Professional Documents

Culture Documents

VBB4423-May 2012

Uploaded by

Shen YenCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VBB4423-May 2012

Uploaded by

Shen YenCopyright:

Available Formats

VBB 4423

1.

a.

Compare the major differences in concept, behaviour and performance

between fixed and floating offshore structures.

[8 marks]

b.

Determine the wind forces on Leg A and on the deck house of the platform

shown in FIGURE Q1. Use the storm criteria for Ruby Vietnam location.

[8 marks]

Deck House 8 m wide

and 5 m high

Plate Girder 2 m

high

Leg A, 1.5 m

dia, 15 m tall

from MSL

FIGURE Q1

VBB 4423

2.

a.

The Root Mean Square (RMS) height for a storm wave at the RubyVietnam location is 5 m. What would be the maximum wave height for a

duration of one week?

[5 marks]

b.

Evaluate the total horizontal force per m length due to wave and current

after a time of 15 s at the centre of the immersed portion of a vertical

cylindrical member of diameter 750 mm immersed 8 m in water as shown

in FIGURE Q2. Assume that the member is fouled and is at a horizontal

distance of -6 m from the origin O. Use the operating criteria for RubyVietnam location as given in APPENDIX II. Take mass density of sea

water as 1025 kg/m3.

[12 marks]

O

8m

6m

FIGURE Q2

VBB 4423

3.

a.

FIGURE Q3 shows the details of a gravity platform.

subjected to a regular wave of 11 s period.

The platform is

Determine the dynamic

amplification factor for the horizontal response of the deck, if the damping

ratio is 10%. Assume the mass density of sea water as 1025 kg/m3, the

unit weight of concrete as 24 kN/m3 and the value of CM as 1.6.

[8 marks]

Deck Weight = 35 MN

MSL

18 m

GBS Outer Diameter 9 m

Thickness 750 mm

E = 40000 MPa

120 m

FIGURE Q3

VBB 4423

3.

b.

Assess the adequacy of the cross section of a jacket leg with details as

given below. Use the API Clauses given in APPENDIX III.

Chord: Diameter D = 750 mm, Thickness T = 20 mm

Yield Stress Fy = 345 MPa

Length between braces = 25 m

Modulus of Elasticity, E = 200 GPa

Fe = Euler Stress/Factor of Safety

Maximum Internal Forces on the Leg

Axial

Bending (OPB)

Bending (IPB)

= -2500 kN

= 360 kNm

= -150 kNm

[9 marks]

VBB 4423

4.

a.

Outline EIGHT (8) parameters that are used to compare the float-over and

crane vessel lifting methods used for topside installation.

[8 marks]

VBB 4423

4.

b.

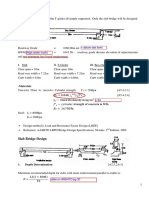

FIGURE Q4 shows a three-leg jack-up platform subjected to wind and

wave loads in the operating condition. For the legs, the cross sectional

area A is 2.5 m2, moment of inertia I is 39 m4, yield stress Fy is 345 MPa

and the modulus of elasticity E is 2 x 105 MPa.

i.

Determine the reactions at the spud cans.

[3 marks]

ii.

Calculate the safety factor against overturning.

[2 marks]

iii.

Determine the safety factor against global buckling for the most

heavily loaded leg.

[4 marks]

FIGURE Q4

VBB 4423

5.

a.

Explain the launching and up-ending operations of a barge-launched

jacket platform using schematic diagrams.

[8 marks]

b.

TABLE Q5 shows the heights of waves H, the periods of waves T,

fractions of time P, and stress amplitudes , at a joint for a particular cross

member of a proposed structure at the site. Determine the fatigue life of

the joint, assuming a stress concentration factor of 1.95. The Stress Vs

Number of Cycles (SN) curve is represented by the following equations.

