Professional Documents

Culture Documents

United States Patent (19) : Grote Et A1

Uploaded by

RodrigoPomaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

United States Patent (19) : Grote Et A1

Uploaded by

RodrigoPomaCopyright:

Available Formats

United States Patent [19]

[11]

4,230,007

Grote et a1.

[45]

Oct. 28, 1980

[54] FLEXIBLE MEAT SLICING BLADE AND

SUPPORT THEREFOR

3,851,554

12/1974

Papai ............................... .. 83/411A

Primary ExaminerJ. M. Meister

[75] Inventors: James E. Grote, Westerville; Thomas

A. Hochandel, Pickerington, both of

Ohio

Attorney, Agent, or FirmRobert E. Stebens

[73] Assignee: J. E. Grote Pepp-A-Matic Co., Inc.,

A ?exible meat slicing blade and support therefor is

provided for utilization in apparatus such as pizza form

Columbus, Ohio

Jul. 27, 1978

[51]

Int. 01.3 ........................ .. B26D 4/42; B26D 4/48

[52]

US. or. ................................... ..83/409.2;83/811;

83/820; 83/871; 83/874

[58]

Field of Search ............... .. 83/871, 870, 872, 707,

83/713, 714, 409.2, 411 A, 437, 874, 810, 811,

812, 820, 102.1

[5 6]

'

ABSTRAUI

ing machines to provide accurately and uniformly

sliced meat products of speci?ed thickness for deposit

[21] Appl. No.: 928,509

[22] Filed:

[57]

References Cited

U.S. PATENT DOCUMENTS

935,805

10/ 1909

1,383,133

6/1921

McDonough ................... .. 83/813 X

Lucke .......................... .. 83/874 X

1,955,360

4/1934

Ferry

2,126,380

8/1938

Folk

2,580,864

1/1952

Upright ..

2,605,799

2,670,768

8/1952

3/1954

Ratti ...... ..

Yohn ................. ..

83/717 X

83/ 102.1

2,670,771

3/ 1954

Lockwood et a1.

83/820 X

2,749,982

6/ 1956

Hardt ........ ..

3,263,537

3,640,166

3,850,061

8/1966

2/ 1972

11/1974

. .. ...

. . . . . . . . . ..

83/717

.. . .. . . .

. . . . . ..

83/ 729

..... .. 83/437

83/ 874

Rehman et al. .

..... ,. 83/871

Michals ........ ..

., 83/411 A

Wirstrom ......................... .. 83/813 X

on a surface of a pizza shell. An elongated ?exible meat

slicing blade of this invention, which may be a continu

ous band, is supported for longitudinal movement in a

cutting plane with the blade disposed at an angle with

respect to that cutting plane. A cutting edge of the blade

is beveled at an angle which is slightly less than the

angle of inclination of the blade to the cutting plane. A

support is provided for the portion of the blade passing

through the cutting plane to maintain the ?exible blade

in precise position with respect to the cutting plane.

This support includes a structurally rigid bar having a

longitudinal groove in which the effective cutting por

tion of the blade is disposed for relative sliding move

ment. This groove is angularly oriented with respect to

positioning of the support to receive and maintain the

blade at the desired angular position with respect to the

cutting plane and maintain the surface of the beveled

cutting edge thereof in predetermined relationship to

the cutting plane.

12 Claims, 7 Drawing Figures

US. Patent

Oct. 28, 1980

Sheet 1 of 3

mm

_row

HTu

4,230,007

US, Patent

Oct. 28, 1980

Sheet 2 of 3

4,230,007

US. Patent Oct. 28, 1980

Sheet 3 of 3

L\\\\\\\\\\\\\\\\S

69

7O

68

67

W H

iii&

FIG. 7

41,230,007

4,230,007

tantly, to obtain at least a minimum thickness slice, it is

FLEXIBLE MEAT SLICING BLADE AND '

SUPPORT THEREFOR

necessary to adjust the thickness of cut so that some

slices of the meat will be thicker than otherwise neces

sary. As a consequence, the cost will be materially in

BACKGROUND OF THE INVENTION

The ?exible slicing blade and support of this inven

tion is designed for primary utilization in machines and

apparatus for the forming of pizzas. Exemplary ma

chines of this type are illustrated in two prior patents

issued to one of the co-inventors of this invention.

These patents, issued to James B. Grote, are US. Pat.

No. 3,760,715 issued on Sept. 25, 1973 and US. Pat. No.

3,633,450 issued on Jan. 11, 1972. The machines or ap

5 creased and thereby constitutes a substantial detriment

to the economics of the semi-automated pizza manufac

turing operations.

SUMMARY OF THE INVENTION

A ?exible meat slicing blade and support therefor is

provided in accordance with this invention to enable

one to maintain the constant linearity of an elongated,

?exible cutting blade over a substantial horizontal plane

such as a length of about three foot. The support and

paratus illustrated in each of the patents includes the

mechanism which provides support for a plurality of 15 blade are positioned to support the required length of

sticks of sausage or pepperoni similar meat products in

the cutting blade in the cutting plane and maintain the

vertical orientation and a band-type slicing blade which

cutting edge thereof at a precise vertical and angular

operates on the lowermost ends of the sticks of meat to

produce a layer of thin meat slices on an underlying

position with respect to that cutting plane. The support ~

for the cutting blade is a structurally rigid bar which is

pizza shell. The support for the sticks of meat is adapted 20 mechanically coupled and secured to the structure of

for reciprocation in parallel relationship to a cutting

the apparatus and is provided with an elongated slot or

plane in which the upper run of the cutting blade is

groove in which a length of the slicing blade is sup

designed to continuously revolve in a linear path. In

ported for linear displacement. Suitable driving means

each of these illustrative machines, the cutting blade

is coupled to the blade and may include a pair of pulleys

25

which is a continuous band, is supported on a pair of

or rollers around which a continuous blade of the band

pulleys disposed at an angle with respect to this cutting

type

may be trained and continuously revolved during

plane. The reason for that inclination is that the cutting

cutting operations.

blade has a beveled cutting edge and it is desired to

In addition to providing a structurally rigid support

present that beveled cutting edge in predetermined

relationship to the cutting plane. A suitable motor is 30 for the blade, particularly as to the portion thereof ex

provided for revolving the continuous band-type blade

tending through the cutting plane, the blade and its

in effecting the cutting of the sticks of meat as the sup

port for those sticks of meat is reciprocated along a

support are relatively con?gured so that the beveled

cutting edge of the blade has a surface which is sup

predetermined path with respect to that cutting plane.

