fig 2.0Analytical model for roof purlin systems

The maximum bending moment :

Mx

My

q y .B 2

8

70, 02.62

315, 09(daN .m)

8

qx .B 2 12,38.62

13,93(daN .m)

32

32

+ Check strength condition follow formula :

x y

Mx My

f . c

Wx Wy

315, 09.100 12,38.100

498, 08(daN / cm2 ) 2100daN / cm 2

77,8

13,3

+ Check the deflection of purlins

2

x

y

B

B

B

B

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

Deflection allowed of purlins under cladding

NATIONAL UNIVERSITY OF

1

B 200

In case of using a bracing purlin at mid-span, need to check the deflection at the mid-span point

(Dy max) and at the point is about z =0,21B=1,26m distance from the tip of purlin.

The relative deflection the mid-span point in the y direction

y

B

5.q cy .B3

384.E.I x

5.57, 47.10 26003

1

1,558.103

6

348.2,1.10 .545

200

The relative deflection at the point is about z =0,21B=1,26m distance from the tip of purlin.

x

qxc .B3

10,3.102.6003

6, 24.10 5

6

B 2954.E.I y 2954.2,1.10 .57,5

y

B

3,1.q cy .B 3

384.E.I x

3,1.57, 47.102.6003

8, 76.104

384.2,1.106.545

1

(6, 24.105 )2 (8, 76.104 )2 8, 78.104

B

200

b, Wind load apply on purlins

The wind load transmit to purlin include dead load and wind

Factored wind load :

q y ,wind Ce .Wo .k .n.

d

d

0,9.( g mc .

g cpurlin ).cos

cos

cos

q y ,wind 0,8.125.1, 082.1, 2.

1, 477

1, 477

0,9.(8.

13,3).cos100 172,31(daN / m)

0

cos10

cos100

Standard wind load

q cy ,wind Ce .Wo .k .

d

d

0,9.( g mc .

g cpurlin ).cos

cos

cos

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

q cy ,wind 0,8.125.1, 082.

NATIONAL UNIVERSITY OF

1, 477

1, 477

0,9.(8.

13,3).cos100 139,85(daN / m)

0

0

cos10

cos10

Dead load in the x direction :

qx 0,9.( g mc .

0,9.(8.

d

g cpurlin ).sin

cos

1,182

13,3).sin100 3,58(daN / m)

0

cos10

Check strength condition :

M wind

M qx

q y ,wind .B 2

8

135,54.6 2

609,93(daN .m)

8

qx .B 2 3,58.6 2

4, 03( daN .m)

32

32

M wind M qx 609,93.102 4, 03.10 2

814, 27 2100daN / cm 2

Wx

Wy

77,8

13,3

Check deflection of the purlin :

y ,wind

B

3,1.q cy ,wind .B 3

384.E.I x

3,1.109,57.10 2.6003

1, 67.103 1/ 200

6

384.2,1.10 .545

3.2 Design cold-formed shapes purlin

+ Vertical factored load (excluding selfweight of purlin) :

g mc .n

8.1,1

q=(p .n p

).d (30.1,3

).1,182 56, 65( daN / m)

cos

cos100

c

+ Wind factored load ( excluding self-weight of purlin )

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

d

d

0,9.( g c .

).cos

cos

cos

1, 477

1, 477

0, 7.125.1, 081.1, 2.

0,9.(8.

).cos100 127,59( daN / m)

0

0

cos10

cos10

q y ,wind =Ce .Wo .k .n.

Choosing the purlin follow wind loads qwind=1,276 kN/m (direction out of the roof ,the length of

bay B = 6000 mm) and in case of using a bracing purlin at midspan

,

looking up table 3.3 => Purlin Z20019, bearing capacity is 1,68(KN/m)

5.Check for selected cross-sections

5.1 Check for cross-section of column

5.1.1 Properties of the cross-section

The maximum internal forces in the columns re at the connection between the column and

foundation.

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

Table 5.1 Internal forces

characteristics

M (daN.m) N (daN)

M max , Ntu , Vtu

Combine 1

N max , M tu , Vtu

Combine 2

40853,58

-11012,1

7112,51

23378,92

-24491,6

5590,43

-56178,9

-7023,1

-11095,8

M max , Ntu , Vtu

Combine 3

V (daN)

Using CCT34 steel : f = 2100 daN/cm2

E = 2.1x106daN/cm2

Table 5.2 The dimension of cross-section (mm)

Top flange

H

800

Web

bottom flange

bf

tf

hw

tw

bf

tf

340

14

772

10

340

14

Table 5.3 geometric properties of the cross section

Jx

Wx

rx

Jy

Wy

ry

(cm4)

(cm3)

(cm)

(cm4)

(cm3)

(cm)

(cm2)

32.79

9177.37

539.85

7.926

172.4

185392.63 4634.82

The length of column :

Lx .H

-In frame plane buckling :

GT

determine

base on :

b.I c

H .I xa

( b = 15 m the half of length of rafter

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

4

I c 185392.63cm 4 I rafter 57578.68cm

,

, H=10,46 m)

GT

b.I c

H .I xa

15.575m

4.

1.489

Lx =>.H

617

=>

- Out of frame plane buckling : Ly The distance between two points at two adjacent columns

which bracing that columns ( the distance between two points which prevent displacements of

two adjacent columns)

Ly =5m

5.1.2 Check for condition about slenderness of the columns

The column slenderness ratio:

Lx

47, 495

rx

Ly

ry

68,53

,

mnh quy c:

x x

f

1,502

E

y y

f

2,167

E

,

The slenderness limit:

180 60.

