Professional Documents

Culture Documents

BETE TF Metric

Uploaded by

ajo2402Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BETE TF Metric

Uploaded by

ajo2402Copyright:

Available Formats

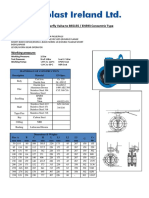

FULL CONE

TF

Wide Range of Flows and Angles

DESIGN FEATURES

SPRAY CHARACTERISTICS

The original spiral nozzle invented by

Wide range of flow rates and spray angles

BETE and continuously improved!

Fine atomization

High energy efficiency

Spray patterns: Full Cone.

One-piece/no internal parts

For Hollow Cone, see page 45

Clog-resistant performance

Spray angles: 50 to 180

High discharge velocity

Flow rates: 2.26 to 10700 l/min

Male connection standard; female

(Higher flow rates available)

connection available by special order

Available with FM approval: N series (page 106), 1/4" TF8 NN, FCN in brass,

1/2" TF24-150 in multiple materials

60, 90, 120 Metal

150, 170

90, 120

Full Cone 60 (NN)

Full Cone 90 (FCN)

Full Cone 150/170

Dimensions are approximate. Check with BETE for critical dimension applications

TF Full Cone Flow Rates and Dimensions

Full Cone, 60 (NN), 90 (FCN or FFCN), 120 (FC or FFC), 150 and 170 Spray Angles, 1/8" to 4" Pipe Sizes, BSP or NPT

PTFE not

recommended

TO ORDER: specify pipe size, connection type, nozzle

number, spray angle, and material.

Male

Available

Pipe Nozzle

Spray Angles

K

Size Number 60 90 120 150170 Factor

0.5

bar

0.7

bar

LITERS PER MINUTE @ BAR above red line

1

2

3

5

bar

bar

bar

bar

Metal Only

above

green line

10

bar

20

bar

Approx. (mm)

Wt. (g)

Free Dim. (mm) for 60 90

Orif. Pass Metal Only*

120

Dia. Dia. A B C Metal Plas.

