Professional Documents

Culture Documents

Influence of Crack Dimensions and Heat Treatment On Fracture Behaviour of AA1050 Alloy Pipes Subjected To Bursting Pressures

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Influence of Crack Dimensions and Heat Treatment On Fracture Behaviour of AA1050 Alloy Pipes Subjected To Bursting Pressures

Copyright:

Available Formats

International Journal of Innovative Research in Advanced Engineering (IJIRAE) ISSN: 2349-2763

Issue 02, Volume 3 (February 2016)

www.ijirae.com

Influence of Crack Dimensions and Heat Treatment on

Fracture Behaviour of AA1050 Alloy Pipes Subjected to

Bursting Pressures

Chennakesava R Alavala

Department of Mechanical Engineering,

JNT University, Hyderabad, India.

AbstractThere are different codes and standards for assessing pipeline flaws depending on the type of flaw.

Corrosion is commonly assessed using ASME B31G, DNV-RP-F101, SHELL-92, RSTRENG. The Finite Element

method is becoming popular for evaluation of crack and corrosion flaws. In this paper 3D finite element analysis and

Taguchi technique were employed to investigate fracture criteria of AA1050 Al-alloy pipes subjected to internal

bursting pressure. The yield strength criterion was used to study the failure of pipes. It was observed that the Jintegral was proportional to the deformation under the applied bursting pressure. It was noticed that the major

dominating control factors which could influence the failure of pipes were the pipe thickness and heat treatment

process.

Keywords AA1050 Al-alloy, bursting pressure, crack length, crack depth, heat treatment, finite element analysis.

I. INTRODUCTION

Pipelines must be safe and efficient for transporting high volumes of oil and gas. However, aged pipelines may

experience flaws, such as cracks or corrosion. AA1050 alloy is known for its excellent corrosion resistance, high ductility

and highly reflective finish. AA1050 alloy is typically used for chemical process plant equipment. The codes such as

ASME B31G [1] DNV-RP-F101 [2], SHELL-92 [3], and RSTRENG [4], are the semi-empirical methods used for the

assessment of the integrity of pipes. The finite element analysis (FEA) is one of the most efficient tools to quantify

reliably the remaining strength of corroded pipes. Elastic-Plastic finite element models have been used to provide more

accurate results in evaluating the corrosion defects as reported [5]-[8].

The present work was aimed at to study the finite element analysis of crack propagation and bursting with predefined

flaws of varying length and depth in AA1050 Al-alloy pipes.

II. MATERIALS AND METHODS

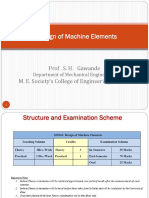

The material of pipes was AA1050 Al-alloy. The chosen control parameters are summarized in table 1. The orthogonal

array (OA), L9 was selected for the present work [9]. The control factors were assigned to the various columns of O.A.

The assignment of control factors along with the OA matrix is given in table 2. A surface notch as shown in Fig. 1(a)

made on the outer surface of the pipe specimen. The dimensions of notch are given in Fig.1(b).

TABLE 1

CONTROL FACTORS AND THEIR LEVELS

Factor

Thickness, mm

Length of crack, mm

Depth of crack

Symbol

A

B

C

Heat treatment

D

where t is pipe thickness

Level1

1.0

25

40%t

H14

Level2

1.2

50

50%t

H16

Level3

1.5

75

60%t

H18

TABLE 2

ORTHOGONAL ARRAY (L9) AND CONTROL FACTORS

Treat No.

1

2

3

4

5

6

7

8

9

A

1

1

1

2

2

2

3

3

3

B

1

2

3

1

2

3

1

2

3

C

1

2

3

2

3

1

3

1

2

D

1

2

3

3

1

2

2

3

1

_________________________________________________________________________________________________

IJIRAE: Impact Factor Value - ISRAJIF: 1.857 | PIF: 2.469 | Jour Info: 4.085 | Index Copernicus 2014 = 6.57

2014- 16, IJIRAE- All Rights Reserved

Page -1

International Journal of Innovative Research in Advanced Engineering (IJIRAE) ISSN: 2349-2763

Issue 02, Volume 3 (February 2016)

www.ijirae.com

Fig. 1. Surface notch created on the pipe(a) and crack dimensions (b).

