Professional Documents

Culture Documents

Drug Release Nanocomp

Uploaded by

TOUFIKCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Drug Release Nanocomp

Uploaded by

TOUFIKCopyright:

Available Formats

Applied Clay Science 8081 (2013) 8592

Contents lists available at ScienceDirect

Applied Clay Science

journal homepage: www.elsevier.com/locate/clay

Research paper

Claypolymer nanocomposites as a novel drug carrier: Synthesis,

characterization and controlled release study of

Propranolol Hydrochloride

Seema, Monika Datta

Analytical Research Laboratory, Department of Chemistry, University of Delhi, Delhi 110007, India

a r t i c l e

i n f o

Article history:

Received 25 May 2012

Received in revised form 17 May 2013

Accepted 1 June 2013

Available online 10 July 2013

Keywords:

Claypolymer nanocomposites,

Montmorillonite

Controlled drug delivery

Antihypertensive drug

a b s t r a c t

Short half life of Propranolol Hydrochloride (PPN), an antihypertensive drug is a prime requirement to develop a formulation which could extend the release of PPN in the human body and also eliminate daily multiple

dosage of PPN. In this study, a system of PPN loaded MontmorillonitePoly lactic-co-glycolic acid (MtPLGA)

nanocomposites has been developed. PPN incorporated PLGA nanoparticles have been compared with

MtPPNPLGA nanocomposites. Mt was used as sustained release carrier for PPN with addition of biodegradable

polymer PLGA by preparing MtPPNPLGA nanocomposites by double emulsion solvent evaporation method.

The drug encapsulation efciency and drug loading capacity of synthesized products were estimated with

HPLC including suitable analytical techniques to conrm the formation of claypolymer nanocomposites

(CPN). The release prole of encapsulated PPN in CPN shows pH dependent release in simulated gastrointestinal uid for a period of 8 h. This study suggests that the methodologies used are suitable for the synthesis of

Mt based PLGA nanocomposites with high drug encapsulation efciency and controlled drug release characteristics and indicates that the MtPPNPLGA nanocomposites are supposed to be better oral controlled drug

delivery system, for a highly hydrophilic low molecular weight antihypertensive drug PPN to minimize the

drug dosing frequency and hence improving the patient compliance.

2013 Elsevier B.V. All rights reserved.

1. Introduction

Drug delivery systems have been of great interest for the past few

decades to realize the effective and controlled drug delivery and minimize the side effects in the eld of pharmaceutics. Oral controlled

drug delivery system is an essential part of the development of new

medicines. The carriers used for control drug release were mainly biodegradable polymers (Langer et al., 1999) and porous inorganic matrix (Suresh et al., 2010; Aguzzi et al., 2007).

In recent years, drug intercalated smectite, especially Montmorillonite

(Mt) pharmaceutical grade clay mineral has attracted great interest of researchers (Joshi et al., 2009a,b). Mt has large specic surface area, exhibits

good adsorption ability, cation exchange capacity, and drug-carrying capability. Mt is hydrophilic and highly dispersible in water and can accommodate various protonated and hydrophilic organic molecules along the

(001) planes which can be released in controlled manner by replacement

with other kind of cations in the release media (Bergaya et al., 2006; Chen

et al., 2010; Iliescu et al., 2011). Therefore the Mt is suggested to be a good

delivery carrier of the hydrophilic drugs. Mt is a potent detoxier with excellent adsorbent properties due to its high aspect ratio. It can adsorb excess water from feces and thus act as anti-diarrhoeic. Mt can also provide

Corresponding author. Tel.: +91 9811487825; fax: +91 11 27666605.

E-mail address: monikadatta_chem@yahoo.co.in (M. Datta).

0169-1317/$ see front matter 2013 Elsevier B.V. All rights reserved.

http://dx.doi.org/10.1016/j.clay.2013.06.009

mucoadhesive capability for the nanoparticles to cross the gastrointestinal barrier (Dong and Feng, 2005; Feng et al., 2009). It has also been

used as a controlled release system. Mt has been proved to be nontoxic

by hematological, biochemical and histopathological analyses in rat

models (Lee et al., 2005). Mt is utilized as a sustained release carrier

for various therapeutic molecules, such as 5 Fluorouracil (Lin et al.,

2002), sertraline (Nunes et al., 2007), vitamin B1 (Joshi et al., 2009a,b),

promethazine chloride (Seki and Kadir, 2006) and buspiron hydrochloride (Joshi et al., 2010).

Propranolol Hydrochloride [(2RS)-1-(1-Methylethyl) amino-3(naphthalen-1-yloxy) propan-2-ol monohydrochloride] an antihypertensive drug is a nonselective, beta-adrenergic receptor-blocking agent

(Dollery, 1991). It is a white crystalline solid, highly soluble in water.

The dose of Propranolol Hydrochloride (PPN) ranges from 40 to

80 mg/day. Due to shorter half life (3.9 h) the drug has to be administrated 2 or 3 times daily so as to maintain adequate plasma levels of

the drug (Chaturvedi et al., 2010). Thus, the development of controlled

release dosage forms would clearly be advantageous (Sahoo et al.,

2008). Sanghavi et al. (1998), prepared matrix tablets of PPN using

hydroxypropyl methylcellulose which exhibited rst order release

kinetics. Velasco-De-Paola et al., 1999, described dissolution kinetics of

controlled release tablets containing PPN prepared using eudragit. Some

other researchers have also formulated oral controlled release products of

PPN by various techniques (Gil et al., 2006; Mohammadi-Samani et al.,

86

Seema, M. Datta / Applied Clay Science 8081 (2013) 8592

2000; Paker-Leggs and Neau, 2009; Patel et al., 2010; Patra et al., 2007).

However, many researchers in the development of PPN sustained release

dosage forms were met with problems, such as the difculty to control

the release of the drug due to the high aqueous solubility of PPN.

Snchez-Martin et al. (1981) and Rojtanatanya and Pongjanyakul

(2010) have reported the interaction of PPN with Mt and magnesiumaluminium-silicate mineral (MAS, a mixture of Mt and saponite) respectively. PPN can intercalate into the interlayer space of MAS and the

obtained complexes showed control of the release of PPN.