ported in generally coplanar relationship to a surface of

The apparatus, as shown in these two specifically 35 the support bar. This surface of the support bar is thus

aligned in the cutting plane and provides additional

noted patents, while operative for the illustrative appa

support for the sticks of meat products during their

ratus is not capable of performing the desired function

travel across the cutting plane and particularly during

with the degree of accuracy as to uniformity and thick

ness of the meat slices and proper adjustment of the

the movement of the meat sticks to a base or starting

thickness of such slices where the apparatus must be

position in a reverse direction across the support bar

operative over a relatively long horizontal span. Some

and cutting blade. In accordance with the invention, the

machines for the forming of pizza are in effect double

cutting blade is formed with a beveled edge and is angu

line machines which are capable of simultaneously op

larly positioned with respect to the support bar so that

erating on two longitudinally moving lines of pizza

the beveled surface is at a slight angle relative to the

shells and two meat supporting structures. With such 45 surface of the support bar. This con?guration places the

long spans for the cutting blade in the upper run which

heel of the blade edge slightly below the support bar

may easily be of the order of three foot, this span is of

surface and thus prevents interference and obstruction

such extent that the ?exible blade is incapable of main

to the reverse travel of the meat sticks across the cutting

taining the necessary linearity throughout its entire

area thereby avoiding the cutting or tearing of the meat

length during cutting operations. Very frequently, dur

during such reverse travel and the otherwise conse

ing such cutting operations, the forces produced in

transporting the vertically supported sticks of meat

across the cutting plane and against the cutting blade,

quent forming of waste meat particles that would inter

fere with further cutting operations and to also reduce

the cost of operation through elimination of this waste.

are suf?cient to cause bowing or bending of the cutting

In addition to providing the novel arrangement of a

blade. The blade may be either a bowed downwardly 55

supporting

bar in combination with a ?exible slicing

out of the cutting plane or bent rearwardly in its own

blade,

this

invention

provides transport plates de?ning a

plane, or there may be a multiple type deformation of

blade to include both bowing and bending with the

cutting plane at either side of the cutting blade which

con?guration throughout its entire length in the cutting

be precisely positioned to effect cutting of meat slices

include means for selective adjustment in a vertical

undesirable result of uncontrollable variations in the

meat slices that are produced. Specifically, the blade is 60 direction. The speci?c means, in combination with the

cutting blade and its support, enables the apparatus to

incapable of being maintained in a linear and planar

having an exact thickness which can be continuously

plane and results in a substantial and highly undesirable

maintained during prolonged operation of the appara

nonuniformity in the thickness of the meat slices as

applied to any particular pizza. In fact, the meat slices 65 tus. The vertical adjustments include a combination of

mechanisms for effecting vertical adjustment of the

across the entire width of a single pizza may vary to

plate preceding the cutting blade with respect to the

such a degree that the pizza is not particularly desirable

cutting blade.

from the standpoint of looks and, even more impor

4,230,007

vertically disposed. The sticks of meat are merely

dropped into the open top ends of the respective cells

and are fed by gravity out through the open bottom

ends. In FIG. 1 only the lower end portions of the sticks

These and other objects and advantages of this inven

tion are readily apparent from the following detailed

description of an illustrative embodiment thereof and

the accompanying drawings.

of meat M are seen projecting below the lowermost

DESCRIPTION OF THE DRAWINGS

edge of that supporting turret 16. The turret 16 itself is

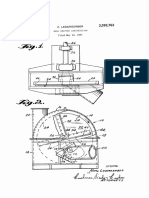

FIG. 1 is a vertical side elevational view of a pizza

mounted for longitudinal sliding reciprocation of elon

forming apparatus including the ?exible meat slicing

gated, horizontally disposed support bars 17. The oppo

blade and support of this invention.

FIG. 2 is a diagrammatic perspective view of a cut

site ends of the support bars are secured in upstanding

brackets 18 that are attached to appropriate elements of

the structural frame 13 and support the turret 16 for

ting blade and its support.

movement in a plane that is parallel to the cutting plane

and the transport plane for the pizza shells P.

FIG. 3 is a fragmentary vertical sectional view on a

substantially enlarged scale taken along line 3--3 of

Also included as a part of the meat product carrier 11

FIG. 2.

FIG. 4 is a fragmentary plan view of a beveled sur 15 are a pair of horizontally disposed plates 19 and 20.

These plates are mounted on and secured to the frame

face of the support bar.

13 with plate 19 normally supporting the meat sticks in

FIG. 5 is a fragmentary sectional view of the support

the turret 16 when it is positioned as shown in a base or

bar taken along line 5--5 of FIG. 4.

starting position. The meat sticks slide on the surface of

FIG. 6 is a fragmentary vertical sectional view taken

20 the underlying plate 19 during transport across the

along line 66 of FIG. 1.

cutting means 12 onto the plate 20 where they are simi~

FIG. 7 is a vertical sectional view taken along line

larly supported. The plate 19 preferably mounted to

77 of FIG. 6.

DESCRIPTION OF THE ILLUSTRATIVE

EMBODIMENT

An apparatus for the slicing of meat products in the

semi-automated formation of pizzas is illustrated in

FIG. 1. This apparatus, as in the case of the apparatus

described and illustrated in the previously issued patents

to one of the co-inventors hereof, speci?cally US. Pat.

Nos. 3,760,715 and 3,633,450 includes a transpactor

conveyor mechanism 10 for the transport of pizza shells

P, a meat product carrier 11 and product slicing means

25

permit relative vertical adjustment of one end the plate

and thereby enable adjustment of the thickness of the

slices of the meat products that may be produced by this

apparatus. Accordingly, it will be seen in FIG. 1, that

plate 19 is secured at an end remote to the slicing means

12 by a hinge structure 21 and the end adjacent the

slicing means disposed in cooperative relationship to an

adjusting mechanism 22. The other plate 20 is mounted

in ?xed relationship to the structural frame 13.

