Professional Documents

Culture Documents

Mil F 25173a Dzus

Uploaded by

acparaujoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mil F 25173a Dzus

Uploaded by

acparaujoCopyright:

Available Formats

Downloaded from http://www.everyspec.com on 2012-08-08T14:20:08.

MIL-F-25173LW3G)

16 FEBRUARY

= F-25173(USAF)

1956

h K 1y 1955

I

KCLITASX SFECIPICA~W

FAsmYEi, COSTSOL PAfAKL,~M-

m~~~

This specMicatlon has bam awro~

by tie ~~~nt

of the Air Force and by tbe UaVJ Bureau of A8r0mutlCa.

1.

Sam

M

2.

~

,.

w.9

MFLICABLS

SP9CifmIti0n

COW-

me fOmUI.IW

spcificatioIIs, s=-,

IIIef;~t on date Of intiwtiO~ f~ bfi, f~

Spmified herein:

.sPBXFICATIONS

QQ-U-151

QQ-P-li16

ly&w&70

w-z-325

P-Q

f----

d=~w,

a~ @licatiOnj

Of *e i$sue

Of ~fi SWC~iCa tiOn tO tie tent

s X

,,.

. .

A3.umdn& Alloy 52S; Plate ad Sheet

#Aaninum PJloY 6=, %=5, SodS, SbIWS

(x)-A-33.8

w-A-325

,)

Of CCQI-1

KJORfP2&

Federal

,,

Om tsm

wire,

!4etals;

2t011B@ or Dram

Omeial

Swcificatio*

for Intictiori of

PI.At&, CJXMW

(E.%ctrdewited)

Wire, Steel,High Carbon, SpriIW, Bright, Music

Zinc.Plating (Slectrodepxited)

Milit.aq

,., .

lfIL-D-5028

MIL-E-17555

,-

Drawings and bat.Lists: Preparation of Mamfactumrs 1

(for F%duction Afrcraft, Oui.dedKissiles, Engines,

Accessories, .ti Otier Awi~=_y

%~~~t)

Electronic Equiwmt

and Asmciated !Mntenance

puts; Pr.=sermtion, Packagiwr, packing md

Marking of

Swmmos

Mlitary

...

IuL-sTO-I.05

Impectim

A&- F0rce4avy Aeronautical .%mdmd

AND10398

Meals

Drawint

- Mfinition

of Dissimilar

Downloaded from http://www.everyspec.com on 2012-08-08T14:20:08.

NIL-F-25173A(ASO)

}

PUBLICATIONS

Aeronautical Bu31eti.n

Air FCRCfJ~+37Y

Specification and S tmdarda; use of

No. W

(coPim of specifications, stamk=-ds, drawings, ad whl~ations

=q*d

by cOntractors in comection with specific promuwm nt functions should be obtained from the

procuring activity or as directed by the contracttig OfflcEr.)

3.

R.FLWIZMINls

3.1

Qualification.- The f astmars furnl~ed under this specification ehell be a

product whi~.,has been tested and has passed the Qualification teats .w8cif led herein.

3.2

Materials..

Selection of materials.- In using mtarials, pruhcts,

snd tm.mites

not

3.2.1

S~CifiCal? J ibimt=d

hereh, applicable SW4ficatiom

and standards shall be selected

in accordalm with ANA Bulletin No. lh3.

3.2.1.1

Met.a16.

- Het-slashall be of the corrosion-resistanttype or suitably

treated to resi=mceion.

h fuels, salt mrv,

Or atispher~

cOnditiO~ tO *ich tie

fasteners ray be subjected when in storage

:: i. during normal service use.

3.2.1.2

Dissimilar metals.- lbde>> suitab4 protected against electrolytic cmrosion, disstiilar metals shall not be usei in intimate contact vith each other. Orating

AND10398 defties dissMMr

rnetah.

.- Fastener studs

screw&~~~~3sk&%?%%s

shall be either

depth of 0.005 to 0.012 inch and to a Rockwell

fabricated of through-hardened steal, shall be

C-30

shall be bardemd to prevent damage to

carburized and surface-hardened to a

bardneea of 15-N-80 to E-N-M,

or K

heat-treated to a Rockwell ha-s

o?

to c-38.

The fastener shall be of the stud-receptacle,strip dmign such that

IMsi

3.3

4- ener is opened, the stud asseubly is retained by the control panel, and the

uhen the fas

receptacle strip is retained by the aircraft structure support.

.

3.3.1

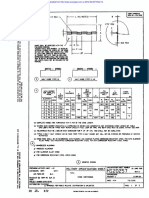

Receptacle strip.-

The receptacle strip shall be in accardance with figm<

1.

----

---

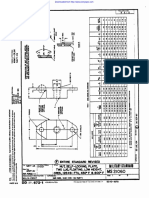

3.3.2 stud.- Detail design of the fastener stud is not a~clfied, and shall be

accomplished me

fsstener manufacturer in accardanee with the performance requirements

and other requiremmts of this 9P cification, and in accordance with tJm dimnsioml

requiremmts of figure 2,

--The stud shall engage the re.eptaole strip within

se direction.

