Professional Documents

Culture Documents

ATB 021 Flowtite Pipe Tapping PDF

Uploaded by

Rajadurai SinghOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ATB 021 Flowtite Pipe Tapping PDF

Uploaded by

Rajadurai SinghCopyright:

Available Formats

ADVISORY TECHNICAL BULLETIN F-ENGR-4

Rev.02

#021

Page 1 of 10

Bulletin Name:

Bulletin Description:

Bulletin Date:

Flowtite Pipe Tapping

Tapping Procedure for Flowtite GRP Pipe

February 9, 2006

NOTE: THIS ADVISORY TECHNICAL BULLETIN IS FOR INFORMATIONAL PURPOSES ONLY. USCPS

ACCEPTS NO RESPONSIBILITY FOR WORK MADE BY OTHERS.

Flowtite GRP Tapping Procedures

1

SCOPE

This procedure outlines the tapping procedure to be used with Flowtite Fiberglass Pipe.

TAPPING WATER PIPELINES UNDER PRESSURE

a. The surface of the exposed main pipe where the tapping is to be done should be clean. An

approved flexible gunmetal tapping saddle should be placed at the designated place. Usually

these saddles are two half circles connected with bolts. The minimum distance between two

saddles is 20 inches and the maximum torque on the bolts should not exceed 10 Nm.

As a standard, the diameter of the outlet will vary from 2 to 4 inches. However other sizes are

also available.

b. Tapping machines vary from one manufacturer to another. Below is a general description of

the tapping method.

Screw the main cock into the saddle after removing the plug.

Install the hole-cutting tool into the tapping machine. The tool should be long

enough to cut throughout the pipe.

Start drilling. These machines could be operated manually, pneumatically or

electrically.

The drill is then raised and the plug closed.

Unscrew the drilling machine.

SADDLE MATERIAL

Any flexible gunmetal tapping saddles can be used. Plastic saddles (polyethylene type) are also

recommended.

DETAILED TAPPING PROCEDURE

A procedure for hot and cold tapping of GRP pipes is presented in this document. The strength

and flexibility of GRP pipes make them well suited for tapping. The structural integrity and sealing

performance of tapped GRP pipes has been verified through extensive research and

development work. The procedure presented herein covers general aspects as well as specifics

for GRP pipes, such as choice and mounting of the tapping sleeve and cutting the hole in the

GRP pipe.

G:\ENGINEERING\Engr Report Documents\Technical Bulletins\ATB 021-Flowtite Pipe Tapping.doc

ADVISORY TECHNICAL BULLETIN F-ENGR-4

Rev.02

#021

Page 2 of 10

4.1 INTRODUCTORY INFORMATION

This procedure is intended to assist the installer and owner of GRP pipe systems in

understanding the requirements and the procedures for successful mounting of tapping sleeves

on existing pipelines. Tapping is convenient for fitting a branch pipe or valve to an already

existing pipeline where it is not practical to use a standard GRP nozzle or tee fitting. The

procedure covers both hot and cold tapping.

This tapping procedure is founded on extensive research and development work. A series of

short and long term pressure tests as well as FEM analysis was performed for qualification of a

tapping sleeve for use on a GRP pipe. Stainless steel material is selected as the material for the

tapping sleeves to get a service life similar to that of the GRP pipe system. Not all types of

tapping sleeves are suitable for this service.

This tapping procedure applies for all properly installed standard GRP pipes carrying water or

water based fluids. The tapping sleeve shall be placed in an area with low local axial pipe

stresses. Extra support may be needed for above ground pipes.

The following definitions apply:

Hot tapping: Installation of a nozzle or branch pipe on an existing pressurized or fluid filled

GRP pipeline using a steel sleeve.

Cold tapping: Installation of a nozzle or branch pipe on an existing empty and nonpressurized GRP pipeline using a steel sleeve.

Flexible stainless steel sleeves (see Figure 1) are recommended for tapping into GRP pipes.

Approved tapping sleeves suitable for GRP pipes are given in Table 1.