Operation of the meat product carrier 11 will be seen

to comprise a longitudinal reciprocating movement of

the meat supporting turret 16 as between the plates 19

12. Each of the three components are illustrated as

being mounted on or carried by a suitable structural 35 and 20. With the supporting structure 16 positioned as

illustrated in FIG. 1, the lower ends of the meat sticks

framework as represented by an elongated frame ele

M are thus resting on the surface of the plate 19 and will

ments 13 in FIG. 1. Supported and carried by this frame

be transferred to the upper surface of plate 20 as the

13 is the conveyor mechanism 10 which is illustrated as

turret 16 is moved to the left of FIG. 1. During the

including an elongated conveyor belt, having upper and

lower runs 14 and 15. Supports and actual construction

course of this movement, the lower ends of the meat

sticks M will thus come into operative engagement with

of the'conveyor belt 10 are not illustrated as these do

the slicing means 12 which will sever a meat slice of a

not form a part of this invention. It will suffice to note

predetermined thickness and which slice is then depos

that the upper run of the conveyor belt 14 is supported

ited onto the pizza shell P. It will be understood that a

to be displaced along a longitudinal plane in substantial

alignment with the frame member 13 and, as will be 45 plurality of such slices are simultaneously produced and

deposited on the shell. This operation is coordinated in

hereinafter noted, in effectively parallel relationship to

order that the pizza shell will be transported at the same

a cutting and transport plane for the meat products. A

rate of movement as the turret 16 thereby resulting in

single pizza shell P is shown supported on the upper run

the several slices being deposited in a predetermined

14 of the conveyor and in the illustrated embodiment

will be noted as being transported from the right to the 50 pattern on the pizza shell. This pattern is determined in

the ?rst instance by arrangement and number of meat

left of FIG. 1. During the course of this transport, the

sticks M that may be contained in the turret 16.

pizza shell P will thus transverse the operative area of

Suitable mechanisms for effecting the concurrent and

the product slicing means 12 and as, in accordance with

simultaneous transport of the supporting structure 16, as

the structures of previously noted patents, will receive a

layer of meat product slices which may be a pepperoni 55 well as the conveyor 10, are not shown and it will be

understood that this operation may be performed manu

or sausage type meat product. The speci?c product is

not material to the desdescription and understanding of

ally by the operator if so desired. However, as an illus

trative example of suitable mechanisms for effecting the

the invention and it will be understood that various

automated operation, it will be understood that the

types of products may be handled by this apparatus and

60 conveyor 10 may be continuously driven and appropri

deposited on the surface of the pizza shell P.

ate mechanized reciprocating devices may be intercon

A meat product carrier 11 is provided, as indicated,

nected with the turret 16 of the meat product carrier.

and includes a supporting turret 16 for these meat prod

ucts which are generally provided in the forms of elon

Control mechanisms, also not shown, would also be

provided and control operations in timed relationship to

gated cylindrical sticks. This turret 16, as in accordance

with the description of the previously noted patents for 65 the advancement of a pizza shell P on the conveyor 10.

Those actuating mechanisms would be operable to dis

such apparatus, includes an interior wall structure form

place the turret 16 at the same rate of travel of the pizza

ing a plurality of individual cells of open ended con?gu

ration in which each of the individual sticks of meat are

shell P and, when the turret 16 has been fully advanced

4,230,007

from the right to the left onto supporting plate 20, these

mechanisms would automatically effect the reverse

movement of the supporting structure to its illustrated

with the requirements of a speci?c cutting and slicing

operation.

Forming at the leading edge of the guide bar 36 is a

starting position at the right of FIG. 1. This would be

accomplished in timed relationship to the advancement

longitudinal edge portion having a V-shaped cross-sec

of successive pizza shells P that may be carried on the

tion of the upper surface 39 of the guide bar. The oppo

upper run 14 for the conveyor.

tion with the one surface thereof 40 being a continua- 1

site surface 41 of this V-shaped edge portion is rela

Improved cutting and precise control of slice, thick

tively divergent thereto in a downwardly and rear

ness is achieved through the novel structural arrange

ment and components of the slicing means 12 of this

invention. Included in the product slicing means 12, is a

edge portion is a longitudinally extending groove or

continuous band-type cutting blade 25 which is trained

about driving and support pulleys 26 and 27. Each of

the pulleys 26 and 27 is journaled on a respective sup

porting bracket 28 and 29 with each bracket being

mounted on and carried by the structural frame 13. It

will be most clearly seen in FIG. 2 that this support of

the band-type cutting blade 25 is also arranged to main

tain the plane of revolution of that blade at an angle in

respect to a horizontal plane which is the cutting plane

of the apparatus. Referring to both FIGS. 1 and 2, it will

be seen that the blade is angled upwardly with respect

to the direction from which the meat supporting turret

16 will be moved in a cutting operation. This upward

inclination of the blade thus enables the blade to better

perform its cutting operation without interference due

wardly directed relationship. Formed in the leading

recess 42 designed to receive the cutting blade 25. This

blade groove 42 is formed in the leading edge portion so

as to open the apex of the surfaces 40 and 41 and is of a

depth such that the blade 25, when fully inserted

therein, will have only its cutting edge 30 projecting

outwardly from the guide bar. The depth of the groove

42 is determined by the width of the blade 25 and is

formed so that only the cutting edge 30 will be project

ing from the apex of the surfaces 40 and 41. The extreme

end edge 43 between the groove 42 and the surface 40

may have a blunt edge but the end edge 44 between the

groove 42 and the surface 41 is preferably knife sharp to

improve separation of the meat slice S as it is severed.

