Professional Documents

Culture Documents

The Formalized Risk Assessment For Excipients - Genial

Uploaded by

tito1628Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Formalized Risk Assessment For Excipients - Genial

Uploaded by

tito1628Copyright:

Available Formats

The Formalized Risk Assessment for Excipients

A Practical Approach

Frithjof Holtz, IPEC Europe Vice-Chair, Merck

Presentation Overview

Regulatory Background

EU FMD and Formalized Risk Assessment

Proposal for Risk Assessment Model

Summary

05. Feb. 2015

IPEC Europe Excipient Forum

Directive 2011/62/EU (EU Falsified Medicines

Directive)*

Art. 46 f

The holder of the manufacturing authorization shall ensure

that the excipients are suitable for use in medicinal products by

ascertaining the appropriate good manufacturing practice on

the basis of a formalized risk assessment. In this risk

assessment, the holder of the manufacturing authorization shall

take into account the source and intended use of the

excipients and previous incidents.

Art. 47

Guideline for formalized risk assessment for ascertaining of

appropriate GMP for excipients shall be adopted by the

Commission in accordance to Art 46 f.

*Directive 2011/62/EU of the European Parliament and of the Council of 8 June 2011 amending Directive

2001/83/EC on the Community code relating to medicinal products for human use, as regards the

prevention of the entry into the legal supply chain of falsified medicinal products

05. Feb. 2015

IPEC Europe Excipient Forum

Guideline on Risk Assessment for

Excipients

EU Commission published 06/02/2013

Guidelines on the formalized risk assessment for

ascertaining the appropriate good manufacturing practice for

excipients of medicinal products for human use

(SANCO/D/6/SF/mg/ddg1.d.6(2013)179263;

http://ec.europa.eu/health/files/gmp/201302_guidelines_excipients_cons.pdf )

Stakeholders are invited to comment on this draft by 30 April

2013 at the latest. Responses should be sent preferably by

e-mail to sanco-pharmaceuticals-d6@ec.europa.eu, or by

post to Unit SANCO/D/6, DM24 02/050, BE-1049 Brussels.

05. Feb. 2015

IPEC Europe Excipient Forum

Risk Assessment Guidelines for

Excipients

The draft guideline is split into three sections

Determination of Appropriate GMP based on type of

Excipient

Determination of Excipient Manufacturer's Risk Profile

Confirmation of Application of Appropriate GMP

Draft Guideline from EC (SANCO/D/6/SF/mg/ddg1.d.6(2013)179263)

05. Feb. 2015

IPEC Europe Excipient Forum

Determination of appropriate GMP based

on Type of Excipient

For each excipient used the Manufacturing Authorisation

Holder should identify the risks presented to the quality,

safety and function of each excipient from its source (be

that animal, mineral, vegetable, synthetic etc.) through to

incorporation in the finished pharmaceutical dose form.

Recommended that ICH Q9 principles are used to assess

the risks presented to the quality, safety and function of each

excipient and to classify the excipient in question as low

risk, medium risk or high risk.

Draft Guideline from EC (SANCO/D/6/SF/mg/ddg1.d.6(2013)179263)

05. Feb. 2015

IPEC Europe Excipient Forum

Determination of appropriate GMP based

on Type of Excipient

Areas for consideration would include:

TSE

Potential for viral contamination

Potential for microbiological or endotoxin/pyrogen

contamination

Potential, in general, for any impurity originating from the raw

materials (e.g. aflatoxins, pesticides) or generated as part of

the process and carried over (e.g. residual solvents and

catalysts)

Sterility Assurance (for excipients claimed to be sterile)

Use of dedicated equipment and or facilities

Environmental control and storage conditions

Draft Guideline from EC (SANCO/D/6/SF/mg/ddg1.d.6(2013)179263)

05. Feb. 2015

IPEC Europe Excipient Forum

Determination of appropriate GMP based

on Type of Excipient

Additionally with respect to the use and function of each

excipient the Manufacturing Authorisation Holder must also

consider:

The pharmaceutical form and use of the medicinal product

containing the excipient (e.g. ointment product, injection/infusion

etc.)

The function of the excipient in the formulation (e.g. lubricant in a

tablet product or preservative material in a liquid formulation etc.)