Log10 (N) = 12.48 3 Log10 (S) for N < 107

Log10 (N) = 16.13 5 Log10 (S) for N > 107

[9 marks]

TABLE Q5

H (m)

T (sec)

P (%)

(MPa)

8-10

15

55

6-8

13

40

4-6

10

30

2-4

20

0-2

93

15

VBB 4423

6.

a.

Explain the important factors that affect the material selection for offshore

structures.

[8 marks]

b.

For a jacket platform using six wells, operated by PETRONAS, the total

area of piles and conductors from mud line to 30 m below mud line is

260 m2. The total area of jacket, caissons, conductor riser etc. from MSL

to mud line is 450 m2. Determine the number of anodes required.

[8 marks]

- END OF PAPER -

VBB 4423

APPENDIX I (WAVE TABLE)

d/L0

d/L

d/L0

d/L

0.000

0.002

0.004

0.006

0.008

0.0000

0.0179

0.0253

0.0311

0.0360

0.20

0.21

0.22

0.23

0.24

0.225

0.234

0.242

0.251

0.259

0.010

0.015

0.020

0.025

0.030

0.0403

0.0496

0.0576

0.0648

0.0713

0.25

0.26

0.27

0.28

0.29

0.268

0.277

0.285

0.294

0.303

0.035

0.040

0.045

0.050

0.055

0.0775

0.0833

0.0888

0.0942

0.0993

0.30

0.31

0.32

0.33

0.34

0.312

0.321

0.330

0.339

0.349

0.060

0.065

0.070

0.075

0.080

0.104

0.109

0.114

0.119

0.123

0.35

0.36

0.37

0.38

0.39

0.358

0.367

0.377

0.386

0.395

0.085

0.090

0.095

0.10

0.11

0.128

0.132

0.137

0.141

0.150

0.40

0.41

0.42

0.43

0.44

0.405

0.415

0.424

0.434

0.443

0.12

0.13

0.14

0.15

0.16

0.158

0.167

0.175

0.183

0.192

0.45

0.46

0.47

0.48

0.49

0.453

0.463

0.472

0.482

0.492

0.17

0.18

0.19

0.200

0.208

0.216

0.50

0.75

1.00

0.502

0.746

0.981

10

VBB 4423

APPENDIX II (PTS CLAUSES)

APPENDIX III (API Clauses)

3.2.2 Axial Compression

3.2.2.a

Column Buckling

The allowable axial compressive stress, Fa should be determined from the following

AISC formulas for members with a D/t ratio equal to or less than 60:

/

/

for Kl/r <

(3.2.2-1)

where

2

(3.2.2-1)

E = Youngs Modulus of elasticity MPa),

K = effective length factor, Section 3.3.1d,

l = unbraced length (m),

r = radius of gyration (m).

11

VBB 4423

3.2.3 Bending

The allowable bending stress,

0.75

for

0.84

1.74

0.72

0.58

3.3

, should be determined from:

,

for

for

300

(3.2.3-1a)

(3.2.3-1b)

(3.2.3-1c)

COMBINED STRESSES FOR CYLINDRICAL MEMBERS

3.3.1 Combined Axial Compression and Bending

3.3.1.a

Cylindrical members

Cylindrical members subjected to combined compression and flexure should be

proportioned to satisfy both the following requirements along their length.

Where

1

1.0

(3.3.1-1)

1.0

(3.3.1-2)

and

0.4

or 0.85, whichever is less

12

You might also like

- TE 1997 and 2003 Course Oct 2009Document492 pagesTE 1997 and 2003 Course Oct 2009Ajay Solate0% (1)

- Introduction to Bridge Engineering: Concrete Bridges Lecture 4 Design (IIDocument163 pagesIntroduction to Bridge Engineering: Concrete Bridges Lecture 4 Design (IIRonnie1478No ratings yet

- ENGM031Document5 pagesENGM031YHTRTRNo ratings yet

- Limit State Design of Liquid Retaining SectionDocument6 pagesLimit State Design of Liquid Retaining Sectionarif_rubinNo ratings yet