N

e . A. f . c

180 60.0,5 150

Max(x , y )

68,53 <

5.1.3 Check for strength condition

a, Combine 1

M= 40853,58 daN.m ; N = - 11012,1 daN ; V = 7112,51 daN

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

e M A

N Wx

The relative eccentricity ratio :

Af

x 5

Aw

13,8

47,5

0, 615

77, 2

, m >5 ,

1, 25

=>

me .m 17, 249 20

The reference eccentricity ratio :

condition)

( Dont need to check for strength

b, Combine 2

M (daN.m)

N(daN)

V(daN)

23378.92

-24491.56

5590.43

e M A

N Wx

The relative eccentricity ratio :

Af

x 5

Aw

3,55

54, 4

0,591

92,16

,m<5,

=>

(1, 75 0,1m) 0, 02 (5 m) (1, 75 0,1.3,55) 0, 02.(5 3,55).1,502 1,351

me .m 4, 798 20

The reference eccentricity ratio :

condition)

( Dont need to check for strength

c, Combine 3

M (daN.m)

N(daN)

V(daN)

-56178.86

-723.1

-11095.8

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

e M A

N Wx

The relative eccentricity ratio :

Af

x 5

Aw

288,988

54, 4

0,591

92,16

, m >5 ,

1, 25

=>

me .m 361, 235 20

The reference eccentricity ratio :

N M

f . c

An Wx

Check according to the condition following :

f . c

(

2100 daN/cm2)

1 1216,3

daN/cm2

2 1207,9

daN/cm2

Satisfy all

5.1.3 Check for overall buckling in frame plane buckling

a, Combine 1

me 20

The reduction factor for column buckling

x 1,502

me 17, 249

TCXDVN 338:2005 (

and

e 0.081

=>

N

788,58daN / cm 2

e . A

f . c 2100daN / cm 2

<

a, Combine 2

,which is determined from table D10

)

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

me 20

The reduction factor for column buckling

x 1,502

me 4, 798

TCXDVN 338:2005 (

,which is determined from table D10

and

e 0.246

=>

N

577, 49daN / cm2

e . A

f . c 2100daN / cm 2

<

C, combine 3

M

f . c

b .Wc

me 20

Check according to the condition :

b

is determined from appendix E TCXDVN 338:2005

2

L .t

a.t w3

8. o f . 1

3

h .b

b f .t f

fk f

=>

h fk

Where :

78,6cm ;

h fk

2

39,3cm ; Lo =5m

0,1 40

0,78 =>

From appendix E1 TCXDVN 338:2005

1,14 1 1,14.(2, 25 0.07. ) 2, 627

=>

2

=>

I h E

1 y .

I x Lo

f

b 0, 68 0, 211 1, 24

3,329 > 0,85 Therefore

b

Choose

b .Wc

f . c 2100daN / cm 2

1212,106 <

5.1.4 Check for overall buckling out of frame plane buckling

>1

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

N

f . c

c. y . A

Coefficient c to account for the effect of the moment Mx (applied in the frame plane ) on the

column buckling out of frame plane buckling

a, Combine 1

M= 40853,58 daN.m ; N = - 11012,1 daN ; V = 7112,51 daN

The maximum bending moment at the middle segment 1/3 length of the column Mx =

292.753kN.m > M/2

Choose Mx = 29275,3 daN.m

mx

Mx A

N Wx

9,89 5 => 5< mx<10

c c5 (2 0.2mx ) c10 (0.2mx 1)

=>

0,141

c10

c5

0, 092

1 .mx

(

c. y . A

1 mx y

b

0,143

)

f . c 2100daN / cm 2

742,584 daN/cm2 <

a, Combine 2

The maximum bending moment at the middle segment 1/3 length of the column Mx = 14059,7

daN.cm >M/2 => Choose Mx = 14059,7 daN.cm

mx

Mx A

N Wx

2,135 => mx< 5

1 .mx

0, 757 1

0,382 (

;

Table 16 TCXDVN 338-2005)

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

c. y . A

NATIONAL UNIVERSITY OF

f . c 2100daN / cm 2

611,346 daN/cm2 <

( Satisfy )

a, Combine 3

The maximum bending moment at the middle segment 1/3 length of the column

Mx M / 2

Mx = =>

mx

Choose Mx = 381.7719 daN.cm

Mx A

N Wx

196,386 => mx >10

1 mx y

b

Ly

ry

0,0065

f 210 N / mm 2

68,53 ;

Table D.8 TCXDVN 338-2005 =>

c. y . A

f . c 2100daN / cm 2

829,068 daN/cm2 <

( Satisfy )

5.1.6 Check for local flange buckling of the column

b0f b0

t f t

Check follows :

b0 f

Where :

b f tw

2

b0f

tf

16,5cm =>

min(x , y )

1,502 =>

0.8 4

11,786

Choose

1,499

b

0,782;

1)

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

b0f

E

(0.36 0.1 )

f

t f

NATIONAL UNIVERSITY OF

b0f

tf

16,134 >

(satisfy)

5.1.7 Check for local web buckling of the column

local web buckling condition :

hw hw

tw tw

hw

tw

;

77,2

+) Combine 1 : M= 40853,58 daN.m ; N = - 11012,1 daN ; V = 7112,51 daN

me < 20

Total buckling of the column denpends on total buckling out of the frame plane buckling, so

need to compute coefficient and average shear stress

N M

y1

A Ix

y1 y2

986,208 daN/cm2 (

hw

38,6 cm )

N M

y2

A Ix

-714,99 daN/cm2

tw .hw

727,705 daN/cm2

1.4(2 1)

1,725 > 1 ;

2,531

hw

(2 1) E

4, 35

(2 2 4 2

tw

=>

3,8

132,502

E

120,67 > 132,502 => choose

hw

tw

132,502

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

hw hw

tw tw

the web doesnt local buckling

E

72,32

f

2,3

NATIONAL UNIVERSITY OF

<

hw

tw

Need ribbed stiffener for the column

+) Combine 2 similar to combine 1

+) Combine 3 : me > 20 Check for local web buckling condition same as structural bending :

hw

tw

3,8

120,67 >

2,3

77,2

hw

tw

E

72,32

f

<

Need ribbed stiffener for the column

5.1.8 Calculation of fillet weld connections between flange and web of the column

The fillet weld connections resist shear forces V which are caused by buckling. Pick combine

internal forces which contain maximum shear force Vmax

hf

VV .S f

2.( f w )min .I x . c

The height of weld lines :

VV

11095,8 daN ;

1

S f b f .t f . h fx

2

1870,68 cm3

( . f w ) min

The strength of weld lines when using electrode N42 :

h f 0, 444cm

=>

h f 6mm

=> choose

1260

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

5.2 Check for cross-sections of rafter

5.2.1 Check for the cross-section of rafter which is at the join between column and rafter

Internal force :

M (daN.m)

N (daN)

V (daN)

-31323

-6195

-6378

Table 5.2 The dimension of cross-section (mm)

H

800

Top flange

Web

bottom flange

bf

tf

hw

tw

bf

tf

340

12

776

10

340

12

Table 5.3 geometric properties of the cross section

Jx

Wx

Jy

Wy

Sx

Sfx

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

(cm4)

(cm3)

(cm4)

(cm3)

(cm3)

(cm3)

(cm2)

129932.658

3248.32

5406.05

318

2360.24

1607.02

144.6

The maximum internal forces

The length of rafter : - in frame plane lx = 30m

- Out of frame plane ly = 1,477 m ( the distance between two adjecient

purlins)

mx

e M

A

N Wx

The relative eccentricity ratio :

49,5cm

b, check for strength condition :

+) Check for the normal stress resistance of the cross-section with axial force and bending

moment about the x axis is required as follow :

N M

f . c

An Wxn

N M

An Wxn

f . c 2100daN / cm 2

-1007,126 daN/cm2 => II<

( The cross sectional area with considering the reduction An =144,6cm2

The elastic section modulus about the x with considering reduction Wx= 3248.32 cm3 )

+) Check for the normal stress resistance of the cross-section with shear force

max

V .S x

I x .tw

max

-115,857 daN/cm2 =>

f v . c 1200daN / cm 2

<

+) Check for the normal stress resistance of the cross-section with axial force bending and shear

force

N M hw

.