1/8

TF6

TF8

60 90 120 150 170 3.19

60 90 120 150 170 5.93

2.26

4.19

2.67

4.96

3.19

5.93

4.5

8.4

5.5

10.3

7.1

13.2

10.1

18.7

14.3

26.5

2.38

3.18

2.38 42.9 14.3 42.9

3.18 42.9 14.3 55.6

28

1/4

TF6

TF8

TF10

60 90 120 150 170 3.19

60 90 120 150 170 5.93

60 90 120 150 170 9.12

2.26

4.19

6.45

2.67

4.96

7.63

3.19

5.93

9.12

4.5

8.4

12.9

5.5

10.3

15.8

7.1

13.2

20.4

10.1

18.7

28.8

14.3

26.5

40.8

2.38

3.18

3.97

2.38 47.6 14.3 47.6

3.18 47.6 14.3 60.3

3.18 47.6 14.3 60.3

35

3/8

TF6

TF8

TF10

TF12

TF14

TF16

TF20

60

60

60

60

60

60

60

3.19

5.93

9.12

13.7

18.5

24.2

37.6

2.26

4.19

6.45

9.67

13.1

17.1

26.6

2.67

4.96

7.63

11.4

15.4

20.2

31.5

3.19

5.93

9.12

13.7

18.5

24.2

37.6

4.5

8.4

12.9

19.3

26.1

34.2

53.2

5.5

10.3

15.8

23.7

32.0

41.8

65.1

7.1

13.2

20.4

30.6

41.3

54.0

84.1

10.1

18.7

28.8

43.2

58.4

76.4

119

14.3

26.5

40.8

61.1

82.6

108

168

2.38

3.18

3.97

4.76

5.56

6.35

7.94

2.38

3.18

3.18

3.18 47.6 17.5 60.5 46

3.18

3.18

3.18

1/2

TF24

TF28

60 90 120 150 170 54.9

60 90 120 150 170 75.2

38.8

53.2

46.0

62.9

54.9

75.2

77.7

106

95.1

130

123

168

174

238

246

336

9.53

11.1

4.76 63.5 22.2 77.7 85

4.76

14

3/4

TF32

60 90 120 150 170 95.7

67.7

80.1

95.7

135

166

214

303

428

12.7

4.76 69.9 28.6 88.9 156

25

TF40

TF48

60 90 120 150 170 153

60 90 120 150 170 217

108

153

128

181

153

216

216

306

264

375

341

484

483

685

683

968

15.9

19.1

6.35 92.1 34.9 111 241

6.35

71

1 1/2

TF56

TF64

TF72

60 90 120 150 170 294

60 90 120 150 170 385

60 90 120 150 170 438

208

272

309

246

322

366

294

385

438

416

545

619

509

667

758

657

861

978

930

1220

1380

1320

1720

1960

22.2

25.4

28.6

7.94

7.94

7.94

111 50.8 137

111 50.8 137 624

111 50.8 143

120

TF88

TF96 1

60 90 120 150 170 638

60 90 120 150 170 806

451

570

534

674

638

806

902

1140

1110

1400

1430

1800

2020

2550

2850

3600

34.9

38.1

11.1

11.1

143 63.5 175 1300 227

176 63.5 178 1530 255

TF112 1 60 90 120150 170 1170

TF128 1 60 90 120150 170 1550

825

1090

976

1290

1170

1550

1650

2190

2020

2680

2610

3460

3690

4891

5220

6920

44.5

50.8

14.3

14.3

219 88.9 235 3230 567

TF160 1 60 90 120

1690

2000

2390

3380

4140

5350

7570

10700

63.5

15.9

257 114

90 120

90 120

90 120

90 120 150 170

90 120 150 170

90 120 150 170

90 120 150 170

2390

Flow Rate ( l min ) = K bar *Dimensions are for bar stock, cast sizes may vary. **60 nozzles slightly longer; call BETE for details

Standard Materials: Brass, 316 Stainless Steel, PVC, Polypropylene, and PTFE

Three turn nozzles

(Poly. not available for TF6 thru TF10).

Spray angle performance varies with pressure. Contact BETE for specific data on critical applications.

20

www.BETE.com

4790 765

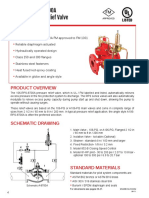

HOLLOW CONE

TF

Wide Range of Flows and Angles

DESIGN FEATURES

The original spiral nozzle invented by

BETE and continuously improved!

High energy efficiency

One-piece/no internal parts

Clog-resistant performance

High discharge velocity

Male connection standard; female

connection available by special order

Hollow Cone 50 (N)

SPRAY CHARACTERISTICS

Wide range of flow rates and spray angles

Fine atomization

Spray patterns: Hollow Cone

For Full Cone, see page 20

Spray angles: 50 to 180

Flow rates: 2.26 to 10700 l/min

(Higher flow rates available)

Hollow Cone 120 (W)

180 Metal

Hollow Cone 180 (XW)

50, 60, 90, 120

180

Dimensions are approximate. Check with BETE for critical dimension applications

TF Hollow Cone Flow Rates and Dimensions

Hollow Cone, 50 (N), 60 (V), 90 (M), 120 (W), and 180 (XW) Spray Angles, 1/4" to 4" Pipe Sizes, BSP or NPT

Available

Spray

Male

Angles

K

Pipe Nozzle

Size Number 50 60 90 120 180 Factor

TF6

PTFE not

recommended

above red line

LITERS PER MINUTE @ BAR

Metal Only

above

green line

Approx. (mm)

Free Dim. (mm) for

Wt. (g)

Orif. Pass. Metal Only*

180

Dia. Dia. A

B

C Metal Plas.

