Professional Documents

Culture Documents

Akjh D Bms Specification

Uploaded by

mohideenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Akjh D Bms Specification

Uploaded by

mohideenCopyright:

Available Formats

AKH COMMERCIAL TOWER

Plot No.47/Sector 1/74-Al Kashlaa, Dahran/Dammam/K.S.A

Tender Volume 3, Part-E

SECTION 25 00 00

BUILDING MANAGEMENT AND CONTROL SYSTEM

Revision History

00

June 2013

Issue to Tender

IBA

TM

HM

Rev.

Date

Description of Revision

Prepared By

Checked By

Approved By

AKH COMMERCIAL TOWER

Plot No.47/Sector 1/74-Al Kashlaa, Dahran/Dammam/K.S.A

Tender Volume 3, Part-E

SECTION 25 00 00

BUILDING MANAGEMENT AND CONTROL SYSTEM

INDEX

1.0

GENERAL ............................................................................................................................................... 3

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

2.0

PRODUCTS........................................................................................................................................... 13

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.8

2.9

2.10

2.11

3.0

REFERENCE.............................................................................................................................. 3

SYSTEM DESCRIPTION .......................................................................................................... 3

QUALITY ASSURANCE .......................................................................................................... 8

ACCEPTABLE BID PROCEDURES ........................................................................................ 9

SUBMITTALS ......................................................................................................................... 11

DELIVERY, STORAGE AND HANDLING: .......................................................................... 11

MANUALS............................................................................................................................... 11

TRAINING ............................................................................................................................... 12

WARRANTY ........................................................................................................................... 13

BMCS CENTRAL HARDWARE ............................................................................................ 13

PORTABLE OPERATORS TERMINALS .............................................................................. 14

REMOTE HVAC CONTROLLER HARDWARE ................................................................... 16

HVAC DATA COMMUNICATIONS...................................................................................... 17

ELECTRICAL AND MECHANICAL CONTROL DEVICES ................................................ 17

ELECTRONIC DATA INPUTS AND OUTPUTS................................................................... 19

OPERATOR STATION SOFTWARE ..................................................................................... 20

REMOTE PANEL SOFTWARE .............................................................................................. 26

PROTECTION OF SOFTWARE RIGHTS .............................................................................. 28

DATA CONTROL (D/C) AND GRAPHICS SUMMARY ...................................................... 28

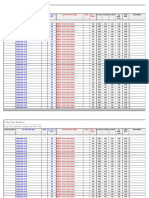

BMCS - POINTS LIST............................................................................................................. 29

EXECUTION......................................................................................................................................... 29

3.1

3.2

3.3

3.4

EXAMINATION ...................................................................................................................... 34

INSTALLATION ..................................................................................................................... 34

LOCATION AND INSTALLATION OF COMPONENTS ..................................................... 35

INTERLOCKING AND CONTROL WIRING ........................................................................ 35

Section 25 00 00: BMS and Control System

Page 2 of 35

Rev.00 June 2013

Tender Documents

AKH COMMERCIAL TOWER

Plot No.47/Sector 1/74-Al Kashlaa, Dahran/Dammam/K.S.A

Tender Volume 3, Part-E

PART 1 - GENERAL

1.1

REFERENCE

1.1.1

Conform to General Requirements for Electrical Services of 26 01 00.

1.1.2

Related Work Specified Elsewhere

Analogue Addressable Fire Alarm System

Emergency Lighting

Lighting Control System

Public Address and Music System

Chilled Water Pumps

Fire Fighting Pumps

Plumbing Pumps

Air Cooled Packaged Chillers

Air Handling Units

Unitary Air Conditioning Equipment

Fan Coil Units

Fans

1.2

SYSTEM DESCRIPTION

1.2.1

Provide a state of the art standalone Building Management and Control System (BMCS) for the

building incorporating Direct Digital Control (DDC), Equipment Monitoring and Control, consisting

of the following elements:

a)

Microcomputer based remote control panels interfacing directly with sensors, actuators

and environmental delivery systems (i.e., HVAC equipment, lighting systems, etc.). The

BMCS shall interface with the chiller PSC (Programmable supervisory controller).

b)

Two-wire communication networks to allow data exchange between remote panels and

between remote panels and the central Building Management computer.

c)

One personal computer (PC) based central and associated operator station(s) and

software functioning as the primary operator interface for the BMCS.

d)

Electronic and electric controls for all items indicated on drawings and described

hereinafter including sensors, control valves and thyristers.

1.2.2

Submittals, data entry and electrical installation, programming, interfacing with other systems, start

up, test and validation, instruction of Employer's representative on maintenance and operation, as

built documentation, and system warranty.

1.2.3

Building Management System

The Integrated Building Management System shall consist of three levels as follows:

a)

Field Level: consists of field sensors, volt-free contacts and intelligent standalone DDC

controllers. All the operation associated with particular equipment shall be achieved in

this level itself without intervention of any higher network devices.

Section 25 00 00: BMS and Control System

Page 3 of 35

Rev.00 June 2013

Tender Documents

AKH COMMERCIAL TOWER

Plot No.47/Sector 1/74-Al Kashlaa, Dahran/Dammam/K.S.A

Tender Volume 3, Part-E

1.2.4

b)

Building Automation Level: consists of system controller shall be capable of handling

and storing the Building Automation functions like Trend, History, Totalization, Alarm

Routing, Co-ordination with field devices for alarms or any information, optimum

start/stop etc.

c)

Information Management Level: consists of person machine interface like Operator

Workstations, Graphics User Interface, Information Management to format in user

preferred way, open protocol availability for ActiveX, ODBC, OLE for Process Control

(OPC), COM/DCOM, Network Integrators etc.

System Architecture

a)

First Layer Network

The first layer network shall be based on a PC industry standard of Ethernet TCP/IP. PC

Workstation LAN controller cards shall be standard off the shelf products available

through normal PC vendor channels.

The BMCS shall network multiple operator workstations, network controllers and

system controllers. The first layer network shall provide communications between

operator workstations and first layer DDC (Direct Digital Control) controllers.

The first layer network shall operate at a minimum communication speed of 10 M baud,

with full peer-to-peer network communication.

Network Controllers and Operator Workstations shall reside on the first layer. All

Network Controllers and Operator Workstations should be directly connected to TCP/IP

network at 10 M baud.

The first layer network will be compatible with other facility-wide networks. The first

layer shall be connected to a facility network by way of standard networking practices.

The structured cabling and IT infrastructure network shall be used as an actual first layer

network. All the network controllers and Operator Workstations shall directly reside on

the first layer network.

b)

Second Layer Network

DDC System Controllers shall reside on the second layer.

Other Application Specific Controller (e.g. Fan Coil Unit Controller, VAV Controller

etc) shall reside on the second layer.

Devices like 3rd party integrators (e.g. Chiller Integrators), Energy Monitoring Units

shall also reside on the second layer network.

All the controllers mentioned above shall be able to communicate on single

communication bus (i.e. one second layer network). Various buses for various types of

controllers at various communication speeds will not be acceptable.

The second layer network shall operate at a minimum communication speed of 9600

baud.

