Professional Documents

Culture Documents

We Make Quality Speak For You: Vision

Uploaded by

Anonymous ZHGywrSOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

We Make Quality Speak For You: Vision

Uploaded by

Anonymous ZHGywrSCopyright:

Available Formats

"

We make Quality speak for you

"

Vision

To establish as one of the top modular furniture manufacturing companies in the

country.

To provide innovative and quality products to our customer meeting their

expectations.

To be committed to seek growth and prosperity achieving a sustainable competitive

share of the industry.

To continue to bring in improvements in quality, productivity, value, innovative

product offerings.

To be a dependable provider of high quality modular office furniture. The

competitive capacity of furniture products on foreign markets is

dependent on price trends and raw materials, materials, utilities,

transportation tariffs and currency exchange fluctuation, whose levels

have reached critical levels for furniture manufacturers in Pakistan and

which had to be compensated by technological updates, to modernize

manufacturing processes and to give minimal remuneration to

employed personnel.

Mission

To establish DM Modular Furniture Systems and the products to be a very dependable

name.

To aim higher to establish very decent global market.

To be a profitable, ethical and market driven company.

To consistently provide reliable products in all categories of modular furniture

systems.

Objectives

"

We deco design something for you to perfect a life around it

"

Believe in focus on core competence in office furniture solution.

Provide one stop solutions including supply of different furniture brands as per the

customer requirement.

Meet the expectations of the customers with the right coordination with architects /

interior designers.

Consultants with highest integrity.

Carry on with the value that drives us give out the best in doing office, educational

and home furniture business.

DM Modular Furniture Systems has set its eyes on two aspects in the progress:

Desirous to get the tag for DM Modular Furniture Systems registered as a Private

Limited Co.

To work in the direction to make a beginning in exporting furniture products to SAARC

Countries and also Gulf countries.

Production analysis:

Product quality is mainly dependant on:

*ongoing research of existing opportunities on the market .

*increasing raw material and material supply demands

*the accuracy of all processing execution

*permanent personnel training in order to ensure client demands are met

There are companies that still have repair and touch-up sectors, some because

of the antiquated production process, others due to improper supply with raw

materials and materials, ineffective production management, as well as due to lack of

an effective production quality control system;

Product price is determined by design complexity, size, the nature and mix of

materials, functionality and the processing technology used.

Product design

A large part of the furniture manufacturers works on the clients model and not

by promoting on the market their own competitive models, even though there are

some furniture design . We see inertia in fast adaptation to market demands.

Product functionality must satisfy the utilitarian destination while creating a

successful combination for providing comfort and have the adequate elegance and

aesthetics.

Innovation, contributes to increasing product competitiveness by innovative

models and functions.

Materials, especially materials used for surfaces, decisively influence the look

of products, especially.

Punctuality in delivering products as well as quickly filling orders are

essential elements in a trade relationship, involving the company's management and

giving it credibility and prestige.

Related services such as marketing, design, trade, consultancy, financial,

training contribute to improving trade development and business success;

Personnel professional training for the technology of the technical equipment

used and of the required product quality.

Key opportunities for improving sector export and competitiveness

performance.

Relevant effects for increasing furniture exporters activity competitiveness can

be secured by improving the component supply system and the existing product

manufacturing method.

This phenomenon involves:

*Developing new furniture component production facilities;

*Supplying furniture plants with furniture component elements from

specialized manufacturers;

*Using excess space in existing plant to create semi-finished products

components necessary to furniture production;

*Investments in high-performance technologies and equipment;

*Extending quality certification system implementation;

*Supporting the development of related services;

Current constraints which, once removed, permit the action of

critical success factors.

Product quality:

*Increasing investment efforts in restructuring and updating manufacturing

technologies and technical equipment by promoting clean highperformance technologies;

*Improving the high-quality raw materials and material supply system;

*Extending the quality certification system and brand implementation;

*Training personnel on all levels;

Product price:

*Carefully prospecting on the markets materials used in product

manufacturing, their quality, design, how they reflect on the finished

products, as well as prices etc.;

*Effectively using personnel;

*Effectively managing and using assets to their fullest capacity and using all

internal resources available;

*Careful and permanent tracking of manufacturing costs by creating diagrams

for products and components, in order to carry out any necessary

interventions;

*Cutting down on administrative expenses by rationalizing the use of raw

materials and materials;

Design:

*Tackling this problem at a national level and properly stimulating designers;

*Extending application of the product, company, country trademark;

*Developing, to an equal extend, modern, practical and reproducible design, in

thigh connection with innovation and the technological process;