The quantity used of the excipient for the manufacture of

medicinal products

Daily patient intake of the excipient

Any known quality defects both globally and at a local company

level related to the excipient

Whether the excipient is a composite

Potential impact on the Critical Quality Attributes of the medicinal

Draft Guideline from EC (SANCO/D/6/SF/mg/ddg1.d.6(2013)179263)

product

05. Feb. 2015

IPEC Europe Excipient Forum

Determination of appropriate GMP based

on Type of Excipient

Having established and documented the risk profile

of the excipient the Manufacturing Authorisation

Holder should establish and document:

The elements of EU GMP that the company believes

are needed to be in place in order to control and maintain

the quality of the excipient, i.e. The Rules Governing

Medicinal Products in the European Union, Eudralex

Volume 4, Part I, Annex 1 and Annex 2, Part II etc.

Draft Guideline from EC (SANCO/D/6/SF/mg/ddg1.d.6(2013)179263)

05. Feb. 2015

IPEC Europe Excipient Forum

GMP for Excipients

Manufacturer and user of excipients do not need

to develop their own GMP for excipients!

Some examples of voluntary industry

standards:

IPEC-PQG GMP Guide, 2006

USP General Chapter <1078>

EXCiPACT

NSF/IPEC/ANSI 363-2014 NEW

The application of these voluntary standards

will in most cases be appropriate

05. Feb. 2015

IPEC Europe Excipient Forum

10

Industry Perspective

How to implement such a risk

assessment?

05. Feb. 2015

IPEC Europe Excipient Forum

11

Industry Approach to Risk Assessment

A substantial contribution to a risk assessment

will be needed from the excipient manufacturer

IPEC Europe and PQG are working together to

develop a risk assessment model for practical

application by the excipient user

The principles are supported by EFPIA

05. Feb. 2015

IPEC Europe Excipient Forum

12

Model proposed

Industry recognizes that ICH Q9 does not mandate one

specific Quality risk assessment (QRA) tool, a number of

tools are available... and allow application on all affected

processes (i.e. also GMP for excipients)

The industry proposed model is one approach describing the

principle areas which must be considered by applying any

tool to excipients GMP

The model fits with existing approaches to supplier risk

management such as the PQG Guide to Supply Chain Risk

Management*

*http://www.pqg.org/pharma/publications/risk-management-guide

05. Feb. 2015

IPEC Europe Excipient Forum

13

Example Excipient Risk Management

Process**

P. Rafidison, F. Holtz, S. Rnninger,

A Practical Approach of Implementing GMP for

Excipients, Pharm. Tech., September, 2014, 26-36

05. Feb. 2015

IPEC Europe Excipient Forum

14

Risk Management Process**

P. Rafidison, F. Holtz, S. Rnninger,

A Practical Approach of Implementing GMP for

Excipients, Pharm. Tech., September, 2014, 26-36

05. Feb. 2015

IPEC Europe Excipient Forum

15

Typical Quality Areas to Consider for the

Risk Assessment**

In the context of manufacturing of excipients, five specific

areas of potential risks should be considered, understood

and assessed when reviewing the excipient manufacturers

quality management system, as applicable.

Quality Management System (QMS)

Supply chain

Manufacturing of the excipient

Route of administration in the drug product

Function of the excipient

P. Rafidison, F. Holtz, S. Rnninger,

A Practical Approach of Implementing GMP for

Excipients, Pharm. Tech., September, 2014, 26-36

05. Feb. 2015

IPEC Europe Excipient Forum

16

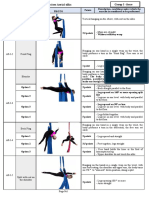

Hazards and Controls**

P. Rafidison, F. Holtz, S. Rnninger,

A Practical Approach of Implementing GMP for

Excipients, Pharm. Tech., September, 2014, 26-36

05. Feb. 2015

IPEC Europe Excipient Forum

17

Basic GMP Elements References**

P. Rafidison, F. Holtz, S. Rnninger,

05. Feb. 2015

A Practical Approach of Implementing GMP for

Excipients, Pharm. Tech., September, 2014, 26-36

IPEC Europe Excipient Forum

18

**Reference: Pharmaceutical Technology Europe

September 2014 PharmTech.com, pages 26 - 36

05. Feb. 2015

IPEC Europe Excipient Forum

19

Summary

The EU Falsified Medicines Directive requires to apply a risk

assessment to ascertain the appropriate GMP for

excipients

The new EU risk assessment guideline gives general

guidance

Industry developed a excipient risk assessment model to:

provide a simple means for the excipient user to source and

confidently use excipients in their end product

help the excipient user recognise and address the unique

hazards and risks associated with excipients due to them being

produced for a wide range of applications

encourage excipient manufacturers and users to work

collaboratively to mitigate risk

provide a excipient specific model that fits with ICH Q9

05. Feb. 2015

IPEC Europe Excipient Forum

20

Acknowledgements

Thanks to all who supported developing the model

Special thanks to:

Patricia Rafidison, Dow Corning

Stephan Rnninger, Amgen (Europe) GmbH

05. Feb. 2015

IPEC Europe Excipient Forum

21

Thank you

05. Feb. 2015

IPEC Europe Excipient Forum

22

You might also like

- Hygeia Pharmaceuticals Registration Form for HYTREX 250mg InjectionDocument133 pagesHygeia Pharmaceuticals Registration Form for HYTREX 250mg InjectionMohammed Zubair100% (1)

- Guide to Pharmaceutical Quality Control Lab InspectionsDocument16 pagesGuide to Pharmaceutical Quality Control Lab Inspectionssubrata1No ratings yet

- LAB 130 Stability Management Procedure SampleDocument3 pagesLAB 130 Stability Management Procedure SampleOdunlamiNo ratings yet

- Cleaning ValidationDocument17 pagesCleaning ValidationMollidain SandeepNo ratings yet

- Job Order CostingDocument6 pagesJob Order CostingJomar Teneza100% (1)

- Rings One Manual Ebook PDFDocument87 pagesRings One Manual Ebook PDFAarif Akbari67% (3)

- The Aerial Sling Manual: Prev Iew Prev IewDocument13 pagesThe Aerial Sling Manual: Prev Iew Prev Iewtito1628100% (1)

- The Aerial Sling Manual: Prev Iew Prev IewDocument13 pagesThe Aerial Sling Manual: Prev Iew Prev Iewtito1628100% (1)

- SAP Movement TypesDocument8 pagesSAP Movement TypesEdmond ThamNo ratings yet

- Aerial Silks Exercises Group I Force MovesDocument23 pagesAerial Silks Exercises Group I Force Movestito1628100% (6)

- Alberto Villoldo Book PDFDocument120 pagesAlberto Villoldo Book PDFtito1628100% (3)

- 2013-09-18 USP Stability 1 RegulationsDocument68 pages2013-09-18 USP Stability 1 RegulationssreekanthsharmaNo ratings yet

- 2 Process Validation QandA Version 4 (June 2011) - Adopted 18th PPWG Meeting PDFDocument4 pages2 Process Validation QandA Version 4 (June 2011) - Adopted 18th PPWG Meeting PDFVishal SomaniNo ratings yet

- Stage Gate Deliverables For Small ProjectsDocument4 pagesStage Gate Deliverables For Small ProjectsTrevor KanodeNo ratings yet

- FMEA - A Guide For Continuous ImprovementDocument36 pagesFMEA - A Guide For Continuous Improvementvipin_chaudhary100% (1)

- IIW/EWF Diploma in Welding QualificationDocument8 pagesIIW/EWF Diploma in Welding Qualificationreezman100% (1)

- ASEAN Guideline On Process Validation - Q& ADocument3 pagesASEAN Guideline On Process Validation - Q& AMuqeet KazmiNo ratings yet

- ICH Quality Guidelines: An Implementation GuideFrom EverandICH Quality Guidelines: An Implementation GuideAndrew TeasdaleNo ratings yet

- Good Manufacturing Practice GMP Guidelines Eudralex Volume 4Document12 pagesGood Manufacturing Practice GMP Guidelines Eudralex Volume 4Editor IJTSRDNo ratings yet

- Hold Time Study Ensures Clean Equipment QualityDocument11 pagesHold Time Study Ensures Clean Equipment QualityMarwa AhmedNo ratings yet

- Master Formula RecordDocument39 pagesMaster Formula RecordAbhijit kanavaje100% (1)

- OMCL Network Guideline for Evaluating and Reporting Test ResultsDocument6 pagesOMCL Network Guideline for Evaluating and Reporting Test ResultsParkhomyukNo ratings yet

- Active Pharmaceutical Ingredients Committee (APIC)Document12 pagesActive Pharmaceutical Ingredients Committee (APIC)Ngoc Sang Huynh100% (1)

- ASEAN Guideline Process OnDocument7 pagesASEAN Guideline Process OnVipin GuptaNo ratings yet

- GLP-GMP-GCP Quality System in Pharma R&DDocument29 pagesGLP-GMP-GCP Quality System in Pharma R&DmghaffarzadehNo ratings yet