0.5

bar

0.7

bar

1

bar

2

bar

3

bar

5

bar

10

bar

20

bar

3.19

5.93

9.12

2.26

4.19

6.45

2.67

4.96

7.63

3.19

5.93

9.12

4.5

8.4

12.9

5.5

10.3

15.8

7.1

13.2

20.4

10.1

18.7

28.8

14.3

26.5

40.8

2.38

3.18

3.97

2.38

3.18

3.18

50 60 90 120 180

13.7

18.5

9.7

13.1

11.4

15.4

13.7

18.5

19.3

26.1

23.7

32.0

30.6

41.3

43.2

58.4

61.1

82.6

4.76

5.56

3.18

3.18

TF16

TF20

50 60 90 120 180

24.2

17.1

20.2

24.2

34.2

41.8

54.0

76.4

108

6.35

3.18

50 60 90 120 180

37.6

26.6

31.5

37.6

53.2

65.1

84.1

119

168

7.94

3.18

1/2

TF24

TF28

50 60 90 120 180

50 60 90 120 180

54.9

75.2

38.8

53.2

46.0

62.9

54.9

75.2

77.7

106

95.1

130

123

168

174

238

246

336

9.53

11.1

4.76

4.76

3/4

TF32

50 60 90 120 180

95.7

67.7

80.1

95.7

135

166

214

303

428

12.7

4.76

69.9 28.6 76.2

85

28

TF40

TF48

60 90 120 180

60 90 120 180

153

217

108

153

128

181

153

216

216

306

264

375

341

484

483

685

683

968

15.9

19.1

6.35

6.35

92.1 34.9 92.2 425

85

TF56

TF64

60 90 120 180

60 90 120 180

294

385

208

272

246

322

294

385

416

545

509

667

657

861

930

1220

1320

1720

22.2

25.4

7.94

7.94

111

170

TF72

60 90 120 180

438

309

366

438

619

758

978

1380

1960

28.6

7.94

TF88

TF96

60 90 120 180

60 90 120 180

638

806

451

570

534

674

638

806

902

1140

1110

1400

1430

1800

2020

2550

2850

3600

34.9

38.1

11.1

11.1

143 63.5 127 1300 227

176 63.5 127 1530 255

TF112

TF128

60 90 120

60 90 120

1170

1550

825

1090

976

1290

1170

1550

1650

2190

2020

2680

2610

3460

3690

4891

5220

6920

44.5

50.8

14.3

14.3

219 88.9

TF160

60 90 120

2390

1690

2000

2390

3380

4140

5350

7570

10700

63.5

15.9

257

1 1/2

Flow Rate (

min

) = K bar *Dimensions are for bar stock, cast sizes may vary.

42.9 14.3

47.6 14.3 47.6

47.6 14.3 47.6

35

21

47.6 17.51 47.6

50

21

63.5 22.2 60.5

85

25

50.8 111

851

114

25.4 mm for 180 Large plastic Spirals (above 2") should not be operated above 1 bar

Standard Materials: Brass, 316 Stainless Steel, PVC, Polypropylene, and PTFE (Poly. not available for TF6 - TF10)

TF8 and TF 24 150 are Factory Mutual approved. Contact BETE for more information.

CALL 413-772-0846

TF14

3/8

TF8

TF10

Call for the name of your nearest BETE representative.

TF12

50 60 90 120

50 60 90 120 180

50 60 90 120 180

50 60 90 120 180

1/4

Spray angle performance varies with pressure. Contact BETE for specific data on critical applications.

www.BETE.com

45

You might also like

- BETE TF Fullcone-MetricDocument1 pageBETE TF Fullcone-MetricFrancisco Ignacio Joselin CruzNo ratings yet

- Ficha Tecnica Boquillas AspersionDocument1 pageFicha Tecnica Boquillas AspersionCesar Muñoz OssesNo ratings yet

- BETE - TF-metric SPIRAL FULL CONEDocument2 pagesBETE - TF-metric SPIRAL FULL CONEOnie Hammamz Oyl100% (1)

- Spray Nozzle (BETE - TF)Document2 pagesSpray Nozzle (BETE - TF)nazmul hasanNo ratings yet

- Type 15082, Type 15083 - Ball Valve Full BoreDocument1 pageType 15082, Type 15083 - Ball Valve Full BoreJay Van BuurninkNo ratings yet

- DEUTSCH DT Series Backshells: Backshell Solutions For DT ApplicationsDocument2 pagesDEUTSCH DT Series Backshells: Backshell Solutions For DT ApplicationsSamir FerreiraNo ratings yet