f c~ti~$e

~~~jr

b,ing~;~ed &%%$;,itim

3.3.6

Dnlcckin&wise rotation.

e positively lceked within 85 la 135 degrees

stud has

~ e t@

*.U been

b mgaged.

A positive stop shall be provided to prevent the stud from

of fill lock.

The stud shall unlock witb$n 85 to 13S degrees of counterclock-

Downloaded from http://www.everyspec.com on 2012-08-08T14:20:08.

MIL-F-25173A@G)

(uuLTIPLS W .3~

ctuNIATIvF# TOLENANCB *.0%

mm OF IU.CSPTACLZ STRIP

.375

*.002

PsR

DRILL .2b2

DBPm .281

TIP

&Ld:;~3~

.1137

+.

-.

.188 *.

)

SSCTION A-A

DRILL .128

~ ~~h~

sT~p

lUWLPTACLS STRIP FASTSNZR WIRE

.0$1 DIA, ~ LOiG1%STAXE IN

PLACE. (s137x21FIcAfi0N

w2-w-b70,

Lmsi mDALLY

M, IMNU4

OR

CONIUTION-Tb,

AS JEQIIIFU?II

!4ATESIAL~lNO

TSS SPECIFICATION

REQUIFENFM. ) FmLsH: CADKIW

PLATE, SPECIFICATION QQ-P-&16,

TWSIIB

CLASSA

ALIJN

SPECIFICATION QQ-A-325,

IMGTN

DZOS FASTSNH+ C~~,.

INIX+W~~

L=LWG711 IN INCM%S AND TROLFMNIS

AS PM?

= l-7/16 MNO OR L W62

D~SIONS

IN HKZD3S.

FIODRS 1.

p~T

SSF?ICMLII.Z

~.. PR 3 l/2-L> OR ~~

M116

~NO.

OULPSS 017iEKWSE !WECIFIZI)7ULZRANGES: DZCIKALS t .016..

Rmeptacle

strip

fastcmar, aircraft equi~nt

control panel

).

Downloaded from http://www.everyspec.com on 2012-08-08T14:20:08.

KIL-F-2S173A(JSG

SILT

rl

.257

+ .C02

-.m

-~_.

-.

-+

.MIJ

~~>

FASTESSS ST~ MOWTIlF3 PF.OVHIOSS SW;

(a) DDW510S

A SSALL SE SUCH TSAT *TALLATIOM OF 27-IS FASTSTiESSTDD

CM BE MADE ISTO IHE?IODSTISOFIUWL310US AS SFllXFXED.

(b) DII!EWILWS AWLY AFTSR I~TALLATIOM.

DlnENs4EN ymm2Cm7S .

.

.

FIOUPX 2.

It

05Ki3S oIHEfbfHE SFEZIFIKO, lWSSANCJLSt ASOLES il,

Stud flstener, aircxaft equipn?mt control panel

Downloaded from http://www.everyspec.com on 2012-08-08T14:20:08.

H?.L-F-25173A(M)

I

3 .IJ

)

the

cOMtructim.-

Fastener

3.1$.1

htmd shall rzti

stud head.- with the fastener stud unlocked, the toP surface

titbti ~ e outline dimensions as shown kn figure 2.

of

screwdriver slot.- The screwdriver slot in tJIefastener stud head sbsXi

3.11.2

Positiun,

conform to the d.i.mnsionsshown in figure 2. with .thafastener In the tied

the acreudriver slot Eha.11be in line uitb the wire of the receptacle strip.

stud munting and rem--NOmt@

Of we fas~~ud *~ h

3JJ.3

~ be possible to renvve a damaged fastener stud

accordance Uiti fi

UImUMY and sui=%III~@I-I

a n~aOne, ~thout ~g~

tie -.

by *e w

Of Shand tm3S nhich rhall be designed by the fmtener manufacturer.

3.5

Performance.-

3.5.1

Lacking tOrqlm.-

3.5.1.1 nnxim. locking tom m.shall.be 8 pmii-imhea .

me

mxlmia

tirque required to lock the fastener

3.5.1.2 M.rAmtm locking tOrque.

shall be 2.5 Pmnd-tithes.

ne

torque re+@red ta lock tie faatermr

The absolute -mm

torque required to lock

3.5.1.3

Absolute maximum tom w.the fatiener shall be 133 Wrcent of Che maximum locking torque with the additim of a

O.010-inch shim between the panel and receptacle.

3.5.1.11 Absolute mlnimnn torque.- lhe absolute mi.nl.mmtorque required to hck

tAe fastener =all be b7 percent of fliemidm.m 10&ing torque.

Unlinking torque.- we torque required to unlock the fastener shall mt

3.5.2

than 30 Percenti and

axceed the torque required to lock that particular fastener by mm

shall be not less than 1.25 prod-inches.

w ,.$h~ in fig~e 3s ter

3.5.3 Lacking stop strength.- me fastener m@.ed

being locked and cont-actingthe stop, sha~ ~ths~~,

~~Out -Ee

~ the tM r

receptacle strip, a.minimum torque of 3Q Fred-inches fOr a duratiOn Or at least 5 secOnds.

3.5.IJ Receptacle strip fastener wire staking strength.-

sha113~%&

di=ction.

~~f

The fastener wire in a 6-inch lewth of receptacle strip

150-pOumi FWll .PPIM

to the fast.emr tire in *. IW@

3.5.lJ.2 staking brakeout.- Tue fastener tire shall not be dislocated from its

staked-in positian nor forced from the receptacle strip when a Mi.nimm load of 150 pounds

is appMed to the wire in the direction perpadicular to tie ads of tbe wire.

3.5.5

3.5.5.1

Tensi3.Elaad.sated tensile ioad.- The rated tensile load for

tbe Za&emr

shall

be

200

pmnds .

The torque requiredto lock the fastener 8hall not have changedin excess

3.5.5.2

of the maxiu.umnor L3sa than the minimm values as a result of the application of the

rated tensile load, flve successive tires, each of 5 seconds dmtion.

Downloaded from http://www.everyspec.com on 2012-08-08T14:20:08.

IUL#-25173A(AS&)

-)

.K6

.812

DSILL .152 1

0 HOLES

l_.62

1.250

H

FASTENER STGII ASSEXSIZ-

r\t=

.0611

D~NSIONS

IN ~m.

0~J2

F.IGGSS3.

ALG!IINW-AIJ.OY SN5T

SPECIFICATIONW-A-318 ,

l/2H

SKSPrAcLs STRIP

sPFzXFIED, TOIXSANCB: DDXHALS *.016.

Typical tension d

torqm apeciuen

Downloaded from http://www.everyspec.com on 2012-08-08T14:20:08.

i

f

!

HIL.F-25173A(Asc)

3.5.5.3

Initial tension.- The initial tension (bearing pressure],masured in

accordancewith he procedure specified herein, shall be mt less @an 15 po!mls.

3.5.5.11 P-l

ad receptacle strip separatim. The Pne

and r&eptacle sePration iha.flnot exceed 3/6k inch when the fastenm b subjected to+ e fated tansile load

test as apacified in IJ.3.2.

B.

The fastener *all WI*stand without fatlure any

3.5.5.5

Temi.Ia overload.tensile load up to 1S0 percent of ratid t.enstleload, five cmcceasive times, ea~ Of 5

seconds.duratlon.