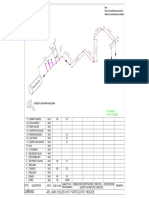

Figure 1: Recommended tapping sleeves for GRP pipes

It is recommended to engage tapping experts for both hot and cold tapping jobs. The tools for

performing the hot and cold tapping may vary.

For hot tapping, the sleeve is mounted on the pressurized pipe. A valve and a tapping machine

containing the cutter are mounted on the sleeve. The valve is opened and a hole drilled. The

cutting device is then retracted, the valve closed and the tapping equipment is removed leaving

the sleeve and the closed valve. A branch pipe can then be fitted on the valve and the valve

opened.

For cold tapping, a branch pipe hole is drilled in a non-pressurized pipe. The tapping sleeve is

then mounted around the pipe with the branch aligned with the hole. A branch pipe or valve can

G:\ENGINEERING\Engr Report Documents\Technical Bulletins\ATB 021-Flowtite Pipe Tapping.doc

ADVISORY TECHNICAL BULLETIN F-ENGR-4

Rev.02

#021

Page 3 of 10

then be fitted to the tapping sleeve. The procedure for hot tapping can also be used for cold

tapping.

4.2 SELECTION AND USE OF TAPPING SLEEVES

GRP approved tapping sleeves are given in Table 1.

Table 1: Approved Tapping Sleeves and Gasket Type

Sleeve Type

Dimensions

Pressure Class

Gasket Type

Supplier

Romacon SST

(Stainless-steel

tapping sleeve)

Up to DN30

Up to 250 psi working

pressure.

SBR Rubber

gasket

Romacon

Pipeline

Products B.V.

www.romacon.nl

Tel: +31 77 3549116

The maximum tapping branch pipe diameter shall be limited to:

20 % of header pipe diameter for SN18 pipe.

25 % of header pipe diameter for SN36 pipe.

30 % of header pipe diameter for SN72 pipe.

Maximum surge (water hammer) pressure that can arise in the pipeline must be accounted for in

the selection of tapping sleeve pressure rating.

The tapped system is qualified for vacuum corresponding to the pipe stiffness.

The tapping sleeves are designed to closely fit the outer diameter of the pipe. The tapping sleeve

will therefore need to match the outer diameter of the GRP pipe.

Thrust that the tapped system may generate must be balanced.

The location of the sleeve shall at a minimum be:

A length of not less than one pipe diameter away from the nearest coupling and/or fitting.

The tapping sleeve shall be placed in an area with low local axial pipe stresses. Extra

support may be needed for above ground pipes.

4.3 TAPPING PROCEDURES

Care must always be exercised when working with pressurized systems. This is especially true

for hot tapping, where pressurized media is irreversibly exposed. Expert advice and proficiency

should always be sought in such cases.

When working in trenches, precautions should be taken to prevent objects from falling into the

trench, or its collapse caused by instability or the position or movements of adjacent machinery or

equipment.

This procedure covers preparation, mounting, bolt torques, cutting, inspection, and testing.

G:\ENGINEERING\Engr Report Documents\Technical Bulletins\ATB 021-Flowtite Pipe Tapping.doc

ADVISORY TECHNICAL BULLETIN F-ENGR-4

Rev.02

#021

Page 4 of 10

4.3.1 Preparations

Adequate access for mounting the tapping sleeve and the tapping machine must be

provided. The pipe must be uncovered if buried. The pipe shall be cleaned thoroughly

prior to mounting the tapping sleeve. Loose particles, dust, sand, and grease, etc. shall

be removed. Normally, no further surface preparation is necessary.

The pipe surface shall be inspected for damage in the area underneath and adjacent to

the tapping sleeve after cleaning. No damage to the pipe is acceptable in this area.

4.3.2 Tapping

Hot and cold tapping procedures are covered below.

4.3.2.1 Hot Tapping

For hot tapping, a specialized tapping machine is always required. In addition to the

tapping sleeve and machine, the assembly consists of a branch valve (gate or ball) and

the cutting device (see Figure 3). The pressure rating of the branch valve and the tapping

equipment shall be at least equal to the pressure rating of the pipeline.