- Design of Syphon AqueductDocument110 pagesDesign of Syphon AqueductD.V.Srinivasa Rao100% (12)

- CPM Seismic LoadDocument823 pagesCPM Seismic LoadRomeo Victor100% (1)

- Lecture No.4BDocument163 pagesLecture No.4BNambi HarishNo ratings yet

- Time: 4 Hours) (Max. Marks: 100 Instructions To The CandidatesDocument3 pagesTime: 4 Hours) (Max. Marks: 100 Instructions To The CandidatesSahil GandhiNo ratings yet

- T.E - 2013Document295 pagesT.E - 2013Sagar DeshpandeNo ratings yet

- Board Diploma Examination, (C-09) APRIL/MAY-2015 Deee-Fourth Semester Examination General Mechanical EngineeringDocument2 pagesBoard Diploma Examination, (C-09) APRIL/MAY-2015 Deee-Fourth Semester Examination General Mechanical Engineeringmass1984No ratings yet

- Dynamics of Machinery r10 May-2016Document20 pagesDynamics of Machinery r10 May-2016Srimanthula SrikanthNo ratings yet

- Cem 704 QBDocument6 pagesCem 704 QBJinshad UppukodenNo ratings yet

- Design of A Modern High Rise Building in Abu-Dhabi (United Arab Emirates University) Graduation Project II Fall 2010Document50 pagesDesign of A Modern High Rise Building in Abu-Dhabi (United Arab Emirates University) Graduation Project II Fall 2010April Ingram100% (1)

- DT Gate-Support StructureDocument11 pagesDT Gate-Support StructureA M Nagabhushan AjwalNo ratings yet

- Raft DesignDocument8 pagesRaft Designramesh_madkatte1082No ratings yet

- T.E Question Papers (2012 Pattern) May 2015Document297 pagesT.E Question Papers (2012 Pattern) May 2015Prof. Avinash MahaleNo ratings yet

- Xvi. Pert-Cpm PDFDocument52 pagesXvi. Pert-Cpm PDFPat SisonNo ratings yet

- 11.a.ii - ME03031 QA 1Document22 pages11.a.ii - ME03031 QA 1Bakkiya Raj100% (1)

- DME Model QuesDocument3 pagesDME Model QuesSiva RamanNo ratings yet

- M.E. (Civil - Structures) (Semester - III) : Time: 3 Hours) (Max. Marks: 50 Instructions To The CandidatesDocument3 pagesM.E. (Civil - Structures) (Semester - III) : Time: 3 Hours) (Max. Marks: 50 Instructions To The CandidatesSahil GandhiNo ratings yet

- Bridge CH 5 Example On Slab BridgeDocument16 pagesBridge CH 5 Example On Slab BridgeHabhaile Asfaw83% (6)

- JNTU BTech Civil Engineering Advanced Structural Analysis Exam QuestionsDocument19 pagesJNTU BTech Civil Engineering Advanced Structural Analysis Exam QuestionsMohammed AbidNo ratings yet

- 4363 111 Machine Design IDocument6 pages4363 111 Machine Design Iyogesh_b_k100% (2)

- Cusat 4th Sem CE Question PaperDocument24 pagesCusat 4th Sem CE Question PaperJinu MadhavanNo ratings yet

- Slab Bridge Design ExampleDocument16 pagesSlab Bridge Design ExampleShita Alemie100% (5)

- Reinforced Concrete Deck Slab Design and DetailingDocument5 pagesReinforced Concrete Deck Slab Design and DetailingbhavanayallavulaNo ratings yet

- Foundation Design for Raft with ColumnsDocument8 pagesFoundation Design for Raft with ColumnsMUMANo ratings yet

- Design of Precast Column PDFDocument54 pagesDesign of Precast Column PDFfarahazura100% (1)

- C4ce22 Hydro Power Engineering Set1Document9 pagesC4ce22 Hydro Power Engineering Set1bhkedarNo ratings yet