A Wx h

-978,198 daN/cm2

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

V .S xf

I x .tw

-78,884 daN/cm2

td 12 3 12

1,15 f c

2

=>

987,69 daN/cm

2415 daN/cm2

<

c, Check for total buckling of the rafter at this cross-section.

lo

bf

lo

= 1,477 =>

4,344

bf

bf bf

lo

0.41

0.0032

(0.73

0.016

)

b

tf

t f h fk

bf

tf

f

19,607

h fk

28,33 ;

78,8 cm )

d, Check for local buckling of flange and web of the rafter.

b0f

E

0,5

tf

f

- The flange of rafter :

b0f

b f tw

2

b0f

tf

165mm ;

0,5

13,75 <

15,811

hw

E

3, 2

tw

f

- The web of rafter :

hw

tw

3, 2

77,6 <

101,193

5.2.2 Check for the unchanged cross-section of rafter

Internal forces :

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

M (daN.m)

N (daN)

V (daN)

11444,43

1651,58

1278,42

Table 5.2 The dimension of cross-section (mm)

H

500

Top flange

Web

bottom flange

bf

tf

hw

tw

bf

tf

340

12

476

10

340

12

Table 5.3 geometric properties of the cross section

Jx

Wx

Jy

Wy

Sx

Sfx

(cm4)

(cm3)

(cm4)

(cm3)

(cm3)

(cm3)

(cm2)

462.634

1278.74

995.52

129.2

57578.68 2303.147 7864.77

mx

The relative eccentricity ratio :

e M A

N Wx

38,872 cm

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

b, check for strength condition :

+) Check for the normal stress resistance of the cross-section with axial force and bending

moment about the x axis is required as follow :

N M

f . c

An Wxn

N M

An Wxn

f . c 2100daN / cm 2

509,687 daN/cm2 <

( the cross sectional area with considering the reduction An = 129,2 cm2

The elastic section modulus about the x with considering reduction Wx= 2959,646 cm3 )

+) Check for the normal stress resistance of the cross-section with shear force

max

V .S x

I x .tw

f . c 2100daN / cm 2

28,392 daN/cm2 <

+) Check for the normal stress resistance of the cross-section with axial force bending and shear

force

N M hw

.

A Wx h

485,836 daN/cm2

V .S xf

1

I x .tw

22,104 daN/cm2

td 12 3 12

=>

1,15 f c

2

487,342 daN/cm <

2415 daN/cm2

5.2.3 Calculation of fillet weld connections between flange and web of the rafter

hf

The height of weld lines :

VV .S f

2.( f w )min .I x . c

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

VV

3493 daN ;

NATIONAL UNIVERSITY OF

1

S f b f .t f . h fx

2

995,52 cm3

( . f w ) min

The strength of weld lines when using electrode N42 :

1260

h f 0, 024cm

=>

h f 6mm

=> choose

5.3 Check for displacement at the tip of column

The displacement must satisty the following condition :

H

300

- The displacement caused by combination of dead load and wind load:

0, 00379 0.0402

0, 0301

1,1

1, 2

m < 0,0349m

- The displacement caused by combination of dead load and crane load:

0, 00379 0.00118

0, 0045

1,1

1,1

2

m>

< 0,0349m

- The displacement caused by combination of dead load ,wind load and crane load:

0, 00379

0, 0402 0, 0024

0,5

0, 0155

1,1

1, 2

1,1

< 0,0349m

6. Calculation for some details of frame

6.1. Fixed connection between column and foundation

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

6.1.1 Internal force for calculation

The couple of internal forces has Nmax and Mtu , Vtu

N1 = - 24492 daN ; M1 = 23379 daN.m ; V1 = 5590 daN

M

The couple of internal force has

max

and Ntu , Vtu

N2 = -723 daN ; M2 = -56179 daN.m ; Q2 = -11096 daN

a) Calculate the base plate

- Assuming that the width of base plate is wider 20 cm that of column

So, the width of base plate : B = bc + 20 = 34 + 20 = 54 (cm)

- The length of base plate is calculated according to following formular :

N

N

6.M

(

)2

2.B. Rb ,loc

2.B. Rb ,loc

B. Rb ,loc

With, Rb,loc : local compressive strength of concrete used for foundation

Rb ,loc .b .Rb

We use B15 grade concrete :

= 1 ; Rb = 85 (daN/cm2) ; Rbt = 7,5 (daN/cm2)

Am

1,5

Abd

b

We choose temporarily

= 1,2

Rb ,loc .b .Rb

= 1.1,2.85 = 102 (daN/m2)

: the factor depend on the feature of distributing loads ; because of ununiform distributed load ,

so = 0,75

- For the first couple of internal force have N1 = - 24492 daN ; M1 = 23379 daN.m ; V1 = 5590

daN

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

24492

24492

6.23379.102

(

)2

61,31(cm)

2.54.0, 75.102

2.54.0, 75.102

54.0, 75.102

We have :

For the second couple of internal force have N2 = -723 daN ; M2 = -56179 daN.m ; Q2 = -11096

daN

L

723

723

6.56179.102

(

)2

90, 24(cm)

2.54.0,75.102

2.54.0, 75.102

54.0, 75.102

We choose L = 100 cm

We choose the second couple of internal force to calculate stress at base plate

max

min

N 6.M

723 6.56179.10 2

62,3( daN / cm2 ) .Rb.loc 76,5

B.L B.L2 54.100

54.1002

N 6.M

723 6.56179.102

62,5(daN / cm2 )

2

2

B.L B.L 54.100

54.100

min

The distance from the point having

y1 100.