Functionality

*Carrying out market and product studies on third party markets;

*Applying European and international standards and regulations;

*Correctly informing clients on materials used in product manufacturing;

*Stimulating R&D, innovation, etc;

Innovation

*Developing and stimulating design;

*Promoting new processing and usage method for ecological materials, with

improved parameters;

*Allocating proper financial resources for research work;

*Developing the concept of production specialization and extending

cooperation with other manufacturers;

Work productivity, even though it has increased almost threefold

cannot be compared to that in advanced countries, because the

organizational system differs a great deal and we have here technological

organization based on the concept of integrated production in most of the

companies as compared to abroad where the specialization-cooperation

system prevails, whereas large companies purchase components from

supplying SME(Small or Medium Enterprise Business Companies & Firm)

You might also like

- Product and Process DesignDocument47 pagesProduct and Process DesignGhanashyam YadavNo ratings yet

- The Product DesignDocument7 pagesThe Product DesignRahul ItankarNo ratings yet

- Develop Operational Strategy GuideDocument24 pagesDevelop Operational Strategy GuideGrishma BarotNo ratings yet

- Pom Notes - 064919Document9 pagesPom Notes - 064919suduh09No ratings yet

- s6 Entrepreneurship Paper 2 NotesDocument48 pagess6 Entrepreneurship Paper 2 NotesNabalema MollyNo ratings yet

- Entrepreneurship DevelopmentDocument4 pagesEntrepreneurship DevelopmentKenny SamNo ratings yet

- Lesson 2 - PRODUCTS, PROCESS AND SCHEDULE DESIGNDocument30 pagesLesson 2 - PRODUCTS, PROCESS AND SCHEDULE DESIGNMazey AustriaNo ratings yet

- Product and Service Design FundamentalsDocument80 pagesProduct and Service Design Fundamentalshabtamu tadesseNo ratings yet

- Chapter Three Design of The Operation SystemDocument79 pagesChapter Three Design of The Operation SystemEyob FekaduNo ratings yet

- Textile Design Economics Tex0: Dr. Tamer F. Khalifa 2018-2019Document13 pagesTextile Design Economics Tex0: Dr. Tamer F. Khalifa 2018-2019Mina Samy abd el zaherNo ratings yet

- DT - Unit 1Document18 pagesDT - Unit 1YoNo ratings yet

- Slides Prepared by John LoucksDocument64 pagesSlides Prepared by John LoucksNigel DouchNo ratings yet

- I Industrial Engineering ManagementDocument25 pagesI Industrial Engineering ManagementAlexNo ratings yet

- Design Economics 4Document19 pagesDesign Economics 4Mina Samy abd el zaherNo ratings yet

- Facilities Planning: Prepared By: Prof. Shuchi MathurDocument27 pagesFacilities Planning: Prepared By: Prof. Shuchi MathurShuchi Prashant SinghNo ratings yet

- DT Notes Unit 1,2,3Document83 pagesDT Notes Unit 1,2,3Akriti JaiswalNo ratings yet

- Product and Service DesignDocument38 pagesProduct and Service DesignCharisa SamsonNo ratings yet

- Om Chapter ThreeDocument38 pagesOm Chapter Threekassahungedefaye312No ratings yet

- Unit 1 POMDocument4 pagesUnit 1 POMAnmolpreet KaurNo ratings yet

- Ambo University Institute of Technology Department of Industrial EngineeringDocument53 pagesAmbo University Institute of Technology Department of Industrial Engineeringmich abiNo ratings yet

- Amit Mudgal - Polymer Technologist With Work Ex of More Than 7 Years in Research & Business DevelopmentDocument4 pagesAmit Mudgal - Polymer Technologist With Work Ex of More Than 7 Years in Research & Business Developmentamit_mudgal2007No ratings yet

- Operation Management MidTermDocument10 pagesOperation Management MidTermNicholas ChiewNo ratings yet

- Product and Service Development and InnovationDocument27 pagesProduct and Service Development and InnovationRayan MukherjeeNo ratings yet

- What is corporate strategy in 40 charactersDocument28 pagesWhat is corporate strategy in 40 charactersHarpinder SinghNo ratings yet

- Chapter 1Document141 pagesChapter 1Berihu GirmayNo ratings yet

- Advanced MFG System MettuDocument178 pagesAdvanced MFG System MettuNetsi FikiruNo ratings yet

- Second Chapter: Product and Service DesignDocument8 pagesSecond Chapter: Product and Service DesignMominul MominNo ratings yet