1.2.5

Protocol Compatibility for Integration

In general the BMCS system shall have an Integration facility with third party equipment/

Section 25 00 00: BMS and Control System

Page 4 of 35

Rev.00 June 2013

Tender Documents

AKH COMMERCIAL TOWER

Plot No.47/Sector 1/74-Al Kashlaa, Dahran/Dammam/K.S.A

Tender Volume 3, Part-E

systems via following methods:

Direct Protocol (Integrator Panel):

a)

The BMCS system shall include appropriate hardware equipment and software to allow

bi-directional data communications between the BMCS system and 3rd party

manufacturers control panels. The BMCS shall receive, react to, and return information

from multiple building systems, including but not limited to the chillers, variable

frequency drives and power monitoring and control system.

b)

All data required by the application shall be mapped into the Network Controllers

database, and shall be transparent to the operator.

c)

Point inputs and outputs from the third-party controllers shall have real-time

interoperability with BMCS software features such as: Control Software, Energy

Management, Custom Process Programming, Alarm Management, Historical Data and

Trend Analysis, Totalization, and Dial-Up and Local Area Network Communications.

d)

The Building Management System shall provide any combination of third-party

controllers on a single network. A minimum of 100 third-party controllers shall be

supported on a single network. Integration shall be via RS-232 or RS-485 technologies.

e)

The system operator shall have the ability to verify, and diagnose communication

messages and point information between third-party controllers and the BMCS. All these

integrators shall reside on the field communication bus i.e. second layer network.

Protocol Integration

a)

The protocol used between systems will be BACnet over Ethernet and comply with the

ASHRAE BACnet standard 135-1995 or Echelon Lontalk.

b)

The BACnet System Integrator (BSI) will allow bi-directional communications between

the host system and a BACnet system over an Ethernet data link. Supported media shall

include fibre, 10base2, and 10baseT.

c)

A complete Protocol Implementation Conformance Statement (PICS) shall be provided

for the Integrator and all BACnet system devices.

d)

The BSI shall conform to BACnet conformance class 4, and provide the ability to

monitor and control BACnet system points from the host system and host system points

from the BACnet system.

e)

The ability to share data and change of state (COS) between the host and BACnet

systems shall be provided.

Employer-Server (OPC)

a)

The neutral protocol used between the BMCS and diverse systems will be the Industry

Standard protocol OLE for Process Control (OPC) over Ethernet.

b)

OPC shall link the BMCS with one or more systems via OPC Servers, providing an

industry-standard, component-based interface to BMCS data.

c)

The OPC Server shall have the following characteristics and functionality:

Run on Windows 95, Windows 98, Windows 2000 and Windows NT machines

Section 25 00 00: BMS and Control System

Page 5 of 35

Rev.00 June 2013

Tender Documents

AKH COMMERCIAL TOWER

Plot No.47/Sector 1/74-Al Kashlaa, Dahran/Dammam/K.S.A

Tender Volume 3, Part-E

connected via Ethernet to the BMCS.

Allow generic components to be used and shared with other OPC-compliant Employers

and systems.

Serve as the translation service for the various languages used by the diverse systems

with which it communicates.

Support multiple OPC Employers running on both local and remote machines in the

network.

Control the interaction and communication between workstation applications (on

Employers) and the BMCS by providing standard methods for sharing and exchanging

data between the BMCS and other systems.

Provide interfaces for browsing, reading, and writing accessibility.

OPC shall connect the BMCS to multiple systems concurrently, without requiring

modification of the existing BMCS architecture.

OPC shall seamlessly integrate diverse proprietary components and systems, and shall

provide the capability to add and integrate other components.

The OPC software shall translate data from multiple systems into one user interface. The

software shall allow an operator to monitor and control data, communication, and

systems through an OPC Employer (workstation).

The ability to share data and change of state (COS) between the BMCS network and the

integrated systems shall be provided via the OPC interface.

d)

Integration/BMCS Specific Requirements

The purpose of integration is to ensure that all the low voltage systems work in coordination with each other as single system. The integration is not limited only to

monitor/control of the 3rd party systems from BMCS. The whole low voltage package

shall work as a one complete system under the umbrella of BMCS.

e)

Open Systems Integration

Chiller Integrator Interface:

i.

The BMCS system shall include appropriate hardware equipment and software

to allow two way data communications between the BMCS system and the

chiller manufacturers chiller control panel.

ii.

It shall be the responsibility of the BMCS Contractor to co-ordinate with the

chiller manufacturer to provide a functional data communications connection.

iii.

All data supported by the chiller communication protocol shall be mapped into

the supervisory DDC controllers database and shall be displayed on a chiller

data screen at the Operator Workstation and shall be transparent to the operator.

iv.

The BMCS Contractor shall furnish either the OSP or BACnet communications

interface as required by the chiller manufacturer.

Section 25 00 00: BMS and Control System

Page 6 of 35

Rev.00 June 2013

Tender Documents

AKH COMMERCIAL TOWER

Plot No.47/Sector 1/74-Al Kashlaa, Dahran/Dammam/K.S.A

Tender Volume 3, Part-E

v.

f)

The chiller manufacturer shall provide all hardware for connection of the

manufacturers processor to BMCS.

VFD Integrator Interface

The BMCS system shall include appropriate hardware equipment and software to allow

two way data communications between the BMCS system and the VFD manufacturers

control panel.

It shall be the responsibility of the BMCS Contractor to co-ordinate with the VFD

manufacturer to provide a functional data communications connection.

All data supported by the VFD communication protocol shall be mapped into the

supervisory DDC controllers database and shall be displayed on data screens at the

Operator Workstation and shall be transparent to the operator.

The BMCS Contractor shall furnish either the OSP or BACnet communications interface

as required by the VFD manufacturer.

The VFD manufacturer shall provide all hardware for connection of the manufacturers

processor to BMCS.

g)

Fire Alarm Integration

The BMCS system shall include appropriate hardware equipment and software to the

communications between the BMCS system and the Fire Alarm panels.

It shall be the responsibility of the BMCS Contractor to co-ordinate with the Fire Alarm

vendor to provide a functional data communications connection.

All data supported by the Fire Alarm Panel shall be mapped into the Network Controller

Database and shall be displayed on floor-wise at the BMCS Operator Workstation and

shall be transparent to the operator.

The BMCS system shall be able to integrate with Digital Public Address System to

announce the fire conditions.

The BMCS Contractor shall furnish either the OSP or BACnet communications interface

as required by the Fire Alarm panel.

h)

Security System Integration (Access Control System & CCTV System)

The BMCS system shall include appropriate hardware equipment and software to the

communications between the BMCS system and the Security system provided by others.

All data in security system (only alarms for CCTV) shall be mapped into the Network

Controller Database and shall be displayed at the BMCS Operator Workstation and shall

be transparent to the operator.

The BMCS Contractor shall furnish either the OSP or BACnet or DDE communications

interface as required by the Security System.

The BMCS system supplier shall provide necessary hardware for connection between

the BMCS and security system.

Section 25 00 00: BMS and Control System

Page 7 of 35

Rev.00 June 2013

Tender Documents

AKH COMMERCIAL TOWER

Plot No.47/Sector 1/74-Al Kashlaa, Dahran/Dammam/K.S.A

Tender Volume 3, Part-E

Intelligent Lighting Control System Integration

It shall be a responsibility of the BMCS supplier to provide appropriate hardware

equipment and software to the communications between the BMCS system and the

Lighting system

All data supported by the Lighting Control System shall be mapped into the Network

Controller Database and shall be displayed on floor-wise at the BMCS Operator

Workstation and shall be transparent to the operator.

The BMCS Contractor shall furnish either the EIB or OSP or BACnet or LonMark

communications interface as required by the Lighting Control System.

k)

Any Other Integration (if required & specified elsewhere in the specifications)

The BMCS system keeps provision for integration with other systems like UPS, Standby

Generators Emergency Lighting Systems as required in their proposal. The systems,

which are not part of ELV scope of supply and required to be integrated, all necessary

provision shall be made by MEP contractor as mentioned in the General Conditions of

this document. These integrations shall be carried out using the standard integration

methods mentioned elsewhere in the specifications.

1.3

QUALITY ASSURANCE

1.3.1

Bids by Wholesalers, Contractors, Franchised Dealers or any firm whose principal business is not

that of manufacturing and installing automatic temperature control, lighting control, fire alarm,

security, and access control systems shall not be acceptable.