- IES Civil Engineering Conventional Paper 2014Document27 pagesIES Civil Engineering Conventional Paper 2014mantuiitNo ratings yet

- Dme Model Key 2019Document25 pagesDme Model Key 2019Siva RamanNo ratings yet

- Barrel CouplingsDocument16 pagesBarrel Couplingsamariei_niculinaNo ratings yet

- Set No: 1: Code No: V3203/R07Document50 pagesSet No: 1: Code No: V3203/R07Polireddi Gopala KrishnaNo ratings yet

- r05322102 Aerospace Vehicle Structures IIDocument12 pagesr05322102 Aerospace Vehicle Structures IISRINIVASA RAO GANTA100% (2)

- April 2017Document2 pagesApril 2017Instagram HelpNo ratings yet

- 07a6ec05 Designofmachinemembers IIDocument11 pages07a6ec05 Designofmachinemembers IIzahid_polyNo ratings yet

- Example - Slab Bridge PDFDocument7 pagesExample - Slab Bridge PDFRefisa Jiru100% (3)

- Abut DesignDocument32 pagesAbut DesignSubir Kunda100% (2)

- Design of A Slab Bridge On Abeya River A PDFDocument13 pagesDesign of A Slab Bridge On Abeya River A PDFAbera Mamo Jaleta100% (1)

- Design of Horizontal Axis Tidal TurbinesDocument8 pagesDesign of Horizontal Axis Tidal TurbinesMarwa ElzalabaniNo ratings yet

- Design of Steel Structures Exam QuestionsDocument3 pagesDesign of Steel Structures Exam QuestionsPiyush BhandariNo ratings yet

- Bridge-Ch-5-Example On Slab Bridge EDITEDFINALDocument15 pagesBridge-Ch-5-Example On Slab Bridge EDITEDFINALkassahun kebede100% (1)

- Aerospace Vehicle Structures AnalysisDocument8 pagesAerospace Vehicle Structures AnalysisYsharath ChandramouliNo ratings yet

- BOX Culvert Load DetailsDocument7 pagesBOX Culvert Load Detailsragalwar100% (1)

- 01028393Document9 pages01028393Powerranger2.0No ratings yet

- Sab 3233Document13 pagesSab 3233xperia30No ratings yet

- 1429r05210804 Engineering MechanicsDocument11 pages1429r05210804 Engineering MechanicsSaivenkat PenuguduruNo ratings yet

- DESIGN OF STAIR WITH QUARTER SPACE LANDINGDocument7 pagesDESIGN OF STAIR WITH QUARTER SPACE LANDINGjaffna0% (1)

- Jet Design 2 Kian LayloDocument11 pagesJet Design 2 Kian LayloKian LayloNo ratings yet

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsFrom EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsNo ratings yet

- Pressure Vessel and Stacks Field Repair ManualFrom EverandPressure Vessel and Stacks Field Repair ManualRating: 4 out of 5 stars4/5 (4)

- Design of Piles Under Cyclic Loading: SOLCYP RecommendationsFrom EverandDesign of Piles Under Cyclic Loading: SOLCYP RecommendationsAlain PuechNo ratings yet

- Form 1Document8 pagesForm 1Shen YenNo ratings yet

- Get Started with T-SQL Using Azure SQL DatabaseDocument12 pagesGet Started with T-SQL Using Azure SQL DatabaseShen YenNo ratings yet

- Spe 147603 MSDocument8 pagesSpe 147603 MSShen YenNo ratings yet

- Group Project Ms Final DraftDocument17 pagesGroup Project Ms Final DraftShen YenNo ratings yet

- SELPHY CP910 Printer User Guide enDocument65 pagesSELPHY CP910 Printer User Guide enShen YenNo ratings yet

- Box Update TutorialDocument4 pagesBox Update TutorialShen YenNo ratings yet

- SIT Guidelines - Ver 03Document61 pagesSIT Guidelines - Ver 03Shen YenNo ratings yet