0

to the point having

62,5

50,1(cm)

62,5 62,3

We choose the thickness of base beam is the same thickness of the web of column tdd = 12 mm.

The thickness of stiffener tsd = 10 mm ; the distance between stiffeners is 110 mm . The detail

dimension is showed below :

In order to determine the thickness of base plate, we determine the maximum stress at the

boundary of each slab :

c 62,5.

- Stress at the edge of column :

40.1

50

50.1

(daN/cm2)

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

- Calculate bending moment in parts of base plate

* Slab 1 ( a slab supported by three position) :

b 0,113

We have : b2/a2 = 26,4/26 = 1,015

M b . .d 2 0,113.50.262 3819, 4

(daN.cm/cm)

* Slab 2 ( a slap supported by three position) :

b 0,085

We have : b2/a2 = 8,8/ 13= 0,677

M b . .d 2 0, 085.62,5.132 895,5

(daN.cm/cm)

* Slab 2 ( a slap supported by two position) :

b2 8,8.

a2 8,8 12,5 15, 2

2

We have :

12,5

7, 23

15, 2

(cm) ;

b2 7, 23

0, 475

a2 15.2

b 0,5

we calculate as console with d = b2 = 7,2

M b . .d 2 0,5.62,5.7, 2 2 1620

(daN.cm/cm)

So , we choose Mmax = 3819,4 (daN.cm/cm) to determine the thickness of base plate

tbd

6.M

6.3819, 4

3,38

f . c

2000.1

(cm) = 33,8 (mm)

We select tbd = 35 (mm)

b) Calculate base beam

Base beam and the flange of column is welded each other. The thickness of the flange of

column is 16 mm, so the minimum height of weld line hfmin = 6 mm, so we choose hf = 7 mm.

The height of base beam according to condition of force transportation

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

N dd

N M

2 hc

hc = 78,6 cm : the distance between the center of two flange of frame

N dd

N M 723 5617900

71113

2 hc

2

78, 6

(daN)

hdd

N dd

71113

1

1 40,3

2.( . w ).h f

2.1260.0, 7

(mm)

. w

We have (

) = 0,7.1800 =1260 (dan/cm2)

We choose hdd = 45 mm

Consider the loading causing bending as uniform one and having the value as following :

q 62,5.(10 26 / 2) 1437,5

(daN/cm)

Base beam is calculated similiarly to console fixed at the flange of column and had span :

L = (54 34 )/2 = 10 (cm)

Bending momment of base beam :

dd

- Checking bend of beam :

Satisfy the condition

c) Calculate bolts

* Determine bolts :

ql 2 1437,5.102

M

71875

2

2

(daN.cm

6.M dd 6.71875

177

tdd hdd2

1, 2.452

(daN/cm2) < 2100 daN/cm2

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

In order to determine bolt, we choose the couple of internal force that cause maximum

tensile force between base plate and foundation. From force combination table we have the most

dangerous force couple : N = -723 daN ; M = -56179 daN.m ; V = -11096 daN

With : Ntt = -8152,6 daN ; Nht = 7429,5 daN ; Mtt = 11841 daN.m ; Mht = -68020 daN.m

Internal force to determine bolt :

N

N tt

8152, 6

.0,9 N ht

.0,9 7429,5 759, 2

1,1

1,1

daN

M

M tt

11841

.0,9 M ht

.0,9 68020 58332

1,1

1,1

daN.m

Stress under base plate :

max

min

N 6.M 759, 2 6.58332.100

64, 67(daN / cm 2 )

2

2

B.L B.L

54.100

54.100

N 6.M 759, 2 6. 58332.100

64,95( daN / cm 2 )

B.L B.L2 54.100

54.100 2

max

The distance between the edge of base plate ( the point having

y2 100.

) and the point having

64.67

49,9

64, 67 64,95

(cm)

The distance from point that the axial force put on to the center of compressive stress diagram

a

L y1 100 49, 9

33, 4(cm)

2 3

2

3

We put bolts at the distance of 5cm from the edge of base plate, so the distance from bolt to the

center of compressive stress diagram : y = 5 + 100/2 + 33,4 = 88,4 (cm)

N bl

Tensile force apply on bolts :

5833200 759, 2.33, 4

66273, 7

88, 4

(daN)

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

We use type of bolt MnSi with fba = 1900 daN/cm2 ; required area of bolt : Abl = 66273,7/1900 =

56mm

2

( Abl = 41 cm2 )

34,4 (cm ) We choose 2 bolts with

d) Calculate stiffener supporting bolts

Choose the thickness of stiffener supporting bolts : tsd = 10 mm ; the height of supporting

stiffener equal to the height of base beam hsd = hdd = 45 mm

Bending moment caused by tensile force of bolt ( the distance between the axis of bolt and

base beam is 13,8 cm)

M = 66273,7.13,8 = 914577 (daN.cm)

+) Check the thickness of stiffener supporting bolts :

t sd

6.( M / 3) 2.914577

2

0, 43

hsd2 . f . c

45 .2100

(cm)

So, with tsd = 1 cm sastify condition

+) Check weld connection between stiffener supporting bolts and base beam :

We choose the height of weld line hf = 9 mm ; there are three stiffener supporting bolts ,

one is right in the middle ane the others is put at two side.Firstly , we welded middle stiffener

with two weld line and then we weld two other stiffener with two weld line. However the

distance between stiffeners is near that caused difficulty in welding duration, so for more safe ,

we can consider weld lines is external weld line of two side stiffener and two weld lines of

middle stiffener that is subjected force.

We calculate the section modulus and the area of four weld line as following :

Wwf 4. f .h f .

(hsd 1) 2

(45 1) 2

4.0, 7.0,9.

813,12

6

6

(cm3)

Awf 4. f .h f .(hsd 1) 4.0, 7.0,9.(45 1) 110,88

(cm2)

Stress caused external force in the weld lines :

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

sd (

NATIONAL UNIVERSITY OF

M 2 N bl 2

914577 2 66273, 7 2

) (

) (

) (

) 1273, 7

Wwf

Awf

813,12

110,88

c

2

(daN/cm ) < fwf.