1.3.2

The system shall be installed by competent mechanics, regularly employed by the BMCS

manufacturer with full responsibility for proper operation of the BMCS including debugging and

proper calibration of each component in the entire system. Supplier shall have an in-place support

facility within Abu Dhabi Emirate with technical staff, spare parts inventory and all necessary test

and diagnostic equipment.

1.3.3

Codes and Approvals:

The complete BMCS installation shall be in strict accordance to the national and local electrical

codes and the electrical section of these specifications. All devices designed for or used in line

voltage applications shall be UL Listed or approved by an equal regulatory authority.

All microprocessor based remote DDC devices shall be UL916 Listed or approved by an equal

regulatory authority.

All microprocessor based remote Field & Supervisory devices shall be UL864 Listed or approved by

an equal regulatory authority.

All BMCS central equipment shall be UL864 Listed or approved by an equal regulatory authority.

All BMCS central and remote equipment used in security applications shall be UL1076 Listed or

approved by an equal regulatory authority.

All BMCS central and remote equipment used in access control applications shall be UL294 Listed

or approved by an equal regulatory authority.

All electrical environmental control and monitoring devices shall be UL429 and/or UL873 Listed or

approved by an equal regulatory authority.

Section 25 00 00: BMS and Control System

Page 8 of 35

Rev.00 June 2013

Tender Documents

AKH COMMERCIAL TOWER

Plot No.47/Sector 1/74-Al Kashlaa, Dahran/Dammam/K.S.A

Tender Volume 3, Part-E

1.3.4

All electronic equipment shall conform to the requirements of FCC regulation Part 15, Section 15

governing radio frequency electromagnetic interference and be so labelled.

1.3.5

System shall be designed to provide satisfactory operation without damage at 110% and 85% of

rated voltage and at + 3 hertz variation in line frequency.

1.3.6

System shall be designed to provide static, transient, and short circuit protection on all inputs and

outputs. Communication lines shall be protected against incorrect wiring, static transients and

induced magnetic interference. Bus connected devices shall be a.c. coupled or equivalent so that any

single device failure will not disrupt or halt bus communication.

1.3.7

All real time clocks shall be battery backed for a minimum period of 365 days.

1.3.8

Plant Control Processors shall comply with ISO 9000..

1.4

ACCEPTABLE BID PROCEDURES

1.4.1

Technical Proposal: It is the intent of this specification to define a state-of-the-art distributed

computerized software Integrated Building Management and Control System which is user friendly,

has known reliability, is extremely responsive, and which is to be designed, installed, implemented,

and supported by a local office of the manufacturer by people skilled in providing functional and

efficient solutions to building system needs.

To allow evaluation of vendors and systems, a detailed technical proposal shall be provided and

formatted strictly in accordance to this outline. Vendors standard literature not complying to this

format and content requirement will not be considered or evaluated. Proposal requirements shall be

as follow:

Proposed system complete with location and block diagram including central computer type and

memory, peripherals, communication interfaces, all LAN cards, all active hubs and repeaters,

network layout, distributed peer bus connected control/monitor panels with location, listing of

equipment directly connected to a DDC controller, and secondary network drivers and connected

systems.

Provide copies of required UL listing cards.

1.4.2

Compliance Checklist - Provide a specification paragraph-by-paragraph listing of strict word-forword compliance or non-compliance. For each item of conditional or non-compliance, spell out the

vendor's substitute response to the feature excepted.

Example:

1.4.3

Paragraph

Comply

2.08 a

2.08 b

2.08 c

Full Compliance

Full Compliance

Covers are polished

Conditional

Comply

X

X

X

NonComply

Justification for NonComply

Computer based central controller features

a)

Day-to-day interactive operator interface description with sample English/Graphic displays,

penetration scheme for display/command and logical configuring, and examples of alarms

and data in various modes (disabled, fixed, not responding, etc.)

b)

Short cut penetration schemes for direct graphic, point, and command access

c)

Colorgraphic system description with sample system displays, colorgraphic penetration and

Section 25 00 00: BMS and Control System

Page 9 of 35

Rev.00 June 2013

Tender Documents

AKH COMMERCIAL TOWER

Plot No.47/Sector 1/74-Al Kashlaa, Dahran/Dammam/K.S.A

Tender Volume 3, Part-E

command schemes, graphic creation means, library of symbols, and curve plot

1.4.4

d)

Interactive data editing scheme for modification of system data base and parameters

including operators, peripheral assignments, system configuration, text, time schedules,

point monitoring limits, event-initiated control, and control application program parameters

e)

Electronic mail/messaging description and samples

f)

Data access control and security scheme

g)

Report descriptions including selection scheme and sample reports for setting up and

displaying extended trend file reports.

h)

Sample sequence of operation and specified flow chart display

j)

Sample custom report

k)

Sample text alarm message

l)

Sample of system and point descriptor text

m)

Technical description of all hardware components

n)

Sample alarm report

o)

Sample alarm acknowledgement report

p)

Sample text terminal menu display

Distributed control panel point architecture, memory, real time clock.

a)

Functional description

b) Scan/Report speed and alarm detection speed

c)

Control and survival capabilities

d) Life safety interfacing

1.4.5

1.4.6

Communications network architecture, points, panels

a)

Protocol description, host independent, bus-cut reaction

b)

Bus limitations, distances between active links and hubs, etc.

c)

d)

Number of devices on bus without repeater.

Error checking, collision prevention, recovery

e)

Controller internal architecture, communication cards, board-to-board communications,

secondary bus drivers.

f)

Point sharing/update scheme

g)

Meantime end-to-end responsiveness for a large fully operational system for analog alarm

report, digital alarm report, panel failure report, host command execution, event command

(within one panel and panel-to-panel)

Available services for full system maintenance, software update and modifications, hardware spare

parts, adds and changes, system training and training classes

Section 25 00 00: BMS and Control System

Page 10 of 35

Rev.00 June 2013

Tender Documents

AKH COMMERCIAL TOWER

Plot No.47/Sector 1/74-Al Kashlaa, Dahran/Dammam/K.S.A

Tender Volume 3, Part-E

1.4.7

Contractor experience/capability, size

a)

Organization with brief resumes for key personnel.

b)

15 years history of local support of management, Engineering,

maintenance locations and business

c)

Local experience on similar jobs with references

d)

Local facility description

installation, and

1.4.8

Vendors standard specification data literature.

1.5

SUBMITTALS

1.5.1

Product Data : Submit manufacturers technical product data for each control device furnished

showing dimensions, weights, capacities, performance characteristics, electrical characteristics,

finishes of materials, installation instruction and startup instruction.

1.5.2

Shop Drawings : Submit shop drawings for each electrical control system, containing the

following information:

a)

Schematic flow diagram of system showing fans, pumps, coils, dampers, valves, and

control devices.

b)

Label each control device with setting or adjustable range of control.

c)

Indicate all required electrical wiring. Clearly differentiate between portions of wiring

that are factory installed and portions to be field installed.

d)

Provide details of fascia of control panels, including controls, instruments, and labeling.

e)

Include written description of sequence of operation.

f)

Include a complete list of components for each proposed panel.

1.5.3

Submit catalogues for all controls and accessories and the recommended spare parts for 2 years

operation and maintenance.

1.5.4

Maintenance Data:

Submit maintenance instructions and spare parts lists, include this data,

product data, and shop drawings in maintenance manuals.

1.6

DELIVERY, STORAGE AND HANDLING:

Provide factory shipping cartons for each piece of equipment, and control device. Maintain

cartons through shipping, storage and handling as required to prevent equipment damage, and to

eliminate dirt and moisture from equipment. Store equipment and materials inside and protected

from weather.