However no report has been available in the literature for the

combination of a biodegradable polymer Poly lactic-co-glycolic acid

(PLGA) and Mt for controlled release of PPN. In this study we have

tried to obtain the synergism of biodegradable and biocompatible polymer which has already been widely explored for controlled drug release

properties, with pharmaceutical grade Mt to produce the oral and controlled drug delivery formulations for PPN. Being a highly hydrophilic

drug molecule, it is very difcult to encapsulate a high amount of PPN

within the hydrophobic polymer matrix. Therefore, in the present

study a modied double emulsion solvent evaporation technique has

been developed to entrap a substantial amount of drug in the synthesized formulations.

PPNPLGA nanoparticles and MtPPNPLGA nanocomposites were

prepared by w/o/w double emulsion/solvent evaporation method by

using biodegradable polymer PLGA and non-ionic Pluronic F68 (a triblock

co-polymer selected as an emulsier and stabilizing agent for the formation of PPNPLGA nanoparticles and MtPPNPLGA nanocomposites).

The synthesized products were characterized for interlayer structural

changes in the solid by XRD, surface morphology and particle size by SEM

and TEM with EDX, physical status of the drug and Mt by thermal studies

and drug loading by HPLC technique. The drug release prole of the synthesized PPNPLGA nanoparticles and MtPPNPLGA nanocomposites

was investigated in simulated gastrointestinal uid. The MtPPNPLGA

nanocomposites obtained were intercalated and partially exfoliated in

nature, spherical in shape with about 50300 nm in size, the favorable

size range for intestinal mucosal membrane uptake. DSC results clearly indicate the degradation of the drug encased within synthesized

PPNPLGA nanoparticles and MtPPNPLGA nanocomposites. The drug

release prole of MtPPNPLGA nanocomposites shows up to 14% of

the drug was released in simulated gastric uid whereas in simulated intestinal uid it shows up to 72% of drug release in a period 8 h. Thus we

can suggest that MtPLGA nanocomposites can be used as a potential

drug carrier for the controlled drug delivery of the low molecular weight

cationic hydrophilic drugs like PPN.

form a w/o/w-emulsion. The middle organic phase separated the internal

water droplets from each other as well as from the external aqueous continuous phase. After solvent evaporation the PPNPLGA nanoparticles

were isolated by centrifugation and washed with double distilled water

before freeze-drying.

2.1.2. Synthesis of PPNPLGAMMT nanocomposites

The synthesis of MtPPNPLGA nanocomposites involved the emulsication of rst w/o emulsion in Pluronic F-68 and Mt aqueous dispersion

(Fig. 1) followed by the same procedure as discussed in Section 2.1.1.

2.2. Characterizations

Powder X-ray diffraction (PXRD) measurements of samples were

performed on a powder X-ray diffractometer (XPERT PRO Pananlytical,

model (PW3040160, Netherland) the measurement conditions were a

Cu K radiation, generated at 40 kV and 30 mA as X-ray source 240

(2) and step angle 0.01/s. The differential scanning calorimetric studies

were conducted on a DSC instrument (DSC Q200 V23.10 Build 79). The

samples were purged with dry nitrogen at a ow rate of 10 ml/min

and the temperature was raised at 10 C/min. The effect of Mt content

on thermal stability of the MtPPNPLGA nanocomposites was assessed

by the thermogravimetric analyzer (TGA 2050 Thermal gravimetric

Analyzer). The surface morphology and particle size of the synthesized

products were examined with the Scanning Electron Microscope (Zeiss

EVO 40) and high resolution transmission electron microscope (TECNAI

G2 T30, U-TWIN) with an accelerating voltage of 300 kV.

2.3. Estimation of drug loading and encapsulation efciency with high

pressure liquid chromatography (HPLC technique)

2.3.1. HPLC apparatus and conditions

The HPLC system consisted of a Shimadzu Model DGU 20 A5 HPLC

pump, a Shimadzu-M20A Diode Array Detector, Shimadzu column oven

2. Materials and methods

2.1. Materials

Mt KSF, PLGA 50:50 (molecular weight 4075,000), Pluronic F-68 and

drug PPN (purity >98%) were ordered from Sigma Aldrich St. Louise

USA. HCl, KCl, NaOH, potassium dihydrogen phosphate of analytical

grade for simulated gastric uid HCl (pH 1.2) and simulated intestinal

uid (PBS, pH 7.4) preparation were ordered from MERCK (Germany).

HPLC grade methanol and water were used for drug estimation by

HPLC technique. All other reagents whether specied or not were of analytical grade. Double distilled water was used throughout the experimental work.

2.1.1. Synthesis of PPNPLGA nanoparticles

In this study, the water/oil/water (w/o/w) double emulsion solvent

evaporation method has been selected to encapsulate highly hydrophilic

drug PPN in the nanoparticles. PPNPLGA nanoparticles were synthesized in two steps. First, PPN was dissolved in water and emulsied in

a solution of methylene chloride containing PLGA under magnetic stirring

followed by sonication. In the second step, the primary w/o emulsion was

emulsied in the external aqueous phase of Pluronic F68 (0.2%, w/v) to

Fig. 1. Schematic representation of claypolymerdrug nanocomposite synthesis.

Seema, M. Datta / Applied Clay Science 8081 (2013) 8592

CTO-10AS governed by a LC Solution software. The detector wavelength

was set at 289 nm. Separation was achieved by low pressure gradient elution by modifying the reported literature (El-Saharty, 2003)

on mobile phase (40:60 ratio v/v) delivered at a ow rate of 1.0 ml/min

at ambient temperature through a C18 analytical column Luna 5

(250 4.6 mm i.d., 5 m particle size).

2.3.2. Stock solutions and standards

Stock solutions of PPN were prepared by dissolving 2.50 mg PPN

in 25 ml HPLC water, resulting in a solutions containing 100 g/ml.

This solution was diluted to give working standard solutions in concentration range of 0.5 to 50 g/ml. Standards were prepared with the following concentrations of 0.5, 1, 2, 4, 6, 8, 10, 15, 20, 25, 30 and 50 g/ml

for PPN.

2.3.3. Preparation of sample solutions

Supernatants recovered after centrifugation of the synthesized

samples were used for the estimation of unloaded drug resulting in

indirect estimation of drug encapsulation efciency. 200 l of supernatant was diluted up to 10 ml in a standard volumetric ask, ltered

by 0.22 m milipore lters. The ltered solutions were injected to

HPLC.

