Professional Documents

Culture Documents

Verification Manual Indian Codes

Uploaded by

Arunkumar AKCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Verification Manual Indian Codes

Uploaded by

Arunkumar AKCopyright:

Available Formats

Autodesk

Robot Structural Analysis

Professional

VERIFICATION MANUAL

FOR INDIAN CODES

March 2014

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

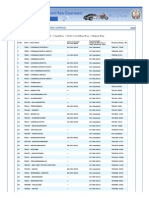

INTRODUCTION ..............................................................................................................................................................................1

STEEL ..............................................................................................................................................................................................2

1. IS 800:2007 - GENERAL CONSTRUCTION IN STEEL (THIRD REVISION) ............................................................................3

GENERAL REMARKS ..................................................................................................................................................................5

VERIFICATION EXAMPLE 1 - DESIGN OF MEMBERS FOR COMPRESSION ....................................................................................10

VERIFICATION EXAMPLE 2 - COMBINED COMPRESSION AND BENDING ABOUT BOTH AXES (LATERAL-TORSIONAL BUCKLING) ........18

CONCRETE ...................................................................................................................................................................................27

1. IS 456:2000 RC BEAMS .........................................................................................................................................................28

VERIFICATION EXAMPLE 1 - DIMENSIONING OF SIMPLY SUPPORTED BEAM ...............................................................................29

VERIFICATION EXAMPLE 2 - DETERMINATION OF CAPACITY OF A BEAM ....................................................................................32

LITERATURE .............................................................................................................................................................................33

2. IS 456:2000 RC COLUMNS ...................................................................................................................................................34

VERIFICATION EXAMPLE 1 - UNIAXIALLY ECCENTRICALLY LOADED BRACED RECTANGULAR COLUMN .........................................35

VERIFICATION EXAMPLE 2 - COLUMN SUBJECTED TO AXIAL LOAD AND BIAXIAL BENDING ...........................................................38

LITERATURE .............................................................................................................................................................................41

March 2014

page i

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

INTRODUCTION

This verification manual contains numerical examples for elements of steel structures prepared and

originally calculated by Autodesk Robot Structural Analysis Professional version 2013. The

comparison of results is still valid for the next versions.

All examples have been taken from handbooks that include benchmark tests covering fundamental

types of behaviour encountered in structural analysis. Benchmark results (signed as Handbook) are

recalled, and compared with results of Autodesk Robot Structural Analysis Professional (signed further

as Robot).

Each example contains the following parts:

- Title of the problem

- Specification of the problem

- Robot solution of the problem

- Outputs with calculation results and calculation notes

- Comparison between Robot results and exact solution

- Conclusions.

March 2014

page 1 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

STEEL

March 2014

page 2 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

1. IS 800:2007 - General

Construction in Steel

(third revision)

March 2014

page 3 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

IMPLEMENTED CHAPTERS of IS 800: 2007 (third revision)

List of Indian Standard General Construction in Steel Code of Practice chapters, implemented to

Autodesk RSA program:

1. Mechanical properties of structural steel (Table 1)

2. Classification of cross-sections - 3.7 and Table 2

3. Partial Safety Factor for Loads f ( Table 4)

4. Partial Safety Factor for Materials M ( Table 5)

for Limit State Design

5. Design of tension members - 6

6. Design of compression members - 7

7. Design of members subjected to bending

Laterally supported beam - 8.2.1

Laterally unsupported beams - 8.2.2

Effective length for simply supported beams Table 15

8. Shear - 8.4

9. Combined axial force and bending moment - 9.3

10. Limit State of serviceability - 5.6 and Table 6

11. Working Stress Design 11

March 2014

page 4 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

GENERAL REMARKS

A.

Job Preferences

If you make first step in RSA program specify your job preferences in JOB PREFERENCES dialog

box (click Menu/ Tools/ Job Preferences). Default JOB PREFERENCES dialog box opens:

You can define a new type of Job Preferences to make it easier for future.

First of all, make selection of documents and parameters appropriate for India from tabs of the list view

in JOB PREFERENCES dialog box.

For example to choose code, first click Design codes tab from left list view, then select code from

Steel/Aluminum structures combo-box or press More codes button which opens Configuration of Code

List:

Put India code into the right list of the box, and then set it as the current code. Press OK.

March 2014

page 5 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

To choose code combination first click Loads tab from left list view in JOB PREFERENCES dialog

box,

Then select code from Code combinations combo-box or press More codes to open the Configuration

of Code List.

Pick Load combinations from combo box. The new list view appears:

Put IS: 875 (Part5) code into the right list of the box, then set it as the current code. Press OK.

March 2014

page 6 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

After the job preferences decisions are set, press Save Job Preferences icon in JOB PREFERENCES

dialog box. It opens SAVE JOB PREFERENCES dialog box.

Type a new name e.g. India Limit State and save it. The new name appears in the combo-box.

Press OK button.

You can check load combination regulations by pressing right button next to Code combinations

combo-box in Loads tab JOB PREFERENCES dialog box. It opens proper Editor of code combination

regulations dialog box.

March 2014

page 7 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

B.

Calculation method

Indian code IS 800: 2007 gives two verification options: Limit State Design and Working Stress

Design. In RSA program you must always manually specify:

1. calculation method

2. load code combination -> appropriate for calculation method

ad.1 calculation method

Calculation method (Limit State or Working Stress) can be chosen on Steel /Aluminum Design layout.

