Professional Documents

Culture Documents

Hydraulic Graphical Symbols: Transmission Line

Uploaded by

BIPIN SHARMAOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydraulic Graphical Symbols: Transmission Line

Uploaded by

BIPIN SHARMACopyright:

Available Formats

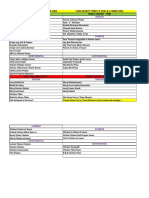

Industrial Hydraulics and Pneumatics

Expt no:

HYDRAULIC GRAPHICAL SYMBOLS

SR.

NO.

NAME

SYMBOL

DESCRIPTION

TRANSMISSION LINE

A pipe, tube or other conductors

of handling major flow in the

circuit

Pilot lines have much small fluid

carrying capacity than working

line

Fluid drain and air exhaust lines

are made of light weight

materials

1.

Working line

2.

Pilot line

3.

Drain line

4.

Passing line

Pipes that cross each other are

drawn with small loop

5.

Joined work line

A connector dot is places to

show junction

6.

Flexible line

Flexible lines are shown with a

curve

7.

Energy flow in one

direction

Hollow arrow for air solid arrow

for liquid

8.

Plugged terminal

point

To block fluid flow plug is used

as indicated

9.

Fixed restriction

A fixed size, non adjustable pipe

restriction is shown

II

FLUID STORAGE

10.

Pipes terminated

above fluid level

Working line doesnt touch

bottom of reservoir

11.

Pipes terminated

below fluid level

Working line is shown touching

the bottom of reservoir

12

Vented tank or

reservoir

Hydraulic fluid reservoir or tank

Industrial Hydraulics and Pneumatics

Expt no:

III

PUMPS

13.

Basic pump symbol

Basic envelope symbol for a

pump is a circle

14.

Fixed displacement

unidirectional

Single triangle denotes

unidirectional flow

15.

Variable

displacement

simplified and

unidirectional

Arrow indicated pump

displacement can be varied

IV

A.

ACTUATORS

MOTORS

16.

Variable

displacement

unidirectional

motor

Motor has a variable

displacement

17.

Motor oscillating

Device doesnt permit rotation in

one direction

B.

CYLINDERS

18.

Single acting

cylinder

It can be actuated only in one

direction

19

Double acting

cylinder

It can be actuated in both

directions

Cylinder, double

end rod

There are identical areas on each

side of piston, and they can

provide equal forces in either

direction

20.

V.

METHODS OF OPERATION

2

Industrial Hydraulics and Pneumatics

Expt no:

21.

Spring control

Check valve with bias spacing

open when inlet > outlet + spring

22

Spring centered

pilot control

Operation is by the release of

pressure and pilot actuated

23.

Detent control

It is used with mechanical or

pilot operated valves

24.

Solenoid control

with pilot actuation

Electrically controlled with

internal pilot supply

25.

Push button

26.

Lever

VI.

Manually operated

VALVES

27.

Flow control valve

with pressure and

temperature

compensation and

integral check

Variation in pressure and

temperature does not affect the

flow control

28.

Relief valve

For overload protection

29.

Sequential valve

To achieve sequencing of

hydraulic actuators

30.

Unloading valve

Pump is unloaded at zero

pressure, thus saving the

horsepower

31.

Check valve

Flow is only in one direction

32.

Three way valve

33.

Four way valve

Industrial Hydraulics and Pneumatics

34.

Four way, spring

centered, three

position, manually

actuated valve

35.

Two position,

spring offset, four

way valve

36.

Air pilot actuated,

four way, three

position, spring

centered direction

control valve

Expt no:

Various center position for three position, four way valve

37.

Open center

38.

Pressure and B

closed, A opened to

tank

39.

All ports closed

40.

Pressure closed, A

& B open to tank

41.

B closed, pressure

opened to tank

through A

Industrial Hydraulics and Pneumatics

42.

Expt no:

Tandem

VII.

Miscellaneous

43.