The HPLC studies indicate that the calibration curve for known PPN

solutions was linear in the concentration range of 0.5 to 100.0 g/ml in

water with a correlation coefcient of 0.99.

2.4. In vitro drug release studies

In vitro drug release studies of PPN were conducted in a constant

temperature bath with the dialysis bag technique (Joshi et al., 2009a,b).

Buffer solution of pH 1.2 (simulated gastric uid) was prepared by

mixing 250 ml of 0.2 M HCL and 147 ml of 0.2 M KCL. Phosphate buffer

solution (PBS) of pH 7.4 (simulated intestinal uid) was prepared by

mixing 250 ml of 0.1 M KH2PO4 and 195.5 ml of 0.1 M NaOH. In vitro release studies were carried out in simulated intestinal uid at pH 7.4 and

simulated gastric uid at pH 1.2 using the dialysis bag technique. Dialysis

sacs were overnight equilibrated with the dissolution medium prior to

experiments. Weighed amount of the synthesized products was taken

in 5 ml of buffer solution in the dialysis bag. The dialysis bag was dipped

into the receptor compartment containing 100 ml dissolution medium,

which was stirred at 100 rpm at 37 0.5 C. The receptor compartment

was closed to prevent the evaporation losses from the dissolution medium. The stirring speed was kept at 100 rpm. 5 ml of the sample was

withdrawn at regular time intervals and the same volume was replaced

with a fresh dissolution medium. Samples were analyzed for drug

PPN content by UV spectrophotometer at max = 289 nm.

87

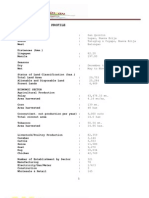

Table 1

Formulations of PPNPLGA nanoparticles and MtPPNPLGA nanocomposites.

S.No.

PPN-01

PPN-02

PPN-03

PPN-04

PPN-05

PPN

(mg)

20

20

20

40

60

Mt

(mg)

20

20

20

P-F68

(mg)

50

50

50

50

50

PLGA

(mg)

50

100

50

50

50

Composite

(mg)

27.16

79.97

30.57

40.00

76.48

A amount of PPN in the

composite

mg

D.L. (%)

E.E. (%)

2.389

2.23

3.540

14.072

46.385

08.6

02.82

11.4

35.17

60.69

11.69

12.16

17.69

35.17

77.30

encapsulated in the MtPPNPLGA nanocomposites increases from 18

to 35% in a linear manner (Table 1) with increase in drug to Mt ratio

from 1:1 to 2:1, however with further increase in drug to Mt ratio up

to 3:1, an increase in encapsulation efciency up to 77.30% was

obtained. This excessive increase of encapsulation may be attributed

to the cationic nature of PPN in the nanocomposites, which could enhance the interaction of PPN with negatively charged Mt and polymer

resulting in high encapsulation efciency. The increase in drug loading

can be attributed to the increase in nal yield obtained which is directly

involved in the calculation of drug loading percentage as per Eq. (1).

Drug loading %

Drug amount within the nanoparticles=Total weight of nanoparticles X 100

Encapsulation efficiency%

Drug amount within the nanoparticles=initial drug amount X 100

3. Results and discussion

In the series of experiment, the concentration of stabilizing agent

Pluronic F-68 was kept constant (0.2% wt/v) as per the reported critical micelle concentration (Schmolka, 1977). In the case of PPNPLGA

nanoparticles PPN-01, the amount of drug encapsulated was found to

be about 12% (Table 1) and with further increase in polymer content

(50 mg) the encapsulation efciency was found to increase by about

0.5%. Therefore, in order to avoid the presence of excess non-emulsied

polymer the amount of PLGA was xed at 50 mg for all formulations. It

has also been observed that in the case of MtPPNPLGA nanocomposites,

the maximum amount of drug (PPN-05) retained was 77%. Variations in

the composition of drug polymerclay nanocomposites were further

studied in detail.

3.1. Effect of PPN content on drug loading and encapsulation efciency

The drug loading and extent of drug encapsulation in MtPPNPLGA

as function of PPN content were studied, The amount of PPN

Fig. 2. XRD patterns of a pristine Mt, b MtPPNPLGA nanocomposites (PPN-03), c

MtPPNPLGA nanocomposites (PPN-04), d MtPPNPLGA nanocomposites (PPN-05),

and e pure PPN.

88

Seema, M. Datta / Applied Clay Science 8081 (2013) 8592

Fig. 3. Diagrammatic representation of I intercalated, II partially exfoliated, and III exfoliated Mt layers.

3.2. XRD studies

The physical status of Mt and PPN in the synthesized MtPPNPLGA

nanocomposites was investigated with the help of XRD. The XRD pattern of pristine Mt shows characteristic diffraction peak at 2 value of

6.4 corresponding to 001 plane with d spacing of 13.6 A (Fig. 2a). In

the case of MtPPNPLGA nanocomposites, PPN03 (1:1 drug to clay

ratio) an increase in intensity of the 001 plane along with the shift in

the 2 value, from 6.4 to 4.04, was observed (Fig. 2b), the hump in

the background from 2 values of 12 to 28 is due to the presence of

a polymer within the MtPPNPLGA nanocomposites. According to

Bragg's law, a shift in 2 value from higher diffraction angle to lower diffraction angle is indicative of an increase in d spacing i.e., from 13.6 A

to 21.4 A (Joshi et al., 2009a,b; Liu et al., 2006; Lin et al., 2002) and

an increase of 8 A has been attributed to the intercalation of polymer

drug moiety (Fig. 3, case-I) and is further supported by the HRTEM

image (Fig. 7b) by the presence of expanded and uniformly spaced Mt

layers in the PPN-03 MtPPNPLGA nanocomposites. However, presence

of a minor component of a population cannot be ruled out because of the

broad nature of 001 reection at 2 value of 4.04.

With the increase in drug to Mt ratio from 1:1 to 2:1 in the case of

(PPN04) and 3:1 in the case of (PPN-05), exfoliation of Mt layers

Fig. 4. TGA curves of, a Pure Mt, b PPNPLGA nanoparticles (PPN-01), c MtPPN

PLGA nanocomposites (PPN-03), and d MtPPNPLGA nanocomposites (PPN-05).