- Product and Process DesignDocument47 pagesProduct and Process DesignJai HindNo ratings yet

- Technology Management 3Document6 pagesTechnology Management 3Joju JohnyNo ratings yet

- Introduction to Product Design ProcessDocument45 pagesIntroduction to Product Design ProcessShivam PrajapatiNo ratings yet

- Production and Operations Management: Reporters: Karl David Al-Shuwayer Riangelli Exconde Mba1A-RDocument13 pagesProduction and Operations Management: Reporters: Karl David Al-Shuwayer Riangelli Exconde Mba1A-RRiangelli ExcondeNo ratings yet

- Project AppraisalDocument27 pagesProject Appraisallechu_16100% (3)

- Topic 3 Product DesignDocument19 pagesTopic 3 Product Designjohn nderituNo ratings yet

- Product and Service DesignDocument66 pagesProduct and Service DesignantehenNo ratings yet

- 2013 Business Studies NotesDocument20 pages2013 Business Studies NotesJim Sinclair-AndersonNo ratings yet

- 3-Operations Management-Chapter ThreeDocument60 pages3-Operations Management-Chapter ThreeAbdiNo ratings yet

- Design of Goods and ServicesDocument15 pagesDesign of Goods and ServicesZeeshan MajeedNo ratings yet

- Operations ManagementUpdatedDocument107 pagesOperations ManagementUpdatedNikita Kossolapov100% (1)

- Product, Process, and Service DesignDocument63 pagesProduct, Process, and Service DesignRupaam DebNo ratings yet

- Mix Concrete Batching Plant Business PlanDocument52 pagesMix Concrete Batching Plant Business Planrasputin0780803494100% (5)

- Addis Ababa Medical and Business College EeeeDocument8 pagesAddis Ababa Medical and Business College EeeemoadagimaNo ratings yet

- Operations ManagementDocument91 pagesOperations ManagementAnup MamenNo ratings yet

- Product Development & DesignDocument96 pagesProduct Development & DesignSankalp Sharma100% (1)

- Design For Quality & Product ExcellenceDocument104 pagesDesign For Quality & Product ExcellenceAbhishek Srivastava100% (1)

- New Product Design ProcessDocument4 pagesNew Product Design Processsonam katiyarNo ratings yet

- 3. Chapter 3Document40 pages3. Chapter 3Girma MeleseNo ratings yet

- Unit 1 8Document39 pagesUnit 1 8piyush.foruppoNo ratings yet

- Production and Total Quality ManagmentDocument8 pagesProduction and Total Quality ManagmentFYS 324 Rochelle GeorgeNo ratings yet

- Unit 3 Notes(PM) by SS (3)Document17 pagesUnit 3 Notes(PM) by SS (3)upadhyaypriyam.50No ratings yet

- Topic 1 - Operations Business Studies NotesDocument17 pagesTopic 1 - Operations Business Studies NotesTom LuoNo ratings yet

- Summary Operation ManagementDocument3 pagesSummary Operation ManagementStefanyNo ratings yet

- Notes OM 1Document2 pagesNotes OM 1Harinarayan ChaudhariNo ratings yet

- Operations Management Process Design and Product DevelopmentDocument140 pagesOperations Management Process Design and Product DevelopmentAnanda KrishnanNo ratings yet

- The Increasing Importance of Product DesignDocument7 pagesThe Increasing Importance of Product DesignTrang QuýtNo ratings yet

- Chapter 3 OM EditedDocument19 pagesChapter 3 OM EditedSeid KassawNo ratings yet

- 2023 OM Poduct Process DesignDocument114 pages2023 OM Poduct Process DesignSuman Samal MagarNo ratings yet

- High-Profit Opportunities in International Market Than The Domestic MarketDocument15 pagesHigh-Profit Opportunities in International Market Than The Domestic MarketAcua RioNo ratings yet

- Top reasons to invest in Oracle EPM Cloud for operational efficiencyDocument3 pagesTop reasons to invest in Oracle EPM Cloud for operational efficiencyemedinillaNo ratings yet

- Materials Set A Part 1. Theory (1pt Each)Document3 pagesMaterials Set A Part 1. Theory (1pt Each)Trixie HicaldeNo ratings yet

- Playing The Digital Transformation GameDocument16 pagesPlaying The Digital Transformation GameDr Thomas Goh100% (1)

- Types of Borrowers A.: Minor: Minors Are People Who Have Not Yet ReachedDocument6 pagesTypes of Borrowers A.: Minor: Minors Are People Who Have Not Yet ReachedAnkit NeupaneNo ratings yet