I

I

3.5.6

shear load.-

3.5.6.1

Ratad shear lead.-

The rated shear load for the fastener cihal.1

be 200

-.

3.5.6.2

The torque requi.md to lock the fastener shall not i me changed in excess

of the maximum nor less than the ndntmnn values as a result of theapplica?im of the

rated shear load, fbe successive times, each of 5 seconde duration.

I

I

The fastener shall withstati without Railure any shear

Shear overload.3.5.6.3

of 5 secOnds

load up to 150 percent of we rated shear load, Cive successive times, ah

duration.

L

3.5.7

Vibration.- The fastener shall with6tard the Vibrat.,n

test as specified

h L.2.2.1 without evfdence Of d~ge

Or im@rmnt.

This ~qui~ent

shall apply f~

any feasible attitude of mounting of the panel, that is, vertical, horizontal, or oblzque.

Endurance.- The fastener shall wi thst.and,without failure, 5 ,OCQ.locking

3.5.8

aml unlocking operational cycles at approximately 110 cpm.

3.5.9

Receptacle strip spacing tolerance.- The fastener s~ds shall satisfactorily

*he locked and unlocked

engage and disengage the receptacle stm P, and shall operate tit-a

the absolute mininnm

~sitions without exceeding the absolute m=tim

or betig less M

e test as specified

torque values when subjected to the Receptacle strip spacing tolek

in 14.3.3.IJ.

Interchangeability.- All parts having tie same manufacturerIs part number

3.6

&all be directly and completely i.ntercbmgeable with each other with respect to installation and performance. ~angoa in manufacturers part number? sha be governed by the

drawing numberreq.ire!nentsof Specf.ficat

ion KIL-D-5028.

stud fastener assembly,

3.7

Finish.- The exterior, normally exposed surfaces of J

shall be c~plated

(class B, type II, black)

in accomlnnce

ulth Specification

cQ-P-l&5 or .inc plated (black) in accordance with Swctfication QQ-z-325.

grRd5&.%%%?%&ing

All detaila or vorlmbmhip shall be in accordance with highpractice for this type of fastener.

1

II.

QUhLIIT ASSURANCE PR!2VXXONS

h.1

classification of tests.- fheinspection and testing c# the fasteners shall

be classified as follows:

>

Qualification

tests

am ~~se

tes~

(a) Qualification tests:

performed

m samples suhtitted for approval as qualified

pmduct9 .

(b) Acceptance tests: Acceptancetests are those tests Performd

on individual lots uhlch have been submitted for 3CCept.WCE

umier contract.

..

>,

Downloaded from http://www.everyspec.com on 2012-08-08T14:20:08.

IUL.F-251?3A(AL3)

A.2

QuaMficati

+.a&..

1$.2.1 sampling imtructions.. The Qualification test sanplesshall c~?ist Or

four lengths of receptacle atrip as sbuwn in fisura 1, eaa 2 feet long; 32 stitaof

fasteners !undBs436M.ed)

as sbwn in ff.gurs2, four apecimms as Bhmm in figure 3, fOUr

SF~US

.ssh~

~ %=

II,

fo~ as *W

in fiIOU= 5, wf two SPcfmms

e~

as

shoun in figures 3, II, and 5, monnted an sheets having a total thickness of O.010 inch

less than th.total nominal thickness swctiied for each. Samples submitted fOr qual.ificat.itmte.:

.ing shall be accompanied by two camplete sets of detail !rMufEiCtting

drawings O{ each fastener item submitted for test. Samples shall be identified with the

manufacture~~s own @t

number and any additional information required by the authorizing

letter (se? 6.lJ).

11.2.2

Tests.- The Qualification tests shall ccumist of all the Acceptance tests

Spcfiied 1e~~i(

the fol.lovingtests. The Qualification tests say, at the option of

the prccuring activity, be supplemented with testi uder act~l se~ice cO~itiWs.

IJ.2.2.1 Vibration.- Fasteners shall be asseubled with a test panel as shown in

figure 5. The assenbly shall be loaded and attached to the tist jig as sbmm in figure

6. The base of I&e test jig shall be vibrated at a frequency varying between 10 and 55

cps at an amplitude of o .O&inch total excursion, t$e frBqUencY vating ~f.fofiY fr~

10 ti 55 CPS and =teg

t.a10 CPS in apmcmtite~

1 ~ute.

me fasteners sha~ be

subjected ta 9U minutes of continuous vibratinn in each of three mutua13y per~ndicular

directions.

L.2.2.2 corrosion resistance.- l%e fastener shall be subjected

cation QQ-K2151 for I.@ hovs.

accordance with-

to salt spray in

Acceptance tests.- FneAccep@nca tests shall consist of all the tests listed

lJ.3

k.3.3, respectively- In ad~tiOn, the

under Samplmg PlarM A, B, and c, L.3.1, L.3.2, @

fastener shall be subjected to any ethm tests which the Inswctor considers necessary

tu determine compliance v?.. ..herequirements of this s~cification.

eners, selected at random from a lot rWtue ~=p,e

are conditions

and submitted for acceptance at substanfa.tJ;~he_*fa=t

tially the st-,

shall be ViSWW.

~ed

fOr wor~naip,

f~isb, and cO~O=nce

to approved dasisn -d materials in accor-me

@tb tie Si%le

-@ins

plans, of

standard NIL-.VTD-105

.

Critical defects.Ore oritical d~fect found in the sample fast@nerS

11.3.1.1

shall be cause ~or rejection of the lot. Production shall be stoppsd until cause of the

critical defects can be foundand corrected.

-31-2

e-

If onB major Idefect is found in the sample fasteners, the

lot shall be re ec e .

Five fasteners shall be selected at random from each lot

of $i4;L2fri%%fA%+Gd

subjetted to the following tests. The rECePQCle StriPS

