Professional Documents

Culture Documents

Summary Vibrocompaction Vibroflotation

Uploaded by

eli2412Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Summary Vibrocompaction Vibroflotation

Uploaded by

eli2412Copyright:

Available Formats

Vibrocompaction and Vibrolfotation: procedure, history, suitable types of soils and aims

Vibrocompaction (VC) and vibroflotation (VF) are methods of ground improvement. They are used on

granular soils to increase their bearing capacity and strength. This is done by applying cyclic

horizontal vibrations in the ground which leads to particle rearrangement, an increase the shear

strength and a reduction in compressibility and void ratio. The compaction device, called vibroflot or

depth vibrator, consists of an eccentric weight within a steel tubular casing and is driven by an

electrical or hydraulic motor, which causes the vibrations. VC and VF are often used as synonymous

to describe the same technique but technically, if the weight is driven vertically, the method is VC,

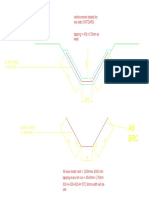

and if it is driven horizontally it is VF. The procedure is as follows: the vibrator is lowered into the soil

under its own weight with the help of flushing water until it

reaches the designed depth; the vibrator is then activated

and is maintained until the power consumption of the vibrator

reaches pre-determined amperage; the device is lifted of

0.5m - 1m and compaction procedure is repeated until it

reaches the surface. The procedure is shown in figure 1. It

can be necessary to compact the surface to a depth of 0.5m

with a surface compacter and also to backfill the hole

Figure 1: Vibrocompaction procedure

produced by the method with material which is then

compacted as part of the process.

The first application of this technique dates back to 1936 when Johann Keller inserted a vibrator into a borehole to increase

the density of the granular soil for the foundation of a large building in Nrenberg, Germany. Since then improvements to the

device, motors and cranes have been made and the method is now used all over the world. Especially important

developments were improvements that avoided the need of a borehole and the finding, in 1942, that the method is not suitable

for silty sands. Vibrocompaction can only be used on non-cohesive soils with a percentage of fines less than 10-15%.

Furthermore, to assess the compactability of the ground, not only the particle size distribution, but also the data from CPT

tests should be used to give a continuous soil profile with information on strength and compressibility. For this purpose two

charts can be used which plot cone resistance (qc,cpt) against friction ratio (qf) from Massarsch (1991) and qc,cpt against sleeve

friction (qs) from Eslami and Fellenius (1997).

This technique can be used to solve a variety of issues. These include increasing the bearing capacity (qb) and strength of the

soil (), improving the ability of the soil to carry dynamic loads, reducing the need for deep foundations, increasing the longterm performance of the treated ground and where deep foundations cant be avoided, the VC of the subsoil can help to

achieve a compaction index that favours piling. In addition, it reduces total and differential settlements to acceptable

magnitudes, mitigates liquefaction in earthquake zones, and reduces permeability for earthworks foundations.

Bibliography

Kirsh, F and Kirsh K. (2010) Ground Improvement by Deep Vibratory Methods. Taylor and Francis, Hoboken.

Kirsh, K. & Moseley, M. P. and Kirsh K. (2004). Ground improvement. 2nd Edition. New York, Taylor and Francis. pp. 67.

Massarsch, K.R. and Fellenius, B.H. (2005). Chapter 19: Deep Vibratory Compaction of Granular Soils. In: Indraratna, B. and

Chu J. Ground Improvement Case Histories. Kidlington, Oxford: ELSEVIER Ltd. 539-562.

You might also like

- Keller-Liquefaction Potential Around Pile FoundationsDocument24 pagesKeller-Liquefaction Potential Around Pile FoundationsnumspyNo ratings yet

- 05 Constructing Load Transfer QZ and TZ Curves From Pile Loading Tests For 3D FEA AnalysisDocument11 pages05 Constructing Load Transfer QZ and TZ Curves From Pile Loading Tests For 3D FEA AnalysislingamkumarNo ratings yet

- Program ReSlope (3.0) Notes: Reinforced Slope DesignDocument28 pagesProgram ReSlope (3.0) Notes: Reinforced Slope Designsimone stanoNo ratings yet

- #-Stoage Tanks On Ground ImprovementDocument40 pages#-Stoage Tanks On Ground ImprovementManuelPérezNo ratings yet