1.7

MANUALS

1.7.1

The following manuals shall be provided:

a)

An Operators Manual with coloured graphic explanations of operator functions. Although

operator functions are to be self-instructional and menu-interactive from the keyboard

terminal, this manual shall be for off-line study and refresher use.

Section 25 00 00: BMS and Control System

Page 11 of 35

Rev.00 June 2013

Tender Documents

AKH COMMERCIAL TOWER

Plot No.47/Sector 1/74-Al Kashlaa, Dahran/Dammam/K.S.A

Tender Volume 3, Part-E

b)

Computerized printouts of all PCP (Plant Control Processor) data file construction

including all point processing assignments, physical terminal relationships, flowcharts of

graphic program. etc.

c)

A user manual for the integrated spreadsheet package.

d)

A manual including revised As Built documents of all shop drawings and materials as

required under the paragraph "SUBMITTALS" on this specification.

e)

Operators Manuals and As Built Manuals shall be provided to the Employer.

1.8

TRAINING

1.8.1

All training shall be by the BMCS manufacturer and shall utilize specified manuals, as-built

documentation, and the on-line help utility. The following training shall be repeated quarterly

during the warranty period.

1.8.2

Operator training shall include two initial six-hour sessions encompassing:

a)

b)

c)

d)

e)

f)

g)

h)

i)

j)

k)

l)

m)

n)

1.8.3

Supervisor training shall include an additional two hour session encompassing:

a)

b)

c)

d)

e)

f)

g)

h)

1.8.4

Sequence of Operation review.

Sign on-Sign off.

Selection of all displays and reports.

Commanding of points, keyboard and mouse mode.

Modifying English text.

Use of all dialogue boxes and menus.

Modifying alarm limits and start-stop times.

System initialization.

Download and initialization of remote panels.

Purge and/or dump of historical data.

Use of Portable Operators Terminals.

Troubleshooting of sensors (determining bad sensors).

Password modification.

Creation and modification of cardholder database.

Password assignment/modification.

Operator assignment/modification.

Operator authority assignment/modification.

Point disable/enable.

Terminal and data segregation/modification.

Use of portable operator terminal.

Use of spreadsheet package with system data.

Creation and modification of site-specific user-defined cardholder fields.

Programmer training shall include two additional three hour sessions encompassing:

a)

b)

c)

d)

e)

f)

Software review of Sequence of Operation and flowcharts.

Use of diagnostics.

System maintenance procedures.

Review of initialization.

Upload/download and off-line archiving of PCP (Plant control Processor) and PC system

software.

Graphic creation.

Section 25 00 00: BMS and Control System

Page 12 of 35

Rev.00 June 2013

Tender Documents

AKH COMMERCIAL TOWER

Plot No.47/Sector 1/74-Al Kashlaa, Dahran/Dammam/K.S.A

Tender Volume 3, Part-E

g)

Programmer training shall be for two Employer personnel and shall be scheduled by the

Employer with two week notice anytime during the warranty period.

1.9

WARRANTY

1.9.1

All components, system software, parts and assemblies supplied by the BMCS manufacturer shall be

guaranteed against defects in materials and workmanship for one year from provisional acceptance

date.

1.9.2

Labor to troubleshoot, repair, reprogram, or replace system components shall be furnished by the

BMCS contractor at no charge to the ENGINEER during the warranty period.

1.9.3

All corrective software modifications made during warranty service periods shall be updated on all

user documentation and on user and manufacturer archived software disks at no charge to

ENGINEER .

PART 2 - PRODUCTS

2.1

BMCS CENTRAL HARDWARE

2.1.1

The BMCS Contractor shall provide and install a personal computer workstation for command

entry, information management, network alarm management, and database management

functions. All real-time control functions, including scheduling, history collection and alarming,

shall be resident in the BMCS controllers to facilitate greater fault tolerance and reliability.

2.1.2

Workstation System Architecture The architecture of the workstation shall be implemented to

conform to industry standard APIs (application specific interfaces), so that it can accommodate

applications provided by the BMCS Contractor and by other third party applications suppliers,

including but not limited to Microsoft Office Applications. Specifically it must be implemented to

conform to the following interface standards:

a)

All historical information contained in Time Series Databases and all configuration data

contained in relational databases must be accessed via ODBC (utilizing ANSI SQL

database query specifications).

b)

All real-time, online building data must be accessible by all applications (including, but

not limited to, graphics, reports, etc.) via OPC (OLE for Process Control).

c)

All real-time event data (including alarms, change of state events, warning events, etc.)

shall be accessible by all applications via OPC (OLE for Process Control).

d)

The BMCS Contractor shall provide all necessary OPC servers for communicating to the

DDC controllers that are provided as part of this contract. In addition, the system shall

accommodate installation and registration of OPC servers provided in the future by other

equipment suppliers.

e)

Workstation Operator Applications architecture Major operator viewing applications

shall be implemented utilizing the current Microsoft Model of an Active-X control, to be

contained in one or more Active-X compliant containers. Specifically, the graphics

application shall be provided as an Active-X control (for example it shall be possible to

embed a graphic in a web page and view it in Internet Explorer). Conversely, it shall be

possible to embed other Active X controlssuch as trends and other third party

available controlsin the real-time graphic application.

f)

PC Hardware The PC for Operator Workstation shall be supplied from Compaq, IBM

or HP. The personal computers shall be configure as follows:

Memory 512 MB Ram PC 266 MHz

Section 25 00 00: BMS and Control System

Page 13 of 35

Rev.00 June 2013

Tender Documents

AKH COMMERCIAL TOWER

Plot No.47/Sector 1/74-Al Kashlaa, Dahran/Dammam/K.S.A

Tender Volume 3, Part-E

CPU Pentium-IV or greater; 2.0 GHz or Faster Clock Speed

Hard Drive 80 GB or greater hard drive

Hard drive backup system OMEGA JAZ 1.3 Optical Drive;

Floppy Drive 3 1/2 Diskette Drive

CD ROM Drive 52X performance

Ports (2) Serial and (1) parallel Ports, ESP

Keyboard 101 Keyboard and Mouse

CRT configuration

i.

Each CRT 17 SVGA Monitor 1280 x 1024 NI resolution minimum. 26 or

better dot pitch and 72 Hz. minimum vertical refresh rate or max resolution;

65K colors.

ii.

CRTs can be configured and operated as either individual monitors or as a

single console system, with a resolution of 1280 x 1024.

iii.

LAN communications Ethernet communications board; 3Comm or equal.

Operating System Software:

Windows NT 4.0, Windows 98, or Windows 2000 Professional.

Complete operator workstation software package, including any hardware or software

keys. Include the original installation disks and licenses for all included software, device

drivers, and Peripherals.

Provide software registration cards to the Employer for all included software.

Peripheral Hardware:

Alarm printers:

Printer Make Epson or equal

Printing Method 24 Pin Dot Matrix, 136 column print width

Print Speed 550 Characters Per Second, Per Line

Buffer 128 Kb

Graphics printing upto 360 x 360 dpi

Interfaces Bi-directional Parallel, USB 1.1

Reports printer:

Printer Make Hewlett Packard Laser Jet

Print Speed Black 25 Pages per minute

Print Quality 1200 x 1200 dpi, black

Memory Standard 32 MB upgradable upto 256MB

2.2

PORTABLE OPERATORS TERMINALS

2.2.1

Portable Operators Terminals (POT) shall be provided for operator readout of system variables,

override control, and adjustment of control parameters at all plant controllers. POTs shall be hand

held. POTs shall be provided which are plug-compatible with PCPs. POTs shall display points with

English-language descriptions.