and specirens necessary for the tests shall be prepared as spec~ied herein.

IJ.3.2.1

DimenAans.- The dimensions shall be measured with an accuracy sufficient

to detertie complianse with tie dimensions and tolerances specified on the applicable

drawings or figures.

JJ.3.2.2 Hardness Of studs.- fhehqrdness of the studs shall be checked on tie face

the stud an either side of he screwdriver slot. Case-hardan9d surfaces shall k tested

on tie 15-11,Rcckwell sup3rficial scale. The heat-trfmted, through-hardenedstuds shall

be tested on the Itocku@31C scale.

of

Downloaded from http://www.everyspec.com on 2012-08-08T14:20:08.

MIL-F-251?3A(~)

1

. .. .

~--

ri-l

~

-1

t.

FAsTmss Sm

A.5sfXSLY

)

yG~/

t= .06L

ti~ NULALWT

~E5T , SPF.CI.FKATION

[ QC-A-318,

ti2

,.

Downloaded from http://www.everyspec.com on 2012-08-08T14:20:08.

HIL-P-25173A(A0)

?.)J38 *.016

1 2

*0L.r~0

mm

I

NFCEPTACLS SIP -/

Lt.

.WL M,mNMLAU4JI

SPECIFICATION WA-318,

smm

tiz H

DIM?.KSIONSIN I??X&S.

FIGOIKS5.

YPical vibration and Sndurance test specimen

Downloaded from http://www.everyspec.com on 2012-08-08T14:20:08.

HIL-F-25173A(IS0

Downloaded from http://www.everyspec.com on 2012-08-08T14:20:08.

lfJ.I.-F-25173A(

ASO)

.J2ikld%%%%%%sh%

b%%2sRx2%%s=lc%%im

.pckm

fabricated

the

tbic~Of PI

*XII

fi~s

3 t ~, ~

5.

to

aS

n~

in

The absolute mirdmum lccki.ngtarque shall be m8aswad on fasteners mmmted on spac&u%na

bating a total thickness of panel of 0,010 inch less than the tital nomina3 thickne.sa

8bmm in figures 3, b, ~

5.

shall

&.3.2.k

Onlocking torriW.- LIMt.erquarequired to unlock the fastener

h have been subjected to the Locking torque test an

on * e samples

a~cfiied in lJ.3.2.3.

be

detemimd

2he fastansr shall be mrunted as shown in figure

IIJ.2.5 Lecklns stop Strength

kftar the faatmer

has been bc?i;; and has cent-=ctedthe locking stip, a ~

-M

Of 30 Foti-inch

Shm

be wli~

at the faate~k t~a SC~v=

bit fOr

a dvration of at least 5 seconds. l%a tarque shall be applied in such manner as to force

the fastaner agatist the locking atop. The width and thickness of the bit shall not

EXCeed ?S percent of the width ad tMckneea, r+wpecti~4,

of the scr~i~er

slti. fie

stud and receptacle strip shall be inspected for any damage or rmchanioal im@mfJnt after

the application of the torque.

3.

11.3.2.6 tieceptaclesttip faate-

vlre attdiingstrength.-

that :i3?L:;13/~i8t::?&r::2&f:e7Y:2dsgi=

one end, and a suffi.dent length is free on the other emi for attachmentto a test fixture.

Tbe aluminum-alloymember of the test ~ckn

*al-l be 6 inches in length. A minimum

force of 60 FGUIIdSshall be applied in the lmgti direction of the fastamar wI- and the

aluminum member shall be held statio~.

AV visible slippage shall be noted.

&.3.2.6.2

.staklng breakout.. With the aluminum maber of the receptacle 6trip

ta tJIeaxis

held stationaq, a minimum 1oad of 250 pahnda HIIallbe applied perrmrWA.ar

of the f astemr

wire through

ang one of the receptacle strip faatanar stad holes. he

fastenerwire sMins

shall be inspected for any tisihle deformation. The load shall be

applied to the fa.$tenerwire through a 3/lGinch flat-ml pin pesitimed perpmiimlnr to

the fastener wire, and so directed that the load tenis to force the fastener wire p-t

the 9t*ing .

11.3;2.7. Initial tenaim.- l%. initial tmsion &ball be established by daterubhs

the temile. lcd that produces a sepa~tian of 0.003 inch between the pmml and receptacle

strip at the area Immediately around the fastener. A tmical tension teat jig ie abcmn

in figure 7.

Sated t%nedla Mad.IJ.3. Z.8

been subjected to the Imcking tO_

the fastener 8RwImm

shown

the

test aS s-titid

in 11.3.2.3,

load AU

be applied nmvd

to the tistpaaql and tending to pu31 the

five sumassire tks,

each of 5 seconds duration. The faatener shall

jected to the Lccki.ngtorque tOSt a. opcified ti 11.3.2.3..

The ~IWE.

the fastener shall ,@ ma.wred.

Affar

in fignm

ITIM

3 bm

bd.b

fastaner apart,

then again be mb~

to lx

4.3.2.9 Pmml and raCeP%ICla strip 59*

tire.. llm fastener shall be landed at its

receptucle sepration at tbe ar69 ~tely

~ofi

ratd tmfle bad.

he -l

m

the fastener shall be meas~.

L.3.2.M

Tensile 0v.3r3.0ad.-A2ter the Initia3 tension, Sated tenal.3Bload Locking

torque. Onlocking torque, and %

LOCking stop strength tests (11.3.2.7,11.3.2.8,~.3.2.3,

11.3.2.t,and 11.3.2.5,mqmtirdy)

b.- been -28, tie f-ten=

s~~

be aW**d

to a

tamile load of 150 ~rcent of the mtad mlm

in ace-e

~~

the ~ed~

~ca~

for the Fiat.-sd

tensile load test as specified in lt.3. 2.8.

opon completion of the Tensile

merload tmt, tbe faotener e.hallbO -td

f= any *~@

Or ~~~c~

-~nt.

32

i

I

Downloaded from http://www.everyspec.com on 2012-08-08T14:20:08.

MIL-F-2S173A(~)

NO. 6-32

sOLTS ANo

NIJIS,

8 EACH =

ASSICATS PLATE ~

FIT SPWXIlIN~

~G

Y

/

)

28

Downloaded from http://www.everyspec.com on 2012-08-08T14:20:08.

HIL-Y-25173A(ASG)

11.3.3

%npling plan C.- Five fasteners shall be selected at randau from each lot

of 10,CCO, or fraction thereof, and ehall be subjetted to the fo31cdng teats. The

receptacle strips and specimens neceseary for the teata ehall be ppared

as s~cified

herein.