(Paul and Robeson, 2008) is being proposed (Fig. 2c & d). This is also supported by the substantial suppression of 001 reection at 2 value of 4.5

and corresponding increase in the intensity of broad hump between 2

values of 1228, which is indicative of the release of polymeric material

from the interlayer gallery (Fig. 3, cases II and III). This fact is further supported by the presence of exfoliated Mt layers in the HRTEM image of

PPN-05 MtPPNPLGA nanocomposites (Fig. 7c).

Excessive amount of polymerdrug moiety within the interlayers

can no longer hold the Mt platelets together. Increase in drug encapsulation efciency from 18% (PPN-03) to 35% (PPN-04) and

77% (PPN-05) can be attributed to the change in the nature of Mt

PPNPLGA nanocomposite from intercalation of the drug polymer moiety (to a small extent) to adsorption of the exfoliated negatively charged

Mt platelets on the drugpolymer moiety. The extent of drug encapsulation seems to be proportional to the extent of exfoliation in the case of

PPN-04 and PPN-05.

Further increase in drug content in the MtPPNPLGA

nanocomposites did not show further enhancement in the encapsulation

efciency indicating complete saturation of negative sites on Mt platelets.

The pure crystalline drug PPN shows intense peaks at 14.56,

17.32, 22.84, 23.47, 31.19, 32.30, 35.05, 36.23 and 37.58 and

the observation is in good agreement with the reported values in the literature (Wang et al., 2002). MtPPNPLGA nanocomposites reveal the

Fig. 5. DSC curves of, a Pure PPN, b PPNPLGA nanoparticles (PPN-01), c MtPPN

PLGA nanocomposites (PPN-03), and d MtPPNPLGA nanocomposites (PPN-05).

Seema, M. Datta / Applied Clay Science 8081 (2013) 8592

89

Fig. 6. SEMEDX images of a PPNPLGA nanoparticles and b MtPPNPLGA nanocomposites.

presence of crystalline PPN in the nanocomposites (Fig. 2), with increase

in drug to Mt ratio, the appearance of characteristic peaks of PPN becomes more evident.

3.3. TGA studies

The Mt shows weight loss of 10% from 30 to 140 C and is attributed

to the loss of adsorbed and interlayer water (Fig. 4a). In the case of

MtPPNPLGA nanocomposites (PPN-03) due to the replacement

of surface and interlayer water by organic moiety no such weight

loss was observed in this region. Hence, the stability was observed

in this region.

In the case of MtPPNPLGA nanocomposites (PPN-05) due to exfoliation of Mt no such weight loss was observed. Hence, the stability

was observed in this region.

In the temperature range of 30 to 425 C PPN-PLGA nanoparticles

(PPN-01), MtPPNPLGA nanocomposites (PPN-03) and (PPN-05) show

100%, 43.2% and 89.6% weight loss respectively (Fig. 4). It could be clearly

understood that weight loss observed in the case of MtPPNPLGA

nanocomposites (PPN-03 and PPN05) is because of the thermal degradation of PPN, PF68 and PLGA contents present in the formulation

(Dong and Feng, 2005). Mt content in the nanocomposites (PPN-03)

and (PPN-05) is about 56.8% and 10.4% respectively.

The MtPPNPLGA nanocomposite (PPN-03) shows less weight loss

as compared to the MtPPNPLGA nanocomposite (PPN-05) because in

the case of the intercalated sample (PPN-03) the polymerdrug moiety

is present within the ordered lattice whereas in the case of PPN-05 the

high weight loss is due to the complete degradation of polymerdrug

moiety which is out of the order lattice due to the exfoliation.

3.4. DSC studies

The appearance of small endothermic peak about 4850 C followed

by a broad endothermic peak in the temperature region of 360 C corresponds to the glass transition temperature (Mukherjee and

Vishwanatha, 2009) and thermal decomposition of the polymer PLGA

in PPNPLGA nanoparticles and MtPPNPLGA nanocomposites indicates no change in the polymer chain structure.

90

Seema, M. Datta / Applied Clay Science 8081 (2013) 8592

of PPN encapsulated within the PPNPLGA nanoparticles and MtPPN

PLGA nanoparticles and nanocomposites (Fig. 5).

Table 2

SEMEDX analysis report.

Element

Series

C norm (wt.%)

C Atom (at.%)

C error (%)

48.77

7.29

0.04

43.90

100.0

55.42

7.11

0.02

37.45

100.0

14.7

2.2

0.0

13.2

nanocomposites

K series

47.48

K series

45.31

K series

1.34

K series

1.26

K series

0.42

K series

2.98

100.0

57.09

40.90

0.69

0.67

0.42

0.22

100.0

14.5

13.9

0.1

0.1

0.1

0.1

a, PPNPLGA nanoparticles

Carbon

K series

Nitrogen

K series

Silicon

K series

Oxygen

K series

Total

b, MtPPNPLGA

Carbon

Oxygen

Silicon

Aluminium

Iron

Gold

Total

3.5. Scanning electron microscopic and EDX studies

PPNPLGA nanoparticles (PPN-01) and MtPPNPLGA nanocomposites (PPN-03 to 05) appear to be 100300 nm spherical particles (inset Fig. 6), the former has a smooth surface and the latter has a

rough surface because of the presence of Mt nano platelets on the

surface which has been further conrmed by SEMEDX studies

(Fig. 6a & b, Table 2).

Due to the presence of carbon polymer chain and organic drug

moiety in case of PPN-01, high content of carbon, oxygen and nitrogen

was seen on the surface (Fig. 6, a) whereas, samples containing Mt,

PPN-03 to 05, additional peaks of silicon, aluminium and iron conrms

the presence of Mt nano platelets on the surface of the MtPPNPLGA

nanocomposites (Fig. 6b).

3.6. Transmission electron microscopic and EDX studies

Pure PPN reveals a sharp endothermic peak at 166 C and a broad

endothermic peak at 292 C followed by an exothermic peak at

300 C corresponding to the melting point and the decomposition

of PPN (Rojtanatanya and Pongjanyakul, 2010). The short broad endothermic region in the temperature range of 276 C to 296 C has

been observed in the case of PPNPLGA nanoparticles and Mt

PPNPLGA nanocomposites prepared and is due to the decomposition

PPNPLGA nanoparticles (PPN-01) are spherical particles of

50200 nm in size (inset Fig. 7a). In the TEM micrograph of PPN03

(Fig. 7b) uniformly spaced Mt layers are in support of intercalation

(Table 3). In the TEM micrograph of PPN-05 (Fig. 7c), the presence of

exfoliated Mt layers is distinct. Both micrographs are also supported

by their corresponding XRD data.

