Professional Documents

Culture Documents

Case Challenge: The Curious Case of High Inventories and Low Availability

Uploaded by

Siddhesh KhadeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Case Challenge: The Curious Case of High Inventories and Low Availability

Uploaded by

Siddhesh KhadeCopyright:

Available Formats

Case Challenge

THE CURIOUS CASE OF

HIGH INVENTORIES AND LOW AVAILABILITY

September 16, 2013

Instructions:

Registered Teams will submit a case analysis/solution document comprising no more than 5 pages of single spaced, 12point font (including illustrations and excluding TOC, Cover page).

Along with the word document each team must submit a 10-slide presentation of the case analysis/solution suggested.

There is no pre-determined structure to analyse the case. Participants are free to use any format which best illustrates

and provides convincing arguments for their idea.

Wherever necessary, the participants must make references to the sources of information and data.

Case presentations will be judged based on the following criteria the originality, creativity and uniqueness of the idea

will receive the highest weightage; the implementability, sustainability and scalability of the idea; its fit with ITCs vision

and the manner in which it can leverage ITCs strengths; the thoroughness of research, analytics and economic logic

used to defend viability and execution of the idea.

Last date for submission of case solutions is 25th September 2013. Teams must send their entries to the email ID

provided for the campus.

For full details please refer to the Interrobang Season 3 Case Challenge Brochure available with your Campus Point of

Contact or contact interrobang@itc.in. The e-Brochure is also available at our Facebook page itchubnscope.

ITC Interrobang Season 3 Case Challenge: Curious Case of High Inventories and Low Availability

THE CURIOUS CASE OF HIGH INVENTORIES AND LOW AVAILABILITY

ITC Interrobang Case Challenge 20131

Personal Care Products Business:

Since its inception, ITCs Personal Care Products Business (PCPB) has been continuously venturing into new categories with

an ambitious plan to be the market leader in emerging opportunities. The business has the advantage of an established

physical distribution network with an unparalleled reach into the hinterlands of the country. PCPB started its journey with

established categories like soaps and shampoos where there is a high degree of predictability. However, as it enters into the

unchartered and premium territories with >30% margins, the supply chain team started facing several teething issues. The

team was stuck with high inventories and low fill rates. Responsiveness to react to changes in consumer demand

preferences and moves by competition became a limiting factor to the competitiveness of business. There have been several

heated discussions in meeting rooms. Consultant from XYZ, Mr Sundaram was appointed to spearhead the team with an

objective of finding feasible & sustainable solutions to the problems haunting the Supply Chain Team.

Meeting Room: ITC Centre:

We are losing on sales due to abysmal availability of stock in the market, pointed a visibly upset Mr Sarang, Head of Sales.

With fill rates as low as these, competitors are getting away with a chunk of market. What a new entrant loses is not one

unit but an opportunity to have a potential relationship with consumers, an opportunity which we may not get again. Sure

fill rates have been lower, but look at the accuracy and fidelity of the estimates. How do we provide service when our

forecasts are so unreliable, the supply manager asked the demand planner.

Chart: Fill rates of premium portfolio:

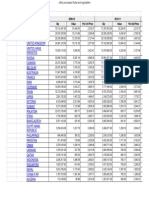

Table: MAPE*:

*MAPE stands for Mean Absolute Percentage Error defined as

MAPE = |Forecast-Actual|/Actual x 100

1This

Case is developed by and is the sole property of ITC Limited. This is for academic purposes only and is not intended to be copied or

displayed or reproduced at any place outside the Campus.

ITC Interrobang Season 3 Case Challenge: Curious Case of High Inventories and Low Availability

Table: Bias

Forecast bias = (Forecast-Actual)/Actual x 100

Products are very seasonal in nature and we dont have enough historical data to forecast. Take for example, a SPF lotion

sells well in summer but has reduced sales in winter. Actual sales data is further skewed due to lost sales on account of no

stock. For a product with 5 months sale period, it is difficult to predict

Chart: Primary and secondary sales over 10 periods

The finance manager looked conspicuously worried. While everyone is crying no stock, I am sitting with a huge value which

will be written-off for expiry and several tons of stock is transitioning from slow moving to non-moving.

Chart: Inventory ageing chart (Factory + WSP)

(These categories have a >50% reach to consumers via modern trade that give no forecasts (shop in shop and mall

formats). Organised players have stringent requirements of >75% freshness limiting system ability to keep inventories.)