il.3.3.l Rated shear had. - lhe fastener .@all be mounted.as shown in I@me k

and tested vith lk test jig shown in figure 8. TM rated shear had shall be app3.ied

wall.el to the test -l

five sM,CES.9iW tinm , eachof 5 8~C011d9duration. The

fastener shall then again be subjectad to ths LCQldmg torque test as s~cflied in k.3.2.3.

TIIetorque required to leek the fastener shall be ieaaumd.

11.3.3.2 Shear overload.- Aftar the Rntad *ear

the fastener shall be subjetted to a shear load of SO

accordance wltb the procedure specified for the Nated

11.3.3.1. Upon completion af the Shear overload tast,

any damge or mechanical impairment.

load test ai specuied in It.3.3.i,

percent of the rated value in

~EIar load test as specified in

tbe fastener shall be inspected for

11.3.3.3 Endurance.- The fastener shall be s~jected tm 5,000 locking and unlccking

operational cycles at apprmi.mtely 110 cpm.

h.3.3.11 Receptacle strip spacing tolerance.- A test pnel. shall be fabricatad as

Ed test panel *a

b tried for fit and fastener opration

shown in figwe 5. The asseinbl

with a test jig as shown in figure 9. Tho fastener studs shall be engaged and disengaged

with the receptacle strip and shall be operated into the locked and unlocked positions

for any spcing of the receptacle strips within @.020 inch of the nominal value, vith a.

skew between opposite hole centers up to 0.010 knch and a difference between the top

surface levels up to 1/16 inch.

JJ.3.11 Degrees

Nokmal, tightened, or reduced inspection in accordbe determined by tie ~ocuring activity.

L.3.5

Rejection ad retest.- Ulen sampling tests are specified on a nmnber of

item that are selected from a production lot, and one or more of M is number faib to

met the specified tast(s), acceptmce of all items still on hand and subsequently produced will be withheld until the extent and cause of fallure are determined. For operational reasons, Acceptance tests ray be continued pending investigation of a sampling

test failure. However, fimd acceptance of the items on hand and subsequently produced

is contingent upon the Inspector#B decision regarding the over-all conformance of the

product to svcif icaticm requirements. h!aencorrective action has been accomplished,

all necessa~ tests shall be repeated. If investigation indicates that tha defects may

exist in items previously accepted, full particulars

concerning tie defects, including

recommendations for correction, shall be furnished to the contracting officer.

5.

PREPARATION FOR OSLIVEU

5.1

Preservation, packaging, Pcklns, and mrkfng f= *i-t

~a~

be fi accO~

stcmge packante witb Specificaticm NIL-E-17555. Method I shall be used far demied

aging. fheshipcat marking nomenclature sha~ be as follows: St@k No. or other

identificationas sPcified in the PIUCbME doc~t~,

F&te~~,

Cm~~

p-l,

fi~r~t

~ti~t.n

*NOTE: The contractor shall enter the Federal Stock No. specified

in the prchase document or aa furnished by ~

procuring activity:

When the Fe&al

StaL No. is not provided or available frmm tbe

procuring activity, lea- space therefor and enter the Stock No.

or other identificationas provided by the PrOCmiIIS acti~ty.

Downloaded from http://www.everyspec.com on 2012-08-08T14:20:08.

MIL-F-25173A(ASG)

-.

-G

/ )

0, .t

-.

,!:

,1

-.

.8

.!

---- J

l)

DIMEMIOHS

IN INCHFS.

FIGUSS 8.

Typical shear test jig

15

).

Downloaded from http://www.everyspec.com on 2012-08-08T14:20:08.

nIL-F-25173A(~@

SPACSS BAS M TIE PIISII!M

IuLQIANCEJdiKl

PSOVIOS WITS lltl.020, INCN SUMS TO GIVB NoMINAL AND XAILMR!

TULXRMJCE DIKS~IONS

SPFJXH2M

(sKB FIGOBB 5

FABSICATE

SKW SSIWSN

-1

.938

*.o16

h

6.5oo

*.031

.562 *.016

)

c.

/

5.622

i .020

BAs mm Sclux

10 IWO

~

w

DIMUISIOW

~~TACLB

IN IBCSES.

STRIP MOtNiTINOR19ETS SPdCEU 1.125 *.016.

FIOOBX 9.

16

-. ._. .

Typical opmation test jig

06L

Downloaded from http://www.everyspec.com on 2012-08-08T14:20:08.

HIL-F-251m(MG)

6.

NGTBS

6.1

Intirded use.- The aircraft equigmmnt control Pnel fastener covered by thiB

intended for attaching equAPwnt control r=nels to tie aircraft strucapeci.flcation

ture.

6.2

ordering da--Proctmement doc-tis

should skcify title, nunber,and dab

of this specification, and whether domestic or Werseas packing is required.

6.3

Definitions..

Critical d6f.9ct.. A critical defect is a defect that judgrmnt and expriencs

6.3.1

Micati

Cda ~gdt in hasardoua or uns~e cOnditicm for individuals using or naln.,

tnlning the fastener.

32

result

in fa ~-w

purpose.

A major defect is a defect, other than critical, that could

or ma erially reduce the usability of tie fastener for its intended

6.3.3

Minor defeet.- A minor defect is a defect that does not materially reduce

the usability of @e f=tener for ita intended Purvose, or is a departure from established

standards having no significant bearing on the effeCtiVe use or o!xration of tha unit.

..

6.11 fiovi.sionsfor Qualification tests.- In the procurement of products requiring

qualification, the right is reserved to nject bids on prcducts that have not been sub.

Jetted to the required tests and found satisfactory for inclusion on a Qualified Products

List . The attention of suppliers Is called to this requirement, and imnufacturers are