Fig. 7. TEM-EDX images of a PPNPLGA nanoparticles (PPN-01), b MtPPNPLGA nanocomposites (PPN-03) and c MtPPNPLGA nanocomposites (PPN-05).

Seema, M. Datta / Applied Clay Science 8081 (2013) 8592

91

As has been observed in the case of SEMEDX studies, the TEMEDX

studies (Fig. 7a b and c; Table 3) also indicate the presence of high content of carbon, oxygen and nitrogen in PPN-01 and additional peaks of

silicon, aluminium and iron in samples PPN-03 and PPN-05 which conrms the presence of Mt in the MtPPNPLGA nanocomposites.

4. Drug release prole

PPN-01 and the samples containing Mt, PPN-03 & 05, have been

selected for the study of drug release kinetics, in simulated intestinal

uid PBS (pH 7.4) (Fig. 8). As per the XRD data, encapsulation of drug

has been found in two kinds of MtPPNPLGA nanocomposites in

which the Mt particles were intercalated (PPN-03) and exfoliated

(PPN-04 to PPN-05). In the latter category PPN-05 has been selected

because of its high yield, loading and encapsulation efciency.

Release of pure drug (PPN) in simulated gastric (HCl, pH 1.2) and

intestinal uid (PBS, pH 7.4) was observed to be 86% (Fig. 9) and 89%

(Fig. 8) over a period of 4 h respectively and in both the cases release

pattern was not in a controlled manner (~36% release per minute). With

PPN-01 only 28% of the encapsulated drug was released over a period of

8 h whereas, the MtPPNPLGA nanocomposites PPN-03 and PPN-05

demonstrated a slow controlled cumulative drug release of 59% and

72% in the PBS (pH 7.4) over a period of 8 h (Fig. 8). The increase in the

amount of drug release with respect to the PPN-01 is related to the presence of Mt platelets in the bulk and on the surface (further conrmed by

SEMEDX and TEMEDX results). The presence of these platelets imparts

porosity to the MtPPNPLGA nanocomposites which results in higher

ease of passage through the MtPPNPLGA nanocomposite because of

which the PPN-05 MtPPNPLGA nanocomposites with higher extent

of exfoliation also shows higher release of PPN in a controlled manner

as represented by Fig. 10.

It is well understood that if a drug delivery system is able to retain

high amount of drug in the stomach uid, it would be able to release

Table 3

TEMEDX analysis report.

Element

Fig. 8. Drug release prole of a pure PPN, b PPNPLGA nanoparticles (PPN-01),

c intercalated MtPPNPLGA nanocomposites (PPN-03) and d exfoliated MtPPN

PLGA nanocomposites, (PPN-05) in simulated intestinal uid (PBS, pH 7.4) at 37 C.

more drug in the intestine (Chaturvedi et al., 2010) which is the desired

site of drug absorption. In this study we found that over a period of 8 h

in simulated gastric uid (HCl, pH 1.2), PPN-01 and Mt containing samples PPN-03 and PPN-05 show 18%, 14% and 28% drug release respectively (Fig. 9). This low release of PPN from PPN-03 is probably related

with the stability of Mt in acidic media which prevents the release of

drug in acidic media (Junping et al., 2006). In the case of the formulation

PPN-05, collapse of Mt layered structure was observed which comes out

to be less effective in the acidic media as compared to the PPN-03.

The controlled behavior of PPN release could also be explained by

the barrier properties or hindrance in the path offered by high amount

of Mt layers to release the drug in both the releasing media (Fig. 10).

5. Conclusion

Weight%

Atomic%

a PPNPLGA nanoparticles (PPN-01)

CK

58.6

NK

2.7

OK

11.3

FK

2.2

Ca K

2.9

Cu K

22.3

Total

100.0

77.3

3.1

11.1

1.8

1.1

5.6

100.0

b MtPPNPLGA nanocomposites (PPN-03)

CK

20.9

NK

6.7

OK

35.7

Mg K

4.1

Al K

4.0

Si K

14.5

KK

0.9

Fe K

3.2

Cu K

9.9

Total

100.0

31.5

8.7

40.4

3.1

2.7

9.4

0.4

1.0

2.8

100.0

c MtPPNPLGA nanocomposites (PPN-05)

CK

27.8

NK

6.9

OK

35.2

Mg K

0.2

Al K

6.2

Si K

12.7

KK

0.5

Fe K

2.1

Co K

0.3

Cu K

11.1

Total

100.0

31.5

8.7

40.4

3.1

2.7

9.4

0.4

1.0

0.1

3.0

100.0

In the present study an oral controlled drug delivery system for

PPN loaded PLGA nanoparticles and MtPPNPLGA nanocomposites

was developed by w/o/w double emulsion solvent evaporation technique. About 77% entrapment efciency and 72% release were achieved

for the highly hydrophilic drug, PPN. Two types of MtPPNPLGA

Fig. 9. Drug release prole of a pure PPN, b PPNPLGA nanoparticles (PPN-01),

c intercalated MtPPNPLGA nanocomposites (PPN-03) and d exfoliated MtPPN

PLGA nanocomposites, (PPN-05) in simulated gastric uid (HCl, pH 1.2) at 37 C.

92

Seema, M. Datta / Applied Clay Science 8081 (2013) 8592

Fig. 10. Diagrammatic representation of drug path within a intercalated and b exfoliated MtPPNPLGA nanocomposites.

nanocomposites (intercalated and exfoliated Mt) were obtained. The

presence of drug within the PPNPLGA nanoparticles and MtPPN

PLGA nanocomposites nanoparticles and nanocomposites was also conrmed by DSC data.

50300 nm spherical PPNPLGA nanoparticles and MtPPNPLGA

nanocomposites was obtained with the Mt platelets on the surface

(conrms by SEMEDX and TEMEDX data). The drug release prole

of PPN was found to be pH dependent, the presence of Mt platelets

within the PPNPLGA formulations results in controlled and higher %

release of drug. Therefore, it can be said that the synthesized formulations have high potential as a controlled drug delivery system for PPN.

Disclosure

The authors report no conicts of interest in this work.