Heaters

44.

Pressure gauge

45.

Strainer or filter

Introduction of heat and energy

into major line

You might also like

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesFrom EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesRating: 1 out of 5 stars1/5 (2)

- Unit 3 - Control Components in Hydraulic SystemDocument63 pagesUnit 3 - Control Components in Hydraulic SystemRishiJpNo ratings yet

- 5 Actuation SystemsDocument78 pages5 Actuation Systemsteklaykibrom3No ratings yet

- Dokumen - Tips Hydraulics and Pneumatics Lab1Document27 pagesDokumen - Tips Hydraulics and Pneumatics Lab1Harinath CNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Module 4Document67 pagesModule 4Achsah K VijuNo ratings yet

- Hydraulics and Pneumatics Lab1Document27 pagesHydraulics and Pneumatics Lab1farhan125100% (1)

- Prevention of Actuator Emissions in the Oil and Gas IndustryFrom EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNo ratings yet

- Department of Mechatronics and Control Engineering University of Engineering and Technology, LahoreDocument34 pagesDepartment of Mechatronics and Control Engineering University of Engineering and Technology, LahoreEman FatimaNo ratings yet

- 2.4.5 Air DryersDocument13 pages2.4.5 Air DryerskhaledNo ratings yet

- Pneumatic System Components ExplainedDocument29 pagesPneumatic System Components Explainedbhadresh100% (1)

- Hydraulics AND Pneumatics Symbols: Presented By: Shashank Jain (A-24) Vipul Jain (A-25) Samar Jain (A-40)Document19 pagesHydraulics AND Pneumatics Symbols: Presented By: Shashank Jain (A-24) Vipul Jain (A-25) Samar Jain (A-40)MaruthiNo ratings yet

- Chapter 7 Pneumatic and Hydraulic SystemsDocument32 pagesChapter 7 Pneumatic and Hydraulic SystemsRoyal Ritesh SharmaNo ratings yet

- Unit 3Document6 pagesUnit 3hariharanbookNo ratings yet

- MEM 341 - Chapter 9 Hydraulic CircuitDocument22 pagesMEM 341 - Chapter 9 Hydraulic CircuitMuhammad AbdullahNo ratings yet

- Fluid Power Technology: Faculty of Engineering Technology Universiti Malaysia PahangDocument21 pagesFluid Power Technology: Faculty of Engineering Technology Universiti Malaysia PahangAniq AmirahNo ratings yet

- Unit 24: Applications of Pneumatics and HydraulicsDocument15 pagesUnit 24: Applications of Pneumatics and HydraulicsEmad ElsaidNo ratings yet

- chp 3& 6 ihp msdteDocument10 pageschp 3& 6 ihp msdteRocky JNo ratings yet

- Extra Notes Pneumatic 2Document27 pagesExtra Notes Pneumatic 2olivia curtisNo ratings yet

- Class 6 Hydraulic ValvesDocument103 pagesClass 6 Hydraulic ValvesSoheilDarvishMotavalli100% (2)

- Lab Report: Instrumentation and ControlDocument7 pagesLab Report: Instrumentation and ControlmjunaidNo ratings yet

- Fluid Power Fluid Power Equipment Tutorial - Other Fluid Power ValvesDocument11 pagesFluid Power Fluid Power Equipment Tutorial - Other Fluid Power ValvesprabhakarmetNo ratings yet

- IHP Pneumatic SymbolsDocument4 pagesIHP Pneumatic SymbolsBIPIN SHARMANo ratings yet

- Chapter 8Document60 pagesChapter 8ryan williamNo ratings yet

- Pneumatic Circuit TrainerDocument5 pagesPneumatic Circuit Trainerdipsankar chatterjeeNo ratings yet

- B.L.D.E.A'S Polytechnic, Bijapur Department of Mechatronics Engineering Electropneumatics Lab Viva Question - AnswersDocument6 pagesB.L.D.E.A'S Polytechnic, Bijapur Department of Mechatronics Engineering Electropneumatics Lab Viva Question - AnswersbharatNo ratings yet

