Professional Documents

Culture Documents

Underground PDF

Uploaded by

jkhgvdj mnhsnjkhgOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Underground PDF

Uploaded by

jkhgvdj mnhsnjkhgCopyright:

Available Formats

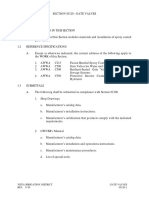

Underground Storage Tank Installation

Business

_________________________________

Contractor

________________________________

Address

_________________________________

Address

________________________________

Telephone

_________________________________

Telephone

________________________________

City Business License ____________________________

Tank 1

Cap. ____________

Type _________

Serial Number ________________________________

Tank 2

Cap. ____________

Type _________

Serial Number ________________________________

Tank 3

Cap. ____________

Type _________

Serial Number ________________________________

Piping

Size _____________

Type _________

Check One -

Tank Supply

Dispenser Supply

Piping

Size _____________

Type _________

Check One -

Tank Supply

Dispenser Supply

Piping

Size _____________

Type _________

Check One -

Tank Supply

Dispenser Supply

1.

2.

3.

DESCRIPTION

Does the Contractor have manufacturers installation and test instructions present on

site, and have they been reviewed prior to installation and test?

Does the installation and location of UGSTs and dispensers comply with approved

stamped plans?

Tank Protection

A. Cathodic protection

Pre-Engineered

B. Listed corrosion protection materials

4.

Custom Engineered (Attach detailed specifications from Engineer)

Tank Location

A. Class I: minimum 1ft. from basements and 3ft. to property line

B: Class II or III: Minimum 1 ft from property line

5.

6.

Tank Burial Depth and Cover

A: Tanks not subject to traffic provided with 2 ft. of earth or 1 ft. of earth and 4 ft. of reinforced concrete

B: Tanks subject to traffic provided with 3ft. of earth or 18" of well-tamped earth and 6" of reinforced concrete or 18"

well tamped earth and 8" of asphaltic concrete. These shall extend 1ft. beyond outline of tank in all directions

Tank Installation

A. Is there a 12" bed of approved material provided for tanks?

B. Is the following material provided for appropriate tank? Crush stone between 1/8" & 1/4" (fiberglass tanks); Pea

Gravel between 1/8" & 3/4" (Fiberglass and Steel); Sand (Steel) ( Fiberglass only if approved by the manufacturer)

C. Distance between tanks or tanks to bank 24 ft. for fiberglass or 12" for Steel.

7.

Test Sump

A. A test sump is provided and properly installed using a 4" perforated pipe, which extends to the lowest point of the

tanks.

B. Test sump is properly identified.

8.

9.

10.

Tank Test

A. Did the primary tank pass the air test? (3-5 psi for horizontal or 2.5max psi on vertical for 30 minutes)

B. Did the secondary tank, if provided, pass the air test? (tested at the same pressure as primary tank. Air is to remain

in primary tank while the secondary tank is being tested.)

C. Was the outer skin of the tank, including all welded seams, valves, and connections soaped to determine if leaks

were present?

Liquid Level Gauge: Is the tank equipped with a device that will sound an alarm at 90% capacity or stop the

flow of product to the storage tank at 95% capacity?

Emergency Shut-off

A. Is there an emergency shut-off switch provided?

B. Is the emergency shut-off switch clearly identified and accessible?

C. Is the emergency shut-off switch no closer than 20 feet and within 100 feet of the dispenser?

D. Does Emergency Shut-off perform properly?

11.

Hoses

A. Are hoses and nozzles UL approved?

B. Are hoses less than 18 feet in length?

C. Are hoses, which dispense Class I liquids, provided with a shear valve?

D. Dispenser hoses are never within 5' of any building opening when fully extended?

YES

NO

NA

Underground Storage Tank Installation

12.

Signs - are the following signs provided as indicated and visible when pumping?

A. WARNING- It is unlawful and dangerous to dispense gasoline into unapproved containers

B. NO SMOKING

C. STOP MOTOR

13.

Piping

Piping subject to traffic

A. Is at least 6 inches of well-compacted backfill bedding provided?

B. Is piping covered with at least 18 inches of backfill and pavement?

Piping within same trench

C. Is piping spaced a minimum of 2 pipe diameters on each level?

D. If two or more levels of piping are provided, is piping separated by a minimum of 6 of well compacted fill?

E. Has Corrosion protection been provided?

14.

Line Test

A. Were all connections, valves and welded joints soaped during air test to determine leaks?

B. Hydrostatic test performed to 150% of Maximum anticipated pressure?

C. Pneumatic test performed to 110% of maximum anticipated pressure, but not less than 5psi gauge at the highest

point of system?

D. Line test performed for a minimum of 10 minutes?

15.

16.