The operating pressure calculation was obtained from ASME B31.8 [10]:

(1)

where P is the design pressure (MPa), is the specified minimum yield strength (MPa), t is the nominal wall thickness

(mm), D is the nominal outside diameter (mm), F is the design factor, E is the longitudinal joint factor and T is the

temperature derating factor.

The cross-section of the pipe was created in 2-D and then it was extruded for the given pipe length along the zdirection. The ANSYS code was used to model the pipe and initial semi-elliptical crack. The pipe was modeled with

tetrahedron elements. Fracture module method for crack generation required that elements be of higher order. Therefore,

out of choice of tetrahedral elements of type SOLID 186 were chosen for accurate results [11]. Fine mesh was used to

model the crack region. The number of elements and nodes were 1,20,442 and 2,50, 108 respectively. A threedimensional semi-elliptical crack was initiated on the shaft surface. The crack was oriented with respect to pipe axis. In

order to create the semi-elliptical crack onto to the surface, a local coordinate system was established. With reference to

the local co-ordinate system and the crack was created on the outer surface of the pipe as shown in Fig. 2. The pressure

obtained from Eq. (1) was applied on the inner surface of pipe.

Fig. 2. Mesh view of crack on the pipe surface.

If the failure is defined by material yielding, it follows that the design goal is to limit the maximum equivalent stress to

be less than the yield strength of the material:

(2)

where, ES is the equivalent stress and YS is the yield strength of AA1050 Al-alloy.

III. RESULTS AND DISCUSSION

The finite element software was carried out twice with two mesh densities according Taguchi design of

experimentation.

A. Static Deformation

Fig. 3 gives the total deformation values of tested pipes with different crack geometry and bursting pressure. It was

observed that the maximum total deformation of 0.0195 mm with trial no.3 and the minimum total deformation of

0.00365 mm with trail no.9. For trials 3 and 9 the thicknesses were 1 mm and 3 mm respectively.

B. Equivalent Stress Distribution Across the Crack

The equivalent stress distribution across the crack for all the test coupons is shown in Fig. 4. The maximum equivalent

stress of test coupons 1, 2, 3, 4, 5, 6, 7, 8 and 9 were found to be 108.11 MPa, 166.53 MPa, 266.07 MPa, 201.95 MPa,

86.31 MPa. 125.73 MPa, 108.97 MPa, 109.53 and 64.95 MPa respectively. The equivalent stresses of trials 1, 5 and 9

were belonging to heat treatment, H14. For trail 1 only the equivalent stress exceeded the yield strength (103 MPa) of

AA1050. The equivalent stresses of trials 2, 6 and 7 were belonging to heat treatment, H16.

_________________________________________________________________________________________________

IJIRAE: Impact Factor Value - ISRAJIF: 1.857 | PIF: 2.469 | Jour Info: 4.085 | Index Copernicus 2014 = 6.57

2014- 16, IJIRAE- All Rights Reserved

Page -2

International Journal of Innovative Research in Advanced Engineering (IJIRAE) ISSN: 2349-2763

Issue 02, Volume 3 (February 2016)

www.ijirae.com

For trail 7 only the equivalent stress did not exceed the yield strength (124 MPa) of AA1050. The equivalent stresses

of trials 3, 4 and 8 were belonging to heat treatment, H18. For trail 8 only the equivalent stress did not exceed the yield

strength (145 MPa) of AA1050.

Fig. 3. Total deformation of test coupons.

Fig. 4. Equivalent stress along crack front.

Fig. 5. J-Integral values of all trials.

