Professional Documents

Culture Documents

En Antichispa

Uploaded by

Anonymous GfPSYi4nCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

En Antichispa

Uploaded by

Anonymous GfPSYi4nCopyright:

Available Formats

TECHNICAL FILE

NON-SPARKING TOOLS

EGA Master Non Sparking Tools are the best alternative for non sparking application purposes

in explosive potential environments. All its tools are forged after casting to achieve the best quality

tools in the market, both in mechanical properties and attractive finishing. We incorporate to our non

sparking tools all our knowledge of decades designing and manufacturing hand tools, making the

most ergonomic, easy to be used and nicest design for them.

All EGA Master Tools are manufactured according to the strict control of ISO 9001-2000,

certified by the most prestigious institution for hand tool manufacturing, TUV-Rheinland.

MATERIALS

Copper-Beryllium Alloy

Composition

Aluminium-Bronze Alloy

Be

1.8%-2%

Ni+Co

0.2%-1.2%

Rest

Cu

Composition

Al

10%-12%

Ni

4%-6%

Fe+Mn

<5.8%

Rest

Cu

Hardness

283-365 Brinell

Hardness

229-291 Brinell

Tensile Strength

1250 N/mm2

Tensile Strength

800 N/mm2

PROPERTIES AND FEATURES

Property

Application or benefit

Non-sparking

Appropriate for explosive potential environments

Non-magnetic safety

Essential for equipments that require complete non-magnetic safety

Corrosion resistant

Specially well suited for applications in corrosive environments like encountered in marine works or fire-fighting applications

Forged after casting

Provides higher mechanical properties and better finishing

Ergonomic designs

The use of bi-material anti-slippery handles, dipping anti-slippery handles, totally ergonomic designs make operations easier, more comfortable and faster

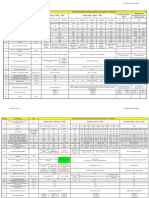

TABLE OF RISKS OF EXPLOSION AND MAXIMUM TEMPERATURE

Explosion group

Temperature of

ignition

I

IIA (Energy of ignition higher than

0.18 mJ)

T1 (450 C) T2 (300C) T3 (200 C) T4 (135 C) T5 (100 C)

300 - 450

C

200 - 300

C

135 - 300

C

Acetone

i-amyl acetate

Amyl alcohol

Acetaldehyde

Ammonia

n- butane

Gasolines

Benzene

n-Butanol

Gas-oil

Etilacetato

1-butene

Heating oil

Methane

Ethyl acetate

n-hexane

Methanol

i-propanol

Propane

Vinyl chloride

450 C

T6 (85 C)

100 - 135 C 85 - 100 C

Methane

Toluene

IIB (Energy of ignition between 0.06

and 0.18 mJ)

Hydrogen

cyanide

1.3-butadiene

Dimethyl

ether

Dietileter

1.4-dioxane Ethyl glycol

Coal gas

(lighting gas)

Etylene

Hydrogen

sulphide

Ethylene

oxide

IIC (Energy of

ignition minor of

0.06 mJ)

Hydrogen

Gas of water

(CO+H2)

Acetylene

bisulphide

of carbon

Ethyl nitrate

The tools made of Cu Be alloy can be used in all groups (I, IIA, IIB, IIC) in a safety way, always

respecting the maximum surface temperature allowed, except with acetylene that can create explosive

acetylite gases.

The tools made of Al Bronze alloy can be used in a safety way, always respecting the maximum

surface temperature allowed, except for the IIC group (Hydrogen, gas of water, acetylene, bisulphide

of carbon, Ethyl nitrate).