Press the Configuration button in CALCULATIONS dialog box.

Here you can choose calculation method

(not regulation of load combination).

March 2014

page 8 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

ad.2a load code combination basic approach

To specify load code combination (Limit State or Working Stress) appropriate for calculation method,

click Menu/ Tools/ Job Preferences. JOB PREFERENCES dialog box opens.

Select earlier prepared job preferences (as defined in Section A.) by clicking its name from combobox. In following dialog box India Limit State job preferences should be selected.

By pressing OK button, you accept chosen job preferences for a current task.

ad.2b load code combination - alternative (tricky-easy) approach

Start in Loads layout. Here, you can prepare load combination for both calculation methods for further

using (for member verification). Create manually Limit State Design LS load combination and

Working Stress Design WSD load combination in Load Types dialog box.

In this case, you can use in verification

appropriate load combination corresponding to

the calculation method.

March 2014

page 9 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

VERIFICATION EXAMPLE 1 Design of members for compression

Example taken from: DESIGNERS GUIDE to EN 1993-1-1 Eurocode 3:

Design of steel structures, general rules and rules for buildings

written by L. Gardner, D. A. Nethercot, 2005

TITLE:

Example 6.7 Buckling resistance of a compression member

SPECIFICATION:

A circular hollow section CHS member used as an internal column in a building. The column has

pinned boundary conditions at each end and the inter-storey height is 4 m. The critical combination of

actions results in a design axial force of 1630 kN. Assess the suitability of hot-rolled 244,5x10 CHS in

grade S275 steel (fy = 275 MPa) for this application, using Limit State Design.

SOLUTION:

Specify appropriate parameters in JOB PREFERENCES dialog box (click Menu/Tools/Job

Preferences). Then, choose calculation method Limit State Design in CONFIGURATION dialog box

(press Configuration button in CALCULATIONS dialog box).

In DEFINITIONS dialog box you can define a new type of member in agreement with structure data

It can be set in Member type combo-box. Pre-defined type of member Column may be initially

opened.

March 2014

page 10 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

For chosen member type, press the Parameters button on Members tab, which opens

MEMBER DEFINITION PARAMETERS dialog box.

Type a new name in the Member type editable field, e.g. column 1. Change parameters to meet

initial data requirements of the structure. In the particular compression case press More button which

opens MEMBER DEFINITION ADDITIONAL PARAMETERS dialog box:

March 2014

page 11 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

Switch on Hot-rolled pipes. Click OK.

In DEFINITIONS dialog box save the newly-created member type, here column 1:

Number of the member must be

assigned to appropriate name

of Member type.

(It is very important when you verify

different member types.)

March 2014

page 12 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

In the CALCULATIONS dialog box set:

-> Verification option; here Member Verification,

-> Loads cases ;

here for no 1 for Limit State Design

-> Limit state ; here only Ultimate Limit state will be analyzed, so switch off Limit stat Serviceability.

Now, start calculations by pressing Calculations button.

MEMBER VERIFICATION dialog box with most significant results data will appear on screen.

Pressing the line with results for the member 1 opens the RESULTS dialog box with detailed results

for the analyzed member. The view of the RESULTS windows are presented below.

March 2014

page 13 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

Simplified results tab

Detailed results tab

Pressing the Calc.Note button in RESULTS Code dialog box opens the printout note for

the analyzed member. You can obtain Simplified results printout or Detailed results printout.

It depends on which tab is active.

The printout note view of Simplified results is presented below.

March 2014

page 14 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

RESULTS for Limit State Design method:

a) In the first step CHS 244,5x10 section was considered. The results are presented below.

STEEL DESIGN

---------------------------------------------------------------------------------------------------------------------------------------CODE: IS800: 2007 Indian Standard - General Construction in Steel - Code of Practice (Third Revision)

ANALYSIS TYPE: Member Verification

---------------------------------------------------------------------------------------------------------------------------------------CODE GROUP:

MEMBER: 1 POINT: 1

COORDINATE: x = 0.00 L = 0.00 m

---------------------------------------------------------------------------------------------------------------------------------------LOADS:

Governing Load Case: 1 STA1

---------------------------------------------------------------------------------------------------------------------------------------MATERIAL:

S275 fy = 275.0 MPa fu = 430.0 MPa

E = 210000.0 MPa

gM0=1.100

gM1=1.250

---------------------------------------------------------------------------------------------------------------------------------------SECTION PARAMETERS: CHS 244.5x10

D=24.4 cm

Avy=46.919 cm2

Avz=46.919 cm2

Ag=73.700 cm2

B=24.4 cm

Iy=5073.000 cm4

Iz=5073.000 cm4

It=10150.000 cm4

tw=1.0 cm

Zey=414.969 cm3

Zez=414.969 cm3

tf=1.0 cm

Zpy=550.236 cm3

Zpz=550.236 cm3

---------------------------------------------------------------------------------------------------------------------------------------INTERNAL FORCES AND CAPACITIES:

N = 1630.0 kN

Nd = 1842.5 kN

Pd = 1669.6 kN

Class of section = 1

---------------------------------------------------------------------------------------------------------------------------------------LATERAL BUCKLING PARAMETERS:

---------------------------------------------------------------------------------------------------------------------------------------BUCKLING PARAMETERS:

About Y axis:

About Z axis:

Ly = 4.00 m

Xy = 0.906

Lz = 4.00 m

Xz = 0.906

ky*Ly = 4.00 m Pdy = 1669.6 kN kz*Lz = 4.00 m Pdz = 1669.6 kN

ky*Ly/ry = 48.213

kz*Lz/rz = 48.213

Lamy = 0.555

Lamz = 0.555

---------------------------------------------------------------------------------------------------------------------------------------VERIFICATION FORMULAS:

Section strength check:

N/Nd = 0.885 < 1.000 (9.3.1.1) OK!