- F FF F: Extra-Wide AngleDocument2 pagesF FF F: Extra-Wide Anglevenis padilla chanNo ratings yet

- Rotork ActuatorsDocument10 pagesRotork Actuatorsthavaselvan80% (5)

- Pressfit 316 Stainless Steel Pipe SystemDocument12 pagesPressfit 316 Stainless Steel Pipe SystemFaull JackmanNo ratings yet

- FirePumpSystem VetnuriModelPFV ProductBrochureDocument2 pagesFirePumpSystem VetnuriModelPFV ProductBrochureGonzalo CastilloNo ratings yet

- Mangueras Flexibles SwagelokDocument28 pagesMangueras Flexibles SwagelokCristian OtivoNo ratings yet

- Especificaciones Tecnicas Codo Hdpe FM Georg FischerDocument1 pageEspecificaciones Tecnicas Codo Hdpe FM Georg FischerRene CALLIRI MAQUERANo ratings yet

- King 7750 Series FlowmeterDocument2 pagesKing 7750 Series Flowmeterehab8320014413No ratings yet

- Flow MeterDocument6 pagesFlow MeterYvoSteentjes100% (1)

- 09 - Ball ValvesDocument10 pages09 - Ball ValvesacildeNo ratings yet

- NF Flat Fan Pattern NozzleDocument1 pageNF Flat Fan Pattern NozzlehendrobamaNo ratings yet

- Bete EztfwlwtDocument2 pagesBete EztfwlwtSheng Chieh ChenNo ratings yet

- Steel Bend SizeDocument3 pagesSteel Bend SizeSaifur RahmanNo ratings yet

- Sae FlangesDocument11 pagesSae FlangesAriel BlankenshipNo ratings yet

- VZBA-4F-L-ASY-PSI-US - 3-Way Ball Valve Assembly VZBA-4F-L and VZBA-4F-TDocument2 pagesVZBA-4F-L-ASY-PSI-US - 3-Way Ball Valve Assembly VZBA-4F-L and VZBA-4F-TGigin PlusNo ratings yet

- NOVA Servo CatalogueDocument7 pagesNOVA Servo CatalogueDip Narayan BiswasNo ratings yet

- Flange Dimensions and Pressure Ratings ChartDocument24 pagesFlange Dimensions and Pressure Ratings Chartgateauxboy100% (2)

- Oddesse Po Mo10 enDocument5 pagesOddesse Po Mo10 enjmeleNo ratings yet

- Lloyds PipesDocument12 pagesLloyds Pipeskiran_16_124477No ratings yet

- Spur Gears 9: Series 101Document52 pagesSpur Gears 9: Series 101Aiam PandianNo ratings yet

- All-Plastic Variable Area Flowmeters GuideDocument4 pagesAll-Plastic Variable Area Flowmeters GuideRoger SanderNo ratings yet

- Mar Win SteamDocument33 pagesMar Win SteamChristopher RequintoNo ratings yet

- Butterfly Valves EgeplastDocument4 pagesButterfly Valves EgeplastdsyashankaNo ratings yet

- Storagetech 100 Pressure Vacuum Relief Valve SMDocument4 pagesStoragetech 100 Pressure Vacuum Relief Valve SMkhaled SAYEDNo ratings yet

- PVC-PP-PVDF Swing Check Valve SpecificationsDocument4 pagesPVC-PP-PVDF Swing Check Valve SpecificationsthangNo ratings yet

- WIKA Pressure GaugeDocument4 pagesWIKA Pressure Gaugepaulo maximoNo ratings yet

- Bellows Sealed GATE VALVES - 800 - Bolted Bonnet - SW PDFDocument1 pageBellows Sealed GATE VALVES - 800 - Bolted Bonnet - SW PDFkhasim15No ratings yet

- TS Apollo 50Document8 pagesTS Apollo 50Carlos GonzalezNo ratings yet

- Bete NFDocument1 pageBete NFRavi Chaitanya VelamarthyNo ratings yet

- Orifice Plate - Multi-Holes: DatasheetDocument10 pagesOrifice Plate - Multi-Holes: DatasheetMarcelo PellizzaNo ratings yet