- Bearing Capacity Failure of Trapezoidal Geosynthetic Reinforced Soil WallsDocument34 pagesBearing Capacity Failure of Trapezoidal Geosynthetic Reinforced Soil WallsAnonymous Re62LKaACNo ratings yet

- Earthquake Design of Tied-Back Retaining WallDocument15 pagesEarthquake Design of Tied-Back Retaining WallEverson BoyDayz PetersNo ratings yet

- Connections in Precast Concrete Structures - Columb Base PlatesDocument22 pagesConnections in Precast Concrete Structures - Columb Base Platestoyi kamiNo ratings yet

- Compressibility of SoilDocument34 pagesCompressibility of SoilCamille LardizabalNo ratings yet

- Lime. Swelling Soils Treatment Using Lime and Sea Water For Roads ConstructionDocument9 pagesLime. Swelling Soils Treatment Using Lime and Sea Water For Roads ConstructionjyjiaNo ratings yet

- Deep Foundation and Earth Retaining Structures for Infrastructure ProjectsDocument47 pagesDeep Foundation and Earth Retaining Structures for Infrastructure ProjectslingamkumarNo ratings yet

- Draft Guidelines On Geo-Synthetics For Coastal Protection and Port WorksDocument51 pagesDraft Guidelines On Geo-Synthetics For Coastal Protection and Port WorksGautham GautiNo ratings yet

- 9 Questions Before Making Shotcrete Mix DesignDocument2 pages9 Questions Before Making Shotcrete Mix DesignMuhammadIqbalMughalNo ratings yet

- Land Filling in MSWDocument83 pagesLand Filling in MSWvenkatraman20No ratings yet

- The Design of Reinforcement Soil Retaining Wall Using TENAX Geogrids PDFDocument30 pagesThe Design of Reinforcement Soil Retaining Wall Using TENAX Geogrids PDFmahmoud meslehNo ratings yet

- Bitcon Pavement Design PDFDocument18 pagesBitcon Pavement Design PDFVaghasiyaBipinNo ratings yet

- Design of R.E. WallsDocument22 pagesDesign of R.E. Wallsvicky925No ratings yet

- 2-Shearwall Final Print PDFDocument147 pages2-Shearwall Final Print PDFCon CanNo ratings yet

- Report On Electrical Resistivity TestDocument9 pagesReport On Electrical Resistivity TestSurajit SahaNo ratings yet

- Bearing Capacity of Single Pile On Sand and ClayDocument31 pagesBearing Capacity of Single Pile On Sand and ClayCarlos FilipusNo ratings yet

- Toe Drain Construction TemplateDocument1 pageToe Drain Construction TemplateFaez NazriNo ratings yet

- EV2 - 93-100 To 94-000Document2 pagesEV2 - 93-100 To 94-000ajorbind.12No ratings yet

- 6 - Johnson, K - Geotechnical Investigations For Dredging Projects PDFDocument16 pages6 - Johnson, K - Geotechnical Investigations For Dredging Projects PDFAhmed GadNo ratings yet

- PVD Design PDFDocument17 pagesPVD Design PDFAndreas Brian V PNo ratings yet

- Submerged Floating TunnelDocument25 pagesSubmerged Floating TunnelAshutosh JainNo ratings yet

- Evaluation of Modulus of Elasticity and Modulus of Subgrade Reaction of Soils Using CBR TestDocument7 pagesEvaluation of Modulus of Elasticity and Modulus of Subgrade Reaction of Soils Using CBR TestJorge Vanegas100% (1)

- Lime Stabilization of Expansive SoilDocument14 pagesLime Stabilization of Expansive Soilعبدالرحمن العليميNo ratings yet

- FEB 402 Slope Stability AnalysisDocument26 pagesFEB 402 Slope Stability AnalysislucyNo ratings yet

- Soil Stabilization Methods for Low-Cost Road ConstructionDocument67 pagesSoil Stabilization Methods for Low-Cost Road ConstructionSarth ShuklaNo ratings yet

- MSE Wall MOdellingDocument176 pagesMSE Wall MOdellingAvishek NepbloodNo ratings yet

- Construction of Slurry WallsDocument22 pagesConstruction of Slurry WallsJOE G PHILIP CENo ratings yet

- Breakwater Vertical BarriersDocument10 pagesBreakwater Vertical BarriersAlbert PranataNo ratings yet