- Starbucks Case AnalysisDocument17 pagesStarbucks Case Analysisytsell30No ratings yet

- Assignment - Cash and CEDocument4 pagesAssignment - Cash and CEAleah Jehan AbuatNo ratings yet

- LITERATURE REVIEW Pricing StrategiesDocument9 pagesLITERATURE REVIEW Pricing StrategiesSiraj Khan63% (8)

- MAMDocument13 pagesMAMKevin T. OnaroNo ratings yet

- Chapter Real Project MiDocument72 pagesChapter Real Project Mimayowa alexNo ratings yet

- Cost of Capital BreakdownDocument2 pagesCost of Capital BreakdownZabir Tahzin HassanNo ratings yet

- Strategic Management - Business Plan ClothesDocument35 pagesStrategic Management - Business Plan ClothesMuhammad Dzikri Tesla BuwonoNo ratings yet

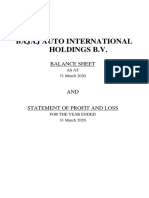

- Bajaj Auto International Holdings B.V.: Balance SheetDocument22 pagesBajaj Auto International Holdings B.V.: Balance SheetPhani TejaNo ratings yet

- Auditors Have A Role in Cyberresilience Joa Eng 1119Document6 pagesAuditors Have A Role in Cyberresilience Joa Eng 1119WPJ AlexandroNo ratings yet

- Kalaari Fintech Report 2016 PDFDocument28 pagesKalaari Fintech Report 2016 PDFPuneet MittalNo ratings yet

- Intern Report - ajoy.ASH 1510049MDocument35 pagesIntern Report - ajoy.ASH 1510049MAjoyNo ratings yet

- Tender B1 Aluminium Glazing WorksDocument114 pagesTender B1 Aluminium Glazing WorksDaliPotter100% (1)

- Request For Quotation (RFQ)Document12 pagesRequest For Quotation (RFQ)AAYAN001100% (1)

- Ude My For Business Course ListDocument107 pagesUde My For Business Course ListHONEYRIKNo ratings yet

- A Study On Working Capital Management With Special Reference To Steel Authority of India Limited, SalemDocument19 pagesA Study On Working Capital Management With Special Reference To Steel Authority of India Limited, SalemCHEIF EDITORNo ratings yet

- MCQ'sDocument14 pagesMCQ'sKawalpreet Singh Makkar71% (7)

- Sales Basics PDFDocument75 pagesSales Basics PDFJamaila jimeno Dagcutan100% (1)

- Resume 2023Document2 pagesResume 2023api-609755079No ratings yet

- Partnership Law Atty. Macmod: Multiple ChoiceDocument10 pagesPartnership Law Atty. Macmod: Multiple ChoiceJomarNo ratings yet

- Module 6 - Lect 3 - Role of CBDocument22 pagesModule 6 - Lect 3 - Role of CBBHAVYA GOPAL 18103096No ratings yet

- Accounting Term PaperDocument22 pagesAccounting Term PaperZaharatul Munir Sarah50% (4)

- Implement Business PlanDocument16 pagesImplement Business PlanGhilany Carillo CacdacNo ratings yet

- Bikeshare Development PlanDocument143 pagesBikeshare Development PlanDistrict Department of Transportation100% (2)

- Xlfinplan Features SatishDocument7 pagesXlfinplan Features SatishrajsalgyanNo ratings yet

- How to Talk to Anyone at Work: 72 Little Tricks for Big Success Communicating on the JobFrom EverandHow to Talk to Anyone at Work: 72 Little Tricks for Big Success Communicating on the JobRating: 4.5 out of 5 stars4.5/5 (36)

- 7 Principles of Transformational Leadership: Create a Mindset of Passion, Innovation, and GrowthFrom Everand7 Principles of Transformational Leadership: Create a Mindset of Passion, Innovation, and GrowthRating: 5 out of 5 stars5/5 (51)

- The Coaching Habit: Say Less, Ask More & Change the Way You Lead ForeverFrom EverandThe Coaching Habit: Say Less, Ask More & Change the Way You Lead ForeverRating: 4.5 out of 5 stars4.5/5 (186)

- The Power of People Skills: How to Eliminate 90% of Your HR Problems and Dramatically Increase Team and Company Morale and PerformanceFrom EverandThe Power of People Skills: How to Eliminate 90% of Your HR Problems and Dramatically Increase Team and Company Morale and PerformanceRating: 5 out of 5 stars5/5 (22)

