Professional Documents

Culture Documents

Information Flow in Supply Chain Management With An Example of Waste Management Company

Uploaded by

judemcOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Information Flow in Supply Chain Management With An Example of Waste Management Company

Uploaded by

judemcCopyright:

Available Formats

ALS

Advanced Logistic Systems

INFORMATION FLOW IN SUPPLY CHAIN MANAGEMENT WITH AN

EXAMPLE OF WASTE MANAGEMENT COMPANY

Joanna Nowakowska-Grunt, Janusz K. Grabara

Czestochowa University of Technology, Management Faculty

Abstract: The paper presents information flow process in management of supply chains. Authors

notices information flows as a driving element of the global supply chain. Authors points also on the

logistics aspects in supply chain of waste management company.

Keywords: information flow, waste management company, supply chain

1. Introduction

Globalisation and growth of competition, from a perspective of European Union accession,

causes that companies search for management concepts which enable the efficiency of

operation to be improved and, consequently, they lead to improvement in competitive

position in the market or to holding current position. Under current conditions, supply chain

management seems to be a concept with fresh perspectives. It is caused by the fact that this

concept does not mean the negation of current relationships between supplier and customer

which are frequently contradictory and focused on taking advantage of the market situation

at the expense of supply chain partner. In return, the concept of supply chain management

focuses on close cooperation of organizations which are the links in the same supply chain in

order to achieve stronger competitive position on the market through effective management.

2. Analysis of the concept of supply chain management

Supply chain management is a relatively new concept, which was first meant by consultants

in the early eighties and since then the concept has gained on popularity in scientific papers

on logistics and management. However, the scientists working on supply chain management

frequently make reference even to scientific output of the fifties or sixties. Practical use of

the concept seems to be proved by the fact that the results of investigations carried out in

1993 in the USA among 325 logistics experts, members of American Council of Logistics

Management indicated growth in importance of cooperation between companies and interinstitutional aspects of supply chain[1]

This mainly concerns specific approach to a group of cooperating companies, which

eliminates many currently existing barriers and which is performed in order to manage and

coordinate flow of goods, from raw materials to finished goods purchased by customers and

other users. This cooperation is focused on achieving high efficiency of each company and

their network as a whole, due to integration and coordination, as well as optimisation of the

added value through all the links in the chain until the product expected by the customer.

- 95 -

ALS

Advanced Logistic Systems

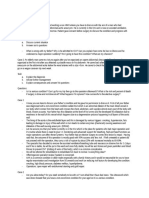

Success of supply chain management depends on integration and coordination of three types

of flow[2] (see Fig. 1):

information

goods

cash.

Suppliers

Manufacture

Wholesaler

Retailers

Customers

Information flows

Flow of goods

Cash flows

Figure 1 Factors of supply chain integration [3]

In practice, the phenomena of relationships and divisions in logistic chain occur [4]:

In procurement, these activities are undertaken and realized which enable delivery

of many various materials and cooperation elements in a defined amount,

assortment and quality in a due time and at possibly lowest cost to the particular

location, i.e. production process. Thus the phenomenon of interrelation of material

stream and cooperation elements occurs.

In distribution, such activities are undertaken and realized which provide the

customers with finished goods in a demanded quantity, assortment, in a due time,

with possibly lowest cost and in defined locations. Thus in distribution networks the

phenomenon of division of finished goods supply stream, as far as to final recipients

occurs.

Each change in location of materials and finished goods and the relevant information in

logistics chain is connected with overcoming the time and space. Time aspect is connected

with necessity to obtain as short time of flow of materials and finished goods as possible for

individual links and in whole logistics chain.

Spatial aspect, however is connected with all necessary activities of relocation of materials

and finished goods from one link in the chain to the another one [4].

Definition of logistics chain according to Bowersox says that logistics channel (chain) means

a number of entities (companies or organizations) which cooperate together in an integrated

way in order to deliver right product to right place in right time while ensuring appropriate

quality at possibly lowest cost [4], which proves its key character.