For hot tapping the following procedure shall be followed:

1. The tapping sleeve shall be located and oriented according to the plans and/or

drawing.

2. Mount the tapping sleeve on the pipe. The installation instructions issued by the

tapping sleeve manufacturer for the tapping sleeve shall be used except for the bolt

torque. Bolt torques applicable for GRP pipes, are given in Section 4.3.2.3.

3. Mount the valve on the tapping sleeve. Follow the instructions for the valve or flange

assembly with respect to bolt torque, seal type, etc.

4. Pressure test to verify sealing of tapping sleeve and valve is recommended prior to

tapping. It should be noted that a test with overpressure between sleeve and pipe is

more demanding on the rubber seal than a pressure test of the tapped pipe.

If the tapping sleeve is equipped with a test plug, this test can be conducted with

the branch valve closed. Otherwise a blind flange with test plug can be mounted

on the valve and the test conducted with open valve. Some tapping machines are

equipped with a test plug rendering the blind flange superfluous.

Fill the space between the pipe and the tapping sleeve with water, see Figure 2,

evacuate entrapped air and pressurise to test the integrity of the seals between

the sleeve and the pipe and between the sleeve and the valve. The test pressure

need not exceed the actual internal pressure of the pipe to be tapped by more

than 3 bars. (If a leak occurs, dismount and inspect for dirt or damage. Do not

increase the bolt torque on the sleeve). The test pressure shall also neither

exceed the maximum test pressure rating of the tapping sleeve nor the pipe, see

Section 4.3.3.

5. Mount the tapping machine on the valve. Follow the instructions for the tapping

machine or flange assembly with respect to bolt torque, seal type, etc.

6. Make sure that the valve is open and perform the cutting operation, see Figure 3.

Detailed instructions for cutters and cutting are given in Section 4.3.2.4.

7. After cutting, the cutting device with the coupon is retrieved through the valve. The

tapping machine with the cutting tool along with the pipe coupon can be removed

once the valve is closed (see Figure 4).

8. Inspection and hydrostatic test of the assembly can be performed upon completion of

installation. See details in Section 4.3.3.

G:\ENGINEERING\Engr Report Documents\Technical Bulletins\ATB 021-Flowtite Pipe Tapping.doc

ADVISORY TECHNICAL BULLETIN F-ENGR-4

Rev.02

#021

Page 5 of 10

Figure 2: Pressure testing of sleeve and valve assembly

Figure 3: Tapping assembly and hot tapping cutting

G:\ENGINEERING\Engr Report Documents\Technical Bulletins\ATB 021-Flowtite Pipe Tapping.doc

ADVISORY TECHNICAL BULLETIN F-ENGR-4

Rev.02

#021

Page 6 of 10

Figure 4: Tapping machine, valve and retrieved coupon

Tapping machine with cutting device

Closed valve

Cutting motor

Tapping machine with cutting device

Pipe wall coupon.

Valve

Tapping sleeve

4.3.2.2 Cold Tapping

For cold tapping the following procedure shall be followed.

1. The tapping sleeve shall be located and oriented according to the plans and/or

drawing.

2. The hole may be cut in advance or after mounting the tapping sleeve for cold

tapping. Detailed instructions for cutting are given in Section 4.3.2.4.

3. The steel sleeve shall be mounted around the existing pipe such that the sleeve

branch tapping hole is aligned with the hole in pipe.

4. The procedure issued by the tapping sleeve manufacturer for mounting of the tapping

sleeve shall be followed except for the bolt torque. Bolt torques applicable for GRP

pipes are given in Section 4.3.2.3.

5. The sealing between the tapping sleeve and the pipe wall may be tested prior to

cutting the hole. Follow the pressure test procedure for hot tapping given in Section

4.3.2.1.

6. The valve or branch pipe can be installed after cutting and assembly of the sleeve for

the cold tapping.

7. Inspection and hydrostatic test of the assembly can be performed upon completion of

installation. See details in Section 4.3.3.