Acknowledgments

We sincerely express our thanks to the director, USIC, University

of Delhi for instrumentation facilities, Director, AIRF, JNU for providing

SEM facilities and UGC/RGNF for providing nancial assistance for this

research work under the project of sch/rgnf/srf/f-10/2007-08. The authors are thankful to Dr. R Nagarajan for his valuable suggestions regarding the interpretation of XRD and TGA data.

References

Aguzzi, C., Cerezo, P., Viseras, C., Caramella, C., 2007. Use of clays as drug delivery systems:

possibilities and limitations. Applied Clay Science 36, 2236.

Bergaya, F., Theng, B.K.G., Lagaly, G., 2006. First edition Handbook of Clay Science. Elsevier.

Chaturvedi, K., Umadevi, S., Vaghani, S., 2010. Floating matrix dosage form for propranolol hydrochloride based on gas formation technique: development and in vitro

evaluation. Scientia Pharmaceutica 78, 927939.

Chen, Y., Zhou, A., Liu, B., Liang, J., 2010. Tramadol hydrochloride/montmorillonite

composite: Preparation and controlled drug release. Applied Clay Science 49, 108112.

Dollery, S.C., 1991. Therapeutic Drugs. Churchill Livingstone, Edinburgh P272P278.

Dong, Y., Feng, S.S., 2005. Poly (D, L-lactide-co-lycolide)/montmorillonite nanoparticles

for oral delivery of anticancer drugs. Biomaterials 26, 60686076.

El-Saharty, Y.S., 2003. Simultaneous high-performance liquid chromatographic assay of

furosemide and propranolol HCL and its application in a pharmacokinetic study.

Journal of Pharmaceutical and Biomedical Analysis 33, 699709.

Feng, S.S., Mei, L., Anitha, P., Gan, C.W., Zhou, W., 2009. Poly(lactide)vitamin E derivative/

montmorillonite nanoparticle formulations for the oral delivery of Docetaxel. Biomaterials 30, 32973306.

Gil, E.C., Colarte, A.I., Bataille, B., Pedraz, J.L., Rodrguez, F., Heinmki, J., 2006. Development and optimization of a novel sustained-release dextran tablet formulation for

propranolol hydrochloride. International Journal of Pharmaceutics 2006 (317),

3239.

Iliescu, R.I., Andronescu, E., Voicu, G., Ficai, A., Covaliu, C.I., 2011. Hybrid materials

based on montmorillonite and citostatic drugs: preparation and characterization.

Applied Clay Science 52, 6268.

Joshi, G.V., Kevadiya, B.D., Patel, H.A., Bajaj, H.C., Jasra, R.V., 2009a. Montmorillonite as a

drug delivery system: intercalation and in vitro release of Timolol maleate. International Journal of Pharmaceutics 374, 5357.

Joshi, G.V., Patel, H.A., Kevadiya, B.D., Bajaj, H.C., 2009b. Montmorillonite intercalated

with Vitamin B1 as drug carrier. Applied Clay Science 45, 248253.

Joshi, G.V., Kevadiya, B.D., Bajaj, H.C., 2010. Design and evaluation of controlled drug

delivery system of buspirone using inorganic layered clay mineral. Microporous

and Mesoporous Materials 132, 526530.

Junping, Z., Hongyan, W., Hong, Z., Lifei, X., Kangde, Y., 2006. Intercalation of amido cationic

drug with montmorillonite. Journal of Wuhan University of Technology-Materials Science Edition 22, 250252.

Langer, R.S., Kathryn, E.U., Cannizzaro, S.M., Shakesheff, K.M., 1999. Polymeric systems

for controlled drug release. Chemical Reviews 99, 31813198.

Lee, Y.H., Kuo, T.F., Chen, B.Y., Feng, Y.K., Wen, Y.R., Lin, W.C., Lin, F.H., 2005. Toxicity

assessment of montmorillonite as a drug carrier for pharmaceutical applications: yeast

and rats model. Biomedical Engineering-Applications Basis Communications 17, 7278.

Lin, F.H., Lee, Y.H., Jian, C.H., Wong, J.M., Shieh, M.J., Wang, C.Y., 2002. A study of puried montmorillonite intercalated with 5-uorouracil as drug carrier. Biomaterials

23, 19811987.

Liu, J., Boo, W.J., Cleareld, A., Sue, H.J., 2006. Intercalation and exfoliation: a review on

morphology of polymer nanocomposites reinforced by inorganic layer structures.

Materials and Manufacturing Processes 20, 143151.

Mohammadi-Samani, S., Adrangui, M., Siahi-Shadbad, M.R., Nokhodchi, A., 2000. An

approach to controlled-release dosage form of propranolol hydrochloride. Drug

Development and Industrial Pharmacy 26 (1), 9194.

Mukherjee, A., Vishwanatha, J.K., 2009. Formulation, characterization and evaluation of

curcumin-loaded PLGA nanospheres for cancer therapy. Anticancer Research 29,

38673876.

Nunes, C.D., Vaz, P.D., Fernandes, A.C., Ferreira, P., Romo, C.C., Calhorda, M.J., 2007.

Loading and delivery of sertraline using inorganic micro and mesoporous materials. European Journal of Pharmaceutics and Biopharmaceutics 66, 357365.

Paker-Leggs, S., Neau, S.H., 2009. Pellet characteristics and drug release when the form of

propranolol is xed as moles or mass in formulations for extruded and spheronized

Carbopol-containing pellets. International Journal of Pharmaceutics 369, 96104.

Patel, J., Patel, D., Raval, J., 2010. Formulation and evaluation of propranolol hydrochlorideloaded carbopol-934p/ethyl cellulose mucoadhesive microspheres. Iranian Journal of

Pharmaceutical Research 9, 221232.

Patra, C.N., Kumar, A.B., Pandit, H.K., Singh, S.K., Devi, M.V., 2007. Design and evaluation of

sustained release bilayer tablets of propranolol hydrochloride. Acta Pharmaceutica 57,

479489.

Paul, D.R., Robeson, L.M., 2008. Polymer nanotechnology: nanocomposites. Polymer 49,

31873204.

Rojtanatanya, S., Pongjanyakul, T., 2010. Propranololmagnesium aluminum silicate

complex dispersions and particles: characterization and factors inuencing drug

release. International Journal of Pharmaceutics 383 (1-2), 106115.

Sahoo, J., Murthy, P.N., Biswal, S., Sahoo, S.K., Mahapatra, A.K., 2008. Comparative study

of propranolol hydrochloride release from matrix tablets with KollidonSR or hydroxy propyl methyl cellulose. AAPS PharmSciTechnol 9, 577582.