- Effect of Lime Treatment On California Bearing Ratio (CBR) of Expansive SoilDocument7 pagesEffect of Lime Treatment On California Bearing Ratio (CBR) of Expansive SoilAnonymous izrFWiQNo ratings yet

- Senior Structural Engineer - Job DescriptionDocument2 pagesSenior Structural Engineer - Job DescriptionKiran D AnvekarNo ratings yet

- Effect of Temperature Loads On Beam Design in Thermal AnalysisDocument4 pagesEffect of Temperature Loads On Beam Design in Thermal AnalysisMohammad AasimuddinNo ratings yet

- 9.7 Pavement Evaluation - Flexible Pavement DistressDocument11 pages9.7 Pavement Evaluation - Flexible Pavement DistressPalanirajan VijayaraghavanNo ratings yet

- Foundations in Expansive SoilsDocument95 pagesFoundations in Expansive SoilsScott Downs100% (1)

- Hot Rolled Structures: Benefits of Fast ConstructionDocument2 pagesHot Rolled Structures: Benefits of Fast ConstructionKawser HossainNo ratings yet

- Lec 06Document18 pagesLec 06Ravindra JagadaleNo ratings yet

- 2020-05-08 SVKM'S, Shirpur, Maharashtra - DBR-R0Document26 pages2020-05-08 SVKM'S, Shirpur, Maharashtra - DBR-R0Sheikh_MutaharNo ratings yet

- Deep Foundation Design MethodsDocument30 pagesDeep Foundation Design MethodschristopherapssNo ratings yet

- Chapter11 Coduto CompressibilityAndSettlementDocument160 pagesChapter11 Coduto CompressibilityAndSettlementTuğçe TürkanNo ratings yet

- Is 13063 - 1991 Structural Safety o Fbuildings On Shallow Foundations On Rocks - Code of PracticeDocument19 pagesIs 13063 - 1991 Structural Safety o Fbuildings On Shallow Foundations On Rocks - Code of PracticePrapa KaranNo ratings yet

- Seepage AnalysisDocument4 pagesSeepage AnalysisAditya Desai100% (1)

- Pot BearingsDocument14 pagesPot BearingsJosue LewandowskiNo ratings yet

- Prefabricated Vertical DrainsDocument26 pagesPrefabricated Vertical DrainsMayank Prakash100% (1)

- Introduction to Ground Modification TechniquesDocument18 pagesIntroduction to Ground Modification TechniquesAli naveedNo ratings yet

- Lect-1 Intro 2014 Web 000Document45 pagesLect-1 Intro 2014 Web 000Junayed Khan100% (1)

- Technical Paper On Plate Load Test PDFDocument138 pagesTechnical Paper On Plate Load Test PDFPushpendra ChouhanNo ratings yet

- Liquefaction of SoilDocument18 pagesLiquefaction of SoilPrabha KaranNo ratings yet

- Numerical analysis of soil-structure interaction for deep foundations using PLAXIS 3DDocument204 pagesNumerical analysis of soil-structure interaction for deep foundations using PLAXIS 3DMekonen MagogaNo ratings yet

- Design of Piled FoundationDocument62 pagesDesign of Piled FoundationMaanvir SatyaNo ratings yet

- Reinforced Concrete Slab Design Using The Empirical MethodDocument9 pagesReinforced Concrete Slab Design Using The Empirical MethodRezky MuliaNo ratings yet

- Slope Stability Analysis Report PDFDocument7 pagesSlope Stability Analysis Report PDFPrakash Singh RawalNo ratings yet

- Ground Improvement Case Studies Chemical Lime PilesDocument14 pagesGround Improvement Case Studies Chemical Lime PilesHanumantha Rao BNo ratings yet

- Vibro ReplacementDocument31 pagesVibro ReplacementChris FindlayNo ratings yet

- Vibro Ground BrochureDocument12 pagesVibro Ground Brochurealphaboi100% (1)

- Vibro Replacement Technique PDFDocument3 pagesVibro Replacement Technique PDFdebpriya1984No ratings yet

- Refer atDocument30 pagesRefer atMoldovan Adrian NeluNo ratings yet

- Ground Improvement TechniquesDocument29 pagesGround Improvement TechniquesRaj Sunil100% (1)