urged to.arrange t.ahave the products that they propxe to affer to the Federal Government tested for qualification in order that they MY be eligible to be awarded contracts

information ~ror orders for the products covered by this s% cification. Bequests for..

taining to qualification of products covered by this specification shcmld be addressed

to the Cow.ander, Wright Air Dev?lopm?nt Center, Wright-Patterson Air Force Base, Ohio,

the activity re~nsible

for qualification, with a copy to the Bureau of Aero~tic~,

Navy DeXtM8nt, Wasbin@.on 25, D. c.

PATENT NOTICE: When Governmnt drawings, spcif icaticm,

or other data are S

for any PIrpme other than in connection with a definitely related Government procurenant

opmration, the Gnited States Governmnt tiereby incurs no

responsibility nor any cbl.lgatianwhatsoever; and the fact

that tbe Governmeti may have formulated, furnished, pr i

any way supplld the said drawings, sw ctfications, or

other data is not tobe regamled by implication or otherwise as In any manner licensing ti-eholder or my other

p-son cm corporation, or conveying any rights or permission

to manufacture, use, or sell any ~tented invention that

may in any way be l-elatedthereto.

custodians:

- Nure.auof Aeromntics

~T

Air F~CO

.-

?.7

Downloaded from http://www.everyspec.com on 2012-08-08T14:20:08.

-..

STANDARDIZATION

1NSTRUCTIONS:

me.

DoD

we

prep.

I or

wud.cts

c..t,.ct.rs,

ring

be

submit

the

in

OF

t.

t.

prep.ri.

ORG4N1ZATIOM

1.

COSI

or

+e

-d

. .

.rt.

-mmenl.

d.1.y.

mmwf.ct.r.r,l

t.

III,.

amend

d.cum-t.

..~d.-

F.ld..

form

do

. ..tr.

there

not

.,

wU1

~.

11..s

O.

.dd,l,.n~

which

.r.

W,i,

.,de.

omply

r.wwm=mt..

i.

..Y

ud

A.

..

. .

. .

RECOMMEND.

. . .

,IONS

COMTRhCT

NUMOER

MATERIAL

PROCURED

UNDER

DOCUMENT

MMeg.

FOR

CREATED

.?40

PROBLEMS

OR

REQuIRED

IMTERPRETAT,

DS.--*,*,

oN

omolNo.

CORRECTING

THE

0EFICIEP4CIES

----L_

(S THE

----cl

AN VOOCUMENT

DOCUMENT

_-\v=~

REQuIREMENT

WNSIOEREDT09

flf-,Y..-,

tittwt,?J?J

REUARXS

JBWITTED

RIGtO

REsTRICTIVE?

NO

BY

(Prlt.d.,

WP.d-I.

mdafdr..s

-0PtlMI.1J

TELEPHoNE

DATE

which

PI...bathin-

COMMENT50

dm.

send

my

a .ctiviQ.

&OORESS

NO.

e.

docume,

thernod.c

.nd

t. WM..

pertinent

form

O-,R=CTCOVE-MU.N,CON,.AC,

USE1

.,

of

c.mer,

pr.c,,,

the

TITLE

ANO

AS ANY PART OF THE

of

.uw!sers

..th.rlzatim

1.

achieve

.6.

staple

Att.ch

.tl.ch

help

.nh.nc.

Pr.,.pe<:ti.e

,...,*.

paper%

OM13APW

.

(No, 22.R2$5

-..

.~.rwis.

c..stt.tut.so.

ct...!

.,

FROPOSAL

..~i.itb-.fi.%.l

mlfilm.m

zo..~...

subm,tted

ibis

AND

IMPROVEMENT

formcs

document(n)

improving

lD.ENT1~lER

this

s...bl.

ctivities,

Comment.

envelope.ddres.ed

AME

.[

rc.

comments

rsferenc.d

os . . .

oCUMEMT

.:

government

to

.Cti.itr.

portica.f

may

Thep.rp.aee

suitsble

invited

DOCUMENT

.... ..,

-...._.

-L

..

IN PROCUREMENT

t,

Downloaded from http://www.everyspec.com on 2012-08-08T14:20:08.

PosTAGE

4MD

FCCS

PAID

*

=

c

OFFICIAL

PEN

MJSIIUM

AI.rY rOR pRIVhTE USEsaw

ASD/EtWES

Wright-Patterson

AFB, OU 4S433

You might also like

- MS25083 KDocument5 pagesMS25083 Kahs23No ratings yet

- Practical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentFrom EverandPractical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentNo ratings yet

- OP 1157 3.5 and 5 in Aircraft Rockets 3.25 Motor 1945Document17 pagesOP 1157 3.5 and 5 in Aircraft Rockets 3.25 Motor 1945FrancescoNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Mil R 24537Document10 pagesMil R 24537巫錦福No ratings yet

- MIL-G-10944 Rev B PDFDocument14 pagesMIL-G-10944 Rev B PDFffincher4203No ratings yet

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- Mil C 9084CDocument20 pagesMil C 9084CNick AlanenNo ratings yet

- Mfaf BK: ScopeDocument23 pagesMfaf BK: ScopesbalajimNo ratings yet

- Plymetal SpecificationsDocument10 pagesPlymetal SpecificationsGiuseppe GoriNo ratings yet

- Hyd. Top Bracing System of ME PDFDocument38 pagesHyd. Top Bracing System of ME PDFKaushalKishoreNo ratings yet

- Mil F 6218CDocument11 pagesMil F 6218CHabu1zeroNo ratings yet

- Transformer BushingDocument11 pagesTransformer BushingNunna BaskarNo ratings yet

- Circuit Breaker Specification MS 24509Document5 pagesCircuit Breaker Specification MS 24509JizzPontesNo ratings yet

- MIL-A-2550C Ammunition General SpecDocument17 pagesMIL-A-2550C Ammunition General Speccpt_suzukiNo ratings yet

- Pipe Reinforcing at SupportDocument12 pagesPipe Reinforcing at SupportSeungmin Paek100% (3)

- Reinforced Concrete Column DesignDocument18 pagesReinforced Concrete Column DesignGeorge LazarNo ratings yet

- CIVIL ENGINEERING (PAPER-IDocument20 pagesCIVIL ENGINEERING (PAPER-IrahulNo ratings yet

- 02-ToE-C945-111 - Service Manual Motoman K6S K10SDocument36 pages02-ToE-C945-111 - Service Manual Motoman K6S K10SBayron López CastilloNo ratings yet

- Project Specification for Machine ScrewsDocument7 pagesProject Specification for Machine ScrewskvammerNo ratings yet

- CAP562 CAIPS 09 Elec EqptDocument128 pagesCAP562 CAIPS 09 Elec EqptVinayNo ratings yet

- Reloading For The M1 Rifle - J. ClarkeDocument5 pagesReloading For The M1 Rifle - J. Clarkebpm990d100% (6)