- Power Generation Boiler Tubes GuideDocument12 pagesPower Generation Boiler Tubes GuidewalitedisonNo ratings yet

- Drill DataDocument5 pagesDrill DataDOBJANNo ratings yet

- Process Nozzles: Propane Super HeatingDocument3 pagesProcess Nozzles: Propane Super HeatingDries VandezandeNo ratings yet

- SWG Data Sheet (TEFLEX)Document7 pagesSWG Data Sheet (TEFLEX)Brion Bara IndonesiaNo ratings yet

- Carbon Steel Fittings Dimensions and SpecsDocument64 pagesCarbon Steel Fittings Dimensions and SpecsfitiranNo ratings yet

- Swagelok HoseDocument28 pagesSwagelok HoseRashi Akmal0% (1)

- High Pressure Needle ValvesDocument11 pagesHigh Pressure Needle ValvesNilesh MistryNo ratings yet

- Ball Two Piece Steel Globe ValveDocument2 pagesBall Two Piece Steel Globe ValveAlicia MartinezNo ratings yet

- IE4 Super Premium Efficiency Motor SpecsDocument6 pagesIE4 Super Premium Efficiency Motor SpecsEdi CarnediNo ratings yet

- 3E AND 110H/210H SERIES Canned Motor Pumps: R S P W C I MDocument16 pages3E AND 110H/210H SERIES Canned Motor Pumps: R S P W C I Mari_prasNo ratings yet

- ANSI B16.5 FlangesDocument24 pagesANSI B16.5 FlangesRaymundo AlarconNo ratings yet

- Manual For Pneumatic Automatic Feeder SpecificationDocument18 pagesManual For Pneumatic Automatic Feeder SpecificationhaisamnagyNo ratings yet

- Rexroth CDT4 NFPA Heavy Duty (3000 PSI) Largr Bore CylindersDocument24 pagesRexroth CDT4 NFPA Heavy Duty (3000 PSI) Largr Bore CylindersDarioNo ratings yet

- Goulds AF: Axial Flow PumpsDocument11 pagesGoulds AF: Axial Flow PumpsKarthick VenkateshNo ratings yet

- Bola CriogenicaDocument1 pageBola CriogenicaagrovadoNo ratings yet

- Pole RssDocument2 pagesPole Rssgenial72No ratings yet

- Product Specifications for FOXTOP Control Valve System PSS 4-24A1 FDocument0 pagesProduct Specifications for FOXTOP Control Valve System PSS 4-24A1 Fcico_ctNo ratings yet

- ANSI ASME B16.5 forged flange dimensionsDocument8 pagesANSI ASME B16.5 forged flange dimensionsEdgar PereiraNo ratings yet

- Tube Axial FanDocument11 pagesTube Axial FanMiroslav AleksicNo ratings yet

- Válvula DurcoDocument12 pagesVálvula DurcoJames Henrry López EspejoNo ratings yet

- AMRI ISORIA Broad Market Type Series Booklet DataDocument12 pagesAMRI ISORIA Broad Market Type Series Booklet Datarudiskw456No ratings yet

- Model 106-RPS-8700A UL / FM Pressure Relief Valve: Key FeaturesDocument3 pagesModel 106-RPS-8700A UL / FM Pressure Relief Valve: Key FeaturesCandela BarbisanNo ratings yet

- Input Parameter Valve and Flange: Fluid Density (KG/M) Insulation Density (KG/M)Document15 pagesInput Parameter Valve and Flange: Fluid Density (KG/M) Insulation Density (KG/M)raobabar21No ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Aquaculture Farming CageDocument2 pagesAquaculture Farming Cageajo2402No ratings yet

- Buoyancy CalculationDocument9 pagesBuoyancy CalculationShiv Raj AnanthNo ratings yet

- Self-Priming Centrifugal Pumps: Operating RangeDocument20 pagesSelf-Priming Centrifugal Pumps: Operating Rangeajo2402No ratings yet