One hand held Portable Operators Terminal or one Lap-Top shall be provided as Portable Operators

Terminal for the Terminal Equipment Controllers (TEC).

Section 25 00 00: BMS and Control System

Page 14 of 35

Rev.00 June 2013

Tender Documents

AKH COMMERCIAL TOWER

Plot No.47/Sector 1/74-Al Kashlaa, Dahran/Dammam/K.S.A

Tender Volume 3, Part-E

2.2.2

The POTs shall be complete with command keys, data entry keys, cursor control keys, and a liquid

crystal alpha-numeric display. Access is to be via self-prompting menu selection with next

menu/previous menu and step forward/step backward within a given menu. Connection of a POT to

a panel shall not interrupt nor interfere with normal network operation in any way, prevent alarms

from being transmitted, or preclude remote initiated commands.

2.2.3

Connection of any TEC POT at any TEC or TEC space sensor shall provide display access to all

TECs on the respective bus

2.2.4

TEC POT functionality shall include:

Display for each zone:

a)

b)

c)

d)

e)

f)

g)

Space temperature

Local setpoint value (Degrees Fo or Co)

Mode: Occupied/Unoccupied

Mode: Heating/Cooling

Valve percent open

Heating status

Zone override status

Display and command for each zone:

a)

b)

c)

d)

2.2.5

Setpoint select (local/remote)

Allowable local setpoint range

Unoccupied setpoint - cooling

Unoccupied setpoint - heating

PCP POT functionality shall be as follows:

Use of a POT at PCPs shall allow the user to display software information; and, via password

control, modify PCP software. Two levels of user controlled passwords shall be provided. The first

level shall allow the user to modify, create, or delete time programs; and the second level shall allow

the user to modify data point text descriptors, reset totalizers, modify setpoints and parameters, set

the system clock, and view trend logs and alarms.

Selecting TIME PROGRAM from the top level POT menu shall present an English menu of all PCP

time programs (such as HEATING ZONE EAST, etc.) Selecting a time program (via up-down scroll

bar) shall present options for the selected program of TODAY, DAILY, WEEKLY, and ANNUAL.

a)

Selecting TODAY shall present the current time program for the selected zone. Each time

program shall list start and stop times along with program commands and/or values (for

time programmed analog commands).

b)

Selecting DAILY, WEEKLY, or ANNUAL time programs shall present similar display

and command options for these programs.

Selecting DATA POINTS from the top level menu shall initiate an interactive process to select any

point via English menu, select manual or analog commanding of the point, select a display of

equipment accumulated runtimes, select a historical trend log display of any trended point, or display

all points whose alarm capability has been suppressed and allow the suppression to be cancelled.

Selecting PARAMETERS from the top level menu shall initiate a scrolling of all PCP parameters

(such as alarm units, control settings, etc.) which may be displayed and commanded.

Selecting ALARMS from the top level menu shall present a menu of four alarm display options.

Selecting ALARM MEMORY shall scroll a list of all alarms in memory with English descriptor,

alarm value or status, alarm type (low alarm limit, etc.), and time of occurrence. Selecting POINTS

Section 25 00 00: BMS and Control System

Page 15 of 35

Rev.00 June 2013

Tender Documents

AKH COMMERCIAL TOWER

Plot No.47/Sector 1/74-Al Kashlaa, Dahran/Dammam/K.S.A

Tender Volume 3, Part-E

IN ALARM will produce a similar display of all points currently in alarm. Selecting CRITICAL

ALARMS shall display critical points currently in alarm. Selecting NON-CRITICAL alarms shall

display non-critical points still in alarm.

Selecting TREND LOG from the top level menu shall initiate a scroll selection bar of English

descriptors of all points being trended, and allow selection of trend values/events with date and time

of each historical occurrence.

Selecting SYSTEM CLOCK from the top level menu shall allow the user to modify the

calendar/time clock and enter a date for automatic change to/from daylight savings time.

Furnish POTs at the chiller plant controller and air handling unit plant controller for use at all PCPs

and TECs, and TEC space temperature sensors.

As an alternative to the POTs, (for HVAC control only) a fixed liquid crystal or LED display and

entry keyboard may be provided per DDC controller. Functional capability must be equal to that

described for the POT as a minimum.

2.3

REMOTE HVAC CONTROLLER HARDWARE

2.3.1

Plant Control Processors shall be 16 bit microprocessor based with EPROM operating system

(O.S.). DDC programs and data files shall be non-volatile EEPROM or flash memory to allow

simple additions and changes. Each PCP shall have an on-board realtime clock with battery backup

of a minimum of 30 days.

2.3.2

Remote PCPs shall be provided where shown or specified with capacity to accommodate

input/output (I/O) points required for the application plus spare points specified. These panels shall

be configured with analog and digital inputs and outputs, and pulse counting totalizers and such that

the primary input, the output and all control logic shall be resident in a single microprocessor to

provide network independent stand-alone closed loop DDC. Each panel shall be provided with a

socket for a Portable Operators Terminal (POT). All panel inputs shall be selected for the

application utilizing sensor types listed under the sensor section of this specification. PCP outputs

shall be binary for On-Off control, and / or true variable voltage (0-10v) for driving analog. Analog

outputs shall have a minimum incremental resolution of one percent of the operating range of the

controlled device.

2..3.3

PCPs shall be designed for complex DDC and energy management applications, peer-to-peer

communications with other PCPs, or optionally for coordination, management, and data

concentration for sub-networks of TECs. Each PCP shall have an integral real-time clock for

true stand-alone operation (software clocks are not acceptable).

2.3.4

PCPs shall have LEDs for continuous indication of peer bus communications, power, and

operational status. PCPs driving TEC busses shall also have LEDs indicating the status of TEC

busses. All LEDs shall be visible without opening the panel door.

2.3.5

All panel electronics shall be installed in enclosures of IP54 rating. Equipment room panels shall

have hinged doors and shall also contain all load relays, transducers, and associated equipment.

2.3.6

Terminal Equipment Controllers shall be based on the latest ECHELON LON Talk technology and

shall be specific for the type of Terminal Equipment used, FCU's in this project. TECs shall be

capable of processing sensor signals of the applications specified, and shall have capability to drive

outputs required by the application. The TECs shall communicate with the zone manager at a speed

of 78K Bauds minimum.

Section 25 00 00: BMS and Control System

Page 16 of 35

Rev.00 June 2013

Tender Documents

AKH COMMERCIAL TOWER

Plot No.47/Sector 1/74-Al Kashlaa, Dahran/Dammam/K.S.A

Tender Volume 3, Part-E

2.4

HVAC DATA COMMUNICATIONS

2.4.1

All PCPs shall be interconnected via a primary communications network. TECs shall also be

connected together via secondary networks managed by PCPs to provide data concentration and

parallel processing such that system expansion does not noticeably affect system response. All

communications shall be via twisted pair wires, shielded where required. DDC microprocessor

failures shall not cause loss of communications of the remainder of any network. All networks shall

support sensor sharing, global application programs, and bus-to-bus communications without the

presence of a host PC.

2.4.2

The PCP communications network shall support true peer protocol such that each PCP has equal

rights for data transfer and shall report in its token passing time slot. No single device shall be

designated as the communications master but each device on the bus shall be capable of taking over

the function of bus monitor to assure that loss of any single device will not cause total bus failure.

Those systems using dedicated communication controllers or other single point of failure devices in

lieu of a true peer protocol shall provide dual redundant transmission media with automatic

switching in the event of line faults.

2.4.3

Full communications shall be sustained as long as there are at least two operational devices on any

segment of the bus.

2.4.4

Error recovery and communication initialization routines are to be resident in each bus connected

device.