With this approach, a logistics chain, according to flow orientation, encompasses cooperating

companies, areas of cooperation and internal areas of company. Thus it comprises many

links which must be related to each other in order for the chain to be reliable. They can

include[4]:

suppliers of materials,

suppliers of cooperation elements,

shipping companies,

- 96 -

ALS

Advanced Logistic Systems

transport companies,

warehousing companies

final product manufactures,

packaging and trans-shipment companies,

wholesalers,

dealers,

agencies,

retailers.

Number of links comprising typical logistics chain may vary. Depending on the logistics

strategy assumed by company it can build more or less complex logistics chains. In present

economic reality a position of a company in effectively operating logistics chain is of great

importance. Thus the need appear to build such a relationships with their market partners so

that, from the point of view of the goals set by the companies, they are effective and give the

opportunities of proper realization of processes of flow of goods and information in the

whole chain. Before building the logistics chain where the company is to operate, the

answers to the following questions should be found:

What are companys strategy and goals?

What does the company need to achieve cooperating with other partners in logistics

chain?

How much financial resources should be spend in order to achieve set goals?

What should be the concept of organization of logistics in company?

Which solution from the suggested alternatives should be chosen?

How the chosen solution should be implemented and developed?

Answers to these questions should be known, justified and accepted by the board and

management in a company before making key financial decisions.

Preparation of concepts of logistics chain in which a company is to exist should start from

specifying and agreeing by all the involved parties the requirements on target system.

Moreover, these requirements should be the result of careful analysis of the needs which

takes into consideration mainly service initiatives of the company in the market.

The focus should also be made on specific goals in a company, which will provide for other

aspects, i.e.:

operation under conditions of competitive market is connected with necessity of

careful monitoring of the competition activities. Planning and implementation of the

structure of supply chain is necessary. Such a structure must be effective both in terms

of expenses incurred on building of it and other factors.

A company confronts the necessity of consideration of strategy of building the supply

chain which enables the set standards of customer service to be achieved.

System approach to building strategy of supply chain described as above ensures right

decisions on choice of organizational solutions to be made. Such an approach leads also to

making the decisions which minimize investment risk and to ensure set business goals to be

achieved. Implementation of an integrated system encompassing both finance/cost and the

sales areas of a companys operation is therefore a necessity.

3. Information system in supply chain in Sita [6, 7]

Sita is a company which cooperates with ca. 2.7m Polish citizens and 3.3 thousand of

companies. A particular attention should be paid to the services for partners who can be

- 97 -

ALS

Advanced Logistic Systems

provided complex services. The company ensures consulting and prepares individual, most

effective systems of service. Such cooperation enables flexible approach to solved problems

and optimization of processes of their realization.

Sita realizes tasks in terms of:

consulting and waste management planning,

collecting and disposal of municipal waste,

collecting and disposal of industrial and hazardous waste,

planting and maintaining the green,

yearlong (mechanical and manual) maintaining of road and squares cleanliness.

The company cooperates closely with the Capital Groups of an international range. It

provides services for PKN Orlen, Pizza Hut, BP, Shell, Statoil, Castorama, Selgross, IKEA.

Sitas partners include biggest Polish building companies: SKANSKA S.A., BUDIMEX

S.A., MITEX S.A., WARBUD S.A., HYDROBUDOWA S.A. Since 2004 it has developed

in terms of providing services for nationwide networks of branches, such as Mc' Donald and

Kredyt Bank S.A., Elektro World, Conforama, CAT Logistic. It offers services all over

Poland for cities, towns and gminas, housing cooperatives, council houses, condominiums

and individual customers. The company ensures that, if possible, the waste is selectively

collected. In many branches throughout the country it realizes selective disposal of municipal

waste with the division into paper, plastics, glass and metal. In several of them the company

is equipped in sorting lines. Thanks to it the recycling materials can be more efficiently

recovered from dry fraction of materials. Selectively collected industrial waste enable choice

of most effective solutions in terms of processing and recycling of the waste. Considerable

store is set by proper hazardous waste treatment, forwarded to the entities which deal with

such an activity. Sita Group manages two installations for industrial waste treatment. The

company aims to minimize fraction of waste which reaches landfills. Only non-recyclable

waste is forwarded to modern landfills with specialized protective and monitoring

equipment.