To achieve the optimum slicing operation, the V

shaped end portion of the guide bar and the angular

relationship between its surfaces 40, 41 and the cutting

blade 25 are determined so that a slice S as it is severed

to the interengagement of the several meat sticks as they

will properly fall from the apparatus onto the pizza shell

pass over the blade. This angular arrangement of the

which is traveling in concurrent relationship thereto.

cutting blade is utilized and shown in the two previ 30 These speci?c angular relationships include the angle of

ously issued patents to the co-inventor hereof.

the beveled edge 30 of the cutting blade and which is

Additionally, it will be noted that the cutting blade

related to the included angle of the surfaces 40 and 41 at

25, at its leading edge, is provided with a cutting edge

leading edge of the guide bar 36. In accordance with

30 having a single beveled surface 31 which is angled

this invention, the angles which have been found to be

with respect to the plane of the blade. This con?gura

most advantageous, is an angular relationship of the

tion can be best seen in FIG. 3 where it will be noted

guide bar slice de?ecting surface 41 to the upper hori

that the beveled surface 31 is disposed in_ substantially

zontal surface 40 of 35 whereas the angle of the blade

parallel relationship to the horizontal cutting plane. In

groove 42, with respect to the surface 41 is 20. This

that ?gure, a lower end portion of a single meat stick M

relationship, as can be best seen in FIG. 3, results in the

is shown in broken lines as passing the cutting blade in 40 extreme edge 43 at the upper surface 40 having a blunt

cutting relationship thereto as in the performance of a

edge even though this edge is of relatively narrow di

slicing operation. During this operation, it will be noted

mension. However, the deflecting edge 43 at the surface

that a relatively thin slice of the meat stick designated S

41 is preferably formed so as to be knife-sharp and thus

will be severed and permitted to drop downwardly onto

result in-a very clean breaking of a meat slice S as it is

a pizza shell as described in the previously noted pa

severed by the blade 25.

tents. .

To further obtain the most advantageous operation,

To improve the ability of the apparatus to precisely

the beveled cutting edge 30 of the blade 25 has an in

cut slices of an exact predetermined thickness across the

cluded angle which is slightly less than the angle of the

entire width of the cutting area, the apparatus includes

a supporting guide 35 for the upper run of the cutting

blade 25. This supporting guide 35 can be best seen in

FIG. 2 and includes an elongated guide bar 36 having

blade with respect to the horizontal. This angle is pref

erably 15 thus resulting in the heel 45 of the cutting

edge surface being slightly below the surface 39 and its

contiguous extension 40 when the extreme cutting point

is positioned in the plane of that surface. The particular

terminal mounting portions 37 at each end, which facili

tate mounting of the guide bar. These terminal end

advantage of this slightly lessor angle is that the blade

portions 37 are secured to respective mounting blocks 55 does not interfere in the return movement of the meat

38 which are secured to respective longitudinal ele

sticks M as they pass from the left to the right of the

ments of the structural frame 13. The guide bar 36 has

apparatus as shown in FIG. 1. If the heel 45 of the

an upper surface 39 which is maintained in a substan

cutting edge surface 31 is also in the plane of that guide

tially horizontal plane when mounted on the apparatus.

bar surface 40 there is a tendency for the meat sticks to

This upper surface 39 is vertically positioned to be sub 60 hang up or be engaged by the blade to a substantial

stantially aligned with the cutting plane and is contigu

extent and thus prevent the relatively free movement of

ous to the upper surface of the plate 20. Also as will be

the meat sticks. This also results in the generation of

described hereinafter the guide 35 is positioned at an

particles of meat that tend to clog the apparatus and

elevation relative to the upper surface of the plate 19 to

interfere with cutting operations.

determine the thickness of the meat slices S severed 65

The structure as hereinbefore described has been

directed to a guide bar 36 wherein the deflecting surface

from the several meat sticks. This relative difference in

41 is a smooth planar surface. This smooth planar sur

vertical elevation is selectively and precisely controlled

by setting of the adjusting mechanism 22 in accordance

face, while particularly useful with respect to meat

4,230,007

products such as pepperoni and sausage, is not entirely

suitable for other types of meat products such as Cana

the desired relative vertical elevation of the plate 19.

Securing the mechanism at the desired position is

dian bacon due to inherent characteristics of such meat

achieved by a locking screw 71 which is threaded into

one of the supporting blocks 60 and has an inner end

products. Canadian bacon, for example, has a substan

tial tendency to adhere to a smooth planar surface and

may remain on the cutting bar rather than freely drop

onto the pizza shell or other article that may be trans

ported beneath the blade thereby either clogging the

cutting blade or producing an undesireable pattern of

that bears against the shaft 61. The shaft 61 provides for

convenient simultaneous elevation of both respective

push rods 65 while the adjusting nuts 67 may be turned

to obtain a precise planar alignment of the plate 19 with

the cutting blade 25 as well as with respect to the de

10 ?ned cutting surface.

meat slices.

From the foregoing detailed description of the illus

To avoid the hanging of a meat slice on the surface 41

trative embodiment of this invention, it will be readily

which is cut from a stick of Canadian bacon, it is pre

apparent that a particularly novel and advantageous

ferred that this de?ecting surface 41 be con?gured as is

structure is provided in the combination of a slicing

shown in FIGS. 4 and 5 of the drawings. In this modi

?ed form of the guide bar 36, the de?ecting surface 41 5 blade and support in a cutting apparatus such as that

incorporated in machines for applying meat slices to

is provided with a number of alternatingly disposed

pizza shells. The providing of a rigid support bar for the

grooves or recesses 50 and ribs 51 which extend trans

portion of cutting blade which extends through the

versely to the longitudinal axis of the guide bar 36.

cutting plane enables the apparatus to maintain a precise

These grooves 50 terminate in rounded closed ends 52

at the end most remote from the edge 44 and are rela

and accurate slice thickness over the entire width and

tively spaced to thereby de?ne the ribs 51. The ends 53

of the grooves 50 and adjacent portions of the ribs 51

are arcuately scalloped due to the tapering of the guide

extent of the cutting area. This arrangement enables the

apparatus to be constructed to accommodate extremely

large sizes of pizzas as well as to accommodate a plural

ity of pizza shells that are transported in side-by-side

bar to a knife edge 44. These grooves and ribs 50 and 51

are particularly effective in reducing the contact surface 25 relationship. Forming the support bar with a speci?

area which engages the meat slices as they are severed

cally con?gured angular relationship of the blade

by the cutting blade thereby signi?cantly reducing the

receiving groove, in combination with the particular

beveled angle of the cutting blade, results in a particu

larly advantageous structure that substantially elimi

nates the tendency of the meat products interfering with

the operation of that blade during reverse travel. The

relatively recessed relationship of the heel of a beveled

cutting surface, with respect to the upper transport

surface of a guide bar, prevents the meat products from

engaging the blade and inadvertently resulting in a

cutting or tearing operation during reverse movement

likelihood that Canadian bacon or similar characteristic

materials will adhere to the surface 41. With such

grooves and ribs, the slices of such materials will also be

cleanly de?ected and thus enable the slices to be depos

ited by gravity on any underlying and suitable support

or transport mechanism or surface.