Global stability check of member:

ky*Ly/ry = 48.213 < (k*L/r),max = 200.000

kz*Lz/rz = 48.213 < (k*L/r),max = 200.000 STABLE

P/min(Pdy,Pdz) = 0.976 < 1.000 (7.1.2) OK!

---------------------------------------------------------------------------------------------------------------------------------------Section OK !!!

March 2014

page 15 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

b) From economical reason try to check the lighter CHS section.

Being still in RESULTS- CODE dialog box, type CHS 273x8 in the editable field below drawing

of section and press ENTER. Calculations (and results) are refreshed instantly.

The results for new selected section are presented below.

March 2014

page 16 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

COMPARISON:

Resistance, interaction expression

For CHS 244,5x10:

RSA

IS 800: 2007

Limit State Design

M0 = 1,1

Handbook

EC3: 2005

M0 = 1,0

1. Cross-section compression resistance

N/ Nd = 1630/ 1842,5

= 0,885

NEd/ Nc,Rd = 1630/2026,8

= 0,804

2. Member buckling resistance

in compression

N/ Pd = 1630/ 1669,6

= 0,976

NEd/ Nb,Rd = 1630/1836,5

= 0,888

CONCLUSIONS:

Underlined values results from handbook (EC3 example) are different then values calculated by RSA

program for Indian code IS 800 because partial safety factors M0 are different in both codes.

If the design resistances from handbook are divided by partial safety factor from IS 800 code

( M0 = 1,1 ):

1. NEd/ (Nc,Rd :1,1) = 1630 / (2026,8 : 1,1 ) = 1630 / 1842,5 = 0,8846 = 0,885

2. NEd/ (Nb,Rd :1,1) = 1630 / (1836,5 : 1,1 ) = 1630 / 1669,5 = 0,9763 = 0,976

.

March 2014

page 17 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

VERIFICATION EXAMPLE 2

- combined compression and bending about both axes

(lateral-torsional buckling)

Example taken from: DESIGNERS GUIDE to EN 1993-1-1 Eurocode 3:

Design of steel structures, general rules and rules for buildings

written by L. Gardner, D. A. Nethercot, 2005

TITLE:

Example 6.10 -- Member resistance under combined bi-axial bending and axial compression

SPECIFICATION:

Verify if H 305x305x240 section in grade S275 has sufficient available strength to support the axial

forces and moments listed below for Limit State Design:

section A-A, x=0

NEd = 3440 kN

My,Ed = 420 kNm

Mz,Ed = 0

section B-B, x=L

NEd = 3440 kN

My,Ed = 420 kNm

Mz,Ed = 110 kNm

Material Properties:

S275 fy = 275 MPa , E= 210GPa

The member is to be designed as a ground floor column in a multi-storey building.

The column of length 4,2 m is fixed in-plane (for buckling about major axis bending) and pinned out-ofplane, with diagonal bracing provided in both directions ( ky =0,8 ; kz=1,0).

The column is laterally and torsionally unrestrained.

SOLUTION:

Specify appropriate parameters in JOB PREFERENCES dialog box (click Menu/Tools/Job

Preferences). Then, choose calculation method Limit State Design in CONFIGURATION dialog box (

press Configuration button in CALCULATIONS dialog box ).

March 2014

page 18 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

In DEFINITIONS dialog box you can define a new type of member in agreement with structure data

It can be set in Member type combo-box. Pre-defined member type Column may be initially opened.

For chosen member type, press the Parameters button on Members tab, which opens

MEMBER DEFINITION PARAMETERS dialog box.

Type a new name in the Member type editable field, e.g. My Mz Nc. Change parameters to meet

initial data requirements of the structure. In this particular combined compression and bending about

both axes case set the following parameters:

1. for Y buckling define appropriate value of ky by manually entering 0,8 value in editable field

or by pressing ky icon which opens BUCKLING DIAGRAM dialog box:

press third icon 0.8 and

switch on Non-sway structure radio button.

March 2014

page 19 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

2. for lateral-buckling define:

lateral buckling type by pressing Lat. buckling type icon which opens LATERAL BUCKLING

TYPE dialog box

select first icon and press OK.

lateral buckling length coefficient by pressing Upper flange or Lower flange button. It opens

EFFECTIVE LENGTH FOR BEAMS, BETWEEN SUPPORTS dialog box:

Change conditions at supports.

Click the first option for unrestrained and free to rotate on plane, press OK.

March 2014

page 20 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

3. for additional code parameters press More button which opens

MEMBER DEFINITION ADDITIONAL PARAMETERS dialog box:

3.1. Click Load type My icon. It opens LOAD TYPE dialog box;

Select first option, press OK. Do the same

for Load type Mz icon.

March 2014

page 21 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

3.2. Switch on Not weakened in Parameters of a weakened section. Click OK.

3.3. Type for gM0= 1,0 and for gM1= 1,0 ; in this particular case it will be helped in results

comparison to EC3 ;

After changes dialog box

looks like:

Now, you can SAVE changes of

the newly-created member type

named e.g. My Mz Nc in

MEMBER DEFINITIONPARAMETERS dialog box.