- How to Lead: Wisdom from the World's Greatest CEOs, Founders, and Game ChangersFrom EverandHow to Lead: Wisdom from the World's Greatest CEOs, Founders, and Game ChangersRating: 4.5 out of 5 stars4.5/5 (94)

- The 7 Habits of Highly Effective PeopleFrom EverandThe 7 Habits of Highly Effective PeopleRating: 4 out of 5 stars4/5 (2564)

- The First Minute: How to start conversations that get resultsFrom EverandThe First Minute: How to start conversations that get resultsRating: 4.5 out of 5 stars4.5/5 (55)

- Leadership Skills that Inspire Incredible ResultsFrom EverandLeadership Skills that Inspire Incredible ResultsRating: 4.5 out of 5 stars4.5/5 (11)

- Spark: How to Lead Yourself and Others to Greater SuccessFrom EverandSpark: How to Lead Yourself and Others to Greater SuccessRating: 4.5 out of 5 stars4.5/5 (130)

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- Billion Dollar Lessons: What You Can Learn from the Most Inexcusable Business Failures of the Last Twenty-five YearsFrom EverandBillion Dollar Lessons: What You Can Learn from the Most Inexcusable Business Failures of the Last Twenty-five YearsRating: 4.5 out of 5 stars4.5/5 (52)

- Scaling Up: How a Few Companies Make It...and Why the Rest Don't, Rockefeller Habits 2.0From EverandScaling Up: How a Few Companies Make It...and Why the Rest Don't, Rockefeller Habits 2.0No ratings yet

- The 4 Disciplines of Execution: Revised and Updated: Achieving Your Wildly Important GoalsFrom EverandThe 4 Disciplines of Execution: Revised and Updated: Achieving Your Wildly Important GoalsRating: 4.5 out of 5 stars4.5/5 (47)

- Management Mess to Leadership Success: 30 Challenges to Become the Leader You Would FollowFrom EverandManagement Mess to Leadership Success: 30 Challenges to Become the Leader You Would FollowRating: 4.5 out of 5 stars4.5/5 (27)

- Work Stronger: Habits for More Energy, Less Stress, and Higher Performance at WorkFrom EverandWork Stronger: Habits for More Energy, Less Stress, and Higher Performance at WorkRating: 4.5 out of 5 stars4.5/5 (12)

- Summary: Choose Your Enemies Wisely: Business Planning for the Audacious Few: Key Takeaways, Summary and AnalysisFrom EverandSummary: Choose Your Enemies Wisely: Business Planning for the Audacious Few: Key Takeaways, Summary and AnalysisRating: 4.5 out of 5 stars4.5/5 (3)

- The ONE Thing: The Surprisingly Simple Truth Behind Extraordinary Results: Key Takeaways, Summary & Analysis IncludedFrom EverandThe ONE Thing: The Surprisingly Simple Truth Behind Extraordinary Results: Key Takeaways, Summary & Analysis IncludedRating: 4.5 out of 5 stars4.5/5 (124)

- The Introverted Leader: Building on Your Quiet StrengthFrom EverandThe Introverted Leader: Building on Your Quiet StrengthRating: 4.5 out of 5 stars4.5/5 (35)

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- The 12 Week Year: Get More Done in 12 Weeks than Others Do in 12 MonthsFrom EverandThe 12 Week Year: Get More Done in 12 Weeks than Others Do in 12 MonthsRating: 4.5 out of 5 stars4.5/5 (410)

- Kaizen: The Ultimate Guide to Mastering Continuous Improvement And Transforming Your Life With Self DisciplineFrom EverandKaizen: The Ultimate Guide to Mastering Continuous Improvement And Transforming Your Life With Self DisciplineRating: 4.5 out of 5 stars4.5/5 (36)

- Unlocking Potential: 7 Coaching Skills That Transform Individuals, Teams, & OrganizationsFrom EverandUnlocking Potential: 7 Coaching Skills That Transform Individuals, Teams, & OrganizationsRating: 4.5 out of 5 stars4.5/5 (27)

- Sustainability Management: Global Perspectives on Concepts, Instruments, and StakeholdersFrom EverandSustainability Management: Global Perspectives on Concepts, Instruments, and StakeholdersRating: 5 out of 5 stars5/5 (1)

- 300+ PMP Practice Questions Aligned with PMBOK 7, Agile Methods, and Key Process Groups - 2024: First EditionFrom Everand300+ PMP Practice Questions Aligned with PMBOK 7, Agile Methods, and Key Process Groups - 2024: First EditionNo ratings yet