= 1800

daN/cm

The weld line satisfy condition

+) Check steel plate what e-cu of bolt is put on :

Because the tensile force in bolt is quite large, so we use two profile steel C12 ( with Wx =

2.50,6 cm3) put on two stiffener supporting bolts. The distance between two the stiffener is l =

140 mm = 14 cm

Bending moment caused by tensile force of bolt :

M max

3.N bl .l 3.66273, 7.14

173968,5

16

16

(daN.cm)

M max 173968,5

1719

WX

2.50, 6

(daN/cm2) < 2100 (daN/cm2)

Stress in the profile :

satisfy

d) Calculate partition stiffener

Partition stiffener works as console and fix at the web of column with span l = 26,4 cm. The

partition stiffener is subjected to compressive stress from base plate. We can consider the stress is

uniform and has value that equal to the value at the centre of bn. The distance from this point

to the outer edge of base plate is : 10 + 26/2 = 23 cm

100 50,1 23

33, 7

62,5

100 50,1

(daN/cm2)

We have :

q 33, 7.(100 50,1 23) 906,53

The load apply on partition :

M

(daN/cm)

906,53.26, 4 2

315987, 6

2

(daN.cm)

V 906,53.26, 4 23932, 4

(daN)

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

hsn

6.M

6.315987, 6

30

tsn . f . c

1.2100.1

- The height of partition stiffener :

(mm)

Choose hsn = 35 mm

- Check two weld line connecting partition to the web of column. We choose the height of

weld line hf = 8 mm ; lw = 35 -1 = 34 mm

Stress appear in weld line :

sd (

M

V

6.315987, 6 2

23932, 4 2

)2 (

)2 (

) (

) 1593,5( daN / cm 2 ) 1800(daN / cm2 )

2

2

2 f .h f .lw

2 f .h f .lw

2.0, 7.0,8.34

2.0, 7.0,8.34

Satisfy condition

e) Calculate weld line connecting column to base plate

According to TCXDVN338:2005 ; the minimum height of weld line hfmin = 9 mm when the

maximum thickness of element is 35 mm

- The maximum height of weld line according to perimeter the flange of column with base plate

:

hfmax = 1,2.tmin = 1,2.16 = 19,2 mm

- The maximum height of weld line according to perimeter the web of column with base plate :

hfmax = 1,2.tmax = 1,2.12 = 14,4 mm

We choose the height of weld line : hf =10 mm

Ax = 2.0,7.1(34+31) + 2.0,7.1.75,2 = 196,28 (cm2)

1. 75,22

Iw = 2.0,7.1.(34.40,52 + 31.38,12) + 2.0,7.

12

Wx

I x .2 141735, 6.2

3457

hc 2

80 2

(cm3)

The couple of internal force to calculate weld line :

N2 = -723 daN ; M2 = -56179 daN.m ; Q2 = -11096 daN

= 141735,6 (cm4)

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

hl (

NATIONAL UNIVERSITY OF

M N 2

Q

56179.100 723 2 11096 2

) ( )2 (

) (

) 1629,7

Wx Ax

Ax

3457

196, 28

196, 28

(daN/cm2)

hl 1800

(daN/cm2)

So

satisfy condition

6.2 Calculate crane runway girlder and console

Choose crane runway girder has the dimension of cross section as following :

hdct = 0,65 (m) ; bf = 0,3 (m) ; tf = 1,4 cm ; tw = 1 cm

Because the crane capacity is not large (Q = 7T) ; so we choose the dimension of section of

brake beam is the top flange of crane runway girder. We consider this beam as simple beam put

on console . To connect the top flange of the beam to the flange of column, we use the angle steel

L90X9 ; and steel plate 170x120x10.

a) Check crane runway girder according to strength condition :

- Internal force is caused vertical pressure

With simple beam , internal force is calculated based on Vinkple principal . It mean that

the maximum moment will happen if combination of all forces applying on the beam R is

symmetric through the middle beam point with force P that be closest to , maximum moment

appear at the point that put on.

Base on diagram of loading , we calculate maximum moment in beam as following :

b) console calculation

distance e between rail centroid and inner column edge e = hc = 100 80 =20 cm

-

Shear force and bending moment in fix cross section

Mv = (Dmax + Gdct).e ; M = (14657+1080)x20 =314740 . daN.cm

Vv = (Dmax + Gdct ); V = 14657+1080= 15737 daN

Select preliminary wing thickness tf=12 mm, the required thickness of console web:

tw

Dmax Gdct

15737

0,14

(b 2t f ). f c . c (30 2.1, 2).3460.1

dct

f

cm

Choose tw = 8 mm

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

Choose the heigh of console at a point Dmax put on h = 40cm.

Select preliminary angle between lower console flange and horizontal direction = 150, hence

console fix section heigh is:

hdv= 40+ 20.tg150 = 45,4 cm

we choose hdv = 50 cm

The required flange area of console :

M v .hdv tw .hdv3 2

314740.50 0,8.503 2

A (

). 2 (

). 2 0, 67

f . c

12 hdv

2100.1

12

hdv

yc

f

(cm2)

select console flange: bf x tf = 30x1.2 cm; Af = 36 cm2 > -0,67 cm2

* Check the selected cross section (neglect console selfweight)

The cross section of console fixed with column

Bng 6.1.geometry properties of fix section

W

x

A

Sx

Sf

Ix

(cm4)

(cm3)

(cm2)

(cm3)

(cm3)

50064,6 2002,6

110,1

1105

878,4

M v 314740

157, 2

Wx 2002, 6

daN/cm2 < 2100 daN/cm2

Vv .S x 15737.1105

434, 2

I x .tw 50064, 6.0,8

daN/cm2 < 1200 daN/cm2

checking equivalent stress :

M v hw 314740 47, 6

.

.

149, 6

Wx h 2002, 6 50

daN/cm2

Vv .S f

I x .t w

15737.878, 4

345,1

50064, 6.0,8

daN/cm2

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

td 12 3. 12 149, 62 345,12 376,1

daN/cm2 < 1,15.2100 = 2415 daN/cm2

-

checking the shear stress at minor section

Bng 6.2. geometry properties of console minor section at the point the

runway girlder put on

Ix

Wx

A

Sx

Sf

(cm4)

30658,4

(cm3)

1532,5

(cm2)

102.1

(cm3)

839,8

(cm3)

698,4

Vv .S x 15737.839,8

538,8

I x .t w 30658, 4.0,8

daN/cm2 < 1200 daN/cm2

- Check the local stability :

bf

30

2,1.106

25

31, 6

t f 1, 2

2100

+ the flange :

stability condition

; so the flange satisfy the local

hw 47, 6

2,1.106

59,5 2, 2.