March 2014

page 22 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

In DEFINITIONS dialog box

number of the member must be

assigned to appropriate name

of Member type.

(very important when you verify

different member types.)

You must press SAVE button to attribute the member type to number of member, here

My Mz Nc to no 1.

In the CALCULATIONS dialog box set:

-> Verification option; here Member Verification,

-> Loads cases ;

here for no 1 for Limit State Design

-> Limit state ; here only Ultimate Limit state will be analyzed, so switch off Limit stat Serviceability.

Check CONFIGURATION dialog box.

Now, start verificiations by pressing Calculations button.

MEMBER VERIFICATION dialog box with most significant results data will appear on screen.

Pressing the line with results for the member 1 opens the RESULTS dialog box with detailed results

for the analyzed member. The view of the RESULTS windows are presented below.

March 2014

page 23 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

Simplified results tab

Detailed results tab

Pressing the Calc.Note button in RESULTS Code dialog box opens the printout note for

the analyzed member. You can obtain Simplified results printout or Detailed results printout.

It depends on which tab is active.

The printout note view of Simplified results is presented below.

March 2014

page 24 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

RESULTS for Limit State Design method:

STEEL DESIGN

---------------------------------------------------------------------------------------------------------------------------------------CODE: IS800: 2007 Indian Standard-General Construction in Steel-Code of Practice (Third Revision)

ANALYSIS TYPE: Member Verification

---------------------------------------------------------------------------------------------------------------------------------------CODE GROUP:

MEMBER: 1 column

POINT:

COORDINATE: x = 1.00 L = 4.20 m

---------------------------------------------------------------------------------------------------------------------------------------LOADS:

Governing Load Case:

1 Limit State Design

---------------------------------------------------------------------------------------------------------------------------------------MATERIAL:

S 275

fy = 275.00 MPa

fu = 430.00 MPa

E = 210000.00 MPa

gM0=1.000

gM1=1.000

---------------------------------------------------------------------------------------------------------------------------------------SECTION PARAMETERS: UC 305x305x240

D=35.26 cm

Avy=239.70 cm2

Avz=81.10 cm2

Ag=306.00 cm2

B=31.79 cm

Iy=64200.00 cm4

Iz=20310.00 cm4

It=1271.00 cm4

tw=2.30 cm

Zey=3641.52 cm3

Zez=1277.76 cm3

tf=3.77 cm

Zpy=4243.00 cm3

Zpz=1945.00 cm3

---------------------------------------------------------------------------------------------------------------------------------------INTERNAL FORCES AND CAPACITIES:

N = 3440.0 kN

My = -420.0 kN*m

Mz = 110.0 kN*m

Vy = -26.2 kN

Nd = 8415.0 kN

Mdy = 1166.8 kN*m

Mdz = 534.9 kN*m

Vdy = 3805.7 kN

Pd = 6639.7 kN

Mndy = 773.7 kN*m

Mndz = 502.7 kN*m

Vz = -200.0 kN

Vdz = 1287.6 kN

Class of section = 1

Mymax = 420.0 kN*m

Mzmax = 110.0 kN*m

---------------------------------------------------------------------------------------------------------------------------------------LATERAL BUCKLING PARAMETERS:

L,LT,low=5.04 m

Mcr = 11963.5 kN*m

fbd = 268.02 MPa

X,LT = 0.975

fcr,b = 2819.59 MPa

Lam,LT = 0.312

Mbdy = 1137.2 kN*m

KLT = 0.892

---------------------------------------------------------------------------------------------------------------------------------------BUCKLING PARAMETERS:

About Y axis:

About Z axis:

Ly = 4.20 m

Xy = 0.976

Lz = 4.20 m

Xz = 0.789

ky*Ly = 3.36 m

Pdy = 8213.3 kN

kz*Lz = 4.20 m

Pdz = 6639.7 kN

ky*Ly/ry = 23.197

Ky = 1.028

kz*Lz/rz = 51.553

Kz = 1.204

Lamy = 0.267

Cmy = 0.400

Lamz = 0.594

Cmz = 0.600

---------------------------------------------------------------------------------------------------------------------------------------VERIFICATION FORMULAS:

Section strength check:

N/Nd = 0.409 < 1.000 (9.3.1.1) OK!

My/Mdy = 0.360 < 1.000 (9.3.1.1) OK!

Mz/Mdz = 0.206 < 1.000 (9.3.1.1) OK!

(My/Mndy)^ 2.000 + (Mz/Mndz)^2.044 = 0.340 < 1.000 (9.3.1.1) OK!

Vy/Vdy = 0.007 < 1.000 (8.4) OK!

Vz/Vdz = 0.155 < 1.000 (8.4) OK!

Global stability check of member:

ky*Ly/ry = 23.197 < (k*L/r),max = 200.000

kz*Lz/rz = 51.553 < (k*L/r),max = 200.000 STABLE

P/Pdy + Ky*Cmy*Mymax/Mbdy + 0.6*Kz*Cmz*Mzmax/Mdz = 0.656 < 1.000 (9.3.2.2) OK!

P/Pdz + KLT*Mymax/Mbdy + Kz*Cmz*Mzmax/Mdz = 0.988 < 1.000 (9.3.2.2) OK!

----------------------------------------------------------------------------------------------------------------------------------------

Section OK !!!