The investigated company is characterized by complex consideration of operation and

logistics subsystems which is realized by supply chain management. The logistics chain is

made up of four fundamental links:

unit which generates waste, which is subject to further processing (e.g. a company,

an inhabitant),

entity responsible for waste collection and its transport by means of leased

containers to another link in the chain,

units whose task is to sort the waste and then its recycling,

last link in the chain is a landfill, where the non-recyclable waste is forwarded.

In the supply chain operating in such a way it is necessary to support the material processes

with the software which optimizes these processes. In the investigated entity i.e. Sita

Czstochowa, an invoicing and accounting software application of RUOM is employed.

Main part of the software is based on CRM solutions. The theorists claim that CRM is not

only an IT system but a comprehensive modern marketing strategy for businesses. CRM is

an abbreviation of Customer Relationship Management. Relationship management means in

this case:

monitoring all the relationships with customers,

monitoring the tasks performed by the employees providing services to the

customers,

monitoring whole projects connected with multiple customers served by the

employee teams.

- 98 -

ALS

Advanced Logistic Systems

All the operations are usually performed using notes, various support applications and most

of data are stored in peoples memory. Implementation of CRM system consists in moving

all customer data and information on processes connected with customer service to the

software. Access to this data and processes is granted to anybody who needs such

information.

Key benefits of implementation of CRM system include:

possession of one, homogeneous and coherent database for all information on

customers,

possibility of fast searching for information on customers according to different

conditions,

independence from knowledge on customer known only to particular employees.

Unfortunately, implementation of CRM system is connected with huge workload and

necessity of maintaining high self-discipline after the implementation in order for database to

be always updated. However, proper implementation of the CRM system and strict

adherence to procedures for registration of data and information on customers, contacts with

them or performed tasks enables prospectively improved customer service.

RUOM system employed for the investigated company is comprised of four main modules;

maintenance module is the most important one, while three remaining are designed for

settlements, invoicing and controlling. The system is used by four divisions of the company,

i.e.:

Accounting,

Bookkeeping,

Maintenance,

Controlling.

Each division can use the data from the system. They can also make corrections and changes

in records concerning a particular customer or various events which took place in a company.

The system also gives opportunities of preparation of reports and analysis on the basis of

data contained within the system; there is also an opportunity to move them and process in

Excel software.

The system shows several benefits which enable the market advantage to be achieved by the

company. By using information flow throughout all the links of logistics system in supply

chain the effective management of these processes and, consequently, making proper

decision in a given area have become possible. Application of the system for improvement of

customer service, which is an overriding task of any supply chain, has become of key

importance.

References

[1] KOT S.: Supply Chain Management in Global Scale. [in:] Enterprises,

Enterpreneurship in the Face of Globalization and European Integration - Economic,

Legislative and Social Challenges. Ed.by Ryszard Borowiecki, Ofic.Wyd.ABRYS,

Krakw 2006

[2] RUTKOWSKI K. (ed.): Zintegrowany acuch dostaw. Dowiadczenia globalne i

Polskie, red. AGH, Warszawa 2002

[3] COYLE J.J, BARDI E.J., LANGLEY C.J: Zarzdzanie logistyczne, PWE Warszawa

2003

[4] SOTYSIK M.: Zarzdzanie logistyczne, AE, Katowice 2000

- 99 -

ALS

Advanced Logistic Systems

[5] ABT S.: Systemy logistyczne w gospodarowaniu. Teoria i praktyka logistyki,

Pozna 1996

[6] BRZOZOWSKI P., WIADEREK R.: Informatyczne wspomaganie procesw

logistycznych w Sita Czstochowa sp. z o.o, w: Informacja i komunikacja w

logistyce pr. zb. pod red. J.K.Grabary i C.Olszak, AE Katowice 2005

[7] www.sita.pl

- 100 -

You might also like

- Low GI Foods Guide for Managing Blood SugarDocument10 pagesLow GI Foods Guide for Managing Blood SugarJennyfer Cayabyab100% (1)