2.4.5

For reliability, maintainability, and performance communication busses shall be extendable to 4000

feet with 29 devices and without active links, hubs, or repeaters.

2.4.6

Other than sensor/data sharing specified (with failure default procedures), under no circumstances

shall DDC programs be reliant on sensor data from another panel.

2.4.7

TECs shall be managed by their Zone Managers. The Zone Managers shall communicate to the

PCPs via an active network to provide alarm detection and reporting, data sharing, and response to

POT data requests and commands. TEC network shall also support POT communications from TEC

to any other networked TEC and from the PCP to any connected TEC.

2.5

ELECTRICAL AND MECHANICAL CONTROL DEVICES

2.5.1

Chilled Water Automatic control valves 2" and smaller shall be screwed type, of red brass material

and valves 2" and larger shall be cast iron type and flanged. Valves shall be ANSI-rated to

withstand the pressures and temperatures encountered. Valves shall have stainless-steel stems and

spring loaded Teflon packaging with replaceable discs. All valves shall have the manufacturers

name/logo embossed on the valve.

2.5.2

Chilled Water Valves shall be sized for a pressure drop greater than or equal to the coil they serve.

2.5.3

Chilled Water valves shall be two-way type as specified in the sequence of operation. Shall be

PN16, bronze body. Stems shall be polished stainless-steel suitable temperature range of 2 to 110C.

2.5.4

All automatically controlled devices shall be provided with electric / electronic actuators sized to

operate their appropriate loads with sufficient reserve power to provide smooth modulating action or

two-position action and tight close-off.

2.5.5

Actuators shall be provided with suitable corrosion resistant linkages for valves or dampers. Except

as specified herein, all actuators shall be sized for the load/close off encountered in strict accordance

with manufacturers recommendations. All actuators on outside air dampers, relief air dampers, and

convertor steam valves shall be heavy duty type with oil immersed gear train. All actuators shall

drive to their "normal" position anytime their associated AHU (etc.) is shut down.

Section 25 00 00: BMS and Control System

Page 17 of 35

Rev.00 June 2013

Tender Documents

AKH COMMERCIAL TOWER

Plot No.47/Sector 1/74-Al Kashlaa, Dahran/Dammam/K.S.A

Tender Volume 3, Part-E

2.5.6

Direct coupled modulating actuators shall be 24 volt type with 2 to 10 VDC control signal. Direct

coupled on/off actuators shall be 24 VAC. The torque and the close off ratings shall match the

application used.

2.5.7

Firestats shall be 135 degrees manual reset type.

2.5.8

Duct Smoke Detectors shall contain an air sampling chamber with sampling tubes extending through

the width of the air duct. Alarm status indicating lights shall be visible on the front of the detector.

2.5.9

DDC/VAV Controller

Controller shall consist of a one piece DDC controller complete with microprocessor, power supply,

self calibrating pressure transducer, and integral actuator. Provide DDC/VAV controller factory fit

and calibrated for the minimum and maximum air flows scheduled on the drawings.

Controller housing shall be UL 94-5 5V or equivalent listed material for use in ceiling plenum

applications without need of special metal enclosure. Cotroller shall work over an ambient

temperature operating range of 0-55oC (32-122oF), 5-95% non condensing humidity. Power supply

to unit shall be 20-30 VAC, 50 Hz, maximum power consumption of 5VA.

For reheat applications, provide factory fitted power relays rated for coils as required. Mount relay

in electric control enclosure and wire to DDC/VAV controller.

Controller shall be UL 916 listed, CE mark compliant, and conform to IEC 801.4 transient and surge

immunity standards. UL and CE marks shall appear on product labels.

Unit shall operate properly over inlet velocity pressure range of 0.00 to 2.00 in WC (0-500 Pa). End

to end accuracy shall be +/- 5% of flow measured at 250 Pa inlet velocity pressure.

Cooling only model DDC/VAV controller shall be used in cooling only applications. Cooling and

reheat model DDC/VAV controller shall be used in reheat applications and contain 3 Form A relays,

pilot duty rated for control of floating proportional, time proportional or staged reheat valves and

coils.

Integral damper actuator shall be 53 lb-in (6 N-m) torque, over the shaft mounting type. Stroke shall

be fully adjustable from 0-90 degrees rotations with visible position indicator. Actuator shall be

equipped with manual position override. The actuator stroke time shall be 3.6 minutes maximum for

90 degree rotation at 50 Hz operation.

Room temperature sensor shall be complete with digital LCD display. Temperature sensor shall

permit local adjustment of temperature setpoint, minimum flow, and maximum flow.

Temperature sensor shall permit display of any of the four variables such as room temperature, room

temperature set point, air flow and maximum flow setpoint.

The VAV room digital thermostat shall also display the following:

Room space temperature (Degree C or in Degree F freely configurable)

Room temperature setpoint (Degree C or in Degree F freely configurable)

Date and time

Ambient temperature

Maximum flow

Minimum flow

Box flow

The room temperature sensor shall be wired to the DDC/VAV controller using a two wire non

polarity sensitive cable.

The room thermostat shall have plug-in facility to a portable operator terminal to get the following

Section 25 00 00: BMS and Control System

Page 18 of 35

Rev.00 June 2013

Tender Documents

AKH COMMERCIAL TOWER

Plot No.47/Sector 1/74-Al Kashlaa, Dahran/Dammam/K.S.A

Tender Volume 3, Part-E

additional operation such as:

Damper percentage opening

Differential pressure across flow sensor

Flow in CFM

VAV box maximum flow

VAV box minimum flow

Heater status

Minimum flow setting for heaters

It shall be possible to modify the VAV controller parameters from the room thermostat key buttons

without the use of any additional devices.

The controller should have the option of working along with a duct thermostat as well.

2.6

ELECTRONIC DATA INPUTS AND OUTPUTS

2.6.1

General

a)

Input/output sensors and devices shall be closely matched to the requirements of the remote

panel for accurate, responsive, noise-free signal input/output. Control input response shall

be high sensitivity and matched to the loop gain requirements for precise and responsive

control. In no case shall computer inputs be derived from pneumatic sensors or

thermocouple.

b)

Temperature sensors shall be Resistance Temperature Detector (RTD) type of 100, 1000,

or 3,000 ohm platinum, or 20,000 ohm.

c)

Space temperature sensors shall be in attractive housing made from flame retardant ABS.

d)

Control relays and analog output transducers shall be compatible with PCP output signals.

Relays shall be suitable for the loads encountered.

2.6.2

Duct temperature sensors shall be rigid stem or averaging type as specified in the sequence of

operation. The terminal box shall be IP54 and of flame retardant plastic. Outside air, return air,

discharge air, space and well sensors shall have + or 0.5 degrees C accuracy between OoC degrees

and 100oC.

2.6.3

Water flow analog sensors shall be IP66 magnetic type, cast steel upto 25 mm and Aluminium alloy

for sizes 40mm and above. Operational accuracy shall be 5%. It shall be suitable for 240 VAC with

a current output of 4-20mA. The electrodes shall be detachable for easy cleaning, it should not

require the removal of the flow meter. The flow meter shall have an 3.5 segment 7 LED indicator.

Water sensors shall be provided with a separable copper, monel or stainless-steel well. The sensor

shall have an accuracy of class B as per DIN IEC 751.

2.6.4

Relative humidity sensors shall be capacitance type with 10% to 90% range. Duct mounted

humidity sensors shall be provided with a sampling chamber. Wall mounted sensors shall be

provided with decorative covers identical to temperature sensors.