- SOP On Calculation of YieldsDocument2 pagesSOP On Calculation of YieldsYousif100% (1)

- Aerial Yoga Manual 2018 Third Edition ADocument156 pagesAerial Yoga Manual 2018 Third Edition Atito1628100% (8)

- Aerial Yoga Manual 2018 Third Edition ADocument156 pagesAerial Yoga Manual 2018 Third Edition Atito1628100% (8)

- Stability Studies - An Overview: - What Is Stability? - Why It Is Required? - What Are The Guidelines?Document24 pagesStability Studies - An Overview: - What Is Stability? - Why It Is Required? - What Are The Guidelines?VidyaNo ratings yet

- Case Study RMWG-07 Defining Process Space1Document6 pagesCase Study RMWG-07 Defining Process Space1Yourecheck NhyoNo ratings yet

- ICH Topic Q 6 BDocument17 pagesICH Topic Q 6 BAprianaRohmanNo ratings yet

- Dmgt525 Materials ManagementDocument202 pagesDmgt525 Materials ManagementArasu RajaNo ratings yet

- Lynne EnsorDocument32 pagesLynne Ensortito1628No ratings yet

- Appendix 2 Compulsory Exercises Aerial Hoop 2018 EngDocument28 pagesAppendix 2 Compulsory Exercises Aerial Hoop 2018 Engtito1628100% (1)

- Railway Steel Grade PDFDocument4 pagesRailway Steel Grade PDFv4lkr3yNo ratings yet

- KELTEC Technolab CECOELDocument40 pagesKELTEC Technolab CECOELEber.CV100% (1)

- Analy Meth DevDocument51 pagesAnaly Meth DevkandasaniNo ratings yet

- Elsanhouty Pharma Hold Time Study NotesDocument6 pagesElsanhouty Pharma Hold Time Study NotesHuỳnh Ngọc SángNo ratings yet

- Microbiological Best Lab Practices & Environmental MonitoringDocument26 pagesMicrobiological Best Lab Practices & Environmental MonitoringNurul Hardiyanthi SadikinNo ratings yet

- Aphrin Pfs BPR p1 v-1Document13 pagesAphrin Pfs BPR p1 v-1ShagorShagorNo ratings yet

- Ippc Guide to Pest Risk Communication: A Guide for National Plant Protection Organizations on Communicating with Stakeholders about Pest RisksFrom EverandIppc Guide to Pest Risk Communication: A Guide for National Plant Protection Organizations on Communicating with Stakeholders about Pest RisksNo ratings yet

- Techno Drugs Raw Material Test ProcedureDocument9 pagesTechno Drugs Raw Material Test ProcedureMd. Moniruzzaman0% (1)

- 2 3 Cleaning Validation Nairobi May 2011Document56 pages2 3 Cleaning Validation Nairobi May 2011Prashant MengshettiNo ratings yet

- 1-5 Equipment QualificationDocument47 pages1-5 Equipment QualificationSandip NajanNo ratings yet

- Nonclinical Safety Assessment: A Guide to International Pharmaceutical RegulationsFrom EverandNonclinical Safety Assessment: A Guide to International Pharmaceutical RegulationsWilliam J. BrockNo ratings yet

- FDS StudyDocument8 pagesFDS StudyAnnisaIndahPNo ratings yet

- 3 2 - MicrobiologicalQualityControl 1Document37 pages3 2 - MicrobiologicalQualityControl 1Tong ChanNo ratings yet

- Asean Process Validation GuidelineDocument6 pagesAsean Process Validation GuidelineWilliam Chandra100% (1)

- Sop For Bio-BurdenDocument5 pagesSop For Bio-BurdenMusyoka UrbanusNo ratings yet

- Pharmaceutical Quality Management System (QMS) Questions and AnswersFrom EverandPharmaceutical Quality Management System (QMS) Questions and AnswersNo ratings yet

- Hold Time Stability StudiesDocument8 pagesHold Time Stability StudiesMartin RongenNo ratings yet

- Biocontamination Control for Pharmaceuticals and HealthcareFrom EverandBiocontamination Control for Pharmaceuticals and HealthcareRating: 5 out of 5 stars5/5 (1)

- An Inside Look at USP71Document22 pagesAn Inside Look at USP71Dante IulliNo ratings yet

- SOP of Stability Study - 2Document3 pagesSOP of Stability Study - 2YousifNo ratings yet

- Mos Galvanizing ProceduresDocument23 pagesMos Galvanizing ProceduresRajeswaran Rajachockalingam100% (1)