G:\ENGINEERING\Engr Report Documents\Technical Bulletins\ATB 021-Flowtite Pipe Tapping.doc

ADVISORY TECHNICAL BULLETIN F-ENGR-4

Rev.02

#021

Page 7 of 10

4.3.2.3 Bolt Torque

The flexibility and pressure expansion of GRP pipes significantly enhances the sealing

performance of a tapping sleeve compared to mounting on rigid pipes like steel or ductile

iron. The bolt torque required for mounting of tapping sleeves on GRP pipes is thus lower

than for inflexible materials, and high torques may indeed be harmful for the system. The

recommended bolt torque for tapping of GRP pipes are given in Table 2. Higher bolt

torques are not recommended.

Table 2: Bolt torque for hot and cold tapping of GRP pipes.

Sleeve Type

Romacon SST

(Stainless

steel

tapping sleeve)

Bolt

Dimensions

(mm)

Torque

(Nm)

M16

70

Comment

The bolt torque is lower for GRP

pipes than for steel pipes.

4.3.2.4 Cutting

Cutting tools suitable for cutting of GRP pipe shall be used for cutting the tapping holes.

The cutting tool must give a clean cut without tearing or breaking the pipe wall. This is

especially important when the cutting device penetrates the inner surface of the GRP pipe

to avoid peeling.

The following shall be observed with respect to cutting the tapping hole:

A special diamond coated cutting device for glass fibre laminates is recommended (see

Figure 5). A closely spaced thin-walled fine tooth steel cutting device may also be

used (see Figure 6); however, this type of device tends to wear out fast.

Advancement rate of the cutter during drilling must be limited to avoid damage and

peeling of the inner surface. A test cut on a pipe wall sample is recommended for

operators and tools not previously exposed to GRP pipes (see Figure 8).

The cut surface may be left as it is after cutting without further surface preparations.

G:\ENGINEERING\Engr Report Documents\Technical Bulletins\ATB 021-Flowtite Pipe Tapping.doc

ADVISORY TECHNICAL BULLETIN F-ENGR-4

Rev.02

#021

Page 8 of 10

Figure 5: Recommended diamond coated cutting device

Figure 6: Alternative cutter with closely spaced teeth

G:\ENGINEERING\Engr Report Documents\Technical Bulletins\ATB 021-Flowtite Pipe Tapping.doc

ADVISORY TECHNICAL BULLETIN F-ENGR-4

Rev.02

#021

Page 9 of 10

Figure 7: Unsuitable cutter with widely spaced teeth. This cutter has few widely spaced teeth and tears

glass fibers from the laminate.

Figure 8: Test cut on pipe wall sample to adjust cutting speed and advance rate

4.4 INSPECTION AND TESTING

Checking, hydrostatic testing, and inspection of the installed pipe assembly shall be performed

according to GRP installation instructions.

For inspection, the following shall be observed:

The tapping sleeve shall not be bulged, deformed or otherwise damaged.

Proper support and thrust restraint is provided.

Hydrostatic testing of the sleeve assembly should be performed after installation according to

GRP installation instructions

G:\ENGINEERING\Engr Report Documents\Technical Bulletins\ATB 021-Flowtite Pipe Tapping.doc

ADVISORY TECHNICAL BULLETIN F-ENGR-4

Rev.02

#021

Page 10 of 10

The test pressure shall not exceed the lowest of the following:

1.5 times the design pressure or pressure rating of the pipeline system as defined in GRP

Installation Instructions, or

Maximum test pressure for the sleeve system as defined for the tapping sleeve.

The buried pipe section can be backfilled according to GRP installation instructions after

inspection and acceptance.