2.6.5

Differential and Static Pressure Sensors and Switches:

a)

Fan proof-of-flow switches shall be of the adjustable set point and differential pressure

type. Switches shall be piped to fan discharge except where fans operate at less than one

inch water column (WC), they shall be piped across the fan. For fractional horsepower and

non-ducted fans, relays or auxiliary contacts may be used. Maximum pressure rating shall

be at least 10 inches water column.

b)

Pump proof-of-flow switches shall be of the adjustable differential pressure or flow type as

specified in the sequence of operation or data point summary. Devices shall be 150 psi

Section 25 00 00: BMS and Control System

Page 19 of 35

Rev.00 June 2013

Tender Documents

AKH COMMERCIAL TOWER

Plot No.47/Sector 1/74-Al Kashlaa, Dahran/Dammam/K.S.A

Tender Volume 3, Part-E

rated except chilled water flow switches shall be provided with totally sealed vapor tight

switch enclosure on 300 psi body. Differential pressure switches shall have valved

manifold for servicing.

c)

Air flow and duct static pressure analog sensors shall be high accuracy suitable for the low

pressures to be encountered.

2.7

OPERATOR STATION SOFTWARE

2.7.1

General:

Operator Station software shall include as a minimum the Operating System (OS) as desirable in

section 2.1, Data Base Manager, Communications Control, Operator Interface (OI), Trend and

History Files, Report Generator, Support Utilities, Scheduler and Time and Event Support Programs.

2.7.2

Real time operating system shall be multitasking providing concurrent execution of multiple

programs and custom program development. When the BMCS software is put in the background it

shall continue to work, sampling the data, printing the alarms / reports, etc.

2.7.3

Data Base manager is to manage all data on an integrated and non-redundant basis. It shall allow

additions and deletions to the data base without any detriment to the existing data. Cross linkages

are to be provided such that no data required by a software program may be deleted by the operator

until that data has been deleted from its respective program.

2.7.4

Communications control, scheduler, trend files, reports, operator interface, and utilities shall be as

specified hereinafter.

2.7.5

Operator Interface Software

Provide a hierarchical linked dynamic graphic operator interface for accessing and displaying system

data and commanding and modifying equipment operation. The interface shall utilize the mouse to

provide "heads up operation" with pull-down menus, dialogue boxes, zoom, coloration and

animation to facilitate operator understanding of the system. A minimum of twenty (20) levels of

graphic penetration shall be provided with the hierarchy operator assignable (for example, area,

building, wing, floor, air handler, sequence of operation pages, dynamic program display, point

group) etc.

2.7.6

Dynamic system data points shall be assignable to each penetration level. Descriptors for graphics,

points, alarms, etc. shall be modified through the operator's station under password control.

2.7.7

Operator access to the system is to be under personal ID and password control for up to 100 unique

operators. Up to 12 alphanumeric characters for personal ID and up to 12 alphanumeric characters

for password shall be assignable to each operator via the operator station. The operator shall be able

to access the system from any operator station in the system by entry of the proper ID and password.

The operators shall be permitted to change their own password without permitting access to any

other password. Sign-off from a station shall be a manual operation via pull-down menu or, if no

mouse or keyboard activity takes place within an assignable time period, shall be automatic.

Automatic sign-off period shall be selectable from ten minutes to 120 minutes for each operator or

may be disabled on a per operator basis. All sign-on/sign-off activity shall be automatically archived

on the operator station disk for subsequent display or printout as desired.

2.7.8

Operator access to system points shall be controlled by individual operator-assigned graphic

hierarchy and by privileges. The hierarchy shall permit access to an operator-assigned initial graphic

and to all graphics linked to and below the initial graphic. The operator shall not have access to

graphics in another hierarchical graphic "tree". For example, an operator may have access to one

building, but not to another building, or to lighting points, but not fire alarm points. Each operator

shall have any combination of user assigned keyboard privileges of alarm acknowledgement, point

commanding, data modification, DOS access, schedule changes, and system configuration changes.

Section 25 00 00: BMS and Control System

Page 20 of 35

Rev.00 June 2013

Tender Documents

AKH COMMERCIAL TOWER

Plot No.47/Sector 1/74-Al Kashlaa, Dahran/Dammam/K.S.A

Tender Volume 3, Part-E

2.7.9

Data to be displayed within a unique graphic shall be assignable regardless of physical hardware

address, communication channel or point type (temperature, humidity, fire alarm, etc.). Graphics are

to be on-line programmable and under ID and password control. Points may be assignable to

multiple graphics where necessary to facilitate operator understanding of system operation and

where specified. Graphics shall also contain calculated or pseudo points. Each physical point and

each other point assigned to a graphic shall be assigned in English descriptor for use in reports.

2.7.10

Data segregation shall be provided for control of specific data routed to an operator station, or to a

given output device such as a printer. Point classes shall be randomly selectable such as all fire

points, fire points second floor, all space temperature points, HVAC points, command points, etc.

Display and/or output of data to printer or color monitor shall occur where there is a match of

peripheral segregation class assignment and the point segregations.

2.7.11

Operators and peripherals shall be assignable and all assignments are to be on-line programmable

and under password control.

2.7.12

Penetration within a graphic hierarchy shall display each graphic name as graphics are selected to

facilitate operator understanding. The "backtrace" shall permit the operator to move upward in the

hierarchy by mouse click on the backtrace. The backtrace shall show at least the previous four

penetration levels. The operator shall be provided the option of showing each graphic full screen size

with the backtrace as the horizontal header or by showing a "stack" of graphics, each with a

backtrace.

2.7.13

All operator accessed data shall be displayed on the color monitor. The operator shall select further

penetration via mouse click on an area, building, floor, fan, etc. The defined linked graphic below

that selection shall then be displayed. Dynamic data shall be assignable to any and all graphics.

2.7.14

The operator shall be provided with a means to directly access any graphic or any point without

going through the penetration path.

2.7.15

Direct access to graphics shall be menu selectable wherein the operator may optionally enter the

name of the graphic system desired or select the desired graphic via cursor positioning on a scroll bar

listing of all graphics, or may be selected via keyboard entry.

2.7.16

Points (physical and pseudo) shall be displayed with dynamic data provided by the system with

appropriate text descriptors, status or value, and ENGINEER ing unit. Coloration shall be used to

denote status and alarm states. Coloration conventions shall be variable for each class of points, as

chosen by the Employer. In addition, animation shall be used to confirm latest status (e.g., fan

rotation, damper position, fluid flow, etc.) where specified. All points shall be dynamic with update

rates user adjustable on a per point basis from 20 seconds to 120 seconds, depending upon the

process dynamics.

2.7.17

For operators with the appropriate privilege(s), points shall be commanded directly from the color

monitor via mouse selection. For a digital command point such as a changeover valve position, the

valve would show its current state (e.g., CLOSED) and the operator could select OPEN via mouse

click. For most operations, a keyboard equivalent shall be available for those operators with that

preference. Upon selection of analog commandable points (such as discharge air static pressure), a

dialogue box shall appear containing the following:

The decimal value of the setpoint with adjacent up-down arrows.

The operator shall be afforded three methods of analog commanding from which to choose as

follows:

Click the cursor on the decimal setpoint value, and enter a new setpoint value via the keyboard

decimal keypad.

Drive the decimal value up or down via the up-down arrows.

Section 25 00 00: BMS and Control System

Page 21 of 35

Rev.00 June 2013

Tender Documents

AKH COMMERCIAL TOWER

Plot No.47/Sector 1/74-Al Kashlaa, Dahran/Dammam/K.S.A

Tender Volume 3, Part-E

"Drag" the set point arrow up or down by moving the cursor to the desired position and clicking.

The bar chart shall also have an associated colored scale showing the current position (scaled value)

of the alarm limits.

2.7.18

An operator shall be permitted to split or resize the viewing screen to show one graphic on the left

half of the screen and another graphic, spreadsheet, bar chart, word processing, curve plot, etc., on

the right half screen. This will allow real time monitoring of one part of the system while displaying

other parts of the system or data from the system to facilitate system operation.