- Ongoing Stability Testing Requirements, Solutions and Potential PitfallsDocument3 pagesOngoing Stability Testing Requirements, Solutions and Potential PitfallssamxuNo ratings yet

- Containment of High-Potency Products in a GMP EnvironmentDocument3 pagesContainment of High-Potency Products in a GMP EnvironmentAnkush PandeyNo ratings yet

- QBD Application in Pharm Industry PDFDocument83 pagesQBD Application in Pharm Industry PDFSetyo Budiarto100% (1)

- Cracking Furnace Tube Metallurgy Part 1 ADocument21 pagesCracking Furnace Tube Metallurgy Part 1 AKaren Romero100% (1)

- EN AGILE P2A PRAC 2015 SamplePaper2 QuestionBk V1.1Document27 pagesEN AGILE P2A PRAC 2015 SamplePaper2 QuestionBk V1.1dinaticoNo ratings yet

- 01-How-to-identify-CQA-CPP-CMA-Final Imp PDFDocument40 pages01-How-to-identify-CQA-CPP-CMA-Final Imp PDFmarwa100% (1)

- Current Good Manufacturing Practices (cGMP) for Pharmaceutical ProductsFrom EverandCurrent Good Manufacturing Practices (cGMP) for Pharmaceutical ProductsNo ratings yet

- Finished Pharmaceutical Product Specifications: Rutendo KuwanaDocument17 pagesFinished Pharmaceutical Product Specifications: Rutendo KuwanaStuNo ratings yet

- In-Use Stability TestingDocument3 pagesIn-Use Stability TestingIsabelLópezNo ratings yet

- Cleaning Validation AlconoxDocument8 pagesCleaning Validation AlconoxEDGARNo ratings yet

- Hold Time Protocol FinalDocument20 pagesHold Time Protocol FinalSolomon0% (1)

- Justification of LimitsDocument6 pagesJustification of LimitsRulli SulaemanNo ratings yet

- A Guide To Blend Uniformity: Overview of Blending Process and EquipmentDocument6 pagesA Guide To Blend Uniformity: Overview of Blending Process and Equipmentmailtorubal2573100% (1)

- Blend UniformityDocument10 pagesBlend Uniformityitung23No ratings yet

- Risk Assessment Template 1.2 PDFDocument5 pagesRisk Assessment Template 1.2 PDFGanesh KashinathNo ratings yet

- Amlodipine and Celecoxib Tablets PDFDocument38 pagesAmlodipine and Celecoxib Tablets PDFNarongchai PongpanNo ratings yet

- Procedure for release of Drug Substance and ProductsDocument4 pagesProcedure for release of Drug Substance and Productsom shankar JhaNo ratings yet

- 2.Pv Semisolid FDADocument37 pages2.Pv Semisolid FDARahayu Maulida RNo ratings yet

- Photostability Testing Guidelines Impact on Generic DrugsDocument11 pagesPhotostability Testing Guidelines Impact on Generic DrugsHaroon RasheedNo ratings yet

- Meclizine HCLDocument10 pagesMeclizine HCLChEng_No ratings yet

- ICH Guidelines IndexDocument5 pagesICH Guidelines Indexyashpandya01No ratings yet

- Dissolution MethodsDocument59 pagesDissolution MethodsShiraz KhanNo ratings yet

- Prosses Validation Protocol For EnrofolxacineDocument22 pagesProsses Validation Protocol For Enrofolxacineمحمد عطاNo ratings yet

- 2 6 Sampling WHO GuidelinesDocument22 pages2 6 Sampling WHO GuidelinesPepeArandaNo ratings yet

- Book For PharmaceuticalsDocument63 pagesBook For PharmaceuticalsPentesh NingaramainaNo ratings yet

- Handouts - GMP Workshop 27-28 Feb 2014Document76 pagesHandouts - GMP Workshop 27-28 Feb 2014tito1628No ratings yet

- HACCP en Drogas AnticancerDocument7 pagesHACCP en Drogas Anticancertito1628No ratings yet

- Tutorial AnillasDocument40 pagesTutorial Anillastito1628No ratings yet

- Skinfold Sume Referencee Valuese For Tope AthletesDocument7 pagesSkinfold Sume Referencee Valuese For Tope Athletestito1628No ratings yet

- Analisis de RiesgoDocument1 pageAnalisis de Riesgotito1628No ratings yet

- Celex 52015XC0321 (02) enDocument4 pagesCelex 52015XC0321 (02) entito1628No ratings yet