G:\ENGINEERING\Engr Report Documents\Technical Bulletins\ATB 021-Flowtite Pipe Tapping.doc

You might also like

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- KL UHP Catalog 2011-02 PDFDocument30 pagesKL UHP Catalog 2011-02 PDFaconibet9040No ratings yet

- Analysis of Piping System Used in Chemical PlantDocument7 pagesAnalysis of Piping System Used in Chemical Plantpipestress100% (1)

- A338 Steel StandardDocument2 pagesA338 Steel StandardguilhermehsssNo ratings yet

- NPS - 'Nominal Pipe Size' and DN - 'Diametre Nominal'Document4 pagesNPS - 'Nominal Pipe Size' and DN - 'Diametre Nominal'Mr. ANo ratings yet

- Copper Pipe SupportDocument2 pagesCopper Pipe SupportAmirudin SallehNo ratings yet

- 3 National Manhole Covers & FramesDocument8 pages3 National Manhole Covers & FramesVhuso Mwafuka MaringeNo ratings yet

- Malleable Iron Pipe Fittings: BS StandardDocument22 pagesMalleable Iron Pipe Fittings: BS StandardDANNYNo ratings yet

- Add02 1060.1Document14 pagesAdd02 1060.1Diego Calderón AlvaradoNo ratings yet

- Manage Structural Steel Production Using BarcodesDocument10 pagesManage Structural Steel Production Using BarcodesajaymrNo ratings yet

- F2620 PDFDocument19 pagesF2620 PDFAhmad Zubair RasulyNo ratings yet

- Piping CodesDocument3 pagesPiping Codesmexx4u2nvNo ratings yet

- E1003-13 Standard Practice For Hydrostatic Leak Testing PDFDocument3 pagesE1003-13 Standard Practice For Hydrostatic Leak Testing PDFudomNo ratings yet

- Flange Bolt Torque Calculation and Pipe Flange Bolt Torque ChartDocument6 pagesFlange Bolt Torque Calculation and Pipe Flange Bolt Torque ChartArya0% (1)

- En P 01 PrinciplesOfBrazingTechnologyDocument14 pagesEn P 01 PrinciplesOfBrazingTechnologySyed Noman AhmedNo ratings yet

- PanelDraw 4.1 ManualDocument420 pagesPanelDraw 4.1 ManualAkula VeerrajuNo ratings yet

- Derakane 515-400Document6 pagesDerakane 515-400Pecel LeleNo ratings yet

- Flow pattern based two-phase frictional pressure drop modelDocument13 pagesFlow pattern based two-phase frictional pressure drop modelSandro Goisis100% (1)

- (VESBO) Catalog en 100317Document55 pages(VESBO) Catalog en 100317AnhNguyen100% (1)

- BS8888 2004 Technical Product Specification PDFDocument8 pagesBS8888 2004 Technical Product Specification PDFnele_anderthalNo ratings yet

- HTTP WWW - Wermac.org Fittings Buttweld Fittings Part5Document4 pagesHTTP WWW - Wermac.org Fittings Buttweld Fittings Part5prabu prasad100% (1)

- 287 Technical Paper Gaskets For Pe Pipe PDFDocument16 pages287 Technical Paper Gaskets For Pe Pipe PDFFranklin Esteban CárdenasNo ratings yet

- Dynamic structural models scalingDocument5 pagesDynamic structural models scalinggauravNo ratings yet

- Coating Structural Steel SystemsDocument28 pagesCoating Structural Steel SystemsSaud PathiranaNo ratings yet

- What marks are shown on the head of a boltDocument3 pagesWhat marks are shown on the head of a bolttanujaayerNo ratings yet

- Preliminary Documents Design Report PDFDocument77 pagesPreliminary Documents Design Report PDFRamanNo ratings yet

- Din en 1320-1996Document18 pagesDin en 1320-1996edcam13No ratings yet

- Coating Thickness: MeasurementDocument3 pagesCoating Thickness: Measurementjmpateiro1985No ratings yet

- Valve Materials - Kitz CorporationDocument2 pagesValve Materials - Kitz Corporationibnuhary100% (1)

- Pyrogel XTE DatasheetDocument2 pagesPyrogel XTE DatasheetLe Thanh HaiNo ratings yet

- The New NSF 350 AND 350-1Document6 pagesThe New NSF 350 AND 350-1Rossy IP100% (1)

- Prefabricated Steel Supports for PipingDocument9 pagesPrefabricated Steel Supports for PipingMuhammed SulfeekNo ratings yet