- 1st Book - Hard Landing by Stephen LeatherDocument270 pages1st Book - Hard Landing by Stephen LeatherRay NichollsNo ratings yet

- Understanding the Importance of Supply Chain ManagementDocument27 pagesUnderstanding the Importance of Supply Chain ManagementParth Kapoor100% (1)

- Supply Chain Principles and ApplicationsDocument12 pagesSupply Chain Principles and ApplicationsRicky KristandaNo ratings yet

- Supply Chain ManagementDocument25 pagesSupply Chain ManagementRizwan BukhariNo ratings yet

- Vegetarian in KoreaDocument4 pagesVegetarian in KoreastuartwallNo ratings yet

- Conversations at A RestaurantDocument26 pagesConversations at A RestaurantStavros G. Lazarides100% (1)

- The Supply Chain RevolutionDocument6 pagesThe Supply Chain RevolutionKea Plamiano Alvarez0% (1)

- Supply Chain MGMT Project1Document40 pagesSupply Chain MGMT Project1arvind_vandanaNo ratings yet

- Supply Chain Management: Coordinating the Flow of GoodsDocument10 pagesSupply Chain Management: Coordinating the Flow of GoodsAnnie CaserNo ratings yet

- Coca-Cola Global Marketing Strategy: Assignment SampleDocument3 pagesCoca-Cola Global Marketing Strategy: Assignment Samplejudemc100% (1)

- Supply Chain ManagementDocument4 pagesSupply Chain ManagementwuuboNo ratings yet

- Optimize Supply Chain LogisticsDocument15 pagesOptimize Supply Chain Logisticsvinivasu06100% (2)

- JSA For Rebar Works Includes Working in ScaffoldingDocument4 pagesJSA For Rebar Works Includes Working in Scaffoldingyc safetyNo ratings yet

- NEF Pre Int Wordlist FrenchDocument27 pagesNEF Pre Int Wordlist Frenchbleuet29No ratings yet

- Supply Chain ManagementDocument11 pagesSupply Chain ManagementrahilkatariaNo ratings yet

- Supply Chain ManagementDocument13 pagesSupply Chain Managementvimal100% (1)

- SCM for Clinical TrialsDocument40 pagesSCM for Clinical TrialsNilesh JetaniNo ratings yet

- Assignment Supply Chain ManagementDocument28 pagesAssignment Supply Chain Managementmailonvikas100% (3)

- SCM manages interconnected businessesDocument14 pagesSCM manages interconnected businessesKiran ThapaNo ratings yet

- Global Logistics and SCM EvolutionDocument12 pagesGlobal Logistics and SCM EvolutionsunithascribdNo ratings yet

- MCQ OSCM Unit 1Document22 pagesMCQ OSCM Unit 1ShammimBegum67% (6)

- Zara's Agile Supply Chain SuccessDocument11 pagesZara's Agile Supply Chain Successr_vivekanand100% (1)

- Supply Chain ManagementDocument6 pagesSupply Chain ManagementSheikh Saad Bin ZareefNo ratings yet

- SCM guide to planning, managing supply chainDocument7 pagesSCM guide to planning, managing supply chainklumba2027No ratings yet

- Supplier Customer Raw Materials Value ChainsDocument44 pagesSupplier Customer Raw Materials Value ChainsniyaramakrishnanNo ratings yet

- Aims LM M5Document17 pagesAims LM M5Sachin NNo ratings yet

- Supply Chain Management SummaryDocument18 pagesSupply Chain Management SummaryrangacharyNo ratings yet

- Research Paper Topics in LogisticsDocument4 pagesResearch Paper Topics in Logisticsqrcudowgf100% (1)