ITC Interrobang Season 3 Case Challenge: Curious Case of High Inventories and Low Availability

Ajay Srivastava, brand manager chips in. I want to offer better value to consumers by providing products with natural

extracts which will increase our sales. But the aggregate pipeline is so high that I have to wait for 3 months before the new

product reaches the consumer.

Chart: Current inventory position (days of cover)

Current Network Design

The Distribution Network is spread across 1500+ WDs and 55+ WSPs. There are approximately 15 logical Modern Trade

WSPs besides these. Modern trade WSP is serviced by WSPs which are located regionally. There are 2 factories- at Haridwar

and Chandigarh where premium SKUs can be manufactured. There is a hub in north (Roorkee) and one in south (near

Warangal).

Figure: Network Map

ITC Interrobang Season 3 Case Challenge: Curious Case of High Inventories and Low Availability

Existing network flow model is fairly linear in nature. ITC manages inventory till wholesale distributors.

Shipment logic:

From Factory to hub/WSP, weekly STRs are used to generate the requirements. STR = Target inventory norm Stock on

hand Stock in transit. The same logic is used to generate delivery requirement (ideal delivery order) at WD

Norms vs. actual:

Norms are defined for each SKU and location combination. Norm for a sample SKU of Category I is as below (days of cover)

Norms

Factory

Hub

WSP

WD

Cat I

20

4.4

14.9

10.0

Manufacturing cycle:

Products have monthly plan and manufacturing cycle. Manufacturing products < 300 kgs results in 40% loss of material and

more importantly results in potential stock-out of input materials in next run.

Shipment of finished goods:

Lead time is different for every location (refer annexure). CS corresponds to time between two truck load connectivity at

WSP.

Problem statement

If you were in place of Mr Sundaram, how what recommendations would you have for business to improve the

supply chain.

What levers would you use to improve the service levels?

How, according to you, should ITC service the modern trade orders?

What should be ITCs shipment and inventory strategy at various echelons of supply chain?

How, according to you, should ITC reduce response time to market?

What are the recommended service levels at various stages?

ITC Interrobang Season 3 Case Challenge: Curious Case of High Inventories and Low Availability

Annexure-I

Table: Transit Times from Source to Destination.

Location

Roorkee Warangal Chandigarh Haridwar

Ahmedabad

Aurangabad

3.6

4.8

4.8

2.4

4.8

7.0

4.8

6.0

Bangalore

9.6

2.4

9.0

8.4

Belgaum

7.2

2.4

6.0

7.2

Bhopal

3.6

3.6

4.8

3.6

Bhubaneshwar

7.2

4.8

8.4

7.2

Calcutta

7.2

6.0

7.2

6.0

Calicut

13.2

3.6

11.0

9.6

Chandigarh

1.2

6.0

1.2

2.4

Chennai

9.6

2.4

10.0

8.4

Delhi

1.2

6.0

1.2

1.2

Ernakulam

10.8

3.6

11

10.8

Ghaziabad

1.2

6.0

2.4

1.2

Guwahati

14.4

8.4

14

12

Haridwar

1.2

6.0

3.0

1.2

Hyderabad

9.6

1.2

7.2

6.0

Jabalpur

4.8

3.6

6.0

4.8

Jaipur

1.2

6.0

2.4

2.4

Jammu

2.4

7.2

2.4

2.4

Jamshedpur

7.2

6.0

7.2

6.0

Jodhpur

2.4

6.0

3.6

2.4

Kanpur

2.4

6.0

3.6

3.6

Karnataka

9.6

2.4

9.0

8.4

Kundli

1.2

6.0

2.4

1.2

Ludhiana

1.2

7.2

1.2

1.2

Mumbai

4.8

3.6

7.2

6.0

Nagpur

4.8

2.4

6.0

4.8

Parwanoo

1.2

6.0

1.2

1.2

Patna

6.0

6.0

6.0

4.8

Pune

6.0

2.4

7.2

6.0

Raipur

8.4

6.0

7.0

6.0

Saharanpur

1.2

6.0

1.2

1.2

Sambalpur

4.8

4.8

7.2

6.0

Siliguri

8.4

10.0

10.0

9.6

Srinagar

6.0

14.0

4.8

3.6

Tirupati

10.8

2.4

10.0

9.6

Trichy

10.8

3.6

9.0

8.4

Varanasi

3.6

4.8

4.8

3.6

Vijaywada

9.6

1.2

8.0

7.2

Vizag

9.6

2.4

8.0

7.2

ITC Interrobang Season 3 Case Challenge: Curious Case of High Inventories and Low Availability