- BS 4504 Slip On Flanges PDFDocument7 pagesBS 4504 Slip On Flanges PDFMaclean ArthurNo ratings yet

- Vecom - Japanese BlackDocument2 pagesVecom - Japanese Blackdiaccessltd_17172961No ratings yet

- Mosi2 Heating Elements (MolyD or Molybdenum Disilicide Manufacturerd by SilcarbDocument10 pagesMosi2 Heating Elements (MolyD or Molybdenum Disilicide Manufacturerd by SilcarbA.K. RawatNo ratings yet

- PFI ES 16 - 2013 EditionDocument11 pagesPFI ES 16 - 2013 EditionArcadio Duran100% (1)

- TR 4 2014Document64 pagesTR 4 2014Afolabi OlaniyiNo ratings yet

- One Team Mega Project SuccessDocument16 pagesOne Team Mega Project SuccessRsn786No ratings yet

- Sfa-5.01 Filler Metal Procurement GuidelinesDocument10 pagesSfa-5.01 Filler Metal Procurement GuidelinesCesar Agustin LimousinNo ratings yet

- v1.0 Rishabh Engineering CS 37 Piping Stress Analysis Horizontal HeaterDocument4 pagesv1.0 Rishabh Engineering CS 37 Piping Stress Analysis Horizontal HeaterJasonChong212No ratings yet

- 10.1.1.144.9002 SW FatigueDocument13 pages10.1.1.144.9002 SW Fatigueb_wooNo ratings yet

- ENG2068 SampleofcontentsDocument10 pagesENG2068 SampleofcontentsKlich77No ratings yet

- Is 4310 Spec Weldeable Steel Pipe Fittings For Marine PurposesDocument12 pagesIs 4310 Spec Weldeable Steel Pipe Fittings For Marine Purposesnarasimhareddy415No ratings yet

- 66-165 - A804 - Fire Penetration Details (Version)Document1 page66-165 - A804 - Fire Penetration Details (Version)Parth DaxiniNo ratings yet

- Product Date Sheet - Swagelok BrocureDocument6 pagesProduct Date Sheet - Swagelok BrocurejulianpirahNo ratings yet

- Riopipeline2019 1078 201906031047ibp1078 19 Managin PDFDocument10 pagesRiopipeline2019 1078 201906031047ibp1078 19 Managin PDFMarcelo Varejão CasarinNo ratings yet

- Heat Transfer Problem 2014Document240 pagesHeat Transfer Problem 2014arminNo ratings yet

- PN01SA0B03Document5 pagesPN01SA0B03Julian GaleanoNo ratings yet

- ASTM's Steel Standards GuideDocument63 pagesASTM's Steel Standards GuideNagarjun ReddyNo ratings yet

- Export Piping Insulation Visibility SettingsDocument1 pageExport Piping Insulation Visibility SettingsNima AriaNo ratings yet

- 20mnmoni55 or Sa 533 GR B CL 1Document10 pages20mnmoni55 or Sa 533 GR B CL 1Jackz UlNo ratings yet

- Flange AS4087 AS2129 BS Table DEDocument2 pagesFlange AS4087 AS2129 BS Table DEadamNo ratings yet

- A New System Design For Supercritical Water Oxidation, Chem Eng J 2015Document9 pagesA New System Design For Supercritical Water Oxidation, Chem Eng J 2015ejhnoramNo ratings yet

- Kinetic ModelingDocument7 pagesKinetic ModelingDiga Gi ObasisNo ratings yet

- Schieber EN2008 PDFDocument144 pagesSchieber EN2008 PDFperfilma2013No ratings yet

- Nace RP 0394-94Document29 pagesNace RP 0394-94ivan100% (1)

- List of Contractors With Demerit PointsDocument3 pagesList of Contractors With Demerit PointstatonyNo ratings yet

- Metallurgical Coatings and Thin Films 1992From EverandMetallurgical Coatings and Thin Films 1992G.E. McGuireNo ratings yet

- Standard PDFDocument4 pagesStandard PDFRajadurai SinghNo ratings yet

- Sound Stick BT 14 With RemoteDocument2 pagesSound Stick BT 14 With RemoteRajadurai SinghNo ratings yet