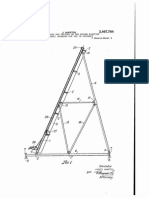

Selective adjustment of the plate 19, as previously

indicated, is accomplished by operation of the adjusting

mechanism 22. This speci?c adjustment mechanism,

which is particularly advantageous for utilization in this

apparatus, is illustrated in greater detail in FIGS. 6 and

of the meat sticks from the one position to the other

across that ' cutting blade.

Formation of the speci?c angled relationship of the

two laterally spaced supporting blocks 60 which are 40 de?ecting surface of the cutting bar also materially aids

7 of the drawings. Included in this mechanism are the

the apparatus is an elongated rod 61 or shaft which is

in the clean separation of the meat slices as they are

severed, to further assure that those meat slices will be

dropped in the desired pattern onto the surface of a

journaled in the respective supporting blocks 60. One

pizza shell that is concurrently transported with the

secured or mounted on the respective side-elements of

the structural frame 13. Extending transversely across

end of this shaft projects a distance outwardly from its 45 meat supporting turret. Also, the alternate formation of

that de?ecting surface, with the series of grooves and

respective block and is provided with an operating knob

intervening ribs, substantially reduces the effective con

62. Mounted in ?xed relationship on the shaft 61 within

tacting surface area which is extremely effective in

an interior cavity 63 of each supporting block 60 is a

preventing the severed meat slices from tending to ad

respective eccentric cam 64. Mechanical coupling of

each section of the adjusting mechanism with the plate

19 is effected by a vertically extending pushrod 65

which extends through a vertically disposed socket 66

opening to the interior of the cavity with the lower end

66 of the push rod contacting the surface of the eccen

tric cam 64. The upper end of the push rod 65 is formed

here to that surface and block or interfere with further

cutting operations. Also, the ability of the groove and

rib surface to cleanly separate the severed meat slices

further assures that these meat slices will be deposited in

the desired pattern on the pizza shell or other support

ing surface.

It will be further noted that the precise control in the

operation of the apparatus, is greatly facilitated through

selected position. A cap element 68 is positioned over

the providing of the illustrative types of verticle adjust

the upper threaded section of each push rod 65 and

ment mechanisms for the support plate. These adjusting

includes an upper end portion 69 that bears against the

lower surface of the plate 19. These caps 68 include an 60 mechanisms, which incorporate both a means for ob

taining precise relative alignment between laterally

elongated socket 70 that opens at the bottom which

spaced points as well as the concurrent and simulta

rests on the nut 67. Turning of the nut 67 thus raises or

neous verticle adjustment, assures that the plate on

lowers the cap 68 and thereby provides a limited degree

which the meat sticks are supported immediately prior

of adjustment of vertical height and is useful in obtain

ing precise alignment of the two adjusting mechanism 65 to a cutting operation are supported at a relative height

with respect to the cutting edge to obtain the predeter

with respect to each other. Turning of the operating

mined thickness meat slice. The combination of the

knob 62 thus will rotate the shaft 61 and simultaneously

adjusting mechanisms and the rigid supporting bar for

angularly position the cams 64in a selected position for

with a threaded section on which a nut 67 is turned to a

4,230,007

10

7. A slicing apparatus according to claim 1 wherein

said guide bar de?ecting surface is formed with a plural

the blade assure that a constant slice thickness is main

tained across the entire width of the cutting area.

Having thus described this invention, what is claimed

ity of longitudinally spaced grooves extending trans

1. A slicing apparatus comprising

versely of said guide bar with the one end thereof termi

nating at said slot.

8. A slicing apparatus according to claim 7 wherein

said grooves cooperatively define a rib between each

1s:

slicing means including an elongated ?exible cutting

blade having a longitudinally extending cutting

adjacent pair of grooves, said ribs being of relatively

edge formed along one marginal edge portion of

narrow

width.

said blade, said cutting edge being formed with a

longitudinally extending beveled surface that is 10 9. A slicing apparatus comprising

slicing means including an elongated ?exible cutting

angularly disposed at a predetermined angle rela

blade, drive means coupled therewith for support

tive to the plane of the blade, and drive means

of at least a portion of said blade in a cutting plane

coupled therewith for support of a longitudinally

extending portion of said blade in linearly disposed

relationship with the plane of the blade disposed in

15

guide means for said cutting blade including a struc

angularly oriented relationship to a cutting plane

and having a longitudinally extending terminal

turally rigid guide bar supported in relatively ?xed

relationship to the cutting plane, said guide bar

edge of the cutting edge projecting into the cutting

having an elongated slot formed therein for receiv

ing the portion of said blade disposed in the cutting

plane and supporting that portion of the blade

against displacement in either axis transverse to the

plane, said drive means operable to effect longitu

dinal displacement of said blade in performance of

cutting operations, and

guide means for said cutting blade including a struc

longitudinal dimension of the cutting blade, '

turally rigid guide bar supported in relatively ?xed

relationship to the cutting plane, said guide bar

having an elongated slot formed therein for receiv

ing the portion of said blade disposed in angularly

oriented relationship to the cutting plane and sup

porting that portion of the blade against displace

and operable to effect longitudinal displacement of

said blade in performance of cutting operations,

a product carrier supported in operative relationship

25

to said slicing means and said guide means for

transport of product to be sliced with respect to

said cutting blade, said product carrier including a

turret which receives the product and displaceable

in a plane parallel to the cutting plane, and a prod

uct support plate disposed at a leading side of said

cutting blade for controlling the thickness of the

ment in either axis transverse to the longitudinal

dimension of the cutting blade, said guide bar in

cluding a support surface and a de?ecting surface

product slices, said product support plate including

with both extending longitudinally of said bar in

colinearly extending relationship to said slot with

the guide bar support surface disposed in substan

thickness adjusting means for positioning an edge

portion of said plate adjacent said cutting blade in

selected spaced relationship to the cutting plane,

said thickness adjusting means including an elon

tially contiguous and parallel relationship to the

cutting plane and having said support and de?ect

ing surfaces disposed in relatively divergent rela

gated shaft extending parallel to the cutting plane

and supported for relative rotation about its longi

tudinal axis, a pair of eccentric cams ?xed on said

tionship to said slot with said slot disposed relative

to said guide bar support surface to place the bev

eled surface of said blade cutting edge adjacent to

shaft in axially spaced relationship for rotation

therewith, and means mechanically coupling said

cams with said product support plate for effecting

the cutting plane and in divergently angled rela

tionship to said support surface and cutting plane.

vertical displacement of the support plate edge

portion in accordance with selective operation of

2. A slicing apparatus according to claim 1 wherein

the adjusting mechanism to rotate said cams.