Snchez-Martin, M.J., Snchez-Camazano, M., Vicente-Hernndez, T., Dominguez-Gil,

A., 1981. Interaction of propranolol hydrochloride with montmorillonite. Journal

of Pharmacy and Pharmacology 33, 408410.

Sanghavi, N.M., Sarawade, V.B., Kamath, P.R., Bijilani, C.P., 1998. Matrix tablets of propranolol hydrochloride. Indian Drugs 26 (8), 404407.

Schmolka, I.R., 1977. A review of block polymer surfactants. Journal of American Oil

Chemists' society 54, 110116.

Seki, Y.S., Kadir, Y.C., 2006. Adsorption of promethazine hydrochloride with KSF montmorillonite. Adsorption 12, 89.

Suresh, R., Borkar, S.N., Sawant, V.A., Shende, V.S., Dimble, S.K., 2010. Nanoclay drug delivery system. International Journal of Pharmaceutical Sciences and Nanotechnology 3,

901905.

Velasco-De-Paola, M.V.R., Santoro, M.I.R.M., Gai, M.N., 1999. Dissolution kinetics evaluation of controlled-release tablets containing propranolol hydrochloride. Drug Development and Industrial Pharmacy 25 (4), 535541.

Wang, X., Wang, X.J., Ching, C.B., 2002. Solubility, metastable zone width and racemic

character of Propranolol hydrochloride. Chirality 14, 318324.

You might also like

- 2-Effect of Blending Sequence On The mechPPties of Ternary PET-SEBSMAH-SGF 2006 3 PDFDocument3 pages2-Effect of Blending Sequence On The mechPPties of Ternary PET-SEBSMAH-SGF 2006 3 PDFTOUFIKNo ratings yet

- Characterisation of Fibre-Polymer Interactions and Transcrystallinity in Short Keratinfibre-PolypDocument8 pagesCharacterisation of Fibre-Polymer Interactions and Transcrystallinity in Short Keratinfibre-PolypTOUFIKNo ratings yet

- 6-OK - P-ABILITY OF CAVITATION - DASARI - Effect of Blending Sequence PA-SEBS NANO 2005 6 PDFDocument6 pages6-OK - P-ABILITY OF CAVITATION - DASARI - Effect of Blending Sequence PA-SEBS NANO 2005 6 PDFTOUFIKNo ratings yet

- Thermal Degradation Studies of Alkyl-Imidazolium SaltsDocument9 pagesThermal Degradation Studies of Alkyl-Imidazolium SaltsTOUFIKNo ratings yet

- Comprehensive Product Catalog 2012-2013Document36 pagesComprehensive Product Catalog 2012-2013TOUFIKNo ratings yet

- Creep Behaviour of Layered Silicate-starch-Polycaprolactone Blends NanocompDocument7 pagesCreep Behaviour of Layered Silicate-starch-Polycaprolactone Blends NanocompTOUFIKNo ratings yet

- Biodegradable confusion explainedDocument3 pagesBiodegradable confusion explainedTOUFIKNo ratings yet

- Biodegradable Jute Cloth Reinforced Thermoplastic Copolyester Compositesfracture and Failure BehaDocument11 pagesBiodegradable Jute Cloth Reinforced Thermoplastic Copolyester Compositesfracture and Failure BehaTOUFIKNo ratings yet

- IMAGEJ User GuideDocument179 pagesIMAGEJ User GuideTOUFIKNo ratings yet

- Influence of Cellulose Nanowhiskers On The Hydrolytic Degradation Behavior of 2011Document8 pagesInfluence of Cellulose Nanowhiskers On The Hydrolytic Degradation Behavior of 2011TOUFIKNo ratings yet

- Stimuli-Deformable Graphene MaterialsDocument11 pagesStimuli-Deformable Graphene MaterialsTOUFIKNo ratings yet

- Understanding The Effect of Nano-Modifier Addition Upon The Properties of Fibre Reinforced Laminates 2008Document9 pagesUnderstanding The Effect of Nano-Modifier Addition Upon The Properties of Fibre Reinforced Laminates 2008TOUFIKNo ratings yet

- SPR - Crystalliz, Hydrolytic Degradation, and Mech. PPties of PTMT Phthalate) - PLADocument11 pagesSPR - Crystalliz, Hydrolytic Degradation, and Mech. PPties of PTMT Phthalate) - PLATOUFIKNo ratings yet

- 123-Effects of Aging On The Thermomechanical Properties of PLADocument10 pages123-Effects of Aging On The Thermomechanical Properties of PLATOUFIKNo ratings yet

- Effect of Hydrolysis On Mechanical Properties of Tricalcium-PLADocument8 pagesEffect of Hydrolysis On Mechanical Properties of Tricalcium-PLATOUFIKNo ratings yet

- Hydrolytic Degradation of Copolymers Based On L-Lactic Acid and Bis-2-Hydroxyethyl Terephthalate 2007Document8 pagesHydrolytic Degradation of Copolymers Based On L-Lactic Acid and Bis-2-Hydroxyethyl Terephthalate 2007TOUFIKNo ratings yet

- Effect of Microstructure On Hydrolytic Degradation Studies of PLLA 2009 HPLCDocument9 pagesEffect of Microstructure On Hydrolytic Degradation Studies of PLLA 2009 HPLCTOUFIKNo ratings yet

- Effect of Copolymer Ratio On Hydrolytic Degradation of 2011Document7 pagesEffect of Copolymer Ratio On Hydrolytic Degradation of 2011TOUFIKNo ratings yet

- Effect of Microstructure On Hydrolytic Degradation Studies of PLLA 2009 HPLCDocument9 pagesEffect of Microstructure On Hydrolytic Degradation Studies of PLLA 2009 HPLCTOUFIKNo ratings yet

- Ageing of Polylactide and Polylactide Nanocomposite Filaments 2008Document7 pagesAgeing of Polylactide and Polylactide Nanocomposite Filaments 2008TOUFIKNo ratings yet

- SPR - Crystalliz, Hydrolytic Degradation, and Mech. PPties of PTMT Phthalate) - PLADocument11 pagesSPR - Crystalliz, Hydrolytic Degradation, and Mech. PPties of PTMT Phthalate) - PLATOUFIKNo ratings yet