DIFFERENCES AND HOW TO MAKE THE CORRECT CHOICE

Concept

Cu-Be

Al-Bron

Hardness

283-365 Brinell

229-291 Brinell

Magnetism

Minimum ferrous component

Non ferrous substance in the commakes them not 100% non-magposition makes it safer when non- netic, although its low magnetism

magnetic applications are required make it proper for non critical nonmagnetic applications

Durability

Much higher due to the higher hardness and tensile strength. Higher

efforts can be afforded

Not as much as Co-Be

Price

Higher price due to the special raw

material used

Around 30% more economic

Risk of ignition

Alloy can be used in all groups

(I, IIA, IIB, IIC)

Alloy can be used in all groups

except IIC

MAIN APPLICATION FIELDS

Petrochemicals

Fireworks Industry

Mines

Refineries

Chemical Industry

Defence

Oil Companies

Paper making Industries

Air Forces

Gas & oil pipe lines

Flour silos and mills

Navy

Power Stations

Breweries

Weapon & ammunition fabrication

Paint Making

Alcohol processing industries

Aerospace Industry

Plastic manufacturing

Distilleries

Automobile Industry

Pharmaceutical Industry

Fire-fighters

Etc.

COPPER OR BRASS TOOLS

Copper or brass tools are safe in explosive environments of risk groups I and IIA. It is safe to

work with them in these environments.

EGA Master has available a complete range of copper and brass hammers and mallets made in

both materials.

It is convenient to know that copper or brass tools can never be considered as alternatives

to aluminum-bronze or copper-beryllium alloy tools, because their hardness is too low for most

applications. There is the temptation to choose copper or brass tools due to their lower cost compared

to aluminum-bronze or copper-beryllium ones. This choice is not only risky in itself, but in the short/

mid term it will be necessary to replace them for new ones for the wearing out suffered due to their

low hardness.

For this reason, copper or brass tools should only be used in those jobs that have to be made

in risky environments (I and IIA), if the same job would be made with copper or brass tools in a nonrisky environment. In case you would use a steel tool in a non-risky environment, than you should

choose for your safety and profitability tools made in aluminum-bronze or copper-beryllium alloys to

make the same jobe in a risky environment. Never a copper or brass tool.

ACETILEX ALLOY

Items with copper compositions higher than 65% should not be used in acetylene environments.

Both aluminum bronze and copper-beryllium alloys do have higher copper compositions than 65%.

The reason is not that copper beryllium can create a spark with enough energy to create the

ignition of acetylene, but that copper can react with acetylene creating highly explosive acetylates.

For this reason, copper-beryllium or aluminum-bronze alloys should not be used in acetylene

environments.

In Ega Master S.A., always commited to find new innovative solutions that will increase safety,

we have developed the ACETILEX alloy, 100% safe to be used in acethylene environments. Once

again, pioneers in safety.

INSTRUCTIONS FOR USE & WARRANTY

Non-Sparking Tools cannot reach the hardness of conventional tools. For this reason the use of

Non-Sparking Tools has to be carried out with special care, avoiding overstraining, heating, etc.

The use of Non-Sparking Tools must not be the only preventive measure in areas which the

items are designed for. Other items, clothes or present material must also be adequate for nonsparking purposes.

EGA Master Non-Sparking Tools are provided with lifetime warranty. In case an EGA Master

tool breaks or fails to perform under normal and correct use, it will be repaired or replaced free of

cost. Any misuse, abuse or normal service wear is considered as an exception to the warranty.

CAUTION: These tools are not classified as anti-static because they DO conduct electricity. Do

no use them in acetylene environments as they can create explosive acetylite gases

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Manual AtvDocument42 pagesManual AtvAnonymous GfPSYi4nNo ratings yet

- Guidelines For Shielded Metal Arc Welding (SMAW)Document28 pagesGuidelines For Shielded Metal Arc Welding (SMAW)soroush1111No ratings yet

- Strength of MaterialsDocument13 pagesStrength of MaterialsPJ Gealone50% (12)

- Calculation of Heat and Mass BalanceDocument18 pagesCalculation of Heat and Mass BalanceJitendra Bhatia100% (3)

- Technical Data Sheet for Emulsified Bituminous PrimerDocument2 pagesTechnical Data Sheet for Emulsified Bituminous Primerhandhammer qatarNo ratings yet

- EIFS performance standardsDocument40 pagesEIFS performance standardsRyan ClarkeNo ratings yet