- Electrical Bonding Materials and SpecificationsDocument28 pagesElectrical Bonding Materials and SpecificationsDaniel GarciaNo ratings yet

- Iuli IiaaDocument20 pagesIuli Iiaaawesome_600No ratings yet

- (KR Kci':) : O-Mo-E.:U (Eco/.Document10 pages(KR Kci':) : O-Mo-E.:U (Eco/.Jure KrenNo ratings yet

- Clarification For DSLP Calculations & Switch Yard Lighting Protection 1Document11 pagesClarification For DSLP Calculations & Switch Yard Lighting Protection 1Ramesh AnanthanarayananNo ratings yet

- Elect Manhole Handhole MetricDocument7 pagesElect Manhole Handhole MetricRom GuarenNo ratings yet

- Rlight Steel FramingDocument204 pagesRlight Steel FramingTopSteel Lda100% (2)

- ./F/Anufe,..: I/1Jaduitut of Wtmlllpllttuliult-3I1Mal NlulitlibttutidtlDocument3 pages./F/Anufe,..: I/1Jaduitut of Wtmlllpllttuliult-3I1Mal NlulitlibttutidtlMajved Ariel HassanNo ratings yet

- ./F/Anufe,..: I/1Jaduitut of Wtmlllpllttuliult-3I1Mal NlulitlibttutidtlDocument3 pages./F/Anufe,..: I/1Jaduitut of Wtmlllpllttuliult-3I1Mal NlulitlibttutidtlMajved Ariel HassanNo ratings yet

- Dynamic Analysis Stranded Wire SpringsDocument71 pagesDynamic Analysis Stranded Wire SpringsJoseph J. ZajkNo ratings yet

- Pomm 9-1005-294-14 Xm177e2 SMG (1967)Document26 pagesPomm 9-1005-294-14 Xm177e2 SMG (1967)pmikel100% (4)

- Oman Electricty Standard For 132 KV LinesDocument72 pagesOman Electricty Standard For 132 KV LinesiaessackjeeNo ratings yet

- Panasonic Alpha1 Chassis Tx2 TV D (ET)Document27 pagesPanasonic Alpha1 Chassis Tx2 TV D (ET)Ahmed SmajilovicNo ratings yet

- Three-phase motors manualDocument25 pagesThree-phase motors manualDimitriu CarmenNo ratings yet

- Parts List: Liuki®Document76 pagesParts List: Liuki®That TawooNo ratings yet

- Carriage Directorate Computer Wing Circular Modification Sheet SpecificationDocument3 pagesCarriage Directorate Computer Wing Circular Modification Sheet SpecificationpradeeepgargNo ratings yet

- Feci. Spec - Cq.A-Z50/@ CH 77, 1967: Fedesal SpecificationDocument7 pagesFeci. Spec - Cq.A-Z50/@ CH 77, 1967: Fedesal SpecificationOzan SümenNo ratings yet

- Propeller Fitting ABSDocument7 pagesPropeller Fitting ABSAngel DavidNo ratings yet

- Electric-Resistance-Welded and Carbonamanganere Boiler Tuôes'Document3 pagesElectric-Resistance-Welded and Carbonamanganere Boiler Tuôes'Joao Osmar CorreaNo ratings yet

- ./Fi'Ttmtfef: &Pmtuu:Ra of Idnnmpartlition-Ll1Ulerni I/Uintiun NlminimrntinnDocument2 pages./Fi'Ttmtfef: &Pmtuu:Ra of Idnnmpartlition-Ll1Ulerni I/Uintiun NlminimrntinnMajved Ariel HassanNo ratings yet

- Mx5 95 1 of 3 EngineDocument90 pagesMx5 95 1 of 3 EngineJennifer Faith EvansNo ratings yet

- Rolastar CatalogueDocument8 pagesRolastar Cataloguearcturus02No ratings yet

- KLS AhuDocument32 pagesKLS AhuKarayev BayramNo ratings yet

- Mil W 13855D PDFDocument20 pagesMil W 13855D PDFjimr6590No ratings yet

- Ship Launching & Upgrading Using Air BagsDocument11 pagesShip Launching & Upgrading Using Air BagswildanNo ratings yet

- Taylorcraft Service Manual BB12Document48 pagesTaylorcraft Service Manual BB12Jessie BechaydaNo ratings yet

- TM 55 1520 236 T 2Document997 pagesTM 55 1520 236 T 2Tod A. Wulff100% (2)

- SAE StandardDocument9 pagesSAE StandardAzizol Wahab50% (4)

- CSR 70 Tech. & Start Up ManualDocument15 pagesCSR 70 Tech. & Start Up ManualteutashNo ratings yet

- Ur s21 Rev5 pdf1338Document14 pagesUr s21 Rev5 pdf1338Huy ChínhNo ratings yet

- Dusterloh Air Winch ManualDocument28 pagesDusterloh Air Winch ManualNirudpal BharaliNo ratings yet

- Brake Holding Power TestDocument6 pagesBrake Holding Power TestCaptIsqanNo ratings yet

- Continental Aileron Cable Rigging Event Criteria: Page 1Document11 pagesContinental Aileron Cable Rigging Event Criteria: Page 1Jose Miguel Atehortua ArenasNo ratings yet

- Mil A 83039b Am3MIL-A-83039B AM32C-10A AIRCYCLE AIRCONDITIONER2c 10a Aircycle AirconditionerDocument29 pagesMil A 83039b Am3MIL-A-83039B AM32C-10A AIRCYCLE AIRCONDITIONER2c 10a Aircycle Airconditionerjohn_gouveia_8No ratings yet

- 3938Document23 pages3938Ritu Saroa0% (1)

- Miller 350 ManualDocument72 pagesMiller 350 Manualbrinniboo2No ratings yet

- Strain Gage Rosette TheoryDocument7 pagesStrain Gage Rosette TheoryHasnain BukhariNo ratings yet

- NAS1836 Light InsertDocument3 pagesNAS1836 Light InsertacparaujoNo ratings yet

- MS20257D HingeDocument2 pagesMS20257D HingeacparaujoNo ratings yet

- IPC de Un Boeing 757Document22 pagesIPC de Un Boeing 757Armando VasquezNo ratings yet

- NAS517Document2 pagesNAS517naveensir100% (1)

- MS35842E Hose ClampDocument2 pagesMS35842E Hose ClampacparaujoNo ratings yet

- NAS1921 Blind RivetDocument20 pagesNAS1921 Blind Rivetacparaujo100% (1)

- MS35842E Hose ClampDocument2 pagesMS35842E Hose ClampacparaujoNo ratings yet

- MS21073G Nutplate CornerDocument2 pagesMS21073G Nutplate CorneracparaujoNo ratings yet

- MS16998E Cap ScrewDocument5 pagesMS16998E Cap ScrewacparaujoNo ratings yet

- MS21060 Nutplate Low HeightDocument3 pagesMS21060 Nutplate Low HeightacparaujoNo ratings yet

- MILITARY SPECIFICATION SHEETDocument5 pagesMILITARY SPECIFICATION SHEETacparaujoNo ratings yet

- MS16995H ScrewDocument9 pagesMS16995H ScrewacparaujoNo ratings yet

- AN970 WasherDocument2 pagesAN970 WasheracparaujoNo ratings yet