_________________________________________________________________________________________________

IJIRAE: Impact Factor Value - ISRAJIF: 1.857 | PIF: 2.469 | Jour Info: 4.085 | Index Copernicus 2014 = 6.57

2014- 16, IJIRAE- All Rights Reserved

Page -3

International Journal of Innovative Research in Advanced Engineering (IJIRAE) ISSN: 2349-2763

Issue 02, Volume 3 (February 2016)

www.ijirae.com

C. J-integral

The path dependence of the J-integral is displayed for all nine specimens are shown in Fig. 5. The maximum value of

J-integral was 0.16329 MJ/mm2 with third trial having the displacement of 0.0195 mm. The minimum value of J-integral

was 0.008724 MJ/mm2 with ninth trial having the displacement of 0.00365 mm. Therefore, the J-integral was directly

proportional to the displacement of the load applied on the pipe. The path dependence of the J-integral was much more

significant in a large deformation analysis [12]. The far field value of J was reached with test coupon 3 latter, whereas in

the test coupon 9 having small deformation the far field value of J was already reached.

D. Stress Intensity Factors

Each test coupon was started with a pre-existing crack of a given length "2a". Mode I was a spreading apart of the two

halves of the crack interface, recognizable as the most severe case. Fig. 6 shows the variations of stress intensity factor,

KI along the initial crack-front for all pipes. The stress intensity factors, KII and KIII are not highly influential factors as

compared stress intensity factor KI. The pipe 3 has the maximum value (114.01) of KI whereas the pipe 9 has the

minimum value (26.42) of KI.

Fig. 6. Stress intensity factors: (a) KI, (b) KII and (c) KIII values of all trials.

E. Failure Criteria

The ANOVA summary of yield strength (YS) failure criterion is given in table 3. The Fishers test column ascertains

the parameters (A, B, C and D) accepted at 90% confidence level influencing the variation in the impact strength. The

percent contribution indicates that the thickness of the pipe only contributed 56.27% of the variation for YS criterion

respectively. The crack length (B) put in 4.85% of variation for YS criterion. The crack depth (C) gave 8.33% of

variation for YS criterion. The heat treatment (D) aids 30.99% of variation for YS criterion.

TABLE 3- ANOVA SUMMARY OF THE YS FAILURE CRITERIA

Source

Sum 1

Sum 2

Sum 3

SS

8.47

6.48

4.52

1.29

0.645

1089.02

56.27

6.62

5.88

6.97

0.11

0.055

92.86

4.85

5.64

6.73

7.10

0.19

0.095

160.40

8.33

5.06

6.91

19.47

0.71

0.355

599.38

30.99

0.0053305

0.0005923

1.00

-0.44

2.2946695

17

Error

T

25.79

26.00

38.05

100

The effect of pipe thickness on the failure criteria is depicted in figure 7a. It is noticed that the failure of pipes

decreases with an increase in the pipe thickness. The failure was minimal for the pipes undergone the heat treatment H14

(figure 7b). This was owing to the reduction of ductility as a result of heat treatment. The elongations of AA1050 Alalloy were 10%, 8% and 7% respectively for H14, H16 and H18 heat treatments. These are strain hardening processes

only. The failure criteria are plotted for all the test coupons in figure 8. The test coupons 5, 7, 8 and 9 are satisfactory

under YS failure criteria.

Fig. 7. Effect of pipe thickness (a) and heat treatment on the failure criterion.

_________________________________________________________________________________________________

IJIRAE: Impact Factor Value - ISRAJIF: 1.857 | PIF: 2.469 | Jour Info: 4.085 | Index Copernicus 2014 = 6.57

2014- 16, IJIRAE- All Rights Reserved

Page -4

International Journal of Innovative Research in Advanced Engineering (IJIRAE) ISSN: 2349-2763

Issue 02, Volume 3 (February 2016)

www.ijirae.com

Fig. 8. Failure criteria of all test coupons.

