Professional Documents

Culture Documents

Installation and Maintenance Instructions For Model Mi-Rhde Plug-In Rate of Rise Temperature Sensors

Uploaded by

abdo samadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation and Maintenance Instructions For Model Mi-Rhde Plug-In Rate of Rise Temperature Sensors

Uploaded by

abdo samadCopyright:

Available Formats

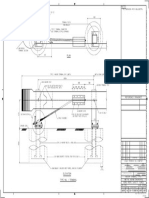

LED

TEST MODULE

SOCKET

TEST

MAGNET

PAINTED

SURFACE

Figure 1. Test Magnet Positioning.

TEST

MAGNET

INSTALLATION AND MAINTENANCE

INSTRUCTIONS FOR MODEL MI-RHDE PLUG-IN

RATE OF RISE TEMPERATURE SENSORS

Before installing detectors, please thoroughly read Morley IAS's Manual I56-407-XX, Guide for the Proper Use of System Smoke Detectors,

which provides detailed information on detector spacing, placement, zoning, wiring, and special applications. Copies of this manual are

available at no charge from Morley IAS.

GENERAL DESCRIPTION

Model MI-RHDE rate of rise thermal detectors use dual thermistor sensing elements for ambient temperature compensation and fast response.

These detectors are designed to provide open area protection and to be used with compatible control panels only. The ability to plug these

detectors into a variety of base options extends panel compatibility and application flexibility.

Two LEDs on each detector light to provide a local 360 visible alarm indication. Remote LED annunciator capability is available as an optional

accessory wired to the standard base terminals. These detectors also have a latching alarm feature. The alarm can be reset only by a

momentary power interruption. These detectors may be tested by activating an internal reed switch with a magnet.

SPECIFICATIONS

Size: Cover Height

60 mm

Cover Diameter

102 mm

Weight

277 g

Installation Temperature Range

-10C to 50C

Operating Humidity Range

10% to 93% Relative Humidity, Non-condensing

Latching Alarm

Reset by momentary power interruption.

This detector has been independently tested and certified to EN54 Part5.

SPACING

Spacing of 7-9 metres on a smooth ceiling without significant air movement may be used as a general guide, however refer to local codes and

guidance from responsible fire brigade officials. Where application conditions or response requirements vary, other spacing may need to be

applied.

BASE SELECTION AND WIRING GUIDE

Refer to the installation instructions supplied with the plug-in detector bases for wiring details. Morley IAS has available a variety of detector bases

for this heat sensor, including standard 2-wire with or without current limiting resistors or schottky diode or changeover relay.

All bases are provided with screw terminals for power, shield, remote indicator connections and relay contact connections, if applicable. The

electrical ratings for each detector-base combination are also included in the base installation instructions.

INSTALLATION

NOTE:

All wiring must conform to applicable local national codes and regulations.

NOTE:

Verify that all detector bases are installed, that the detector monitoring circuits have been tested and that the wiring is correct.

(Refer to detector base instructions for testing procedure)

WARNING

Remove power from detector monitoring circuits before installing detectors.

1. Install Detectors:

a. Place the detector into the detector base.

b. Rotate the detector clockwise with gentle pressure until the detector drops into place.

c. Continue rotating the detector clockwise to lock it in place.

2. Tamper-Resistance: The detector bases include a feature that, when activated, prevents removal of the detector without the use of a

tool. See the installation instructions for the detector base for details of how to use this feature.

3. After all detectors have been installed, apply power to the detector monitoring circuits.

4. Test the detector as described under TESTING.

5. Reset the detector at the system control panel.

6. Notify the proper authorities that the system is in operation.

LED

TESTING

Detectors must be tested after installation and following periodic maintenance. However, before

testing, notify the proper authorities that the system is undergoing maintenance and the system

will be temporarily out of service. Disable the zone or system undergoing maintenance to

prevent unwanted alarms.

Test the detector as follows:

A. Test Magnet (Model M02-24 - optional)

1. Test the detector by positioning the optional test magnet against the detector body

approximately 2cm from LED1 in the direction of the metering socket (see Figure 1).

2. Both LEDs should latch on within 30 seconds, indicating an alarm and activating the

panel.

B. Calibrated Sensitivity Test (MOD400R)

1. Use the MOD400R Test Module with a digital or analogue voltmeter to check detector

sensitivity as described in the test module manual.

C. Direct Heat Method (Hair dryer of 1000-1500 watts)

1. From the side of the detector, direct the heat toward the sensor. Hold the heat source

about 15cm away to prevent damage to the cover during testing. Note: If a detector goes

into alarm, it will only reset if the detector has cooled and if its power is momentarily

interrupted. Check the control panel being used to determine whether the RESET switch

(or some other auxiliary device or control) momentarily cuts off power to the detector loop.