March 2014

page 25 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

COMPARISON:

RSA

IS 800: 2007

Limit State Design

Handbook

EC3: 2005

(Annex B, method 2)

M0 = 1,0

M0 = 1,0

1. Cross-section compression resistance

N/ Nd = 3440/ 8415 =

0,409

NEd/ Nc,Rd = 3440/ 8415

= 0,409

2. Cross-section bending resistance

My/Mdy =420/ 1166,8

= 0,360

My,Ed/My,c,Rd = 420/1168

= 0,360

Mz/Mdz =110/ 534,9

= 0,206

Mz,Ed/Mz,c,Rd= 110/536,5

= 0,205

(9.3.1.1) = 0,340

(6.2.9.1.(6)) = 0,340

Resistance, interaction expression

For UB 305x305x240:

4. Cross-section resistance under

My+Mz+V+N

5. Member buckling resistance

N/ Pdy= 3440/8213,3 = NEd/ Ny,b,Rd =3440/8314,0

in compression

= 0,414 ; (ky=0,7)

0,419 ;(ky=0,8)

ky - buckling length coefficient Y

N/ Pdz= 3440/6639,7 = NEd/ Ny,b,Rd =3440/6640

= 0,518

0,518

6. Member buckling resistance in bending

-lateral buckling length

-critical M for lateral-torsional buckling

7. Member buckling resistance in combined

bending and axial compression

My/Mdy =420/1137,2 =

0,369

My,Ed/Mb,Rd =420/1152

= 0,36

LLT = 5,04 m

Mcr = 11 963,5 kNm

Lcr = 4,2 m

Mcr = 17 114 kNm

0,656

0,988

(9.3.2.2)

(9.3.2.2)

0,66

0,97

(6.61)

(6.62)

CONCLUSIONS:

The calculation example was made according to:

- IS:800 code using RSA program and

- EC3:2005 code taken from handbook.

To make comparison more adequate, the same value of the partial safety factors M0=1,0 were

assumed in both methods.

The small differences in results are caused generally by:

small differences in values for elastic and plastic section modulus about Y & Z axis;

different values for buckling length coefficients in both codes;

different way of lateral buckling length coefficient description in both codes (effective length for

beams between supports are different); in Indian code there is very precision method to define

conditions at support;

different accuracy of parameters (e.g. the cross-sectional properties) in calculations.

March 2014

page 26 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

CONCRETE

March 2014

page 27 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

1. IS 456:2000 RC beams

March 2014

page 28 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

VERIFICATION EXAMPLE 1

- Dimensioning of simply supported beam

Example based on:

[1] S. N. Sinha, Reinforced Concrete Design, Second Edition, 2002, Example 6.1, pp. 239

DESCRIPTION OF THE EXAMPLE:

Design a simply supported beam. In this example, the results of the program are compared against

[1]. The comparison concerns the amount of longitudinal reinforcement and shear reinforcement.

LOADS:

uniformly distributed: p=50

GEOMETRY:

clear span: l0=6

support width: a=30

cross section: 30x60

MATERIAL:

Concrete:

Steel:

[kN/m]

[m]

[cm]

[cm]

M20

Fe 415

IMPORTANT STEPS:

Define the geometry of the beam (Fig.1.1) and the loads (Fig.1.2). Select support type in dialog box

Dimension definition/Span geometry as Masonry (shear will be calculated from the axis of the

support). Set proper materials (Calculation Options).

Fig. 1.1 Beam geometry

March 2014

page 29 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

Fig. 1.2 Loads and the calculation model

RESULTS OF LONGITUDINAL

CALCULATION:

REINFORCEMENT

(REINFORCEMENT

FOR

BENDING)

The theoretical areas of reinforcement determined by the program are presented on the graph in

Fig.1.3. The values in the midspan, compared with [1], are presented in the table below.

Theoretical areas

tension reinf. Ast

tension reinf. Asc

[1]

23.65 cm2

7.87 cm2

ROBOT

23.77 cm2

7.97 cm2

Fig. 1.3. Theoretical (required) areas of reinforcement in beam.

The real reinforcement generated by ROBOT is different than in [1], but it fulfills the capacity

requirements as well. The real reinforcement in the midspan is compared in the table below.

Real reinforcement

[1]

ROBOT

tension reinf. Ast

3 28 + 2 20

(24.75 cm2)

3 32

(24.13 cm2)

tension reinf. Asc

3 20

(9.42 cm2)

4 16

(8.04 cm2)

RESULTS OF TRANSVERSAL REINFORCEMENT (SHEAR REINFORCEMENT) CALCULATION:

In [1] the beam is divided into three segments with idealised diagrams of shear force assumed. In the

first and last segment (close to supports) the redistribution of sheaf force is assumed. To enable the

distribution in ROBOT select Calculation Options/Advanced/Redistribution of a shear force near

supports.

The shear force on the distance equal to effective height d from the support is assumed as at the end

of this distance. This way, the reduced shear force is equal to 211.57 kN, while the maximum shear

force is 257.51 kN, Fig.1.4.

March 2014

page 30 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

Fig. 1.4. Diagram of shear force in beam (blue) and reduced shear force (green).

The shear reinforcement generated automatically by the program is bigger than this determined in [1].

The reason is following: the authors of [1] assume the full area of longitudinal bars influencing the

shear strength of concrete c. This is not a case in ROBOT, where the area of steel is assumed taking

into account the development length. The area of bars develops from zero in point where the bar

starts and reaches the maximum (full) area at the distance equal to development length (see Fig.1.5).