- MZU-SEM I-MBA-Fundamentals of Logistics and Supply Management-Unit 2Document37 pagesMZU-SEM I-MBA-Fundamentals of Logistics and Supply Management-Unit 2Rahul GoudaNo ratings yet

- TOPIC 2.1: Products, Services, Information and Financial TransactionsDocument5 pagesTOPIC 2.1: Products, Services, Information and Financial TransactionsNhsyyNo ratings yet

- Research Paper Topics For LogisticsDocument4 pagesResearch Paper Topics For Logisticswohekam1d0h3100% (1)

- Evolution of SCMDocument3 pagesEvolution of SCMDwayne AndradeNo ratings yet

- 1 J.witkowski B.rodawski The Essence...Document22 pages1 J.witkowski B.rodawski The Essence...johnSianturiNo ratings yet

- Rationale Behind Doing This ProjectDocument60 pagesRationale Behind Doing This Projectarun060283shukla7692No ratings yet

- Metro Cash & CarryDocument13 pagesMetro Cash & Carryafreenessani0% (1)

- Manage every step of supply chainDocument4 pagesManage every step of supply chainAhmed Noor KhawajaNo ratings yet

- Fundamentals of Logistics XI - 2023Document45 pagesFundamentals of Logistics XI - 2023saiyaNo ratings yet

- SCM & Lean SystemsDocument15 pagesSCM & Lean SystemsshiningdewNo ratings yet

- Unit 1 - NotesDocument8 pagesUnit 1 - NotesAnas K MakNo ratings yet

- Logistics IndustryDocument8 pagesLogistics Industrysubbu2raj3372No ratings yet

- Supply Chain ManagementDocument15 pagesSupply Chain Managementsaif125No ratings yet

- Integrated Logistics Management - An Opportunity For Met A HeuristicsDocument27 pagesIntegrated Logistics Management - An Opportunity For Met A HeuristicsRai Waqas Azfar KhanNo ratings yet

- Research Paper On Logistics and Supply Chain ManagementDocument4 pagesResearch Paper On Logistics and Supply Chain Managementgz3ezhjcNo ratings yet

- Supply Chain Management Must Address The Following ProblemsDocument2 pagesSupply Chain Management Must Address The Following ProblemsVineet RamanNo ratings yet

- Supply Study TvsDocument20 pagesSupply Study TvsSiva RatheeshNo ratings yet

- ISM Notes Part IIDocument20 pagesISM Notes Part IIGeet GoelNo ratings yet

- 2015SCMResearchJournal PDFDocument36 pages2015SCMResearchJournal PDFPatric Ian EsposoNo ratings yet

- A Study On Supply Chain Management in DSM Textile in KarurDocument82 pagesA Study On Supply Chain Management in DSM Textile in Karurk eswariNo ratings yet

- A I T S C: N Ntroduction O Upply HainDocument33 pagesA I T S C: N Ntroduction O Upply HainSmn BoparaiNo ratings yet

- Rintu SeminarDocument9 pagesRintu SeminarRenjith NgNo ratings yet

- Supply ChainDocument38 pagesSupply ChainHemant SharmaNo ratings yet

- Supply Chains of The FutureDocument38 pagesSupply Chains of The FutureVishakha JainNo ratings yet

- Logistics and Supply Chain Management: A Seminar Report ONDocument9 pagesLogistics and Supply Chain Management: A Seminar Report ONVivek D DeshmukhNo ratings yet

- JerusalemDocument12 pagesJerusalemYaikob MaskalaNo ratings yet

- Merge in TransitDocument29 pagesMerge in TransitMauricio FurtadoNo ratings yet

- Project Report On SCMDocument16 pagesProject Report On SCMmanas sibal0% (1)

- Supply Chain Management EssayDocument18 pagesSupply Chain Management EssayChris Ba Aiden Mabuwa100% (1)

- Role of Transport in Logistics ChainsDocument14 pagesRole of Transport in Logistics ChainsArun RaiNo ratings yet