- Automation System PSS 4000 - Modules With Approval For The Railway SectorDocument4 pagesAutomation System PSS 4000 - Modules With Approval For The Railway SectorRadu George CristianNo ratings yet

- Henry Berger ResumeDocument1 pageHenry Berger Resumeapi-581806915No ratings yet

- Suryamoorthy M: +91 9751550400 Chennai, IndiaDocument3 pagesSuryamoorthy M: +91 9751550400 Chennai, IndiaSuryaNo ratings yet

- Software Engineering Question BankDocument6 pagesSoftware Engineering Question BankDr. A. Pathanjali Sastri100% (1)

- Astm A53-A53m 2018Document23 pagesAstm A53-A53m 2018Lewis M. Nixon100% (4)

- MMRP1 Mae Moh Replacement Power Project 1 MMRP1 Mae Moh Replacement Power Project 1Document14 pagesMMRP1 Mae Moh Replacement Power Project 1 MMRP1 Mae Moh Replacement Power Project 1Mohammed Ibrahim AsifNo ratings yet

- Cold-Formed Steel Structures To The AISI Specification - 0824792947Document405 pagesCold-Formed Steel Structures To The AISI Specification - 0824792947irdl92% (12)

- Hilti - Anchor Fastening Technology ManualDocument0 pagesHilti - Anchor Fastening Technology ManualDavid Salomão Pinto Castanho BizarroNo ratings yet

- Aecom Brochure PDFDocument23 pagesAecom Brochure PDFAlexandru GateiuNo ratings yet

- Importance of English Communication For Engineering Students From Rural Areas and Its RemediesDocument4 pagesImportance of English Communication For Engineering Students From Rural Areas and Its RemediesbilbilNo ratings yet

- Portal Frame Purlin Design CalculationsDocument8 pagesPortal Frame Purlin Design CalculationsNasrul Torres0% (1)

- ADC, Autopilot, EFIS, EICAS, EADI, Lec 6Document37 pagesADC, Autopilot, EFIS, EICAS, EADI, Lec 6aahsan345100% (7)

- Series V Cooling Towers SpecificationsDocument6 pagesSeries V Cooling Towers SpecificationsGeelissonNo ratings yet

- 1 IntroCourse PDFDocument12 pages1 IntroCourse PDFArmenio OsvaldoNo ratings yet

- Final Penn Work 08 091webDocument75 pagesFinal Penn Work 08 091webJames LowderNo ratings yet

- Ktu Ex Ii#1 5300 2018Document4 pagesKtu Ex Ii#1 5300 2018adarshanadhu1No ratings yet

- Associate Engineer - ElectricalDocument1 pageAssociate Engineer - ElectricalGVR MurthyNo ratings yet

- ORA Lab Measurement TraceabilityDocument7 pagesORA Lab Measurement TraceabilityOsman Aita100% (1)

- Characteristics of A Good Software Requirements SpecificationDocument2 pagesCharacteristics of A Good Software Requirements Specificationmaheshraj_rNo ratings yet

- AY1415 FYP Available List 20140626Document25 pagesAY1415 FYP Available List 20140626Joanna LockNo ratings yet

- DOMOTICSDocument359 pagesDOMOTICSl_dumitruNo ratings yet

- UNIFORMAT II Classification for Building ElementsDocument64 pagesUNIFORMAT II Classification for Building Elementsrainbird7100% (1)

- Analysis of Electric Machinery Krause Manual Solution PDFDocument2 pagesAnalysis of Electric Machinery Krause Manual Solution PDFKuldeepNo ratings yet

- Commonwealth Act No 294Document22 pagesCommonwealth Act No 294Eymann JalaNo ratings yet

- Arrancador Monfasico ATS01N106FT SchneiderDocument2 pagesArrancador Monfasico ATS01N106FT SchneiderJulian Lopez LopezNo ratings yet

- Column design details for rectangular columnDocument27 pagesColumn design details for rectangular columnnsureshbabu0% (1)

- 6.letter of RecommendationDocument3 pages6.letter of Recommendationvsureshkannanmsec100% (1)

- Equipment ScheduleDocument5 pagesEquipment ScheduleKushal PatilNo ratings yet

- BBDM2153 Operations Management 1Document27 pagesBBDM2153 Operations Management 1Keith GabrielNo ratings yet

- Compass 1.5 Dealer Guide1Document290 pagesCompass 1.5 Dealer Guide1williamNo ratings yet