- Sound Stick BT 14 With RemoteDocument2 pagesSound Stick BT 14 With RemoteRajadurai SinghNo ratings yet

- 2018 05 Cese NotfnDocument2 pages2018 05 Cese NotfnRajadurai SinghNo ratings yet

- Leaflet Gangways 031047Document1 pageLeaflet Gangways 031047Rajadurai SinghNo ratings yet

- Cleaning LiquidsDocument1 pageCleaning LiquidsRajadurai SinghNo ratings yet

- Orifice Plate ManualDocument3 pagesOrifice Plate ManualRajadurai SinghNo ratings yet

- Excel Critical Path TrackerDocument176 pagesExcel Critical Path Trackerislouma2No ratings yet

- DiskAshur ManualDocument23 pagesDiskAshur ManualRajadurai SinghNo ratings yet

- 2018 05 Cese Notfn PDFDocument26 pages2018 05 Cese Notfn PDFshanmugamNo ratings yet

- Verhoef Brochure PDFDocument6 pagesVerhoef Brochure PDFRajadurai SinghNo ratings yet

- Deluge Valve C1Document16 pagesDeluge Valve C1Rajadurai SinghNo ratings yet

- Comprehensive Admission Policy (Cap) : Parent's Requisition Form - Online Parent's Requisition Form - OfflineDocument1 pageComprehensive Admission Policy (Cap) : Parent's Requisition Form - Online Parent's Requisition Form - OfflineRajadurai SinghNo ratings yet

- HowtoInstallTamilFont 1Document3 pagesHowtoInstallTamilFont 1suthasankarNo ratings yet

- Deluge Valve C1Document16 pagesDeluge Valve C1Rajadurai SinghNo ratings yet

- LNG 2Document17 pagesLNG 2Rajadurai SinghNo ratings yet

- IIT Registration Form 2015 16Document8 pagesIIT Registration Form 2015 16Rajadurai SinghNo ratings yet

- Adapters Instantaneous Male With BSP and NH ThreadsDocument1 pageAdapters Instantaneous Male With BSP and NH ThreadsRajadurai SinghNo ratings yet

- Letter Writing EnglishDocument10 pagesLetter Writing EnglishRajadurai SinghNo ratings yet

- ATB 021 Flowtite Pipe Tapping PDFDocument10 pagesATB 021 Flowtite Pipe Tapping PDFRajadurai SinghNo ratings yet

- HottapDocument6 pagesHottaprodofgodNo ratings yet

- List of Compulsory / Restricted Holidays For The Acadmic Year 2015-16Document1 pageList of Compulsory / Restricted Holidays For The Acadmic Year 2015-16Rajadurai SinghNo ratings yet

- Ideal House Planning GuideDocument9 pagesIdeal House Planning GuideRajadurai Singh100% (1)

- GuidelinesDocument6 pagesGuidelines143rajuanuNo ratings yet

- 25.supply of MaterialsDocument1 page25.supply of MaterialsRajadurai SinghNo ratings yet

- MortarsDocument20 pagesMortarsmnc19No ratings yet

- Health TipsDocument36 pagesHealth TipsAmit PandeyNo ratings yet

- NullDocument7 pagesNullapi-25909027No ratings yet

- Chapter IIIDocument12 pagesChapter IIIRajadurai SinghNo ratings yet

- Brickwork Specifications and TerminologyDocument30 pagesBrickwork Specifications and TerminologyRajadurai Singh100% (1)

- 1 Wire Instruction ManulalDocument6 pages1 Wire Instruction ManulalhdnutzNo ratings yet

- 3 FTP - 2-WT PDFDocument34 pages3 FTP - 2-WT PDFMohama KarimiNo ratings yet

- Handbook of Analysis and Its Foundations 2Document882 pagesHandbook of Analysis and Its Foundations 2Luis Francisco Trucco PassadoreNo ratings yet