IV. CONCLUSIONS

The failure of pipes decreases with the increase of pipe thickness. The strength of AA1050 Al-alloy increases with

strain hardening processes H14, H16 and H18. However, the ductility decreases. The failure of pipes under bursting

pressure was low for the pipes treated with H14 because of high ductility as compared to H18 heat treatment. The Jintegral is directly proportional to the displacement of the load applied on the pipe. As per yield strength failure criteria,

the failure was low for the pipes having 1.5 mm thickness, 75 mm crack length, 0.75 mm crack depth and heat treated

under H14 conditions.

REFERENCES

[1]

A. C. Reddy, Prediction of bursting pressure of thin walled 316 stainless steel pipes based on ASME B31G criterion, National

Conference on Advances in Design Approaches and Production Technologies (ADAPT-2005), Hyderabad, 22-23rd August 2005,

pp. 225-228.

[2] A. C. Reddy, Estimation of bursting pressure of thin walled 304 stainless steel pipes based on DNV RP F101criterion,

National Conference on Advances in Design Approaches and Production Technologies (ADAPT-2005), Hyderabad, 22-23rd

August 2005, pp. 229-231.

[3] A. C. Reddy, Reliability assessment of corrosion cracks in cold rolled 302 stainless steel pipes based on SHELL-92 criterion,

National Conference on Advances in Design Approaches and Production Technologies (ADAPT-2005), Hyderabad, 22-23rd

August 2005, pp. 232-234.

[4] A. C. Reddy, Trustworthiness judgment of corrosion cracks in cold rolled 305 stainless steel pipes based on RSTRENG

criterion, National Conference on Advances in Design Approaches and Production Technologies (ADAPT-2005), Hyderabad,

22-23rd August 2005, pp. 235-237.

[5] D.U.M. Manikanta and A. C. Reddy, Fracture Behavior of 6061 Al-Alloy Pipes under Bursting Loads with Crack Depth

Variation, International Journal of Scientific & Engineering Research, vol. 6, no.3, pp. 338-343, 2015.

[6] R. V. S. K. Varma, A. C. Reddy, Optimization of Bursting Behavior of AA2090 Al-Alloy Pipes Using Taguchi Techniques and

Finite Element Analysis, International Journal of Scientific Engineering and Research, vol.3, no. 12, pp. 35-38, 2015.

[7] M. Akhil, A. C. Reddy, Evaluation of Structural Integrity under Bursting Conditions of Heat Treated 2219 Al-Alloy Pipes

Using Finite Element Analysis, International Journal of Scientific Engineering and Research, vol. 3, no. 12, pp. 39-43, 2015.

[8] A. Sreeteja, A. C. Reddy, Influence of Crack Size on Fracture Behavior of Heat Treated 2011 Al-Alloy Pipes Using Finite

Element Analysis, International Journal of Scientific Engineering and Research, vol. 3, no. 12, pp. 47-50, 2015.

[9] A. C. Reddy and V.M. Shamraj, Reduction of cracks in the cylinder liners choosing right process variables by Taguchi

method, Foundry Journal, vol.10, no.4, pp.47-50, 1998.

[10] American National Standards Institute (ANSI) / American Society of Mechanical Engineers (ASME): Manual for determining

the remaining strength of corroded pipelines, ASME B31G, 1991.

[11] C.R. Alavala, Finite Element Methods: Basic Concepts and Applications, PHI Learning Pvt. Ltd., New Delhi, 2008.

[12] J. Newman, I.S. Raju, An Empirical Stress-Intensity Factor Equation for the Surface Crack, Engineering Fracture Mechanics

vol.15, pp.185192, 1981.

_________________________________________________________________________________________________

IJIRAE: Impact Factor Value - ISRAJIF: 1.857 | PIF: 2.469 | Jour Info: 4.085 | Index Copernicus 2014 = 6.57

2014- 16, IJIRAE- All Rights Reserved

Page -5

You might also like

- SSR Damping Using GCSC and TCSC in Wind FarmsDocument10 pagesSSR Damping Using GCSC and TCSC in Wind FarmsIJIRAE- International Journal of Innovative Research in Advanced EngineeringNo ratings yet