Table: Cycle of replenishment

Location

CS

Ahmedabad

Aurangabad

10

Bangalore

10

Belgaum

10

Bhopal

12

Bhubaneshwar

Calcutta

18

Calicut

Chandigarh

10

Chennai

Delhi

Ernakulam

10

Ghaziabad

10

Guwahati

Haridwar

Hyderabad

Jabalpur

10

Jaipur

Jammu

Jamshedpur

10

Jodhpur

10

Kanpur

18

Karnataka

10

Kundli

10

Ludhiana

Mumbai

Nagpur

16

Parwanoo

10

Patna

10

Pune

Raipur

11

Saharanpur

Sambalpur

Siliguri

18

Sri Nagar

14

Tirupati

20

Trichy

Varanasi

17

Vijaywada

17

Vizag

18

You might also like

- SIXSupply Chain CoordinationNOTES Synthese 1Document59 pagesSIXSupply Chain CoordinationNOTES Synthese 1Arnaud LiegeoisNo ratings yet

- Licious Meat Market StrategyDocument5 pagesLicious Meat Market Strategyakanksha0% (1)

- Guidelines For Business PlanDocument4 pagesGuidelines For Business PlanJetsson SoNo ratings yet

- 7 Ways Everyone Can Cut Supply Chain CostsDocument7 pages7 Ways Everyone Can Cut Supply Chain CostsbumbiazarkaNo ratings yet

- Indroduction To Supply Chain 1Document38 pagesIndroduction To Supply Chain 1Tansen John100% (2)

- DMC 216Document4 pagesDMC 216sailesh chaudhary0% (1)

- SCM Assignment No 1Document5 pagesSCM Assignment No 146 Gaurav PawarNo ratings yet

- Free Research Papers Supply Chain ManagementDocument5 pagesFree Research Papers Supply Chain Managementfvet7q93100% (1)

- Supply Chain & Logistics Analytics - Session 7 Analytics in Sourcing, Transportation, WarehousingDocument36 pagesSupply Chain & Logistics Analytics - Session 7 Analytics in Sourcing, Transportation, WarehousingArya KeoliyaNo ratings yet

- Assessment 2 Group Case Study PresentationDocument3 pagesAssessment 2 Group Case Study PresentationSenisaaNo ratings yet

- Chapter 2 - Supply Chain Performance: Achieving Strategic Fit and ScopeDocument2 pagesChapter 2 - Supply Chain Performance: Achieving Strategic Fit and ScopeseifSamhanNo ratings yet

- Assignment 2 - Supply ChainDocument5 pagesAssignment 2 - Supply ChainHeena SharmaNo ratings yet

- Homeworksimchi Levidesigningandmanagingsupplychain 140401173556 Phpapp01Document50 pagesHomeworksimchi Levidesigningandmanagingsupplychain 140401173556 Phpapp01Anish Mathew88% (32)

- Flow CastingDocument13 pagesFlow CastingSanya MohindraNo ratings yet

- Managing Trade Off in Automobile Supply Chains Responsiveness Vs Efficiency.Document11 pagesManaging Trade Off in Automobile Supply Chains Responsiveness Vs Efficiency.Venkateshwar Rao. RokandlaNo ratings yet

- Making Business Sense of E-OpportunityDocument14 pagesMaking Business Sense of E-Opportunityarun1974No ratings yet

- SCM AssignmentDocument57 pagesSCM AssignmentYousufNo ratings yet

- Homework Chapter 1 Introduction To Supply Chain ManagementDocument5 pagesHomework Chapter 1 Introduction To Supply Chain Managementbuggs1152No ratings yet

- Strategy& PwC Booz Casebook Consulting Case Interview Book思略特 - 博斯 - 普华永道咨询案例面试Document14 pagesStrategy& PwC Booz Casebook Consulting Case Interview Book思略特 - 博斯 - 普华永道咨询案例面试issac li100% (3)

- Final Exam for English for Logistics Course Covers Key Supply Chain ConceptsDocument5 pagesFinal Exam for English for Logistics Course Covers Key Supply Chain ConceptsKevin RodriguezNo ratings yet

- Supply Chain ManagementDocument17 pagesSupply Chain ManagementfathathassnainNo ratings yet

- Tutorial 7Document6 pagesTutorial 7jaslynNo ratings yet

- A.T. Kearney ATK Casebook consulting case interview book科尔尼咨询案例面试Document25 pagesA.T. Kearney ATK Casebook consulting case interview book科尔尼咨询案例面试issac li100% (1)