'

said cutting edge projects laterally out of said guide bar 45 10. A slicing apparatus according to claim 9 wherein

slot with an opposite longitudinal edge of said blade

said thickness adjusting means includes a pair of verti

disposed in sliding contacting engagement with a bot

cally extending push rods mechanically coupling said

tom of said slot.

cams with said product support plate, said push rods

3. A slicing apparatus according to claim 1 wherein 50 each having one end disposed in contacting engagement

the angle of slot with respect to said guide bar support

with a respective cam and the other end in contacting

surface is about 20 degrees, and the included angle of

engagement with said product plate.

said blade cutting edge is about 15 degrees.

11. A slicing apparatus according to claim 10 wherein I

4. A slicing apparatus according to claim 1 wherein

said guide bar de?ecting surface terminates at said slot

in a sharp edge.

5. A slicing apparatus according to claim 4 wherein

the included angle between said guide bar support sur

face and said de?ecting surface is about 35 degrees.

6. A slicing apparatus according to claim 1 wherein

said guide bar de?ecting surface is formed with a

smooth planar surface.

said push rods are independently adjustable axially as to

relative length.

12. A slicing apparatus according to claim 10 wherein

said product support plate is supported for rotational

movement by hinge means disposed in spaced relation

ship to said push rods, said push rods disposed adjacent

the edge portion of said product support plate disposed

adjacent said cutting blade.

*1

65

it

I.

it

1|

You might also like

- AMS-2249-Chemical Check Analysis LimitsDocument6 pagesAMS-2249-Chemical Check Analysis LimitsSinan Yıldız100% (1)

- Shaper MachineDocument19 pagesShaper MachineMark Joseph Nambio Nieva0% (1)

- Previews AWS A5 12M A5 12 2009 PreDocument12 pagesPreviews AWS A5 12M A5 12 2009 PreMani VannanNo ratings yet

- Title - Wood Chipper ConstructionDocument4 pagesTitle - Wood Chipper Constructionمحمد عبدالدايمNo ratings yet

- Us1955360 PDFDocument8 pagesUs1955360 PDFRodrigoPomaNo ratings yet

- MillingDocument54 pagesMillingVickyVenkataramanNo ratings yet

- "A1.h.. May,: June 4, 1929. A. B. Kerr 1,715,929Document7 pages"A1.h.. May,: June 4, 1929. A. B. Kerr 1,715,929Guillermo Avila RiveraNo ratings yet

- US5687784Document8 pagesUS5687784Bruno BaroniNo ratings yet

- United States Patent (19) : Filed: July 27, 1976 57Document3 pagesUnited States Patent (19) : Filed: July 27, 1976 57Alexandre Magno Bernardo FontouraNo ratings yet

- Ex5 Milling MCDocument5 pagesEx5 Milling MCMuhammad RazaNo ratings yet

- United States Patent (19) : GullettDocument7 pagesUnited States Patent (19) : GullettMaJoy GarciaNo ratings yet

- Milling Machine Report DelyDocument10 pagesMilling Machine Report DelyFazdly Azilan0% (2)

- Locking Knife Mechanism PatentDocument6 pagesLocking Knife Mechanism PatentBarmak CheraghiNo ratings yet

- Coco Inven PDFDocument4 pagesCoco Inven PDFsushil-funNo ratings yet

- WWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANDocument6 pagesWWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANRodrigoPomaNo ratings yet

- How To Use A Milling MachineDocument44 pagesHow To Use A Milling MachineGhazali ZuberiNo ratings yet

- Instructions How To Use A Milling MachineDocument58 pagesInstructions How To Use A Milling MachineEng-Ramy El-MorsyNo ratings yet

- Gear Hobbing Process GuideDocument4 pagesGear Hobbing Process Guidesaurabhsingh2121No ratings yet

- Handout131Milling Machines and CuttersDocument23 pagesHandout131Milling Machines and CuttersPamela SidicNo ratings yet

- 3023 Machine Tools M3Document43 pages3023 Machine Tools M3arunsumesh.vfbvmNo ratings yet

- Title - Wood Chipper Disc and Knife MountingDocument5 pagesTitle - Wood Chipper Disc and Knife Mountingمحمد عبدالدايمNo ratings yet

- 19mg WK.: June 1, 1954 J. H. Breisch 2,579,786Document5 pages19mg WK.: June 1, 1954 J. H. Breisch 2,579,786Azri LunduNo ratings yet

- Garrett's lawn mower gearing designDocument3 pagesGarrett's lawn mower gearing designAlecsandrNo ratings yet

- Planer Machine:: DiagramDocument4 pagesPlaner Machine:: Diagramtanish vermaNo ratings yet

- Everything You Need to Know About Shaping Machines and Scotch Yoke MechanismsDocument36 pagesEverything You Need to Know About Shaping Machines and Scotch Yoke Mechanismsvijay vijay33% (3)

- Milling NotesDocument16 pagesMilling Notesvelavansu100% (1)

- Bonelle GrinderDocument11 pagesBonelle Grinderjohnjohn520% (1)

- Milling MachineDocument8 pagesMilling Machinegirma workuNo ratings yet

- MP GTU Study Material E-Notes Unit-5 06042020034257PMDocument36 pagesMP GTU Study Material E-Notes Unit-5 06042020034257PMChandresh RanaNo ratings yet

- Vertical Turret Lathe & Horizontal Boring MillDocument12 pagesVertical Turret Lathe & Horizontal Boring MillALLEN FRANCISNo ratings yet

- United States Patent (191: Andersen Et A1Document5 pagesUnited States Patent (191: Andersen Et A1khoagleNo ratings yet

- MC-MT R16 - Unit-4Document29 pagesMC-MT R16 - Unit-4Anonymous GEHeEQlajbNo ratings yet