- AN525 ScrewDocument1 pageAN525 ScrewacparaujoNo ratings yet

- Tom Swift PaperDocument53 pagesTom Swift Paperimran_chaudhryNo ratings yet

- Wind Load CompututationsDocument31 pagesWind Load Compututationskim suarezNo ratings yet

- Engineering QuotesDocument10 pagesEngineering QuotesGendakenNo ratings yet

- EI Manifold Pressure ManualDocument12 pagesEI Manifold Pressure Manualjkloepping_634367970No ratings yet

- Case Study-R12 12Document81 pagesCase Study-R12 12ranjitpandeyNo ratings yet

- Peanut Brittle LabDocument2 pagesPeanut Brittle LabMary Bacon HillebrandNo ratings yet

- CP 05 - Determine The Young S Modulus of A MaterialDocument2 pagesCP 05 - Determine The Young S Modulus of A MaterialABBIE ROSENo ratings yet

- The Weka Guard and Protector - Weka MarineDocument2 pagesThe Weka Guard and Protector - Weka MarineJoko SusiloNo ratings yet

- Contactor Cap Lc1dDocument4 pagesContactor Cap Lc1dAlfiansyah Dharma Setia DjaketraNo ratings yet

- SPINTRONICSDocument33 pagesSPINTRONICSSyam Pradeep ReddyNo ratings yet

- As 2560.2.1-2003 Sports Lighting Specific Applications - Lighting For Outdoor TennisDocument7 pagesAs 2560.2.1-2003 Sports Lighting Specific Applications - Lighting For Outdoor TennisSAI Global - APAC0% (1)

- Acee 2018 039Document13 pagesAcee 2018 039threedlabsNo ratings yet

- Appendix 400.4 - Traffic Count TemplateDocument7 pagesAppendix 400.4 - Traffic Count TemplateOgunranti RasaqNo ratings yet

- Thermostats and Dial Thermometers PDFDocument252 pagesThermostats and Dial Thermometers PDFAsep MustopaNo ratings yet

- Construction of Multistoried Boys Hostel by Kanwarjot SinghDocument22 pagesConstruction of Multistoried Boys Hostel by Kanwarjot SinghvipinNo ratings yet

- NPN Silicon Transistor: High Voltage Switch Mode ApplicationDocument6 pagesNPN Silicon Transistor: High Voltage Switch Mode ApplicationManuel PradoNo ratings yet

- What Is A Gantt Chart - Gantt Chart Information, History and SoftwareDocument3 pagesWhat Is A Gantt Chart - Gantt Chart Information, History and SoftwareShaikh Saeed AlamNo ratings yet

- Measurement & Calculation of Vehicle Center of Gravity Using Portable Wheel ScalesDocument11 pagesMeasurement & Calculation of Vehicle Center of Gravity Using Portable Wheel ScalesVedant KodagiNo ratings yet

- Dissolved OxygenDocument2 pagesDissolved OxygenAnonymous atBeojaNo ratings yet

- User's Guide: BondekDocument8 pagesUser's Guide: BondekMing ChongNo ratings yet

- TI Oxydur PTB 206 - en PDFDocument5 pagesTI Oxydur PTB 206 - en PDFgonzalogvargas01100% (1)

- Pure Chem p2 - 26pgDocument26 pagesPure Chem p2 - 26pgJhomer CrespoNo ratings yet

- Bel Adv Details For Senior Assistant Engineer Posts - Jobalertshub 2Document5 pagesBel Adv Details For Senior Assistant Engineer Posts - Jobalertshub 2Palani AppanNo ratings yet

- Nurul Ain - nurulain@gmail.comDocument32 pagesNurul Ain - nurulain@gmail.comMuhamad FarhanNo ratings yet

- Trigonox101 PdsDocument3 pagesTrigonox101 PdsPaula RiveraNo ratings yet

- CPU Vs vCPUDocument14 pagesCPU Vs vCPUainseanNo ratings yet

- Industrial Insulation Applications: Green Engineering-1 Insulation Spreadsheets - ContentDocument55 pagesIndustrial Insulation Applications: Green Engineering-1 Insulation Spreadsheets - ContentRashel HasanNo ratings yet

- Zw3d2022 Lite Vs Cadbro 2022Document4 pagesZw3d2022 Lite Vs Cadbro 2022Carlos LimaNo ratings yet

- American English File Starter Ichecker - File 3Document3 pagesAmerican English File Starter Ichecker - File 3Daniel AugustoNo ratings yet

- MEITRACK MVT100 User Guide V2.4Document19 pagesMEITRACK MVT100 User Guide V2.4MeitrackNo ratings yet

- Sant Gadge Baba Amravati University: Backlog From Session Winter-2019Document2 pagesSant Gadge Baba Amravati University: Backlog From Session Winter-2019Prashant pandeNo ratings yet

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (50)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionFrom EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionRating: 4.5 out of 5 stars4.5/5 (3)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Basic Alarm Electronics: Toolbox Guides for Security TechniciansFrom EverandBasic Alarm Electronics: Toolbox Guides for Security TechniciansJohn SangerRating: 4 out of 5 stars4/5 (1)

- The Laws of Thermodynamics: A Very Short IntroductionFrom EverandThe Laws of Thermodynamics: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (10)

- Control of Power Electronic Converters and Systems: Volume 1From EverandControl of Power Electronic Converters and Systems: Volume 1Rating: 5 out of 5 stars5/5 (1)

- Quantum Mechanics 4: Spin, Lasers, Pauli Exclusion & Barrier PenetrationFrom EverandQuantum Mechanics 4: Spin, Lasers, Pauli Exclusion & Barrier PenetrationRating: 1 out of 5 stars1/5 (1)

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)

- Design of Foundations for Offshore Wind TurbinesFrom EverandDesign of Foundations for Offshore Wind TurbinesRating: 5 out of 5 stars5/5 (3)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideFrom Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideRating: 3.5 out of 5 stars3.5/5 (7)

- Rolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsFrom EverandRolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsNo ratings yet