69, 6

tw

0,8

2100

+ the web :

stability condition

; so the web satisfy the local

- The heigh of flange- web weld connection :

hf

Vv .S f

2.( . f w ) min .I x . c

15737.698, 4

0,142

2.1.1260.30658, 4.1

(cm)

We choose hf = 6 mm

* calculate welding link between console and column flange

We choose the height of the welding connection hf = 6 mm ; we have :

Aw = 2.0,7.0,6.(29 + 26 + 46) = 84,84 (cm2)

crane

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

Iw = 2.0,7.(29.0,6.252 + 26.0,6.23,82 )+ (0,6.463)/12 = 34489,6 (cm4)

Ww

Ix

34489, 6

1379, 6

h/2

25

hl (

(cm3)

M 2

V

314740 2 15737 2

) ( )2 (

) (

) 294,83

Wx

Ax

1379, 6

84,84

hl

= 294,83 daN/cm2 < 1800 daN/cm2

So ,

satisfy condition

Check equivalent stress in column web

In column web, position connected to console flange, is subjected horizontal force. it will

appear complex stress state. therefore check the equivalent stresses according to the following

formula :

td 3. 1,15. f . c

2

M

N

Wcot Acot

with

(V H )

Ab

The internal force of the column at position connecting to console :

M = - 22462 daN.m ; N = - 22488 daN ; V = 5590 (daN)

Wcot = 4634,8 (cm3) - elastic column section modulus

.

Acot = 172,4 (cm2) ; Ab = 77,2 (cm2) - respectively the area of cross section of whole column

and the web of column.

H

- Horizontal force due to console effect on column :

314740

6294,8

50

M

N

22462.100 22488

615,9

Wcot Acot

4634,8

172, 4

(daN/cm2)

(V H ) 5590 6294,8

178,3

Ab

77, 2

(daN/cm2)

daN

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

td 2 3. 2 615,9 2 3.178,32 689

(daN/cm2) < 1,15.2100 = 2415 daN/cm2

* The dimension of stiffener

- stiffen for console

The height of the stiffener : hs = h 2.tf = 40 2.1,2 = 37,6 (cm)

bs

The width :

hs

376

40

40 52,53

30

30

(mm) we choose bs = 12 cm

The thickness of the stiffener is chosen based on condition of local buckling of stiffener

bs

E

0,5.

ts

f

ts

12

2100

.

0, 753

0, 5 2,1.106

; so

Choose ts = 0,8 cm

- stiffen for the web of column :

The height of the stiffener : hs = hwc = 76,8 cm

bs

The width :

hs

768

40

40 65, 6

30

30

(mm) we

choose bs = (bf tw)/2= (34-1,2)/=16,4

ts

The thickness :

16, 4

2100

.

1

0,5 2,1.106

,1 (cm) We choose ts = 1,2 cm

6.3 Design the connection between column and rafter

The maximum internal forces combinations :

M = -31323,4 daN.m ; N = -7351,2 daN ; V = 4993,8 daN

M = 26289 daN.m ; N = 3620daN ; V = -3500daN

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

The combine :

M = -31323,4 daN.m ; N = -7351,2 daN ; V = 4993,8 daN

Regard as the connection rotates around edge bolt row (on the right) :

+) Design and check :

Choose 12 bolts ,the diameter of each bolt is 20mm.Bolts of grade 8.8

Abn

The actual area of each bolt :

Abl

2

2,45 cm ; the area of each bolt

f tb 4000daN / cm 2

The tensile strength

3,14 cm2

f vb 3200daN / cm2

, The shear strength

- Check for the tensile resistance of bolts :

h1 78cm

Neglect bolt rows near center of rotation , (

N b max

M .h1

3132340.78

2

2. hi 2.(782 662 542 )

h2 66cm h3 54cm

;

;

):

9146,55 daN

N tb Abn . ftb

The tensile strength of bolts :

- Check for the shear resistance of bolts :

N b max

9800daN >

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

N vb

Shear force applies to one bolt :

4993,8

416,15daN

12

N vb 3,14.0,9.3200 9043, 2daN

The shear strength of the bolt :

N vb

>

+) Calculation of joint plates:

-The thickness of joint plates :

N2

N1.h2 9146,55.66

h1

78

7739,38 daN

N3

N1.h3 9146,55.54

h1

78

6332,23 daN

tbb 1,1

g. N max

2.(bbb g ). f

1,1

14.2.9146,55

2.(34 14).2100

1,24cm

tbb 1,1

g . N i

2.(bbb g ). f

1,1

14.2.(9146,55 7739,38 6332, 23)

2.(34 14).2100

2 cm

tbb

Choose

2 cm

Combine : M = 26289 daN.m ; N = 3620daN ; V = -3500daN

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

Regard as the connection rotates around edge bolt row (on the left) :

N b max

( M N .e).h1 (2628900 3620.45,5).78

2. hi2

2.(782 662 542 )

N tb

8157,44 daN<

b, Calculation of fillet weld connections between joint plates and column (rafter)

Follow table 43 TCXDVN 338 -2005 : the minimum height of fillet weld : 7mm

The maximum height of fillet weld between joint plates and the flange of column:

1,2tmin = 1,2tf = 14,4 mm => choose 8mm

The maximum height of fillet weld between joint plates and the web of column:

1,2tmin = 1,2tw = 12 mm => choose 8mm

AW 2.0,7.0,8(33 31) 2.0,7.0,8.76 156.8cm4

cm2

3

0,8.76

IW 2.0, 7(33.0,8.40 31.0,8.38, 4

) 151303,82

12

2

WW

2.I w

151303,82

1854, 2

hc 2.0,8 80 2.0,8

cm3

With the internal force combination at this :

M = -31323,4 daN.m ; N = -7351,2 daN ; V = 4993,8 daN

cm4

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

2

N

V

hl

WW AW A W

NATIONAL UNIVERSITY OF

31323, 4.100 7351, 2 2 4993,8 2

) (

) 1736, 5daN / cm 2 1800daN / cm2

1854, 2

156,8

156,8

-Calculating the welding line between butt plate and column, rafter.

We choose : height of weld is 8mm

Axial force N and moment applied on the welding line of flange

Nc

N

M

7351, 2 31323, 4.100

7650, 65

2 hTK C

2

788

daN

Nc

7650, 65

147,13

h f (b f 1) h f (b f t w 1) 0,8.33 0,8.32

daN/cm2<0,7.1800=1260

daN/cm2

Welding line of column web subjected to shear force which is : V=4993,8 daN

tw

Stress of welding line on web:

It can be capable bearing!