After completion of all tests notify the proper authorities that the system is operational.

Detectors that fail these tests should be cleaned as described under MAINTENANCE and retested. If the detectors still fail these tests they should be returned for repair.

WARNING

LIMITATIONS OF HEAT SENSORS

Heat sensors are designed to protect property, not life. They do not provide early warning of fire and cannot detect smoke, gas,

combustion particles or flame. The MI-RHDE alarms when temperature at the heat sensor reaches 60C. Given the rapid growth of certain

types of fire, heat sensors cannot be expected to provide adequate warning of fires resulting from smoking in bed, inadequate fire protection

practices, violent explosions, escaping gas, improper storage of flammable liquids like cleaning solvents, other safety hazards or arson.

Heat sensors do not always detect fires because the fire may be a slow smouldering, low-heat type (producing smoke) or because

they may not be near where the fire occurs or because the heat of the fire may bypass them. Heat sensors will not detect smoke, gas,

flames or combustion particles.

Heat sensors are components in professionally installed fire alarm systems. They will not function if they have been improperly wired into

the fire alarm system or if power to them is cut for any reason.

Heat sensors cannot last forever. They should be tested and maintained following the instructions in this manual. To be safe, they should be

replaced after they have been installed for 15 years.

Morley IAS Fire Systems, Charles Avenue, Burgess Hill, West Sussex, RH15 9UF

M400-02-00

Figure 2. Sensor and Base.

MAINTENANCE

Before cleaning, notify the proper authorities that the system is undergoing maintenance and will

be temporarily out of service. Disable the system to prevent unwanted alarms.

1. Remove the detector to be cleaned from the system.

2. Use a vacuum cleaner to remove dust from the sensing chamber.

3. Reinstall the detector.

4. When all detectors have been cleaned, restore power to the system and test the detector(s)

as described in the TESTING section of this manual.

System Sensor 2000

I56-1285-000

You might also like

- Finished: Power Supplies Price List - 2008Document5 pagesFinished: Power Supplies Price List - 2008abdo samadNo ratings yet

- Solutions PDFDocument17 pagesSolutions PDFIsmael KhalilNo ratings yet

- SD0018801 HfesposseditorialDocument2 pagesSD0018801 Hfesposseditorialabdo samadNo ratings yet

- EarthDocument9 pagesEarth0b0biyd,u,uNo ratings yet

- A250 A250M-01 Electric-Resistance-Welded Ferritic Alloy-Steel Boiler and Superheater TubesDocument4 pagesA250 A250M-01 Electric-Resistance-Welded Ferritic Alloy-Steel Boiler and Superheater Tubesabdo samadNo ratings yet

- CVC 01017Document6 pagesCVC 01017Sowjanya VenigallaNo ratings yet

- Abstract PDFDocument1 pageAbstract PDFIsmael KhalilNo ratings yet

- RoHS Health Safety StatementDocument1 pageRoHS Health Safety Statementabdo samadNo ratings yet

- Process Industry Practices Process Control: Pip Pcsel01D Data Sheet For Instrumentation Junction BoxesDocument3 pagesProcess Industry Practices Process Control: Pip Pcsel01D Data Sheet For Instrumentation Junction Boxesabdo samadNo ratings yet

- Notes:: M88 M DB-950098 005 00Document1 pageNotes:: M88 M DB-950098 005 00abdo samadNo ratings yet

- Process Industry Practices PipingDocument5 pagesProcess Industry Practices Pipingabdo samadNo ratings yet

- QTP5 2X24-39/220-240 UNV1: Product DetailsDocument1 pageQTP5 2X24-39/220-240 UNV1: Product Detailsabdo samadNo ratings yet

- Notes:: DB-950133 001 00 P M88Document1 pageNotes:: DB-950133 001 00 P M88abdo samadNo ratings yet

- Astm A285 A285m (2001)Document4 pagesAstm A285 A285m (2001)Luz DuarteNo ratings yet

- Process Industry Practices PipingDocument5 pagesProcess Industry Practices Pipingabdo samadNo ratings yet

- Process Industry Practices PipingDocument5 pagesProcess Industry Practices Pipingabdo samadNo ratings yet

- 01SD0J01Document5 pages01SD0J01raobabar21No ratings yet

- Process Industry Practices PipingDocument5 pagesProcess Industry Practices Pipingabdo samadNo ratings yet

- Process Industry Practices PipingDocument5 pagesProcess Industry Practices Pipingabdo samadNo ratings yet

- N Normas Pdvsa Mid Pip Pn01cs1j01Document5 pagesN Normas Pdvsa Mid Pip Pn01cs1j01Douglas E Ana PereiraNo ratings yet