Vent Lines- Class I Liquid

A. Are vent pipes a minimum of 12 high?

B. Are vent lines a minimum of 3 above roofline?

C. Is the inside diameter of the vent lines a minimum of 1.25?

D. Is the vent line protected from corrosion?

E. Are the vent lines protected to prevent damage from vehicles?

F. Are the vent lines equipped with approved caps?

Fill Openings

A. Are the fill openings tight fill types?

B. Are the fill openings protected from overflow?

C. Are the fill caps color code identified?

D. Are waterproof caps provided for fill openings?

17.

Dispensers

A. Are the dispensers protected against physical damage?

B. Are the dispensers UL listed?

C. Are the dispensers located a minimum of 10 feet from the property line or combustible construction?

D. Are impact valves level?

E. Are the impact valves anchored?

F. Have the clips been removed from the impact valve?

G. Has the impact valve been checked for proper operation?

H. Are dispensers visible to the attendant?

I. Is there a fire hydrant provided within 500 feet of the dispensers by vehicle access?

18.

Has approval from the City Electrical department been granted? (attachment)

Explain all No answers.

_________________________________________________________________________________________________________

_________________________________________________________________________________________________________

_________________________________________________________________________________________________________

_________________________________________________________________________________________________________

_________________________________________________________________________________________________________

_________________________________________________________________________________________________________

_________________________________________________________________________________________________________

_________________________________________________________________________________________________________

_________________________________________________________________________________________________________

Completion Date ___________

Contractors Signature ___________________________ Print ___________________________

Inspectors Signature ____________________________ Print __________________________

2

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- RISA Training ManualDocument352 pagesRISA Training ManualSergey100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Erection & Commissioning Bar ChartDocument8 pagesErection & Commissioning Bar Chartrjpatil19100% (1)

- PP MFG End UserDocument92 pagesPP MFG End Userprasadpandit123No ratings yet

- CJ 6A Checklist Version 1 PDFDocument10 pagesCJ 6A Checklist Version 1 PDFairdudeNo ratings yet

- Audit Checklist Master-HEMSA - June2010Document6 pagesAudit Checklist Master-HEMSA - June2010jkhgvdj mnhsnjkhgNo ratings yet

- SAP Wage TypesDocument4 pagesSAP Wage TypesSanjay MuralidharanNo ratings yet

- Asme Y14.32.1m - 1994Document17 pagesAsme Y14.32.1m - 1994achmadnureddin8228No ratings yet

- Rack Server Teech Sheet ManualDocument20 pagesRack Server Teech Sheet ManualTim WiseNo ratings yet

- List of Software Companies in IndiaDocument158 pagesList of Software Companies in IndiaSurya HarishNo ratings yet

- Process Analysis Note PDFDocument10 pagesProcess Analysis Note PDFPierrePMMartinNo ratings yet

- ISO 5211 Drilling Patterns Imperial SizesDocument1 pageISO 5211 Drilling Patterns Imperial Sizesjkhgvdj mnhsnjkhgNo ratings yet

- Low VoltageDocument92 pagesLow VoltageMohammad AmerNo ratings yet

- API 608 Floating Ball ValvesDocument2 pagesAPI 608 Floating Ball Valvesjkhgvdj mnhsnjkhgNo ratings yet

- API 608 Floating Ball ValvesDocument2 pagesAPI 608 Floating Ball Valvesjkhgvdj mnhsnjkhgNo ratings yet

- 12v 6a 92 4w Tec 12706 Thermoelectric Cooler PeltierDocument5 pages12v 6a 92 4w Tec 12706 Thermoelectric Cooler Peltierjkhgvdj mnhsnjkhgNo ratings yet

- 12v 6a 92 4w Tec 12706 Thermoelectric Cooler PeltierDocument5 pages12v 6a 92 4w Tec 12706 Thermoelectric Cooler Peltierjkhgvdj mnhsnjkhgNo ratings yet

- 12v 6a 92 4w Tec 12706 Thermoelectric Cooler Peltier PDFDocument5 pages12v 6a 92 4w Tec 12706 Thermoelectric Cooler Peltier PDFjkhgvdj mnhsnjkhgNo ratings yet

- En 12201Document33 pagesEn 12201jkhgvdj mnhsnjkhgNo ratings yet

- Cantilever Retaining Wall Design PDFDocument2 pagesCantilever Retaining Wall Design PDFjkhgvdj mnhsnjkhgNo ratings yet

- 12v 6a 92 4w Tec 12706 Thermoelectric Cooler Peltier PDFDocument5 pages12v 6a 92 4w Tec 12706 Thermoelectric Cooler Peltier PDFjkhgvdj mnhsnjkhgNo ratings yet

- Handling PigBasket GADocument1 pageHandling PigBasket GAjkhgvdj mnhsnjkhgNo ratings yet

- 12v 6a 92 4w Tec 12706 Thermoelectric Cooler PeltierDocument5 pages12v 6a 92 4w Tec 12706 Thermoelectric Cooler Peltierjkhgvdj mnhsnjkhgNo ratings yet

- ASTM Method D1945-96: Analysis of Natural GasDocument1 pageASTM Method D1945-96: Analysis of Natural GasJosep JaamNo ratings yet