Fig. 1.5. Diagram of theoretical (blue) and real (red) area of reinforcement.

Taking this effect into account, the c near support is equal to 0.288 MPa and not 0.639 MPa as in [1].

This leads to the spacing of stirrups equal to 12cm within the end segment.

In order to verify the calculations of shear in ROBOT based on [1], the spacings will be manually

defined and the anchorage of main bars will be increased (in order to increase the area of still taken

for determination of c ). This allows us to check the calculations of shear capacity carried out in

ROBOT.

First, define the spacing of stirrups as in [1]. Then, increase the length of hooks of main bottom bars.

Next, select Results/Freeze reinforcement. In Reinforcement Pattern/General dialog box enable

Consider hook length in anchorage length.

The capacity for shear is presnted in Fig.1.6. This proves, that taking into consideration the need of

proper anchorage of longitudinal bars, the calculation of shear leads to a similar results as in [1].

Fig. 1.6. Diagram of distribution of shear force (green) and shear capacity (red) for the spacing of

stirrups as in [1]

March 2014

page 31 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

VERIFICATION EXAMPLE 2

- Determination of capacity of a beam

Example based on:

[1] S. N. Sinha, Reinforced Concrete Design, Second Edition, 2002, Example 3.14, pp. 107

DESCRIPTION OF THE EXAMPLE:

Determine the bending moment capacity of the beam with the assumed reinforcement. Two cases of

reinforcement given in [1] are analysed here. The reinforcement is defined and the results concerning

capacity are compared.

REINFORCEMENT:

Case

I

Tension steel

Compression steel

4 22

4 16

II

4 25

4 16

GEOMETRY:

Cross-section:

case I: 30x53.6

[cm]

case II: 30x53.8

[cm]*

* In example, there is no height of the section given, instead the effective depth is assumed and the

clear cover of bars. This means, that for two cases of reinforcement, where different diameters of bars

are used, different height of the beam must be defined.

The length of the beam and other geometrical parameters are variables that have no influence on the

analysed results since we analyze the capacity of the section.

MATERIAL:

Concrete:

Steel:

M20

Fe 415

RESULTS OF THE CALCULATION:

The capacity determined by ROBOT (Fig. 2.1) for the reinforcement assumed in [1] is found to be in

agreement with the results in [1].

Case

I

II

March 2014

[1]

250.69 kNm

309.32 kNm

ROBOT

250.78 kNm

309.32 kNm

page 32 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

Fig. 2.1. Diagrams of the moment capacities (red) for the two cases of reinforcement.

LITERATURE

[1] S. N. Sinha, Reinforced Concrete Design, Second Edition, 2002

March 2014

page 33 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

2. IS 456:2000 RC columns

March 2014

page 34 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

VERIFICATION EXAMPLE 1

- Uniaxially eccentrically loaded braced rectangular column

Example based on:

[1] S. N. Sinha, Reinforced Concrete Design, Second Edition, 2002, Example 9.20, pp. 497

DESCRIPTION OF THE EXAMPLE:

Design the rectangular column in a braced (non-sway) frame. Column is subjected to uniaxial

eccentrical load.

In the following example, the results of the program, concerning the calculations of longitudinal

reinforcement and capacity are compared to the results of [1].

LOADS:

Ultimate axial load:

P = 2000 [kN]

Ultimate axial moment: Mx = 400 [kNm]

GEOMETRY:

Unsupported length

Effective lengths:

Cross section:

lu=3.5 [m]

lx = 3 [m]

ly = 2.75 [m]

40x60 [cm]

MATERIAL:

Concrete

: M 25

Longitudinal reinforcement : Fe 415

IMPORTANT STEPS:

In the dialog box Buckling length set buckling parameters (Fig.1.1.).

Fig. 1.1. Buckling parameters of the column.

March 2014

page 35 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

In the Calculation Option/ General dialog box select the proper method of calculation (Fig. 1.2.).

Fig. 1.2. Selection of calculation method.

In order to compare the results of calculation with the final solution assumed in [1], select the same

diameter of main bars as in [1]. The diameter of bars may be set in Reinforcement pattern/Longitudinal

bars dialog box (Fig. 1.3.).

Fig. 1.3. Parameters of main bars.

RESULTS OF CAPACITY CALCULATION:

March 2014

Quantity

[1]

Robot

(results presented

in calculation note)

1.4765

1.4645*

Muy,l

Muz,l

Capacity coefficient

421.2

247.2

1/0.996=1.004

436.6 **

264.5 **

1.026

page 36 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

NOTES:

* - In [1] the equation Puz 0.446 f ck 0.75 fyAsc is used, while Robot uses the equation

given in code [2], which is Puz 0.45 f ck 0.75 fyAsc

** - In [1] the simplification takes place due to the use of approximated interaction curves.

Robot calculates the capacity based on the equilibrium of forces in section.

RESULTS OF LONGITUDINAL REINFORCEMENT CALCULATION:

Reinforcement generated by the program (Fig.1.4), after assuming that the diameter 28mm should be

used, is the same as determined in [1].

Fig. 1.4. Reinforcement generated by the program (8 28).