- The PalmGHG Calculator - The RSPO Greenhouse Gas Calculator For Oil Palm Products, Beta-version-English PDFDocument56 pagesThe PalmGHG Calculator - The RSPO Greenhouse Gas Calculator For Oil Palm Products, Beta-version-English PDFajo2402No ratings yet

- GR PumpDocument8 pagesGR Pumpajo2402No ratings yet

- PWC High Frequency Trading Dark Pools PDFDocument12 pagesPWC High Frequency Trading Dark Pools PDFajo2402No ratings yet

- Broch EquipmentDocument8 pagesBroch Equipmentajo2402No ratings yet

- Act 341 (Fire Service Act) PDFDocument47 pagesAct 341 (Fire Service Act) PDFhideakizawaNo ratings yet

- 0186 - Rubine SF Product BrochureDocument16 pages0186 - Rubine SF Product Brochureajo2402No ratings yet

- Black & Decker The Complete Guide To KitchensDocument145 pagesBlack & Decker The Complete Guide To KitchensRaymundo Gomez100% (17)

- Manufacturing LOTO ProceduresDocument90 pagesManufacturing LOTO Proceduresajo2402No ratings yet

- Home LivingDocument20 pagesHome Livingajo2402No ratings yet

- Series 50 52 Delval Butterfly ValvesDocument4 pagesSeries 50 52 Delval Butterfly Valvesajo2402No ratings yet

- Broch EquipmentDocument8 pagesBroch Equipmentajo2402No ratings yet

- Manufacturing LOTO ProceduresDocument90 pagesManufacturing LOTO Proceduresajo2402No ratings yet

- TT Oil Flooded Rotary Air CompressorDocument2 pagesTT Oil Flooded Rotary Air Compressorajo2402No ratings yet

- Bide M D Combimass Ga M en r06 Datenblatt Combimass Ga MDocument3 pagesBide M D Combimass Ga M en r06 Datenblatt Combimass Ga Majo2402No ratings yet

- Roadmap To PuncakalamDocument1 pageRoadmap To PuncakalamMUHAMMAD NAQIUDDIN100% (2)

- CP5WN R1 1Document2 pagesCP5WN R1 1ajo2402No ratings yet

- Aerospace Honeycomb NomexDocument1 pageAerospace Honeycomb Nomexajo2402No ratings yet

- Basic Data On Biogas - Sweden 2007Document7 pagesBasic Data On Biogas - Sweden 2007ajo2402No ratings yet

- 10.13 Schnell 20slidesDocument20 pages10.13 Schnell 20slidesajo2402No ratings yet

- RUMAH SEWADocument7 pagesRUMAH SEWAajo2402No ratings yet

- PART V-Examination of Competent PersonDocument2 pagesPART V-Examination of Competent Personajo2402No ratings yet

- Rumah Solar Front Isometric ViewDocument1 pageRumah Solar Front Isometric Viewajo2402No ratings yet

- Roadmap To PuncakalamDocument1 pageRoadmap To PuncakalamMUHAMMAD NAQIUDDIN100% (2)

- Stream CatalogueDocument10 pagesStream Catalogueajo2402No ratings yet

- IBBK Int Biogas Training 2014Document2 pagesIBBK Int Biogas Training 2014ajo2402No ratings yet

- BAU 012 07 FD BAUER Helix e PreviewDocument4 pagesBAU 012 07 FD BAUER Helix e Previewajo2402No ratings yet

- Lizmontagens Group ProfileDocument5 pagesLizmontagens Group ProfileRui Carlos Delgado Lopes AlvesNo ratings yet

- Chemical Handling Glove GuideDocument32 pagesChemical Handling Glove GuideLinhNguyeNo ratings yet

- Act 3 ConclusionDocument13 pagesAct 3 ConclusionVon A. DamirezNo ratings yet

- Nickyta Tanryan - 2106729915 - UtsgamtekDocument2 pagesNickyta Tanryan - 2106729915 - UtsgamtekNickyta TanryanNo ratings yet

- ECE OLED TechnologyDocument22 pagesECE OLED TechnologyRavvy ChhimpaNo ratings yet