- Tip Sheet 9 Web Version DocumentDocument2 pagesTip Sheet 9 Web Version DocumentKarun NooneyNo ratings yet

- Tolerancesspecifications & DimensionsDocument1 pageTolerancesspecifications & DimensionswernhowNo ratings yet

- MSG 00018Document7 pagesMSG 00018jkhgvdj mnhsnjkhgNo ratings yet

- Indian Standards For Natural Gas Pipeline SystemDocument5 pagesIndian Standards For Natural Gas Pipeline SystemNapidduNo ratings yet

- LowVoltage Feb19thDocument6 pagesLowVoltage Feb19thShreyas EsheNo ratings yet

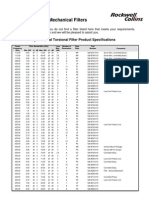

- Collins Torsional Mechanical Filters: Symmetrical Torsional Filter Product SpecificationsDocument2 pagesCollins Torsional Mechanical Filters: Symmetrical Torsional Filter Product SpecificationsGdfsndh GfdvhjzdNo ratings yet

- BZC 14Document1 pageBZC 14jkhgvdj mnhsnjkhgNo ratings yet

- Lawctd 603Document5 pagesLawctd 603Nguyen Anh TuanNo ratings yet

- Semiconductor DevicesDocument524 pagesSemiconductor Devicesapuinwork100% (1)

- 05120Document4 pages05120jkhgvdj mnhsnjkhgNo ratings yet

- File 1361847746Document8 pagesFile 1361847746jkhgvdj mnhsnjkhgNo ratings yet

- Datasheet 1mbhDocument5 pagesDatasheet 1mbhnguanjukNo ratings yet

- Carmagen 6 10Document3 pagesCarmagen 6 10ikhleifNo ratings yet

- 164200252Document92 pages164200252jkhgvdj mnhsnjkhgNo ratings yet

- 0871Document1 page0871jkhgvdj mnhsnjkhgNo ratings yet

- Material GradesDocument2 pagesMaterial Gradespankaj_pawar89No ratings yet

- 570 Examination Sample ItemsDocument3 pages570 Examination Sample ItemsMaria_Victoria_5742No ratings yet

- Allan D. Cruzat: Position Applied: Pipe Fitter Educational AttainmentDocument15 pagesAllan D. Cruzat: Position Applied: Pipe Fitter Educational AttainmentRaymond Manalo PanganibanNo ratings yet

- Advanced Logistics and Material Management CourseDocument8 pagesAdvanced Logistics and Material Management CourseSaikumar SelaNo ratings yet

- Accounting Assignment 3. Investment AppraisalDocument4 pagesAccounting Assignment 3. Investment AppraisalChaminda Madanayake50% (2)

- Travel Buddy - White - PaperDocument14 pagesTravel Buddy - White - PaperAdam WinterfloodNo ratings yet

- PIA Business Policy ProjectDocument68 pagesPIA Business Policy ProjectRao Waqas100% (1)

- CRM Final Ppt-6Document21 pagesCRM Final Ppt-6Niti Modi ShahNo ratings yet

- Lecture07 RecoveryDocument27 pagesLecture07 RecoveryHarsha PaniaNo ratings yet

- CBE HQ Design ProjectDocument7 pagesCBE HQ Design ProjectAzaria MesfinNo ratings yet

- Use Case StudyDocument4 pagesUse Case StudyDustin ShepherdNo ratings yet

- Specification (GTX-35VS Kaveri) : Afterburning TurbofanDocument18 pagesSpecification (GTX-35VS Kaveri) : Afterburning Turbofanandrw1987No ratings yet

- Es 200Document10 pagesEs 200Livian TeddyNo ratings yet

- Part A IFB Full Project Final REPORTDocument37 pagesPart A IFB Full Project Final REPORTSrinivas Gowda100% (2)

- Retail and Enterprise POS Localization For BrazilDocument10 pagesRetail and Enterprise POS Localization For BrazildmontNo ratings yet

- High-Productivity Turning CenterDocument4 pagesHigh-Productivity Turning CenterthyskieNo ratings yet

- Module6-Detailed Project Report and EPCDocument10 pagesModule6-Detailed Project Report and EPCJames K. BitokNo ratings yet

- P3 December 2009 Examiner ReportDocument3 pagesP3 December 2009 Examiner ReportKhurram AxENo ratings yet

- Specification For Bonding Fresh Concrete To Hardened Concrete With A Multi-Component Epoxy AdhesiveDocument10 pagesSpecification For Bonding Fresh Concrete To Hardened Concrete With A Multi-Component Epoxy AdhesiveRandolph CamaclangNo ratings yet

- OceanSaver AS - Kashif Javaid PDFDocument28 pagesOceanSaver AS - Kashif Javaid PDFvangeliskyriakos8998No ratings yet

- Aerospace America April2011 PDFDocument52 pagesAerospace America April2011 PDFErhanNo ratings yet

- Assignment 2 (Database Systems)Document4 pagesAssignment 2 (Database Systems)muhammad waseemNo ratings yet