- v5 305 324Document20 pagesv5 305 324Shen YenNo ratings yet

- SPWLA 2008 V49n1a2Document8 pagesSPWLA 2008 V49n1a2Shen YenNo ratings yet

- OTC 20718 Wettability Studies Using Low-Salinity Water in Sandstone ReservoirsDocument15 pagesOTC 20718 Wettability Studies Using Low-Salinity Water in Sandstone ReservoirsShen YenNo ratings yet

- Gas Field Engineering Tutorial CalculationsDocument3 pagesGas Field Engineering Tutorial CalculationsShen YenNo ratings yet

- Group Project Ms 1st DraftDocument15 pagesGroup Project Ms 1st DraftShen YenNo ratings yet

- Top Tensioned RiserDocument1 pageTop Tensioned RiserShen YenNo ratings yet

- Color CodeDocument1 pageColor CodeShen YenNo ratings yet

- Well Flowing Performance - Section2Document10 pagesWell Flowing Performance - Section2Ali ZareeforoushNo ratings yet

- Problem Statement and ObjectivesDocument2 pagesProblem Statement and ObjectivesShen Yen80% (10)

- QUICK LOOK INTERPRETATION TO BUILD STATIC MODEL FOR FDPDocument25 pagesQUICK LOOK INTERPRETATION TO BUILD STATIC MODEL FOR FDPShen Yen100% (2)

- Ass 1Document1 pageAss 1Shen YenNo ratings yet

- Chapter 1 SeparatorDocument33 pagesChapter 1 Separatordinesh_hsenidNo ratings yet

- Authorization Letter Collect Voucher BB1MDocument1 pageAuthorization Letter Collect Voucher BB1MAnonymous 7JrRc0OLcNo ratings yet

- Steel Catenary RiserDocument1 pageSteel Catenary RiserShen YenNo ratings yet

- QUICK LOOK INTERPRETATION TO BUILD STATIC MODEL FOR FDPDocument25 pagesQUICK LOOK INTERPRETATION TO BUILD STATIC MODEL FOR FDPShen Yen100% (2)

- Assignment 1 May 2015Document1 pageAssignment 1 May 2015Shen YenNo ratings yet

- Schedule For TalksDocument1 pageSchedule For TalksShen YenNo ratings yet

- Chapter 2Document67 pagesChapter 2dinesh_hsenidNo ratings yet

- Oil and Gas Company Contact Details ListDocument4 pagesOil and Gas Company Contact Details ListShen YenNo ratings yet

- Course IntroductionDocument12 pagesCourse IntroductionShen YenNo ratings yet

- EEE 1st TypeDocument2 pagesEEE 1st TypeShen YenNo ratings yet

- Rising Above Vice: Religious Promotion of Morality & SpiritualityDocument19 pagesRising Above Vice: Religious Promotion of Morality & SpiritualityShen YenNo ratings yet

- Caso de Estudio 14.1, 14.2 y 14.3Document6 pagesCaso de Estudio 14.1, 14.2 y 14.3Rodolfo G. Espinosa RodriguezNo ratings yet

- Examining Oral Communication FunctionsDocument5 pagesExamining Oral Communication FunctionsJoshua Lander Soquita CadayonaNo ratings yet

- In The Shadow of The CathedralDocument342 pagesIn The Shadow of The CathedralJoy MenezesNo ratings yet

- Onward Journey Ticket Details E Ticket Advance ReservationDocument1 pageOnward Journey Ticket Details E Ticket Advance ReservationAnonymous yorzHjDBdNo ratings yet

- Work Instruction For Coil Taping Process of EE14 (1&4 Pin)Document6 pagesWork Instruction For Coil Taping Process of EE14 (1&4 Pin)k.mehaboob bashaNo ratings yet

- Cathodic Disbonding TesterDocument1 pageCathodic Disbonding TesterfelavinNo ratings yet

- Educ 61 Module 5 ActivityDocument4 pagesEduc 61 Module 5 ActivityMitchille GetizoNo ratings yet