- Managing Ammonia WastewaterDocument19 pagesManaging Ammonia WastewaterAnonymous GfPSYi4nNo ratings yet

- Jarvis: Model Buster V Beef Splitting Band SawDocument16 pagesJarvis: Model Buster V Beef Splitting Band SawAnonymous GfPSYi4nNo ratings yet

- Operation Manual: Rotavapor R-220 ProDocument108 pagesOperation Manual: Rotavapor R-220 ProAnonymous GfPSYi4nNo ratings yet

- FGSR Example Gas Emergency Escape PlanDocument36 pagesFGSR Example Gas Emergency Escape PlanAnonymous GfPSYi4nNo ratings yet

- Nit 5Document6 pagesNit 5Anonymous GfPSYi4nNo ratings yet

- 55 Amot Sas Product Document PDFDocument8 pages55 Amot Sas Product Document PDFAnonymous GfPSYi4nNo ratings yet

- Disclosure To Promote The Right To InformationDocument14 pagesDisclosure To Promote The Right To InformationAnonymous GfPSYi4nNo ratings yet

- Xxiii Paper 44Document8 pagesXxiii Paper 44JesusNo ratings yet

- MSDS Sikafloor Cure Hard 24Document6 pagesMSDS Sikafloor Cure Hard 24Anonymous GfPSYi4nNo ratings yet

- BR CH Spark Arrestors 0911 Rev2 USADocument4 pagesBR CH Spark Arrestors 0911 Rev2 USAAnonymous GfPSYi4nNo ratings yet

- Model JC III Air Powered Dehider: - . - . - . - . - . - . - . - . - Equipment SelectionDocument12 pagesModel JC III Air Powered Dehider: - . - . - . - . - . - . - . - . - Equipment SelectionAnonymous GfPSYi4nNo ratings yet

- Rapid depressurization of pressure vessels: predicting hazardous behaviorDocument4 pagesRapid depressurization of pressure vessels: predicting hazardous behaviorthlim19078656No ratings yet

- Electrostatic risks and trucks under the ATEX DirectiveDocument2 pagesElectrostatic risks and trucks under the ATEX DirectiveAnonymous GfPSYi4nNo ratings yet

- Hazards FineDocument33 pagesHazards FineAnonymous GfPSYi4nNo ratings yet

- 2002-Worldw ExProt TechDocument7 pages2002-Worldw ExProt TechAnonymous GfPSYi4nNo ratings yet

- Polymeric ChemicalsDocument22 pagesPolymeric ChemicalsAnonymous GfPSYi4n100% (1)

- Jarvis: Model BN 003 Pneumatic BalancerDocument8 pagesJarvis: Model BN 003 Pneumatic BalancerAnonymous GfPSYi4nNo ratings yet

- Catalogue SD 1Document4 pagesCatalogue SD 1Anonymous GfPSYi4nNo ratings yet

- Working at Heights Code of PracticeDocument16 pagesWorking at Heights Code of PracticeAnonymous GfPSYi4nNo ratings yet

- Glove Chart 2Document11 pagesGlove Chart 2Anonymous GfPSYi4nNo ratings yet

- Milk Powder: Etc., Recombined Milks and Other Liquid BeveragesDocument5 pagesMilk Powder: Etc., Recombined Milks and Other Liquid BeveragesSUTHANNo ratings yet

- Appendix E FinalDocument27 pagesAppendix E Finalnk_icetNo ratings yet

- Diffusive Monitor 1Document23 pagesDiffusive Monitor 1Anonymous GfPSYi4nNo ratings yet

- MRGNC MNGMNT PNNNG EngDocument73 pagesMRGNC MNGMNT PNNNG EngAnonymous GfPSYi4nNo ratings yet

- Diffusive MonitorDocument19 pagesDiffusive MonitorAnonymous GfPSYi4nNo ratings yet

- Chemical AccidentDocument36 pagesChemical AccidentAnonymous GfPSYi4nNo ratings yet