- Effect of Rolling Conditions On Ductile Fracture During PiercingDocument6 pagesEffect of Rolling Conditions On Ductile Fracture During PiercingJJNo ratings yet

- Hebel Cored Block DownloadDocument2 pagesHebel Cored Block DownloadCarlos BastiasNo ratings yet

- Cement Technology: ReclaimerDocument17 pagesCement Technology: ReclaimerYana Damayanti100% (1)

- IIW-ANB Refresher Course: Gas Welding, Brazing, Soldering and Cutting ProcessesDocument81 pagesIIW-ANB Refresher Course: Gas Welding, Brazing, Soldering and Cutting ProcessesAsad Bin Ala QatariNo ratings yet

- History of Cryogenics - A Cryo Central Resource From The CSA PDFDocument7 pagesHistory of Cryogenics - A Cryo Central Resource From The CSA PDFJaque BauerNo ratings yet

- Oil Well Cementing Instruments Data Acquisition and Control SystemDocument2 pagesOil Well Cementing Instruments Data Acquisition and Control Systemसागर फुकटNo ratings yet

- Wax Glue2Document6 pagesWax Glue2Gamal FouadNo ratings yet

- Optimization and Development of Contact Wire For High Speed LinesDocument9 pagesOptimization and Development of Contact Wire For High Speed Linesdineshsoni29685No ratings yet

- Concrete Pavers Roof Decks - Tech Spec 14 PDFDocument12 pagesConcrete Pavers Roof Decks - Tech Spec 14 PDFbatteekhNo ratings yet

- CDH Product Catalogue 2018 19Document340 pagesCDH Product Catalogue 2018 19Matriya NitinNo ratings yet

- Band Saw Arg-400-PlusDocument10 pagesBand Saw Arg-400-PlusOccasionmachinesMetalworkingNo ratings yet

- Mandatory Appendix 41: EIH Support Plate DesignDocument5 pagesMandatory Appendix 41: EIH Support Plate DesignHanafi BasriNo ratings yet

- LPS precision fastener manufacturerDocument16 pagesLPS precision fastener manufacturerHiren SonarNo ratings yet

- Merabet - Sonolytic and Ultrasound-Assisted Techniques For Hydrogen Production A Review Based On The Role of Ultrasound Review 2022Document15 pagesMerabet - Sonolytic and Ultrasound-Assisted Techniques For Hydrogen Production A Review Based On The Role of Ultrasound Review 2022Michel AertsNo ratings yet

- Gunpowder, Explosion, and Explosive MaterialsDocument23 pagesGunpowder, Explosion, and Explosive MaterialsEmelie TipayNo ratings yet

- How To Build A Catalytic Test Reactor: Raoul Naumann D'alnoncourtDocument55 pagesHow To Build A Catalytic Test Reactor: Raoul Naumann D'alnoncourtFrançois LeroyNo ratings yet

- Elektroenerģētikas TehnoloģijasDocument6 pagesElektroenerģētikas TehnoloģijasMihails LarionovsNo ratings yet

- PN JunctionDocument36 pagesPN JunctionTiniNo ratings yet

- Sae Ams 2355K - 2011 PDFDocument16 pagesSae Ams 2355K - 2011 PDFNav TalukdarNo ratings yet

- SL Series Compact Loose Central Tube Fiberoptic CableDocument5 pagesSL Series Compact Loose Central Tube Fiberoptic CableJhon SanabriaNo ratings yet

- Ultra Thin WhitetoppingDocument21 pagesUltra Thin WhitetoppingDHRUV KDMC ProjectsNo ratings yet

- Heterogeneous Reaction Kinetics: Determining the Rate-Controlling StepDocument35 pagesHeterogeneous Reaction Kinetics: Determining the Rate-Controlling StepDaniel OmolewaNo ratings yet

- MMUP EXAM JMQDocument3 pagesMMUP EXAM JMQmaninambiramNo ratings yet

- Sand Casting Over View and Defect AnalysisDocument29 pagesSand Casting Over View and Defect AnalysisNindya HauraNo ratings yet

- B31.3 QuestionsDocument17 pagesB31.3 Questionsemaanazeem67% (6)