- GITAM Guidelines For MBA Project Work - 2018Document6 pagesGITAM Guidelines For MBA Project Work - 2018Telika RamuNo ratings yet

- Harvard Referencing ManualDocument31 pagesHarvard Referencing ManualАлина ЛовицкаяNo ratings yet

- Aadhaar is proof of identity, not citizenshipDocument1 pageAadhaar is proof of identity, not citizenshipPARTAPNo ratings yet

- Career Paralysis (PT 1) - Five Reasons Why Our Brains Get Stuck Making Career DecisionsDocument99 pagesCareer Paralysis (PT 1) - Five Reasons Why Our Brains Get Stuck Making Career DecisionsToni ErdfeldNo ratings yet

- Regulation of AlternatorDocument6 pagesRegulation of Alternatorkudupudinagesh100% (1)

- Specification of PCB800099 Controller Board V1.0Document10 pagesSpecification of PCB800099 Controller Board V1.0benabdullahNo ratings yet

- Life Model For Rolling Contact, Applied To The Optimization of A Tripode Constant Velocity JointDocument244 pagesLife Model For Rolling Contact, Applied To The Optimization of A Tripode Constant Velocity Jointbee140676No ratings yet

- Universal Chargers and GaugesDocument2 pagesUniversal Chargers and GaugesFaizal JamalNo ratings yet

- Viavi: Variable Optical Attenuators (mVOA-C1)Document6 pagesViavi: Variable Optical Attenuators (mVOA-C1)gwNo ratings yet

- EPC Contractor Rep. Authority/Authority's EngineerDocument6 pagesEPC Contractor Rep. Authority/Authority's Engineersunil kuldeepNo ratings yet

- Ata 47-NGS R25Document148 pagesAta 47-NGS R25NadirNo ratings yet

- Some Reading Problems of Arab EFL Students: Dr. Kamal R. MourtagaDocument17 pagesSome Reading Problems of Arab EFL Students: Dr. Kamal R. MourtagaANOOOSANo ratings yet

- Paper 2Document17 pagesPaper 2Khushil100% (1)

- Nordson EFD Ultimus I II Operating ManualDocument32 pagesNordson EFD Ultimus I II Operating ManualFernando KrauchukNo ratings yet

- Hydro Cyclone: Centripetal Force Fluid ResistanceDocument10 pagesHydro Cyclone: Centripetal Force Fluid ResistanceMaxwell ToffahNo ratings yet

- Speedface-V5L (Ti) : Face & Palm Verification and Thermal Imaging Temperature Detection TerminalDocument2 pagesSpeedface-V5L (Ti) : Face & Palm Verification and Thermal Imaging Temperature Detection TerminalardiNo ratings yet

- Planning GPS Data Collection: Software Is Provided On The TEC7133 CD-ROM. You Can Also Download ThisDocument5 pagesPlanning GPS Data Collection: Software Is Provided On The TEC7133 CD-ROM. You Can Also Download ThisDoniansyah Mai PutraNo ratings yet

- BDSM - Google SearchDocument1 pageBDSM - Google SearchporcogalliardsgfNo ratings yet

- Mastering EES Chapter1Document66 pagesMastering EES Chapter1mianvaherNo ratings yet

- Desktop HDD, Processors, and Memory DocumentDocument13 pagesDesktop HDD, Processors, and Memory DocumentsonydearpalNo ratings yet

- Spe 143287 MS PDocument11 pagesSpe 143287 MS PbvkvijaiNo ratings yet

- TAURI User ManualDocument23 pagesTAURI User ManualChris Sad LHNo ratings yet

- The 4th International Conference of the International Forum on Urbanism (IFoU) 2009 Amsterdam/Delft - FiberCity as a Paradigm Shift of Urban DesignDocument4 pagesThe 4th International Conference of the International Forum on Urbanism (IFoU) 2009 Amsterdam/Delft - FiberCity as a Paradigm Shift of Urban DesignChris de VriesNo ratings yet