6.4 Connection details of rafter.

4993,8

41,1daN / cm 2 1260 daN / cm 2

2.0,8.76

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

710

500

476

360

130

115

45

165 10 165

115

45 130

8M20

95 75 75 95

340

16

16

The Internal force of cross-section 1-1:

M=105,52 (KN.m)= 10552 (daN.m) N= 43,22 ( KN) =4322(daN) V= 26,51 (KN)=2651 (daN)

a, Interconnection Calculation according to conception 1:

+ Number of Bolts:

Choose 8 bolts with diameter is

20 ,kind of 8.8 and shown as the figure.

Net bolt area is Abn=3,14 (cm2), gross bolt area is Abl=2,45 (cm2), calculates tensile strength of

bolts ftb=4000 daN/cm2 and calculates shearing strength of bolts fvb=3200 daN/cm2

+ Check the pull of resistant bolts:

Safely, Bolts is viewed as rotate outside bolt row in cross-section of rafter. The maximum force

at outside bolt row. ( y= 31 cm, h1=62 cm , h2=49 cm )

N b max

( M N . y ).h1 (1055200 4322.31).62

5944,95(daN )

2. h 2 i

2(622 492 )

Tensile Bearing capacity of bolts: [N]tb=Abn.ftb=2,45.4000=9800 (daN)

N b max 5944,95

Condition: [N]tb =9800 (daN) >

=

(daN) (satisfaction )

+ Shear force influence a bolt:

Nvb=2651/8=331,38 (daN)

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

Shear bear capacity of a bolt : [N]vb=3,14.0,9.3200=9043,2 (daN)

Condition: [N]vb=9043,2 (daN) > 331,38 (daN) (satisfaction )

Butt plate calculation.

+ The thickness of butt plate. Tension force of each bolt

N2

N1.h2 5944,95.49

4690,33

h1

62

(daN)

tbb 1,1

tbb 1,1

g. N Max

1,1

15.2.5944,95

1, 02cm

2(34 15).2100

g . N i

1,1

15.2.(5944,95 4690,33)

1,37cm

2(34 15).2100

2(bbb g ) f

2(bbb g ) f

For safety, We choose : tbb=1,6 cm

Check couple internal force:

M=114,44 (KNm) = 1144400 (daN.m), N=18,53 (KN) = 1853 (daN), V=12,79(KN)=1279 (daN)

The maximum force of a bolt at outside bolt row.

Nb max

( M N . y ).h1 (1144400 1853.31).62

6010, 76( daN )

2. h 2 i

2(622 492 )

Tensile Bearing capacity of bolts: [N]tb=Abn.ftb=2,45.4000=9800 (daN)

N b max

Condition: [N]tb =9800 (daN) >

6010, 76( daN )

=

(satisfaction )

The load applied on a bolt: Nvb=1279 /8=159,88 (daN)

Shear bear capacity of a bolt : [N]vb=3,14.0,9.3200=9043,2 (daN)

Condition: [N]vb=9043,2 (daN) > 159,88 (daN) (satisfaction )

b, Calculation of welding line for connecting between butt plate and rafter

According appendix 43 in TCVN 338:2005: The minimum height of automatic welding line is 5

mm when the maximum thickness of the butt plate was 16 mm.

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

The maximum height of welding line between the flange of rafter and the butt plate is:

1,2tmin=1,2tf=1,2.12=14,4 mm => we choose : 5mm

The maximum height of welding line between the web of rafter and the butt plate is:

1,2tmin=1,2tw = 1,2.10=12 mm=> we choose: 5 mm

Aw=2.0,7.0,5.(33+31) +2.0,7.0,5.45,6=76,72 (cm2 )

0,5.45,63

Iw=2.0,7(33.0,5.252 +31.0,5.23,32+

)=31749,3 cm4

12

Iw .2

31749,3 .2

=

=> Ww= h d+ 2.0,5 50+2.0,5

=1245,1 cm3

M=105,52 (KN.m)= 10552 (daN.m) N= 43,22 ( KN) =4322(daN) V= 26,51 (KN)=2651

(daN)

M

N 2

V 2

1055200 4322 2

2651 2

(

) (

) (

) (

) 904,5

Ww Aw

Aw

1245,1 76,72

76, 72

thl=

daN/cm2

<1800daN/cm2

The welding line was sufficient bearing capacity

6.5 The top of rafters.

The Internal forces at top of rafter.

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

110 32 110

130

115

45

165 10 165

115

45 130

710

500

476

360

8M20

16

16

95 75 75 95

340

M=86,39 (KN.m)= 8639 (daN.m) N= -41,63 ( KN) =-4163 (daN) V= 7,34 (KN)=734 (daN)

=> consider the following General coordinates ( OXY) : M=86,39 (KN.m)= 8639 (daN.m)

V= -4163.cos(80*)-734cos(10*)=-1445,75 (daN)

a, Bolt Calculation

+ Number of Bolts:

Choose 8 bolts with diameter is

20 ,kind of 8.8 and shown as the figure.

Net bolt area is Abn=3,14 (cm2), gross bolt area is Abl=2,45 (cm2), calculates tensile strength of

bolts ftb=4000 daN/cm2 and calculates shearing strength of bolts fvb=3200 daN/cm2

+ Check the pull of resistant bolts:

Safely, Bolts is viewed as rotate outside bolt row in cross-section of rafter. The maximum force

at outside bolt row. (y= 31cm, h1=62 cm , h2=49 cm)

N b max

( M ).h1 (863900).62

4288,37( daN )

2. h 2 i 2(622 492 )

Tensile Bearing capacity of bolts: [N]tb=Abn.ftb=2,45.4000=9800 (daN)

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

N b max

Condition: [N]tb =9800 (daN) >

4288,37

=

(daN) (satisfaction )

+ Shear force influence a bolt:

Nvb=1445,75 /8=180,72 (daN)

Shear bear capacity of a bolt : [N]vb=3,14.0,9.3200=9043,2 (daN)

Condition: [N]vb=9043,2 (daN) > 180,72 (daN) (satisfaction )

Butt plate calculation.

+ The thickness of butt plate. Tension force of each bolt

N2

N1.h2 4288,37.49

3389, 2

h1

62

(daN)

tbb 1,1

tbb 1,1

g . N Max

1,1

15.2.4288,37

0.87cm

2(34 15).2100

g . N i

1,1

15.2.(4288,37 3389, 2)

1, 2cm

2(34 15).2100

2(bbb g ) f

2(bbb g ) f

We choose : tbb=1,6 cm

Check internal force in combination 2:

M=82,39 (KNm) = 8239 (daN.m), N=-39,72 (KN) = -3972(daN), V=7,01(KN)=701 (daN)

Consider the following General coordinates ( OXY):

M=82,39 (KNm) = 8239 (daN.m), V=-3972.cos(80)-701cos(10=1380,1 (daN)

The maximum force of a bolt at outside bolt row.