2.7.19

An on-line context-sensitive "help" utility shall be provided to facilitate operator training and

understanding. The help feature shall be a hypertext document with the ability to bridge to further

explanation of selected keywords. The document shall contain text and graphics to clarify system

operation. At a minimum, help shall be available for every menu item and dialogue box. If the help

utility does not have this ability to bridge on keywords for more information, four complete sets of

user manuals shall be provided with quarterly updates and additional training as hereinafter

described.

2.7.20

Electronic messaging facility shall be provided on the operator station for any operator to enter a

message to another operator by selecting the MAIL menu item, selecting the receiving operator's ID

and entering the message (such as CLEAN PRE-HEAT STRAINER ON AHU-16"). When an

operator with a queued message signs onto the operator station, the "Mail Message" area of the

dialogue box shall indicate that a message is waiting. Upon selecting a mail display, the operator

shall be presented an index of the title or subject of each from which he may select the order of

display. Upon displaying a mail message, the display shall prompt the operator with three message

options to execute; delete, print, or save. Messages shall also include the time and date the message

was sent, the sender's personal ID, and be 300 characters minimum length, plus a brief title or

subject description.

2.7.21

Site Specific Customizing Software.

Provide software which will allow the user to modify and tailor the BMCS to the specific and unique

requirements of the equipment installed, the programs implemented, and to staffing and operational

practices. Online modification of system configuration, program parameters, and data base shall be

provided via menu selection and keyboard entry of data into preformatted self-prompting templates.

As a minimum, the following modification capability shall be provided.

a)

Operator assignment capability shall include designation of operator passwords,

privilege(s), starting graphic and auto sign off duration.

b)

Peripheral assignment capability shall include assignment of segregation groups to consoles

and printers, and designation of backup printers.

c)

System configuration/diagnostic capability shall include communications and peripheral

port assignments, PCP enable/disable, assignment of command trace to points and initiation

of diagnostics.

System text add/change capability shall include action messages for alarms and runtime,

and trouble condition messages.

d)

e)

Time/Schedule change capability shall include time/date set, time/occupancy schedules,

holiday schedules, and daylight savings time schedules. All time and calendar scheduling

and schedule modification shall be accomplished graphically via color bars and calendars

in a hardware independent manner.

f)

Points shall be uniquely defined as to coloration, animation, audible rate and duration, point

descriptors, operator messages (480 characters minimum), printer options, alarm archival

option, alarm and warning limits, and ENGINEER ing units. All messages specified and

all physical and pseudo point descriptors shall be entered by the vendor.

Section 25 00 00: BMS and Control System

Page 22 of 35

Rev.00 June 2013

Tender Documents

AKH COMMERCIAL TOWER

Plot No.47/Sector 1/74-Al Kashlaa, Dahran/Dammam/K.S.A

Tender Volume 3, Part-E

g)

Point related change capability shall include system/point enable/ disable; run time

enable/disable; assignment of points to point classes, analog value offset, lockout, run time

limits, and setting a fixed input value or output status.

Graphic construction is specified under Graphic Creation.

2.7.22

Alarm handler software shall be provided to respond to alarm conditions sensed and transmitted

from PCPs and TECs. First in, first out handling of alarms in accordance with alarm priority ranking

(fire alarm first, security second, etc.) is required with buffer storage for a minimum of 20 alarms in

case of simultaneous multiple alarms. Alarm handler shall be active in both the Signed On and

Signed Off modes to assure that alarms will be processed even though an operator is not currently

signed on.

Alarms shall be displayed in a dialogue box of the color monitor. Display shall include as a

minimum:

a)

Indication of alarm condition; i.e., ABNORMAL OFF, HI ALARM/LO ALARM, analog

value or status, and English point identification.

b)

An unique per point alarm action message; i.e., "The fan has shutdown due to an

excessively high discharge duct pressure. There is a strong indication of a system

malfunction such as an inlet vane drive failure, or major fire damper closure. The switch

should not be manually reset until a thorough check of the cause is conducted" of up to 480

characters.

Alarms are to be directed to appropriate operators, operator stations, and printers for segregation

assignments as specified in previous sections of this specification.

Alarm silencing shall be by selecting the "silence" button or by authorized operator's

acknowledgment. In all cases, alarm acknowledgment shall only be allowed by operators authorized

to acknowledge a point in alarm.

Each point shall be assigned to an alarm class, with no limit to the quantity of alarm classes. Each

alarm class shall be uniquely assignable to any combination of the following alarm processing

attributes:

a)

Audible beep duration (none, 10 seconds, 20 seconds, continuous)

b)

Audible beep rate (slow-medium-fast)

c)

Alarm historically archived (yes or no)

d)

Alarm printed, with printer ID

e)

Associated coloration with any of 256 colors, with separate brightness control, assignable

to each alarm state (high alarm, etc.) and similarly be distinguished with different colors for

each possible state.

Alarms shall be displayed and/or printed at each peripheral to which its segregation allows, but only

those operators having proper privilege level will be allowed to acknowledge alarms.

An unacknowledged alarm indicator shall be provided on the color monitor display to alert the

operator that there are unacknowledged alarms in the system.

Symbols for points in a graphic display that are in an unacknowledged alarm state shall flash red;

when in an acknowledged state, the symbol shall be non-flashing-red.

Run time limit messages shall be presented and processed as alarm messages except the action

message shall be of a maintenance directive nature.

Section 25 00 00: BMS and Control System

Page 23 of 35

Rev.00 June 2013

Tender Documents

AKH COMMERCIAL TOWER

Plot No.47/Sector 1/74-Al Kashlaa, Dahran/Dammam/K.S.A

Tender Volume 3, Part-E

2.7.23

Standard reports shall be provided which shall be operator selectable to appear on the operator

station, any selected printer or both. A "terminate report" command shall be available to allow the

operator to stop any report in the process of being printed. In the event of failure of any printer,

subsequent reports directed to that printer shall be automatically redirected to an operator preassigned backup printer located at the operator station. The following standard pre-formatted reports

to be provided shall include:

Point summary reports may be requested at any penetration level (facility, building, area, system)

and shall include only points at and below that level. Point summary reports shall include the

current value/status and condition, English system and point descriptors for all points. Point

summary reports shall be selectable for all points, only those points in alarm, fixed points, disabled

points locked out points, locked out and in alarm points, analog input or output points, digital input

or output points. All reports shall be capable of being scheduled to run at a specific time and/or

interval via an operator function supported by necessary data entry templates and interactive

prompts.

Dynamic trends shall provide up to six points and show real time activity of the associated points.

This information shall be printed and/or displayed in numeric, bar chart, curve plot, pie chart, etc., as

selected by the operator. Graphic plots shall allow a unique color for each point. As new point

values are sampled, they shall be processed, scaled, and dynamically appended to any plot being

displayed. Sample interval of points selected for dynamic trend shall be user selectable from five

seconds to sixty minutes.

Alarm and run time reports shall be automatically issued to assigned printers immediately upon

occurrence, and shall consist of the point descriptor, the status or value of the point with

ENGINEER ing unit, the time and date, and an action taking alarm message.

The user shall be provided with a command trace feature selectable on a per point basis allowing the

archiving of all commands issued to each point. The archived trace shall include the command, the

command source, the point ID, and the time and date. Command trace reports shall be output upon

operator demand.

A custom report capability shall be provided to allow the user to format reports of any mix of text,

points with status/value and descriptors, and points with status/value only. Custom reports may be

scheduled or requested manually. A spreadsheet program similar to Microsoft Excel shall be

provided fully integrated with the BMCS data base, and available to the user. Spreadsheet packages