- Supply Chain ManagementDocument16 pagesSupply Chain ManagementSnigdho Shokal100% (1)

- Supply Chain Management - Wikipedia, The Free EncyclopediaDocument11 pagesSupply Chain Management - Wikipedia, The Free EncyclopediaKptt LogeswaranNo ratings yet

- Businesses Product Service Supply Chain Raw MaterialsDocument4 pagesBusinesses Product Service Supply Chain Raw MaterialsSyed Bilal MahmoodNo ratings yet

- ISCMDocument21 pagesISCMcsrajmohan2924No ratings yet

- Seminar Project ReportDocument40 pagesSeminar Project ReportMankul GoyalNo ratings yet

- Supply Chain ManagementDocument15 pagesSupply Chain ManagementMehak GuptaNo ratings yet

- Logistical Challenges of Warehousing and TransportingDocument5 pagesLogistical Challenges of Warehousing and Transportingiamcheryl2098No ratings yet

- Chapter 1 - Revised2Document12 pagesChapter 1 - Revised2Wan HamizaNo ratings yet

- Acute Renal Failure On Chronic Renal FailureDocument1 pageAcute Renal Failure On Chronic Renal FailurejudemcNo ratings yet

- Acute Exacerbation of COPDDocument2 pagesAcute Exacerbation of COPDjudemcNo ratings yet

- Acute PyelonephritisDocument1 pageAcute PyelonephritisjudemcNo ratings yet

- Acute Confusion in A Postoperative PatientDocument2 pagesAcute Confusion in A Postoperative PatientjudemcNo ratings yet

- Acute Coronary SyndromeDocument1 pageAcute Coronary SyndromejudemcNo ratings yet

- Acute Myocardial InfarctionDocument2 pagesAcute Myocardial InfarctionjudemcNo ratings yet

- Acute DiverticulitisDocument1 pageAcute DiverticulitisjudemcNo ratings yet

- Acute Cholangiti1Document2 pagesAcute Cholangiti1judemcNo ratings yet

- Swotanalysisofpharmaceuticalmarketingfocusingoninternationalbusiness 141118104224 Conversion Gate02Document23 pagesSwotanalysisofpharmaceuticalmarketingfocusingoninternationalbusiness 141118104224 Conversion Gate02judemcNo ratings yet

- Acute Alcoholic HepatitisDocument1 pageAcute Alcoholic HepatitisjudemcNo ratings yet

- Acute Cholangiti1Document2 pagesAcute Cholangiti1judemcNo ratings yet

- ML13 349Document7 pagesML13 349worldontopNo ratings yet

- Acute Alcoholic HepatitisDocument1 pageAcute Alcoholic HepatitisjudemcNo ratings yet

- Acute Brain SyndromeDocument2 pagesAcute Brain SyndromejudemcNo ratings yet

- ICU Stay & AAA Surgery RecoveryDocument2 pagesICU Stay & AAA Surgery RecoveryjudemcNo ratings yet

- Planning For Sustainable AquacultureDocument39 pagesPlanning For Sustainable AquaculturejudemcNo ratings yet

- Assessing Dietary Intake Eating and Exercise Attitudes and FitnessDocument98 pagesAssessing Dietary Intake Eating and Exercise Attitudes and FitnessjudemcNo ratings yet

- Blue Sky MarketingPlanDocument7 pagesBlue Sky MarketingPlanMBA103003No ratings yet

- Supply Chain Analysis of Ready-To-use Therapeutic Foods For The Horn of AfricaDocument136 pagesSupply Chain Analysis of Ready-To-use Therapeutic Foods For The Horn of AfricajudemcNo ratings yet

- Blue Sky MarketingPlanDocument7 pagesBlue Sky MarketingPlanMBA103003No ratings yet

- Aquaculture Industry Potential and IssuesDocument6 pagesAquaculture Industry Potential and IssuesjudemcNo ratings yet

- Short Food Chains Discussion Paper 2014 enDocument25 pagesShort Food Chains Discussion Paper 2014 enjudemcNo ratings yet