Nb max

( M ).h1 (823900).62

4089,8(daN )

2. h 2 i 2(622 492 )

Tensile Bearing capacity of bolts: [N]tb=Abn.ftb=2,45.4000=9800 (daN)

N b max

Condition: [N]tb =9800 (daN) >

6105.19( daN )

=

(satisfaction )

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

The load applied on a bolt: Nvb=1380,1 /8=172,51 (daN)

Shear bear capacity of a bolt : [N]vb=3,14.0,9.3200=9043,2 (daN)

Condition: [N]vb=9043,2 (daN) >172,51 (daN) (satisfaction )

b, Calculation of welding line for connecting between butt plate and rafter

According appendix 43 in TCVN 338:2005: The minimum height of automatic welding line is 5

mm when the maximum thickness of the butt plate was 16 mm.

The maximum height of welding line between the flange of rafter and the butt plate is:

1,2tmin=1,2tf=1,2.12=14,4 mm => we choose : 5mm

The maximum height of welding line between the web of rafter and the butt plate is:

1,2tmin=1,2tw = 1,2.12=14,4 mm=> we choose: 5 mm

Aw=2.0,7.0,5.(33+31) +2.0,7.0,5.45,6=76,72 (cm2 )

0,5.45,6

Iw=2.0,7(33.0,5.25 +31.0,5.23,3 +

12

2

Iw .2

31749,3 .2

=

Ww= h d+ 2.0,5 50+ 2.0,5

)=31749,3 cm4

=1245,1 cm3

M=86,39 (KN.m)= 8639 (daN.m) N= -41,63 ( KN) =-4163 (daN) V= 7,34 (KN)=734

(daN)

M

N 2

V 2

863900 4100 2

723 2

(

) (

) (

) (

) 747,3

Ww Aw

Aw

1245,1 76, 72

76, 72

thl=

daN/cm2

<1800daN/cm2

The welding line was sufficient bearing capacity

STRUCTURAL STEEL PROJECT.

CIVIL ENGINEERING (NUCE)

NATIONAL UNIVERSITY OF

You might also like

- Biomass Pellet-Fired BoilersDocument17 pagesBiomass Pellet-Fired BoilersAmjad PervazNo ratings yet

- Pellet BurnerDocument11 pagesPellet BurnerAmjad PervazNo ratings yet

- Wood Pellets BurnerDocument16 pagesWood Pellets BurnerAmjad PervazNo ratings yet

- Millat Equipment RFQ for PLC PartsDocument1 pageMillat Equipment RFQ for PLC PartsAmjad PervazNo ratings yet

- Single Room CO-Hut PlanDocument1 pageSingle Room CO-Hut PlanAmjad PervazNo ratings yet

- Pelltech Model PV 50Document2 pagesPelltech Model PV 50Amjad PervazNo ratings yet

- Analysis of The Cutting Parameters in Uence During Machining Aluminium Alloy A2024-T351 With Uncoated Carbide InsertsDocument10 pagesAnalysis of The Cutting Parameters in Uence During Machining Aluminium Alloy A2024-T351 With Uncoated Carbide InsertsAmjad PervazNo ratings yet

- Yadon-Powered by SchulerDocument1 pageYadon-Powered by SchulerAmjad PervazNo ratings yet

- Automatic Edge Banding Machine For ABS PVC by Tiffany Price 9,230.00 USDDocument2 pagesAutomatic Edge Banding Machine For ABS PVC by Tiffany Price 9,230.00 USDAmjad PervazNo ratings yet

- ZK Cold Press QuotationDocument2 pagesZK Cold Press QuotationAmjad PervazNo ratings yet

- Schneeberger Linear Bearing BMB45Document4 pagesSchneeberger Linear Bearing BMB45Amjad PervazNo ratings yet

- Fazail M Eid+FitrDocument8 pagesFazail M Eid+FitrAmjad PervazNo ratings yet

- Abid FilterDocument3 pagesAbid FilterAmjad PervazNo ratings yet

- Mazznine ModelDocument1 pageMazznine ModelAmjad PervazNo ratings yet

- XL200 Technical Reference Installation GuideDocument150 pagesXL200 Technical Reference Installation GuideAmjad PervazNo ratings yet

- Steel Wall PanelDocument4 pagesSteel Wall PanelAmjad PervazNo ratings yet

- Special Steel Sheet: Cat - No.B1E-005-04Document16 pagesSpecial Steel Sheet: Cat - No.B1E-005-04Arnaldo Macchi MillanNo ratings yet

- Stevil Corporation: Steel Structure PEB, PFB and LGSFH From A 2 ZDocument2 pagesStevil Corporation: Steel Structure PEB, PFB and LGSFH From A 2 ZAmjad PervazNo ratings yet

- Shipping Container Weldable Twist Locks Drawing CHWTLDocument1 pageShipping Container Weldable Twist Locks Drawing CHWTLAmjad PervazNo ratings yet

- Burmuda Triangle MysteryDocument4 pagesBurmuda Triangle MysteryAmjad PervazNo ratings yet

- Islamicus No.4,2010 PDFDocument229 pagesIslamicus No.4,2010 PDFRifqiSyuja'HilmanAsyaNo ratings yet

- HSS Stamping Design ManualDocument67 pagesHSS Stamping Design ManualjschuryNo ratings yet

- Buckwheat Fact Sheet Provides Crop DetailsDocument2 pagesBuckwheat Fact Sheet Provides Crop DetailsstevicablNo ratings yet

- Breakfast Recipes PDFDocument61 pagesBreakfast Recipes PDFmutton moonswamiNo ratings yet

- Engine Block CastingDocument34 pagesEngine Block CastingAmjad Pervaz100% (1)

- EFT For Back PainDocument310 pagesEFT For Back Paindanaxor100% (16)

- Tools For PFBDocument28 pagesTools For PFBAmjad PervazNo ratings yet

- Anwar Masood - Deewaar E GiryaDocument72 pagesAnwar Masood - Deewaar E GiryaAmjad PervazNo ratings yet

- LGSF Container Front WallDocument1 pageLGSF Container Front WallAmjad PervazNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)