- Literature Review Inventory SystemDocument7 pagesLiterature Review Inventory Systemc5ngamsd100% (1)

- Operations and Supply Chain StrategiesDocument10 pagesOperations and Supply Chain StrategiesRochak SinglaNo ratings yet

- Assignment Unit 4 Capacity PlanningDocument10 pagesAssignment Unit 4 Capacity PlanningPriyank LashkariNo ratings yet

- Supply Chain Management-The New NormalDocument27 pagesSupply Chain Management-The New NormaldfNo ratings yet

- Logistics Problems and SolutionsDocument11 pagesLogistics Problems and SolutionsSailpoint CourseNo ratings yet

- 1a EDADocument4 pages1a EDASam RomarioNo ratings yet

- Supply Chain & Logistics Analytics - Session 6 Analytics in Inventory Management MOQ, EOQ, Inventory Optimization Part IIDocument36 pagesSupply Chain & Logistics Analytics - Session 6 Analytics in Inventory Management MOQ, EOQ, Inventory Optimization Part IIArya KeoliyaNo ratings yet

- Triple A Supply Chain Strategy for Sustainable AdvantageDocument4 pagesTriple A Supply Chain Strategy for Sustainable AdvantageNitin KhannaNo ratings yet

- Supply Chain Management AssignmentDocument26 pagesSupply Chain Management Assignmentedo100% (1)

- SCM Udemy NotesDocument6 pagesSCM Udemy NotesPraphulNo ratings yet

- Supply Chain Management NotesDocument35 pagesSupply Chain Management NotesRazin GajiwalaNo ratings yet

- Full Download At:: Operations Management Operations and Supply Chain Management 14th Edition JacobsDocument12 pagesFull Download At:: Operations Management Operations and Supply Chain Management 14th Edition JacobsHoàng Thiên LamNo ratings yet

- Study Case Outsourcing Reda Ouchain PDFDocument5 pagesStudy Case Outsourcing Reda Ouchain PDFReda Ouchain75% (4)

- Performance and Supply Chain Strategies of Amazon and Wal-MartDocument4 pagesPerformance and Supply Chain Strategies of Amazon and Wal-MartGirish BhangaleNo ratings yet

- CASE STUDY-1 and 2 - WORDDocument7 pagesCASE STUDY-1 and 2 - WORDAbdul Khaliq Choudhary100% (1)

- Easychair Preprint: Archit BansalDocument8 pagesEasychair Preprint: Archit Bansalferdyanta_sitepuNo ratings yet

- Madura Coats Optimizes Supply Chain Through Order Frequency AnalysisDocument20 pagesMadura Coats Optimizes Supply Chain Through Order Frequency Analysismohitegaurv87No ratings yet

- Business UnderstandingDocument11 pagesBusiness UnderstandingSY ECE51 SHEJUL YUVRAJNo ratings yet

- Case StudiessDocument2 pagesCase StudiessRodrigoNo ratings yet

- Distribution & Logistics Management V3Document5 pagesDistribution & Logistics Management V3solvedcareNo ratings yet

- SCM IntroductionDocument75 pagesSCM Introductionmushtaque61No ratings yet

- Supply Chain TerminologyDocument5 pagesSupply Chain TerminologyMehroz KhanNo ratings yet

- CBS Casebook 2011-2012Document93 pagesCBS Casebook 2011-2012yahya_c100% (2)

- Question 6 (5 Points - Max 150 Words) : Grading CriteriaDocument3 pagesQuestion 6 (5 Points - Max 150 Words) : Grading CriteriaroyNo ratings yet

- Strategic Use of Information ResourcesDocument37 pagesStrategic Use of Information ResourcesKaziRafiNo ratings yet

- Nhóm 5-QLCCUDocument47 pagesNhóm 5-QLCCUanhtuyet.ng12No ratings yet

- End Term Exam SSCM PGP19-21Document3 pagesEnd Term Exam SSCM PGP19-21Asawari JoshiNo ratings yet

- Scasher Mgmt471w Sbu Strategic Plan FinalDocument33 pagesScasher Mgmt471w Sbu Strategic Plan FinalwerfsdfsseNo ratings yet

- Strategies For Manufacturing and Services (SMS)Document9 pagesStrategies For Manufacturing and Services (SMS)Iti SharmaNo ratings yet

- Dabur - ERPDocument20 pagesDabur - ERPavradeepmallik0% (1)

- GBE LO2.3 (Student)Document58 pagesGBE LO2.3 (Student)210349nghiem.nhiNo ratings yet