- SPR - Crystalliz, Hydrolytic Degradation, and Mech. PPties of PTMT Phthalate) - PLADocument11 pagesSPR - Crystalliz, Hydrolytic Degradation, and Mech. PPties of PTMT Phthalate) - PLATOUFIKNo ratings yet

- Effect of Hydrothermal Polylactic Acid DegradationDocument7 pagesEffect of Hydrothermal Polylactic Acid DegradationTOUFIKNo ratings yet

- Thermal Analysis of Hydrolysis and Degradation of Biodegradable Polymer and Bio-CompositesDocument8 pagesThermal Analysis of Hydrolysis and Degradation of Biodegradable Polymer and Bio-CompositesTOUFIKNo ratings yet

- Hygrothermal Effects On Interfacial StressTransfer Characteristics of CarbonNanotubes-reinforcedDocument19 pagesHygrothermal Effects On Interfacial StressTransfer Characteristics of CarbonNanotubes-reinforcedTOUFIKNo ratings yet

- Tributyl Citrate Oligomers As Plasticizers For PLA 2003Document10 pagesTributyl Citrate Oligomers As Plasticizers For PLA 2003TOUFIKNo ratings yet

- Use of Triethylcitrate Plasticizer in The Production PF PLA Implants With Different Degradation TDocument7 pagesUse of Triethylcitrate Plasticizer in The Production PF PLA Implants With Different Degradation TTOUFIKNo ratings yet

- Synthesis, Characterization, and Hydrolytic Degradation Of... PLADocument6 pagesSynthesis, Characterization, and Hydrolytic Degradation Of... PLATOUFIKNo ratings yet

- Migration and Emission of Plasticizer and Its Degradation Products During ThermalDocument16 pagesMigration and Emission of Plasticizer and Its Degradation Products During ThermalTOUFIKNo ratings yet

- Morphological, Crystallization and Plasticization Studies On Isomorphic Blends of PVF and PVDF - UDocument5 pagesMorphological, Crystallization and Plasticization Studies On Isomorphic Blends of PVF and PVDF - UTOUFIKNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- IAAS, CAAS and Serverless AutomationDocument55 pagesIAAS, CAAS and Serverless AutomationHAMDI GDHAMINo ratings yet

- Entreprenuership: Ej Faith Tabia ABM 12-CDocument11 pagesEntreprenuership: Ej Faith Tabia ABM 12-CErica Faye JometanoNo ratings yet

- Mactan Cebu International Airport Vs Lozada, JRDocument3 pagesMactan Cebu International Airport Vs Lozada, JRVincent Catotal100% (2)

- Psoriasis and Dermatitis AtopicDocument11 pagesPsoriasis and Dermatitis AtopicsayasajaNo ratings yet

- Motion to Compel Discovery in Personal Injury LawsuitDocument6 pagesMotion to Compel Discovery in Personal Injury LawsuitAmanda ZelinskyNo ratings yet

- Design Rules and Implementation SupportDocument57 pagesDesign Rules and Implementation SupportMadeehah AatifNo ratings yet

- BE-Final Year Project Thapathali PDFDocument41 pagesBE-Final Year Project Thapathali PDFBigyan Upadhayay50% (2)

- Sample Complaint Letter Bank Fees IIDocument2 pagesSample Complaint Letter Bank Fees IIRoshan Khan100% (1)

- Phaser 7100Document40 pagesPhaser 7100luterocoruna8342No ratings yet

- SRMDocument75 pagesSRMmanda RamuNo ratings yet

- Entrepreneurship - B.Com (Hons), University of DelhiDocument10 pagesEntrepreneurship - B.Com (Hons), University of DelhiViren MehraNo ratings yet

- PartnershipDocument44 pagesPartnershipAngelo Raphael B. DelmundoNo ratings yet

- Digest of Adoption, Habeas Corpus and Change of NameDocument15 pagesDigest of Adoption, Habeas Corpus and Change of NamelonitsuafNo ratings yet

- Municipal Profile of Umingan, PangasinanDocument51 pagesMunicipal Profile of Umingan, PangasinanGina Lee Mingrajal Santos100% (1)

- 70 20 10 PrincipleDocument8 pages70 20 10 PrincipleYogesh BhatNo ratings yet

- M&E 2014 Session 9 Feasibility BBDocument17 pagesM&E 2014 Session 9 Feasibility BBsidNo ratings yet

- T&B WorksheetDocument11 pagesT&B WorksheetAmir ZeidabadiNo ratings yet

- 7th Pay Commission Constitution GODocument3 pages7th Pay Commission Constitution GOBharath UGNo ratings yet

- Question Bank Food&Wine Pairing PDFDocument4 pagesQuestion Bank Food&Wine Pairing PDFRose Sibi100% (1)

- Chesterton - Outline of SanityDocument82 pagesChesterton - Outline of SanityKeith BuhlerNo ratings yet

- Importance of flat filesDocument52 pagesImportance of flat filesLuiz RamosNo ratings yet

- Bela I Crvene Tigrova MastDocument5 pagesBela I Crvene Tigrova MastNadrljanskiDusanNo ratings yet

- Fluid Power Formulas GuideDocument4 pagesFluid Power Formulas GuidemahaveenNo ratings yet

- DIN-8SW8: Crestron Green Light™ DIN Rail High-Voltage Switch Operations & Installation GuideDocument32 pagesDIN-8SW8: Crestron Green Light™ DIN Rail High-Voltage Switch Operations & Installation Guidewid ndoNo ratings yet

- WHL-001-SB-0323 Heat Air Propane Brochure HQ - PDF 60054Document2 pagesWHL-001-SB-0323 Heat Air Propane Brochure HQ - PDF 60054canalet1952No ratings yet

- Flagship Programmes by Government of IndiaDocument3 pagesFlagship Programmes by Government of IndiamakmgmNo ratings yet

- Power+BI Cheat+SheetDocument1 pagePower+BI Cheat+SheetNitin Yashawant SuryavanshiNo ratings yet

- Operating Manual: Air Band TransceiverDocument60 pagesOperating Manual: Air Band TransceiverDaniel GoodNo ratings yet

- Learn Enough Custom DomainsDocument139 pagesLearn Enough Custom DomainsRenan VieiraNo ratings yet

- 2021 ZX10R KMDocument77 pages2021 ZX10R KMefrain100% (2)