- Evaluation Mechanism For Similarity-Based Ranked Search Over Scientific DataDocument5 pagesEvaluation Mechanism For Similarity-Based Ranked Search Over Scientific DataIJIRAE- International Journal of Innovative Research in Advanced EngineeringNo ratings yet

- An Adaptive Datagathering To Improve The Network Lifetime in Wireless Sensor NetworkDocument6 pagesAn Adaptive Datagathering To Improve The Network Lifetime in Wireless Sensor NetworkIJIRAE- International Journal of Innovative Research in Advanced EngineeringNo ratings yet

- Concept Design and Analysis of Multipurpose Farm Equipment: M.V.Achutha Sharath Chandra. N Nataraj.G.KDocument7 pagesConcept Design and Analysis of Multipurpose Farm Equipment: M.V.Achutha Sharath Chandra. N Nataraj.G.KIJIRAE- International Journal of Innovative Research in Advanced EngineeringNo ratings yet

- Microstructural and Mechanical Characteristic of Potential Ferro Laterite Soil As Sub-Base MaterialDocument7 pagesMicrostructural and Mechanical Characteristic of Potential Ferro Laterite Soil As Sub-Base MaterialIJIRAE- International Journal of Innovative Research in Advanced EngineeringNo ratings yet

- Enhanced ID3 Algorithm Based On The Weightage of The AttributeDocument7 pagesEnhanced ID3 Algorithm Based On The Weightage of The AttributeIJIRAE- International Journal of Innovative Research in Advanced EngineeringNo ratings yet

- Classification of Machine Learning AlgorithmsDocument6 pagesClassification of Machine Learning AlgorithmsIJIRAE- International Journal of Innovative Research in Advanced EngineeringNo ratings yet

- Steady State Analysis On HVLF-AC Transmission For Offshore Wind Power by Modern XLPE Submarine CableDocument5 pagesSteady State Analysis On HVLF-AC Transmission For Offshore Wind Power by Modern XLPE Submarine CableIJIRAE- International Journal of Innovative Research in Advanced EngineeringNo ratings yet

- Green Enterprise Computing - Approaches Towards A Greener ITDocument5 pagesGreen Enterprise Computing - Approaches Towards A Greener ITIJIRAE- International Journal of Innovative Research in Advanced EngineeringNo ratings yet

- Microstructural and Mechanical Characteristic of Potential Ferro Laterite Soil As Sub-Base MaterialDocument7 pagesMicrostructural and Mechanical Characteristic of Potential Ferro Laterite Soil As Sub-Base MaterialIJIRAE- International Journal of Innovative Research in Advanced EngineeringNo ratings yet

- Contractual Steps For Smooth Delivery of Infrastructure ProjectsDocument11 pagesContractual Steps For Smooth Delivery of Infrastructure ProjectsIJIRAE- International Journal of Innovative Research in Advanced EngineeringNo ratings yet

- 04 Fbae10090 PDFDocument8 pages04 Fbae10090 PDFIJIRAE- International Journal of Innovative Research in Advanced EngineeringNo ratings yet

- Improving The Performance of Mapping Based On Availability-Alert Algorithm Using Poisson Arrival For Heterogeneous Systems in Multicore SystemsDocument7 pagesImproving The Performance of Mapping Based On Availability-Alert Algorithm Using Poisson Arrival For Heterogeneous Systems in Multicore SystemsIJIRAE- International Journal of Innovative Research in Advanced EngineeringNo ratings yet

- 04 Fbae10090 PDFDocument8 pages04 Fbae10090 PDFIJIRAE- International Journal of Innovative Research in Advanced EngineeringNo ratings yet

- Steady State Analysis On HVLF-AC Transmission For Offshore Wind Power by Modern XLPE Submarine CableDocument5 pagesSteady State Analysis On HVLF-AC Transmission For Offshore Wind Power by Modern XLPE Submarine CableIJIRAE- International Journal of Innovative Research in Advanced EngineeringNo ratings yet

- 18 Dcae10082 PDFDocument6 pages18 Dcae10082 PDFIJIRAE- International Journal of Innovative Research in Advanced EngineeringNo ratings yet