- Milling MachineDocument21 pagesMilling MachineZahra BatoolNo ratings yet

- Machine Tools - Milling MachineDocument11 pagesMachine Tools - Milling Machinejineesha p jNo ratings yet

- United States Patent (19) : Anderson Et Al. 54 Yacht Mast 11) 4,072,121Document7 pagesUnited States Patent (19) : Anderson Et Al. 54 Yacht Mast 11) 4,072,12112348No ratings yet

- Prepared by S.sanyasirao, Assistant Professor, VITS College of Engg., Sontyam, VizagDocument14 pagesPrepared by S.sanyasirao, Assistant Professor, VITS College of Engg., Sontyam, Vizagsanyasirao1No ratings yet

- United States Patent (19) : Miiller (45) Date of PatentDocument8 pagesUnited States Patent (19) : Miiller (45) Date of PatentRodrigoPomaNo ratings yet

- Patente TrituradoraDocument11 pagesPatente TrituradoraDany ChimborazoNo ratings yet

- Dual Acting ShaperDocument30 pagesDual Acting ShaperAbhijeet NaikNo ratings yet

- BME Lecture 5 ShaperDocument6 pagesBME Lecture 5 ShaperRoop LalNo ratings yet

- Multi-Purpose Oscillating Sifter MachineDocument4 pagesMulti-Purpose Oscillating Sifter MachineSantos JustinNo ratings yet

- Bridgeport Milling Machine OperationDocument40 pagesBridgeport Milling Machine OperationALLEN FRANCIS100% (3)

- Assignment 1: Aliaa Nabila Binti Abdul Muta'Ali (Ha15025)Document8 pagesAssignment 1: Aliaa Nabila Binti Abdul Muta'Ali (Ha15025)Aliaa Nabila100% (1)

- Milling (Machining) - WikipediaDocument102 pagesMilling (Machining) - WikipediaQuelton NgulubeNo ratings yet

- Us20030075626 PDFDocument28 pagesUs20030075626 PDFprouserdesigner77No ratings yet

- Chaff CutterDocument6 pagesChaff Cuttertibem100% (6)

- MILLING MACHINE GUIDEDocument10 pagesMILLING MACHINE GUIDEshNo ratings yet

- Dec. 5, 1967 Hiroshi Utashiro Eta.L 3,355,922: Filed Sept. 28, 1965 2 Sheets-SheetDocument6 pagesDec. 5, 1967 Hiroshi Utashiro Eta.L 3,355,922: Filed Sept. 28, 1965 2 Sheets-SheetEstebanPortilloNo ratings yet

- Us 4207797Document7 pagesUs 4207797fghdfjerNo ratings yet

- Gear Cutting Attachment For Lathe: SynopsisDocument4 pagesGear Cutting Attachment For Lathe: Synopsismadhu kumarNo ratings yet

- Milling Machines: Milli e Ains A Ause e H Ma - Why A - Up Rio e E, MD IsDocument10 pagesMilling Machines: Milli e Ains A Ause e H Ma - Why A - Up Rio e E, MD Isnitin gaikwadNo ratings yet

- Full download book Integrating Educational Technology Into Teaching With Etext Access Code Pdf pdfDocument22 pagesFull download book Integrating Educational Technology Into Teaching With Etext Access Code Pdf pdflouise.cowell660100% (13)

- Machining and Tools 6 PDFDocument34 pagesMachining and Tools 6 PDFAman KumarNo ratings yet

- Gear Shaving Process ExplainedDocument8 pagesGear Shaving Process Explainedd_a0nNo ratings yet

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- Paper-Cutting Machines: A Primer of Information about Paper and Card Trimmers, Hand-Lever Cutters, Power Cutters and Other Automatic Machines for Cutting PaperFrom EverandPaper-Cutting Machines: A Primer of Information about Paper and Card Trimmers, Hand-Lever Cutters, Power Cutters and Other Automatic Machines for Cutting PaperNo ratings yet

- Wood Turning - The Lathe and Its Accessories, Tools, Turning Between Centres Face-Plate Work, Boring, PolishingFrom EverandWood Turning - The Lathe and Its Accessories, Tools, Turning Between Centres Face-Plate Work, Boring, PolishingNo ratings yet

- LM 7805 RegulatorDocument12 pagesLM 7805 RegulatorFadel BairuniNo ratings yet

- Us1223254 PDFDocument7 pagesUs1223254 PDFRodrigoPomaNo ratings yet

- 1 ChuquisacaDocument6 pages1 ChuquisacaRodrigoPomaNo ratings yet

- Large Batch Hard Candy and LollipopsDocument2 pagesLarge Batch Hard Candy and LollipopsRodrigoPomaNo ratings yet

- Us2467764 PDFDocument10 pagesUs2467764 PDFRodrigoPomaNo ratings yet

- Us 4106436Document10 pagesUs 4106436RodrigoPomaNo ratings yet

- Diagrama Bases 1Document1 pageDiagrama Bases 1RodrigoPomaNo ratings yet

- Nov. 25, v1941. J, R, Mcmahon Eral 2,264,048: Apparatus For Applying Protective Coatings T0 SuspendedDocument7 pagesNov. 25, v1941. J, R, Mcmahon Eral 2,264,048: Apparatus For Applying Protective Coatings T0 SuspendedRodrigoPomaNo ratings yet

- Us659197 PDFDocument3 pagesUs659197 PDFRodrigoPomaNo ratings yet

- United States Patent: Dreve, Jr. (45) May 16, 1972Document6 pagesUnited States Patent: Dreve, Jr. (45) May 16, 1972RodrigoPomaNo ratings yet

- US Patent for Cutting Food Products MachineDocument4 pagesUS Patent for Cutting Food Products MachineRodrigoPomaNo ratings yet

- United States Patent: Dreve, Jr. (45) May 16, 1972Document6 pagesUnited States Patent: Dreve, Jr. (45) May 16, 1972RodrigoPomaNo ratings yet

- M. Schwafel: Derrick Safety CageDocument4 pagesM. Schwafel: Derrick Safety CageRodrigoPomaNo ratings yet

- Us 2296645Document4 pagesUs 2296645RodrigoPomaNo ratings yet

- WWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANDocument6 pagesWWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANRodrigoPomaNo ratings yet