March 2014

Quantity

[1]

Robot

Reinforcement

8 28

8 28

page 37 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

VERIFICATION EXAMPLE 2

- Column subjected to axial load and biaxial bending

Example based on:

[1] S. N. Sinha, Reinforced Concrete Design, Second Edition, 2002, Example 9.24, pp. 509

DESCRIPTION OF THE EXAMPLE:

Design the rectangular column in a braced (non-sway) frame. Column is subjected to biaxial

eccentrical load. In the following example, the results of the program, concerning the calculations of

longitudinal reinforcement and buckling analysis are compared to the results of [1].

LOADS:

Ultimate axial load:

Ultimate axial moments:

GEOMETRY:

Unsupported length

Effective lengths:

Cross section:

P = 2000 [kN]

Mx1 = 225 [kNm]

Mx2 = 175 [kNm]

My1 = 125 [kNm]

My2 = 75 [kNm]

lu=9.0 [m]

lx = 8 [m]

ly = 6 [m]

40x60 [cm]

MATERIAL:

Concrete

: M 25

Longitudinal reinforcement : Fe 415

IMPORTANT STEPS:

In the dialog box Buckling length set buckling parameters (Fig.2.1.).

Fig. 2.1. Buckling parameters of the column.

March 2014

page 38 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

In the Calculation Option/ General dialog box select the proper method of calculation (Fig. 2.2.).

Fig. 2.2. Selection of calculation method.

In the Calculation Option/ General dialog box enable the use of k coefficient for calculation of the

additional moments (Fig. 2.3.).

Fig. 2.3. Parameter k for calculation of additional moments.

In order to compare the results of calculation with the final solution assumed in [1], select the same

diameter of corner and intermediate bars as in [1]. The diameter of bars may be set in Reinforcement

pattern/Longitudinal bars dialog box (Fig. 2.4.).

Fig. 2.4. Parameters of main bars.

Define loads (Fig. 2.5.).

Fig. 2.5. Loads definition.

March 2014

page 39 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

RESULTS OF LONGITUDINAL REINFORCEMENT CALCULATION:

Reinforcement generated by the program (Fig.2.6.) is the same as determined in [1] (after the same

diamteres were assumed).

Fig. 2.6. Reinforcement generated by the program (4 28 + 8 25).

Quantity

[1]

Robot

Reinforcement

4 28 + 8 25

4 28 + 8 25

RESULTS OF BUCKLING ANALYSIS:

Quantity

[1]

ky

kz

Muy

Muz

0.8223

0.7896

292.71

176.06

Robot

(results presented

in calculation note)

0.8590*

0.7899

296.63

176.10

NOTES:

* - This difference is caused by different Pub and Puz values. In [1] Pub are calculated based on

approximated tables, while in Robot the exact calculations are carried out. Moreover, in [1] the

equation Puz 0.446 f ck 0.75 fyAsc is used, while Robot uses the euqtion given in code [2], which

is Puz 0.45 f ck 0.75 fyAsc .

RESULTS OF CAPACITY CALCULATION:

March 2014

Quantity

[1]

Robot

(results presented

in calculation note)

1.4118

1.3886*

Muy,l

Muz,l

Capacity coefficient

493.2

292.8

1/0.964=1.037

527.7**

316.5**

1.085

page 40 / 41

Autodesk Robot Structural Analysis Professional - Verification Manual for Indian Codes

NOTES:

* In [1] the equation Puz 0.446 f ck 0.75 fyAsc is used, while Robot uses the euqtion given

in code [2], which is Puz 0.45 f ck 0.75 fyAsc .

** - In [1] the simplification takes place due to the use of approximated interaction curves.

Robot calculates the capacity based on the equilibrium of forces in section. Moreover the capacity is in

[1] found for the assumed percentage of reinforcement. At the end however, the greater reinforcement

is assumed, thus capacities are in [1] underestimated. In Robot, capacities are calculated for the real

reinforcement.

LITERATURE

[1] S. N. Sinha, Reinforced Concrete Design, Second Edition, 2002

[2] Indian Standard IS 456:2000 Plain and Reinforced Concrete Code of Practice (Fourth Revision),

2003

March 2014

page 41 / 41

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Loads and Loading Combinations For CE157 StudentsDocument48 pagesLoads and Loading Combinations For CE157 StudentsemssNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Airy PointsDocument13 pagesAiry PointsDirajen PMNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- I-Section properties comparison chartDocument8 pagesI-Section properties comparison chartArunkumar AK100% (1)

- Strength of Materials - Viva QuestionsDocument5 pagesStrength of Materials - Viva Questionsyogesh366373% (15)

- Wallace - PEER - Coupling Beams - Wallace - Oct 13 2009 FinalDocument41 pagesWallace - PEER - Coupling Beams - Wallace - Oct 13 2009 FinalStef22100% (1)

- EM 1110-2-2504 - Design of Sheet Pile Walls 1Document75 pagesEM 1110-2-2504 - Design of Sheet Pile Walls 1PDHLibrary100% (2)

- Pushover Example LargeDocument39 pagesPushover Example LargeCapt Reza100% (6)

- Guide To Safe Lifting & ProppingDocument34 pagesGuide To Safe Lifting & ProppingAlly KhooNo ratings yet

- Plate Load Test Is.1888.1982Document16 pagesPlate Load Test Is.1888.1982cmthebossNo ratings yet

- BS 5400 Part 4Document2 pagesBS 5400 Part 4ekia_my0% (2)

- Response Spectrum Method ExcelDocument9 pagesResponse Spectrum Method ExcelArunkumar AK100% (1)