- Concept Design and Analysis of Multipurpose Farm Equipment: M.V.Achutha Sharath Chandra. N Nataraj.G.KDocument7 pagesConcept Design and Analysis of Multipurpose Farm Equipment: M.V.Achutha Sharath Chandra. N Nataraj.G.KIJIRAE- International Journal of Innovative Research in Advanced EngineeringNo ratings yet

- Contractual Steps For Smooth Delivery of Infrastructure ProjectsDocument11 pagesContractual Steps For Smooth Delivery of Infrastructure ProjectsIJIRAE- International Journal of Innovative Research in Advanced EngineeringNo ratings yet

- Studies On Stabilized Mud Block As A Construction MaterialDocument6 pagesStudies On Stabilized Mud Block As A Construction MaterialIJIRAE- International Journal of Innovative Research in Advanced Engineering100% (1)

- Performance Study of Silicone Rubber Polymer Was Filled Fly Ash As Insulator Material On High Voltage Transmission TowerDocument5 pagesPerformance Study of Silicone Rubber Polymer Was Filled Fly Ash As Insulator Material On High Voltage Transmission TowerIJIRAE- International Journal of Innovative Research in Advanced EngineeringNo ratings yet

- Dynamically Partitioning Big Data Using Virtual MachineDocument4 pagesDynamically Partitioning Big Data Using Virtual MachineIJIRAE- International Journal of Innovative Research in Advanced EngineeringNo ratings yet

- Error Resiliency For H.264/Advance Video CodecDocument5 pagesError Resiliency For H.264/Advance Video CodecIJIRAE- International Journal of Innovative Research in Advanced EngineeringNo ratings yet

- Power Quality Improvement Using GUPFCDocument6 pagesPower Quality Improvement Using GUPFCIJIRAE- International Journal of Innovative Research in Advanced EngineeringNo ratings yet

- Barriers To Implement Lean Principles in The Indian Construction IndustryDocument6 pagesBarriers To Implement Lean Principles in The Indian Construction IndustryIJIRAE- International Journal of Innovative Research in Advanced EngineeringNo ratings yet

- Study of The Effect of Length and Inclination of Tube Settler On The Effluent QualityDocument5 pagesStudy of The Effect of Length and Inclination of Tube Settler On The Effluent QualityIJIRAE- International Journal of Innovative Research in Advanced EngineeringNo ratings yet

- 17 Dcae10110 PDFDocument8 pages17 Dcae10110 PDFIJIRAE- International Journal of Innovative Research in Advanced EngineeringNo ratings yet

- Approaches and Models of Professional Competence: Definition of Competence in The Training of Engineers in Latin AmericaDocument11 pagesApproaches and Models of Professional Competence: Definition of Competence in The Training of Engineers in Latin AmericaIJIRAE- International Journal of Innovative Research in Advanced Engineering100% (1)

- Relevance of Higher Education. How To Measure It? The Case of Masters of Engineering in PeruDocument12 pagesRelevance of Higher Education. How To Measure It? The Case of Masters of Engineering in PeruIJIRAE- International Journal of Innovative Research in Advanced EngineeringNo ratings yet

- 15 Dcae10108 PDFDocument10 pages15 Dcae10108 PDFIJIRAE- International Journal of Innovative Research in Advanced EngineeringNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 21.7 Coordinate Systems in Post-ProcessingDocument9 pages21.7 Coordinate Systems in Post-Processingjingyong123No ratings yet

- Shear Strength Reduction Analysis TutorialDocument12 pagesShear Strength Reduction Analysis TutorialMarcos MaNo ratings yet

- Effect of Reinforcement Corrosion On Bond StrengthDocument7 pagesEffect of Reinforcement Corrosion On Bond Strengthdebabrata duttaNo ratings yet

- Fatigue in The Shell of A Conveyor Drum: Ch. Affolter, G. Piskoty, R. Koller, M. Zgraggen, T.F. Ru TtiDocument15 pagesFatigue in The Shell of A Conveyor Drum: Ch. Affolter, G. Piskoty, R. Koller, M. Zgraggen, T.F. Ru TtiSamir KulkarniNo ratings yet