- Envision - 8.3 Multiply Fractions and Whole NumbersDocument3 pagesEnvision - 8.3 Multiply Fractions and Whole NumbersMohamed A MoneimNo ratings yet

- Lpile Input ParametersDocument1 pageLpile Input ParametersKresno N SoetomoNo ratings yet

- H Ex PDFDocument24 pagesH Ex PDFelgawadhaNo ratings yet

- CIGRE-367 - Reliability of TransformersDocument6 pagesCIGRE-367 - Reliability of TransformersDileepa Sachithra DaulagalaNo ratings yet

- BP Chapter 13 - Understanding the Causes of FoxingDocument23 pagesBP Chapter 13 - Understanding the Causes of FoxingSonia KataNo ratings yet

- West 6010+Document180 pagesWest 6010+Tlacaélel SánchezNo ratings yet

- Prerequ QFTDocument1 pagePrerequ QFTHassan FawazNo ratings yet

- Geo-Mechanics IntroductionDocument27 pagesGeo-Mechanics IntroductionRitik ThakurNo ratings yet

- Design and Manufacturing of Pneumatic Pipe Bending MachineDocument5 pagesDesign and Manufacturing of Pneumatic Pipe Bending MachineSriram MuruganNo ratings yet

- Determination of Specific Energy in Cutting Process Using Diamond Saw Blade of Natural StoneDocument9 pagesDetermination of Specific Energy in Cutting Process Using Diamond Saw Blade of Natural StoneIrina BesliuNo ratings yet

- LS Dyna Crack PDFDocument28 pagesLS Dyna Crack PDFEren KalayNo ratings yet

- UT PCN NotesDocument113 pagesUT PCN NotesThiru Raja95% (19)

- SMB101 PDFDocument4 pagesSMB101 PDFJeya RamanNo ratings yet

- Chapter 5Document2 pagesChapter 5farhansuperfyenNo ratings yet

- D5035 11 Breaking Force and Elongation of Textile Fabrics (Strip Method)Document8 pagesD5035 11 Breaking Force and Elongation of Textile Fabrics (Strip Method)Raj SontakkeNo ratings yet

- Reliable Hot Water Piping SystemDocument6 pagesReliable Hot Water Piping SystemAzher ANo ratings yet

- EFL - ESL General Knowledge Quiz Questions PDFDocument7 pagesEFL - ESL General Knowledge Quiz Questions PDFBaloram DeyNo ratings yet

- For The Classes of Crystal: For Searching Project ReportsDocument15 pagesFor The Classes of Crystal: For Searching Project ReportsDhanapal PalNo ratings yet

- Deep Foundation CourseDocument23 pagesDeep Foundation CourseDedi ApriadiNo ratings yet

- Energy Conversion and Management: Ümmühan Basßaran Filik, Ömer Nezih Gerek, Mehmet KurbanDocument13 pagesEnergy Conversion and Management: Ümmühan Basßaran Filik, Ömer Nezih Gerek, Mehmet Kurbanakash_chandraya4200No ratings yet

- GFK K.pusczak-Sample Size in Customer Surveys - PaperDocument27 pagesGFK K.pusczak-Sample Size in Customer Surveys - PaperVAlentino AUrishNo ratings yet

- Polycrystalline Type VBMS250 255 260AE04Document2 pagesPolycrystalline Type VBMS250 255 260AE04walter_lopezvNo ratings yet

- Advantages of Bladder Surge TanksDocument8 pagesAdvantages of Bladder Surge TanksChrisHogbenNo ratings yet

- Maxima and Minima ProblemsDocument44 pagesMaxima and Minima ProblemsMeggy Villanueva100% (2)

- Sy 2021 2022 Science 2 q4 w6 Full Sped GTDocument5 pagesSy 2021 2022 Science 2 q4 w6 Full Sped GTJUNILLE B. YALUNGNo ratings yet

- Fundasurv Module 1Document28 pagesFundasurv Module 1Kyle Henzy RiveraNo ratings yet

- 6 Programming With MATLAB PDFDocument66 pages6 Programming With MATLAB PDFAugusto De La Cruz CamayoNo ratings yet