- Division of Taxpayers - CentreDocument1,451 pagesDivision of Taxpayers - Centresundar111167% (3)

- Ub PadstoneDocument2 pagesUb PadstoneMihai CojocaruNo ratings yet

- Thesis Final Document Tall BuildingsDocument194 pagesThesis Final Document Tall BuildingsPab Fer Man100% (3)

- Dubai Metro Footbridge DesignDocument17 pagesDubai Metro Footbridge DesignCharles Wong100% (2)

- Ijftr 23 44Document5 pagesIjftr 23 44Arunkumar AKNo ratings yet

- Intro To RefDocument62 pagesIntro To RefArunkumar AKNo ratings yet

- Resolution FAQ-refunDocument4 pagesResolution FAQ-refunArunkumar AKNo ratings yet

- MultiBeast Features 9.1Document9 pagesMultiBeast Features 9.1Adinan MoraesNo ratings yet

- Snacks Time Menu ListDocument4 pagesSnacks Time Menu ListArunkumar AKNo ratings yet

- Sale 04122019Document2 pagesSale 04122019Arunkumar AKNo ratings yet

- FsDocument7 pagesFsArunkumar AKNo ratings yet

- 45 - Foundry Sand Utilisation As A Partial Replacement of Fine Aggregate For Establishing Sustainable Concrete PDFDocument4 pages45 - Foundry Sand Utilisation As A Partial Replacement of Fine Aggregate For Establishing Sustainable Concrete PDFArunkumar AKNo ratings yet

- Instructions To CandidateDocument43 pagesInstructions To CandidateArunkumar AKNo ratings yet

- Barbeque Nation: Dal MakhaniDocument1 pageBarbeque Nation: Dal Makhaniradhika1991No ratings yet

- Chapter 14 Cellular Cofferdams PDFDocument15 pagesChapter 14 Cellular Cofferdams PDFonyejekwe100% (1)

- Videocard Supported Upto 300mmDocument2 pagesVideocard Supported Upto 300mmArunkumar AKNo ratings yet

- Concrete shear strength design chartDocument4 pagesConcrete shear strength design chartArunkumar AKNo ratings yet

- Simply Supported Beam AnalysisDocument7 pagesSimply Supported Beam AnalysisArunkumar AKNo ratings yet

- Rto TNDocument4 pagesRto TNArunkumar AKNo ratings yet

- Design Comparison of Different ReinforceDocument8 pagesDesign Comparison of Different ReinforceALINo ratings yet

- Flexural Strength of Concrete Bridges Presressed by ExternaDocument8 pagesFlexural Strength of Concrete Bridges Presressed by ExternaKedarNo ratings yet

- Approach Form Camber Specifications With CautionDocument4 pagesApproach Form Camber Specifications With CautionDonald HamiltonNo ratings yet

- Bridge Design - Loads4Document42 pagesBridge Design - Loads4Juan FernandezNo ratings yet

- Shear & Diagonal Tension in BeamsDocument29 pagesShear & Diagonal Tension in BeamsS. M. ZAHIDUR RAHMAN 1301129No ratings yet

- Companion Document To en 1992-1-1 Eurocode 2Document52 pagesCompanion Document To en 1992-1-1 Eurocode 2Andrew Kreimer100% (1)

- Torsion of Prismatic BarDocument6 pagesTorsion of Prismatic BarPramod Sharma PNo ratings yet

- Engineering Mechanics Lab ManualDocument10 pagesEngineering Mechanics Lab Manualabdul hameed khanNo ratings yet

- Concealed Purlin Cleats: Exposed Rafter To Wall Fixing Exposed Rafter To Ridge Beam FixingDocument2 pagesConcealed Purlin Cleats: Exposed Rafter To Wall Fixing Exposed Rafter To Ridge Beam FixingFei XiongNo ratings yet

- (2017) Performance of Wulung Bamboo Reinforced Concrete BeamsDocument10 pages(2017) Performance of Wulung Bamboo Reinforced Concrete BeamsAlpin MaulidinNo ratings yet

- GS 146-1 PDFDocument33 pagesGS 146-1 PDFHardik Acharya100% (1)

- Infrastructures: Feasibility of Reusing Damaged Steel Beams in Temporary StructuresDocument24 pagesInfrastructures: Feasibility of Reusing Damaged Steel Beams in Temporary Structureslouis donyNo ratings yet

- Re: Review of 2014 Canadian Highway and Bridge Design Code With Respect To Mflnro Design StandardsDocument21 pagesRe: Review of 2014 Canadian Highway and Bridge Design Code With Respect To Mflnro Design StandardsAna CoelhoNo ratings yet

- Let OffDocument3 pagesLet OffLondon StNo ratings yet

- Design Manual - Kemrock - NewDocument235 pagesDesign Manual - Kemrock - NewkbrozzzNo ratings yet

- Chapter 6Document51 pagesChapter 6Jarred JacksonNo ratings yet

- RRS Group2 Mod3 Bose & AswinDocument76 pagesRRS Group2 Mod3 Bose & AswinPriyamvada BijuNo ratings yet

- CH 3Document30 pagesCH 3dhanya1995No ratings yet

- SM1004 Beam DatasheetDocument3 pagesSM1004 Beam Datasheetsinghmanjinder8872No ratings yet

- Dissertation SuspensionDocument153 pagesDissertation SuspensionJudoThrowNo ratings yet