- Supply Chain Management Tools and EvolutionDocument11 pagesSupply Chain Management Tools and EvolutionanawadeNo ratings yet

- SC Working Capital: Virtual IntegrationDocument7 pagesSC Working Capital: Virtual Integrationarsenal GunnerNo ratings yet

- An Introduction to Global Supply Chain Management: What Every Manager Needs to UnderstandFrom EverandAn Introduction to Global Supply Chain Management: What Every Manager Needs to UnderstandNo ratings yet

- Consulting Interview Case Preparation: Frameworks and Practice CasesFrom EverandConsulting Interview Case Preparation: Frameworks and Practice CasesNo ratings yet

- Managing The Cold Chain For Quality and SafetyDocument31 pagesManaging The Cold Chain For Quality and Safetyletmez100% (1)

- Manufacturing Dissector CorrectionsDocument1 pageManufacturing Dissector CorrectionsSiddhesh KhadeNo ratings yet

- GD TopicsDocument1 pageGD TopicsSiddhesh KhadeNo ratings yet

- Timestamp log of customer feedback survey for hotelsDocument22 pagesTimestamp log of customer feedback survey for hotelsSiddhesh KhadeNo ratings yet

- RequirementsDocument2 pagesRequirementsSiddhesh KhadeNo ratings yet

- Construction Project Controls - Cost, Schedule and Change ManagementDocument20 pagesConstruction Project Controls - Cost, Schedule and Change ManagementSiddhesh KhadeNo ratings yet

- Ans. SheetDocument149 pagesAns. SheetSiddhesh KhadeNo ratings yet

- Managerial AccountingDocument22 pagesManagerial AccountingSiddhesh KhadeNo ratings yet

- 180 CMA FinalDocument7 pages180 CMA FinalSiddhesh KhadeNo ratings yet

- Costing Prob FinalsDocument52 pagesCosting Prob FinalsSiddhesh Khade100% (1)

- CBMRDocument5 pagesCBMRSiddhesh KhadeNo ratings yet

- Project Feasibility AssignmentDocument2 pagesProject Feasibility AssignmentSiddhesh KhadeNo ratings yet

- HHGGHHDocument4 pagesHHGGHHSiddhesh KhadeNo ratings yet

- Seminar Topics For Final B.Tech FET Sem VII /july 2010Document1 pageSeminar Topics For Final B.Tech FET Sem VII /july 2010Siddhesh KhadeNo ratings yet

- Processed fruits and vegetables trade data by countryDocument12 pagesProcessed fruits and vegetables trade data by countrySiddhesh KhadeNo ratings yet

- Six Sigma QuestionsDocument5 pagesSix Sigma Questionssabztomaz100% (3)

- NyhjjDocument2 pagesNyhjjSiddhesh KhadeNo ratings yet

- HhfgffdyttDocument8 pagesHhfgffdyttSiddhesh KhadeNo ratings yet

- GfhhyytffcggDocument1 pageGfhhyytffcggSiddhesh KhadeNo ratings yet

- 2009-10 2010-11 2011-12 Country Qty Value Per Unit Price Qty Value Per Unit Price QtyDocument10 pages2009-10 2010-11 2011-12 Country Qty Value Per Unit Price Qty Value Per Unit Price QtySiddhesh KhadeNo ratings yet

- 299 Words GreDocument2 pages299 Words GreFarah FazalNo ratings yet

- Global trade data for dried and preserved vegetablesDocument10 pagesGlobal trade data for dried and preserved vegetablesSiddhesh KhadeNo ratings yet

- GGFFBVDGDocument7 pagesGGFFBVDGSiddhesh KhadeNo ratings yet

- HhfgffdyttDocument8 pagesHhfgffdyttSiddhesh KhadeNo ratings yet

- Haas School of BusinessDocument20 pagesHaas School of BusinessalokmbaNo ratings yet

- NITIE Training 2007 - Excel 1.0Document41 pagesNITIE Training 2007 - Excel 1.0Siddhesh KhadeNo ratings yet

- Global trade data for dried and preserved vegetablesDocument10 pagesGlobal trade data for dried and preserved vegetablesSiddhesh KhadeNo ratings yet

- Formula in Short: Data Text To ColumnDocument4 pagesFormula in Short: Data Text To ColumnSiddhesh KhadeNo ratings yet

- Exam Preparation Progress Tracking APICS CPIM SMR 2013 TemplateDocument1 pageExam Preparation Progress Tracking APICS CPIM SMR 2013 TemplateSiddhesh KhadeNo ratings yet