- Oil Separation 010Document1 pageOil Separation 010Ismael KhalilNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 20004921997.electricity Bill PDFDocument1 page20004921997.electricity Bill PDFRakibul HassanNo ratings yet

- Uc 3906Document9 pagesUc 3906ป๊ะป๋า ณัฐNo ratings yet

- AM Trans-ReceiverDocument39 pagesAM Trans-ReceiverSivaranjan GoswamiNo ratings yet

- Datos Técnicos Del Compressor - L63B752DBLB 208-230V60Hz 200-220V50Hz 3Document1 pageDatos Técnicos Del Compressor - L63B752DBLB 208-230V60Hz 200-220V50Hz 3Julio César Samamé VegaNo ratings yet

- Static Characteristics of SCR Experiment 1 Aim: To Study The Static Characteristics of SCR Apparatus: Multism Theory: SCR Works in Three ModesDocument9 pagesStatic Characteristics of SCR Experiment 1 Aim: To Study The Static Characteristics of SCR Apparatus: Multism Theory: SCR Works in Three ModesHoward TimbangNo ratings yet

- HVDCProjectsListingMarch2012 ExistingDocument2 pagesHVDCProjectsListingMarch2012 ExistingHARLEY SANDERSNo ratings yet

- Nexus Charge AmplifierDocument16 pagesNexus Charge AmplifierGeorge JosephNo ratings yet

- Distance Sensor Dx35 Quickstart: Set KeyDocument2 pagesDistance Sensor Dx35 Quickstart: Set KeyNassNo ratings yet

- TEKO DAS Part C-Safety - Warnings - 91 080 0783-03Document20 pagesTEKO DAS Part C-Safety - Warnings - 91 080 0783-03test321yNo ratings yet

- Rectifier Module User Manual (UM1R481000), Revision KDocument24 pagesRectifier Module User Manual (UM1R481000), Revision KBysNo ratings yet

- New Microsoft Excel WorksheetDocument1 pageNew Microsoft Excel Worksheetprashant jindalNo ratings yet

- KM-3035, KM-4035, KM-5035 Service ManualDocument350 pagesKM-3035, KM-4035, KM-5035 Service Manualdmcampos50% (2)

- Corrosion (Study Material)Document8 pagesCorrosion (Study Material)SANDEEP NAYAKNo ratings yet

- 3kw Off-Grid Solar System Installation GuideDocument11 pages3kw Off-Grid Solar System Installation GuideVasanth Kumar VNo ratings yet

- Chapter 7-Induction Motors Part1 PDFDocument18 pagesChapter 7-Induction Motors Part1 PDFMohammadrezaÖztürkNo ratings yet

- Datasheet KDocument7 pagesDatasheet KdanielalbertomcNo ratings yet

- LM 747Document10 pagesLM 747thuanbk090792No ratings yet

- 1LG0 Catalogue (En)Document23 pages1LG0 Catalogue (En)Sandi AslanNo ratings yet

- Application ModrobDocument6 pagesApplication Modrobharimadhavareddy80% (10)

- DHC 6 XGDocument18 pagesDHC 6 XGRishan RanatungaNo ratings yet

- Ramachandra College of Engineering: EluruDocument34 pagesRamachandra College of Engineering: ElurujaganmohanrsNo ratings yet

- Selecting Transformers For Hydro Power PlantsDocument16 pagesSelecting Transformers For Hydro Power PlantsDIPAK VINAYAK SHIRBHATE100% (1)

- Manual User 2 24v DG r1b All in Rev.03 EngDocument28 pagesManual User 2 24v DG r1b All in Rev.03 EngMalton Ayala100% (1)

- MOSFETs 2015 02 23Document197 pagesMOSFETs 2015 02 23楊易儒No ratings yet

- 03 Appendix A - Technical Compliance SheetsDocument41 pages03 Appendix A - Technical Compliance SheetsHayman AhmedNo ratings yet

- Guidelines For Grounding and Bonding Telecom SystemsDocument5 pagesGuidelines For Grounding and Bonding Telecom SystemsSDE BSS KollamNo ratings yet

- Full Adder Design Using LEDITDocument22 pagesFull Adder Design Using LEDITGaurav Soni0% (1)

- EVC16-DH60 180k7P3UE-Three Charging guns-DC Charger Specification - 20230810Document14 pagesEVC16-DH60 180k7P3UE-Three Charging guns-DC Charger Specification - 20230810shamsur rahman opuNo ratings yet

- Class A and Class B Amplifier Analysis with SimulationDocument6 pagesClass A and Class B Amplifier Analysis with SimulationSabrina SaimaNo ratings yet

- Assignment 2Document4 pagesAssignment 2rohit_648499138No ratings yet