- Proposal On Aquaculture in Recirculating Aquaculture SystemsDocument8 pagesProposal On Aquaculture in Recirculating Aquaculture SystemsjudemcNo ratings yet

- Closed System AquacultureDocument81 pagesClosed System AquaculturejudemcNo ratings yet

- Aquaculture ResearchDocument80 pagesAquaculture ResearchjudemcNo ratings yet

- Deli ImDocument172 pagesDeli ImImad IsmailiNo ratings yet

- Coca Cola Marketing StrategyDocument3 pagesCoca Cola Marketing StrategyjudemcNo ratings yet

- Introduction To Business PlanDocument3 pagesIntroduction To Business PlanSandra HassanNo ratings yet

- Indirect Tax Laws Vol.-Iii (Practice Manual) - g2Document231 pagesIndirect Tax Laws Vol.-Iii (Practice Manual) - g2caatulgarg6023100% (1)

- Trademark Updates for Water Purification DevicesDocument1,040 pagesTrademark Updates for Water Purification DeviceskamaldeepNo ratings yet

- Porter's Five Forces ModelDocument4 pagesPorter's Five Forces ModelNguyễn DungNo ratings yet

- Panasonic NA 107VC4Document40 pagesPanasonic NA 107VC4killerhAPPyNo ratings yet

- Supply Chain ExamplesDocument3 pagesSupply Chain Examplesmano555No ratings yet

- Department of Education: Cookery 9 Quarter 1 LAS Number 2 (Week 3-4)Document2 pagesDepartment of Education: Cookery 9 Quarter 1 LAS Number 2 (Week 3-4)Catherine Dubal100% (1)

- Salma HussainDocument0 pagesSalma HussainAnup GuptaNo ratings yet

- Copeland Scroll Low Temperature Compressors For Refrigeration en Us 5399944Document2 pagesCopeland Scroll Low Temperature Compressors For Refrigeration en Us 5399944suresh muthuramanNo ratings yet

- Pioneer Deh p9300Document6 pagesPioneer Deh p9300Eric SerticNo ratings yet

- MM Case StudyDocument5 pagesMM Case StudyPurushottam NanjappaNo ratings yet

- Pincon Spirit Acquires 5 Retail Outlets in Kolkata (Company Update)Document4 pagesPincon Spirit Acquires 5 Retail Outlets in Kolkata (Company Update)Shyam SunderNo ratings yet

- Youngman Telescopic Ladder: Use and Care InstructionsDocument8 pagesYoungman Telescopic Ladder: Use and Care InstructionsnicehornetNo ratings yet

- RadioDigest 24-11-15Document42 pagesRadioDigest 24-11-15Enache DanielNo ratings yet

- Saravana Bhavan KuwaitDocument7 pagesSaravana Bhavan KuwaitkkpaliathNo ratings yet

- Ingredients For Making Puto MayaDocument6 pagesIngredients For Making Puto MayaVicky Alvarez FlorNo ratings yet

- Zero Inex Blast CabinetDocument8 pagesZero Inex Blast CabinetEduardo Efrain RubioNo ratings yet

- 00 Unit 1 - KCDocument21 pages00 Unit 1 - KCwindyfebriandaniNo ratings yet

- Kimberly-Clark Company Case Assign4Document3 pagesKimberly-Clark Company Case Assign4Ahmad Elsayed MohammedNo ratings yet

- Rubin RCH-BOXLINE-90SS Hood + RGH-Prado2B-B - New - Kitchen & Appliances For Sale Selangor - MudahDocument2 pagesRubin RCH-BOXLINE-90SS Hood + RGH-Prado2B-B - New - Kitchen & Appliances For Sale Selangor - MudahnamasralNo ratings yet

- Physical Distribution SystemDocument6 pagesPhysical Distribution Systemhinasaxena100% (1)

- Unit 03 Workbook AkDocument1 pageUnit 03 Workbook AkEd OrtizNo ratings yet