- Grain Bin Safety: How to Avoid Suffocation HazardsDocument8 pagesGrain Bin Safety: How to Avoid Suffocation HazardsAnonymous GfPSYi4nNo ratings yet

- Methods For Waste Waters Treatment in Textile IndustryDocument5 pagesMethods For Waste Waters Treatment in Textile Industryjpsingh75No ratings yet

- Ch. 13 Carbonyl (1) Answers: Organic Chem II-1Document38 pagesCh. 13 Carbonyl (1) Answers: Organic Chem II-1Nguyễn A.ThưNo ratings yet

- PV Module IonDocument4 pagesPV Module IonrmalewarNo ratings yet

- Protons, Neutrons, and Electrons Practice WorksheetDocument2 pagesProtons, Neutrons, and Electrons Practice WorksheetRedHoeBeerNo ratings yet

- Solomons Testbank1 Struktur Bindn + SvarDocument7 pagesSolomons Testbank1 Struktur Bindn + SvarTahirat NasiruNo ratings yet

- Stoichiometry Questions & AnswersDocument2 pagesStoichiometry Questions & Answersnosirat aladeNo ratings yet

- J Parenter Enteral Nutr - 2015 - Frank - Thiamin in Clinical PracticeDocument18 pagesJ Parenter Enteral Nutr - 2015 - Frank - Thiamin in Clinical Practicejuhh tavaresNo ratings yet

- Equipment for Drilling Fluid Laboratory TestingDocument14 pagesEquipment for Drilling Fluid Laboratory TestingAlok SinghNo ratings yet

- Brook CromptonDocument28 pagesBrook Cromptonsumitsharma2010100% (1)

- Lenox Catalogue PDFDocument40 pagesLenox Catalogue PDFInvotexNo ratings yet

- GDocument3 pagesGjeas grejoy andrewsNo ratings yet

- Amino Acid For NeonateDocument13 pagesAmino Acid For NeonateHerti PutriNo ratings yet

- Investigations On Fouling Rate in Convective BundlesDocument11 pagesInvestigations On Fouling Rate in Convective BundlesAnitha Kumari SivathanuNo ratings yet

- Chemistry Trial-Exam SPM 2012 Marking SchemeDocument21 pagesChemistry Trial-Exam SPM 2012 Marking SchemeHarun Din HairuddinNo ratings yet

- Build Up MaterialsDocument5 pagesBuild Up MaterialsMishell CarolinaNo ratings yet

- CVDocument2 pagesCVyadse100% (1)

- Determination of Relative Fluorescence Quantum Yield Using The Agilent Cary EclipseDocument6 pagesDetermination of Relative Fluorescence Quantum Yield Using The Agilent Cary EclipseRosinaldo AparicioNo ratings yet

- Group 11-Operations Management - Systems ViewDocument6 pagesGroup 11-Operations Management - Systems ViewRohit MenonNo ratings yet

- Palm Oil Fiber ConcreteDocument9 pagesPalm Oil Fiber ConcreteGladys Eras ValladolidNo ratings yet

- T06002.006 Viva E System Onsite Training Workbook Eff Date 09-13-21Document66 pagesT06002.006 Viva E System Onsite Training Workbook Eff Date 09-13-21Zitouni LamineNo ratings yet

- Hough - The Crystallography, Metallography and Composition of Gold PDFDocument6 pagesHough - The Crystallography, Metallography and Composition of Gold PDFSantiaGoAlejandRoNo ratings yet

- ALM Refrigeration Air DryerDocument34 pagesALM Refrigeration Air DryerJunaid AhmedNo ratings yet

- Dyeing Fabrics InvestigationDocument13 pagesDyeing Fabrics InvestigationShubham KumarNo ratings yet

- 1 PBDocument12 pages1 PBLela MaelaNo ratings yet

- Acid Base SaltMay 24, 2023Document6 pagesAcid Base SaltMay 24, 2023Archi SamantaraNo ratings yet

- MSDS 853021 Dry Charge BatteryDocument3 pagesMSDS 853021 Dry Charge Batteryjian0889No ratings yet