- BH2 S4CLD2208 BPD en inDocument18 pagesBH2 S4CLD2208 BPD en inSibucharanNo ratings yet

- Manual Aeroccino 3Document30 pagesManual Aeroccino 3UltrabetoNo ratings yet

- Homework 7 Traffic Accident Data AnalysisDocument5 pagesHomework 7 Traffic Accident Data AnalysisRagini P0% (1)

- Clinical ChemistryDocument23 pagesClinical ChemistryRezzy Mae Panadero OraNo ratings yet

- Fundamental analysis of ACC Ltd and India's cement industryDocument5 pagesFundamental analysis of ACC Ltd and India's cement industryDevika SuvarnaNo ratings yet

- Blackman Et Al 2013Document18 pagesBlackman Et Al 2013ananth999No ratings yet

- BAMBUDocument401 pagesBAMBUputulNo ratings yet

- Wang Yunshan ReflectionDocument4 pagesWang Yunshan Reflectionapi-286742915100% (1)

- Myth / Fact: Known and Suspected Terrorists / Special Interest Aliens - Homeland SecurityDocument4 pagesMyth / Fact: Known and Suspected Terrorists / Special Interest Aliens - Homeland SecurityRoger OgdenNo ratings yet

- Core Strategy - Statement of Consultation February 2010Document168 pagesCore Strategy - Statement of Consultation February 2010Aimee-NonaNo ratings yet

- Data Sheet Sylomer SR 28 ENDocument4 pagesData Sheet Sylomer SR 28 ENlpczyfansNo ratings yet

- Krautkramer USN 58R: The Ultrasonic Instrument For The Workshop, Even For Automated InspectionsDocument1 pageKrautkramer USN 58R: The Ultrasonic Instrument For The Workshop, Even For Automated InspectionsAli MohsinNo ratings yet

- Set Up A Mail Server On LinuxDocument56 pagesSet Up A Mail Server On Linuxammurasikan6477No ratings yet

- Danh sách đ tài Đ c nglunvăn ề ề ươ ậ HK1/19-20Document47 pagesDanh sách đ tài Đ c nglunvăn ề ề ươ ậ HK1/19-20LONG Trương MinhNo ratings yet

- Group Project in Patient RoomDocument14 pagesGroup Project in Patient RoomMaida AsriNo ratings yet

- Action Plan Stratcom PDFDocument5 pagesAction Plan Stratcom PDFDaniel SolisNo ratings yet

- ACCT601 Australian Auditing and Assurance Services 201660Document15 pagesACCT601 Australian Auditing and Assurance Services 201660Rafayel MarufNo ratings yet

- Panasonic Th-42pd50u Chassis Gp8duDocument147 pagesPanasonic Th-42pd50u Chassis Gp8du02ury05No ratings yet

- International Journal of Computer Science and Innovation - Vol 2015-n1 - Paper1Document6 pagesInternational Journal of Computer Science and Innovation - Vol 2015-n1 - Paper1sophiaNo ratings yet

- Circumferential CrackingDocument6 pagesCircumferential CrackingMagdykamelwilliamNo ratings yet

- Inbound 6094510472110192055Document2 pagesInbound 6094510472110192055MarielleNo ratings yet

- Defences of Illegality in England, Canada and the USDocument11 pagesDefences of Illegality in England, Canada and the USBetteDavisEyes00No ratings yet

- INTERNSHIP DIARY - SESSION 2019-2020Document28 pagesINTERNSHIP DIARY - SESSION 2019-2020Nilotpal RaiNo ratings yet

- Osisense XX Xx518a3pam12Document6 pagesOsisense XX Xx518a3pam12Paulinho CezarNo ratings yet

- Resume of Thomas Qiao SAP FICO (5yrs Version 4.7) : ProfileDocument3 pagesResume of Thomas Qiao SAP FICO (5yrs Version 4.7) : ProfileVenkata AraveetiNo ratings yet

- DO 178B DetailedDocument25 pagesDO 178B DetailedSenthil KumarNo ratings yet

- Best Practices in Non-Revenue Water en FinalDocument96 pagesBest Practices in Non-Revenue Water en FinalEddiemtonga100% (1)

- Data SheetddddDocument31 pagesData SheetddddEm GomezNo ratings yet

- Stare DecisisDocument7 pagesStare DecisisBirolal Jamatia100% (1)

- Leader in Water Purification Systems RougingDocument16 pagesLeader in Water Purification Systems RougingtomcanNo ratings yet