- United States Patent (19) : Miiller (45) Date of PatentDocument8 pagesUnited States Patent (19) : Miiller (45) Date of PatentRodrigoPomaNo ratings yet

- Measure cheese with this compact dispenserDocument5 pagesMeasure cheese with this compact dispenserRodrigoPomaNo ratings yet

- Us2678614 PDFDocument6 pagesUs2678614 PDFRodrigoPomaNo ratings yet

- Datasheet UA741CPDocument19 pagesDatasheet UA741CPlcruz_86No ratings yet

- June 16, 1964: C. R. Steele Disintegrator Having Downwardly Inclined Baffles Filed Nov. 17, 1960Document6 pagesJune 16, 1964: C. R. Steele Disintegrator Having Downwardly Inclined Baffles Filed Nov. 17, 1960RodrigoPomaNo ratings yet

- Us4589264 PDFDocument6 pagesUs4589264 PDFRodrigoPomaNo ratings yet

- MikroDocument5 pagesMikroAmir Si KetengNo ratings yet

- Musical Intelligence: Let's Cut It Off! I Guess You Are Out of TuneDocument1 pageMusical Intelligence: Let's Cut It Off! I Guess You Are Out of TuneHenry GutierrezNo ratings yet

- MXTVXVW PDFDocument3 pagesMXTVXVW PDFRodrigoPomaNo ratings yet

- Cba The GPSDocument7 pagesCba The GPSRodrigoPomaNo ratings yet

- A9 PDFDocument25 pagesA9 PDFRodrigoPomaNo ratings yet

- Us116842 PDFDocument6 pagesUs116842 PDFRodrigoPomaNo ratings yet

- H. J. Smith: Potato Cutting Machine 28 Filed 00Document3 pagesH. J. Smith: Potato Cutting Machine 28 Filed 00RodrigoPomaNo ratings yet

- Datasheet MOC301Document6 pagesDatasheet MOC301Vam PireNo ratings yet

- Aznar v. Ybañez - LTDDocument8 pagesAznar v. Ybañez - LTDoniksukkieNo ratings yet

- Pittman Express 2011 CatalogDocument15 pagesPittman Express 2011 CatalogElectromateNo ratings yet

- Ross Kenneth Kennedy - Understanding, Measuring, And Improving Overall Equipment Effectiveness_ How to Use OEE to Drive Significant Process Improvement-Productivity Press_Taylor & Francis, CRC Press (Document93 pagesRoss Kenneth Kennedy - Understanding, Measuring, And Improving Overall Equipment Effectiveness_ How to Use OEE to Drive Significant Process Improvement-Productivity Press_Taylor & Francis, CRC Press (basma hassaniNo ratings yet

- Internship Contract Agreement: PartiesDocument4 pagesInternship Contract Agreement: PartiesParishrut17No ratings yet

- Iec60034-9 Rotating Mach.-Noise LimitsDocument29 pagesIec60034-9 Rotating Mach.-Noise Limitsmahmoud hassan selimNo ratings yet

- AASHTO T-27 Sieve Analysis of Fine and Coarse AggregatesDocument5 pagesAASHTO T-27 Sieve Analysis of Fine and Coarse AggregatesJason CardalicoNo ratings yet

- E-Library - Information At Your FingertipsDocument7 pagesE-Library - Information At Your FingertipsEzra RamajoNo ratings yet

- Leo Kwan: MingCha Brand BenefitsDocument20 pagesLeo Kwan: MingCha Brand BenefitsLeo CL KwanNo ratings yet

- Habana Vs RoblesDocument2 pagesHabana Vs RoblesRex TrayaNo ratings yet

- Sniper RifleDocument2 pagesSniper RifleDashaun SmithNo ratings yet

- Horus Reticle Man PDFDocument32 pagesHorus Reticle Man PDFglaz276No ratings yet

- Antenna Commscope CSH 6516A VTDocument2 pagesAntenna Commscope CSH 6516A VTvohoangphuNo ratings yet

- Media and Information Literacy (Mil)Document41 pagesMedia and Information Literacy (Mil)rehina lopezNo ratings yet

- 1 UFC PHILIPPINES, INC. vs. BARRIO FIESTA MANUFACTURING CORPORATIONDocument25 pages1 UFC PHILIPPINES, INC. vs. BARRIO FIESTA MANUFACTURING CORPORATIONCJ RomanoNo ratings yet

- Buffalo Wild Wings 2014 1994 - BWW - Style GuideDocument24 pagesBuffalo Wild Wings 2014 1994 - BWW - Style GuidecnmbhqNo ratings yet

- Hydrogen Standardization Interim Report: Tanks, Piping, and PipelinesDocument12 pagesHydrogen Standardization Interim Report: Tanks, Piping, and PipelinesShajahan ShagulNo ratings yet

- Jean-Jacques Rousseau, Gérard Mairet - Du Contrat Social, Ou, Principes de Droit Politique Et Autres Écrits Autour Du Contrat Social-LGF (1996)Document335 pagesJean-Jacques Rousseau, Gérard Mairet - Du Contrat Social, Ou, Principes de Droit Politique Et Autres Écrits Autour Du Contrat Social-LGF (1996)Nicoleta AldeaNo ratings yet

- Tal U No LX UsermanualDocument18 pagesTal U No LX UsermanualElliotNo ratings yet

- Is 2720 Part28 Soil Replacement MethodDocument23 pagesIs 2720 Part28 Soil Replacement MethodJoe Ps100% (3)

- Full Body IK (FBIK) GuideDocument86 pagesFull Body IK (FBIK) GuideRayTracer57No ratings yet

- GFR CatalogDocument137 pagesGFR CatalogironeousNo ratings yet

- LST HandbookDocument33 pagesLST HandbookAparna SinghNo ratings yet

- Three Kids and A RocketDocument21 pagesThree Kids and A Rocketkarthick pNo ratings yet

- Actual Patents of Mind Control and Behavior Modification TechnologyDocument10 pagesActual Patents of Mind Control and Behavior Modification TechnologyJeover Giraldo Hurtado100% (1)

- 01.02 - Cariño vs. Insular Government (7 Phil 132)Document5 pages01.02 - Cariño vs. Insular Government (7 Phil 132)JMarcNo ratings yet

- Astm D2444Document8 pagesAstm D2444Hernando Andrés Ramírez GilNo ratings yet