- BETONARME 1 - Ders8 - Eng PDFDocument21 pagesBETONARME 1 - Ders8 - Eng PDFSami AydnNo ratings yet

- Excavacion PDFDocument25 pagesExcavacion PDFLuis Alejandro Godoy OrdenesNo ratings yet

- ECADocument83 pagesECAdavidmn19No ratings yet

- Tunnel System Performance Based On Different Case Histories: S.A.MazekDocument7 pagesTunnel System Performance Based On Different Case Histories: S.A.MazekPablo Cesar TrejoNo ratings yet

- KANNUR UNIVERSITY BTech S8 CE. SyllabusDocument12 pagesKANNUR UNIVERSITY BTech S8 CE. SyllabusManu K MNo ratings yet

- Dynamics of Double Pendulum Model in COMSOLDocument40 pagesDynamics of Double Pendulum Model in COMSOLunagi greenNo ratings yet

- CE 452 Transportation Engineering Sessional II (Manual) : Department of Civil EngineeringDocument43 pagesCE 452 Transportation Engineering Sessional II (Manual) : Department of Civil EngineeringjulesNo ratings yet

- Prestressed Concrete Structures - AssignmentDocument14 pagesPrestressed Concrete Structures - AssignmentGanesh MistercoolNo ratings yet

- Slidingmesh GearboxDocument27 pagesSlidingmesh GearboxalebiegashityNo ratings yet

- Nasa CR-1457Document385 pagesNasa CR-1457mwd1323100% (1)

- B.E. Automobile Engg.Document63 pagesB.E. Automobile Engg.Vijil RajNo ratings yet

- 1 Mech 260 PresentationDocument22 pages1 Mech 260 Presentation777894292No ratings yet

- HW 1Document1 pageHW 1azizieh5701No ratings yet

- Stadium Raker Beam Analysis Using EC2Document13 pagesStadium Raker Beam Analysis Using EC2Bogdan Constantin-BabiiNo ratings yet

- Chapter 2. Blasting Effects and Their ControlDocument14 pagesChapter 2. Blasting Effects and Their ControlLuis Iparraguirre Tandaypan100% (1)

- SlopeDeflectionFiniteDifferenceDocument1 pageSlopeDeflectionFiniteDifferencevik03223No ratings yet

- Unit I DME I 13 09 2021Document68 pagesUnit I DME I 13 09 2021Vaibhav JainNo ratings yet

- Formalized Procedure For Quality Assessment of Cast-In-Place Shafts Using Sonic Pulse Echo MethodsDocument9 pagesFormalized Procedure For Quality Assessment of Cast-In-Place Shafts Using Sonic Pulse Echo MethodsBaraNo ratings yet

- Compressibility From CoreDocument18 pagesCompressibility From CoreginozkyNo ratings yet

- Engineering Materials 1 4th Edition Jones Solutions ManualDocument25 pagesEngineering Materials 1 4th Edition Jones Solutions ManualKennethRiosmqoz100% (48)

- Repairing and Maintaining Old Industrial Masonry ChimneysDocument13 pagesRepairing and Maintaining Old Industrial Masonry ChimneysmahakNo ratings yet

- Mechanical Properties of PolymersDocument16 pagesMechanical Properties of PolymersMalcolm EmileNo ratings yet

- Design of Steel Tension MembersDocument39 pagesDesign of Steel Tension MembersamruthaNo ratings yet

- RocSupport Tutorial ManualDocument81 pagesRocSupport Tutorial ManualAndrés Dinamarca GallardoNo ratings yet

- Allowable Nozzle Loads: Page 1 of 5Document5 pagesAllowable Nozzle Loads: Page 1 of 5ndrarlyNo ratings yet

- Structural and thermal analysis of gear technologyDocument10 pagesStructural and thermal analysis of gear technologyjay bhavsharNo ratings yet