- Shamal 1206Document134 pagesShamal 1206tito1628No ratings yet

- FDA Guidance - Submission of CMC Info For RDDPs and MAbsDocument30 pagesFDA Guidance - Submission of CMC Info For RDDPs and MAbsNelson Alejandro FierroNo ratings yet

- Workshop 2 Spanish FDA RequirementsDocument29 pagesWorkshop 2 Spanish FDA Requirementstito1628No ratings yet

- Business System ReviewDocument12 pagesBusiness System Reviewtito1628No ratings yet

- A Historical View of Human Resource ManagementDocument12 pagesA Historical View of Human Resource Managementtito1628No ratings yet

- CCP - en European CTD PDFDocument7 pagesCCP - en European CTD PDFtito1628No ratings yet

- EffectivenessofTrainingArthur Etal PDFDocument12 pagesEffectivenessofTrainingArthur Etal PDFIrene KangNo ratings yet

- S3 Guo Sherry Temperature ExcursionDocument51 pagesS3 Guo Sherry Temperature Excursiondian fitri anandaNo ratings yet

- CCP - en European CTD PDFDocument7 pagesCCP - en European CTD PDFtito1628No ratings yet

- Online OgilvieDocument7 pagesOnline Ogilvietito1628No ratings yet

- Optimized Interval Training ProtocolDocument6 pagesOptimized Interval Training Protocoltito1628No ratings yet

- Logistics in The System Life CycleDocument15 pagesLogistics in The System Life CycleBianca Asis100% (1)

- Slide GatesDocument4 pagesSlide GatesBoy Alfredo PangaribuanNo ratings yet

- Metal Composition of 1 Rs CoinDocument15 pagesMetal Composition of 1 Rs Coinrupali parmarNo ratings yet

- How Mine Milling Section ReportDocument16 pagesHow Mine Milling Section ReporttkubvosNo ratings yet

- Yd-134 TDSDocument3 pagesYd-134 TDSMOHAMEDNo ratings yet

- Eee-Viii-Industrial Management - Electrical Estimation and e (06ee81) - NotesDocument123 pagesEee-Viii-Industrial Management - Electrical Estimation and e (06ee81) - NotesDilip TheLipNo ratings yet

- Winter Project ReportDocument23 pagesWinter Project ReportSARAVANANNo ratings yet

- V2 enDocument5 pagesV2 endharmeshkher7265No ratings yet

- Chapter 16 - Lean Systems Answers To Questions, Problems, and Case Problems Answers To QuestionsDocument13 pagesChapter 16 - Lean Systems Answers To Questions, Problems, and Case Problems Answers To QuestionsomkarNo ratings yet

- DOZC OL22420 en PDFDocument4 pagesDOZC OL22420 en PDFปรีชาลิ่มเศรษฐกานต์No ratings yet

- SHAW 101.2 EPD EcoWorxCommercialCarpetTile 29november2012Document14 pagesSHAW 101.2 EPD EcoWorxCommercialCarpetTile 29november2012ignaciovillanuevaNo ratings yet

- Pt. Duta Utama Tehnik Abadi: Daily ReportDocument6 pagesPt. Duta Utama Tehnik Abadi: Daily ReportMa'rifatullahNo ratings yet

- Oga 2019 Updated Participating Companies 16062019Document61 pagesOga 2019 Updated Participating Companies 16062019krishnakumarsistNo ratings yet

- Production and Operations ManagementDocument24 pagesProduction and Operations ManagementEmjhaeMharieSherreidaraNo ratings yet

- ISSUANCE AND ACCEPTANCE OF AIRCRAFT DESIGN CERTIFICATESDocument9 pagesISSUANCE AND ACCEPTANCE OF AIRCRAFT DESIGN CERTIFICATESSahil KhanNo ratings yet

- Lean Software Development - A Tutorial PDFDocument7 pagesLean Software Development - A Tutorial PDFwahyuthp43100% (1)

- MRP ErpDocument32 pagesMRP ErpburhanNo ratings yet

- Alkhrdaji - ACI 562 - Design Strength LimintsDocument26 pagesAlkhrdaji - ACI 562 - Design Strength Limintseros100% (1)

- Ch-10 Grinding and FinishingDocument121 pagesCh-10 Grinding and FinishingMANJEET KUMARNo ratings yet

- Week 7 Production and Cost in The Short Run-1Document25 pagesWeek 7 Production and Cost in The Short Run-1emeraldNo ratings yet