- Control Components in Hydraulic SystemDocument68 pagesControl Components in Hydraulic SystemYashwanth Mg100% (1)

- Coin Box Based Automatic WheelDocument52 pagesCoin Box Based Automatic WheelAakash DindigulNo ratings yet

- Report: Pneumatic UTMDocument14 pagesReport: Pneumatic UTMadibah ismail50% (2)

- Control ValveDocument31 pagesControl ValveMohammed AhmedNo ratings yet

- Pneumatic Control ValvesDocument28 pagesPneumatic Control ValvesKartik UpadhyayNo ratings yet

- Hydraulics Pneumatics QuestionDocument29 pagesHydraulics Pneumatics QuestionSenthilvel C100% (1)

- Unit 3 Control Components in Hydraulic SystemDocument16 pagesUnit 3 Control Components in Hydraulic SystemAbhishek KumbalurNo ratings yet

- BMT7L1-Fluid Power Automation LabDocument37 pagesBMT7L1-Fluid Power Automation LabvamshimohanNo ratings yet

- Basic HydraulicsDocument70 pagesBasic HydraulicsAlex TacuriNo ratings yet

- Control Valve ActuatorsDocument31 pagesControl Valve ActuatorsMuhammad ImtiazNo ratings yet

- AHP NotesDocument26 pagesAHP NotesDr.R.Pugazhenthi Associate Prof.No ratings yet

- 4B-4013 - Air CompressionDocument11 pages4B-4013 - Air Compressionaaquib76No ratings yet

- Manual Cm-760 - 780 InglesDocument121 pagesManual Cm-760 - 780 InglesULISCHAP100% (1)

- Hydraulic ValvesDocument19 pagesHydraulic ValvesRahul SinghNo ratings yet

- Valves 4Document78 pagesValves 4Gurmeet MehmaNo ratings yet

- 5.pneumatic Trainer KitDocument7 pages5.pneumatic Trainer KitAlmas 1710No ratings yet

- Control Valve (Actuator)Document31 pagesControl Valve (Actuator)Junior7100% (1)

- Williams V Series Pump IomDocument32 pagesWilliams V Series Pump IomHectorMaldonado100% (1)

- Control ValveDocument16 pagesControl ValvedileepNo ratings yet

- 6 Intro To Hydraulic-Pneumatic Schematic Symbols Rev2Document46 pages6 Intro To Hydraulic-Pneumatic Schematic Symbols Rev2Rich FurtNo ratings yet

- Fluid Power PDFDocument13 pagesFluid Power PDFtony0% (1)

- PT18PCMTL5 - Applied Hydraulics & Pneumatics LabDocument37 pagesPT18PCMTL5 - Applied Hydraulics & Pneumatics LabvamshimohanNo ratings yet

- Erhard Sewage Air Valve BrochureDocument12 pagesErhard Sewage Air Valve BrochureSivaprasad SasidharanNo ratings yet

- Pe-4030 CH 4 Pneumatic and Hydraulic Actuation System Oct 29Document99 pagesPe-4030 CH 4 Pneumatic and Hydraulic Actuation System Oct 29Charlton S.InaoNo ratings yet

- Rig equipment monitoring systemDocument13 pagesRig equipment monitoring systemDennyVAnggaraNo ratings yet

- Mechatronics Lab Manuaol 2Document130 pagesMechatronics Lab Manuaol 2prabu51No ratings yet

- Pneumatics CircuitDocument69 pagesPneumatics CircuitAjay Chacko100% (2)

- Essential Pneumatic Symbols and SchematicsDocument11 pagesEssential Pneumatic Symbols and Schematicsaa23XbNo ratings yet

- Unit - 3: Control Components in Hydraulic SystemDocument64 pagesUnit - 3: Control Components in Hydraulic SystemchoispunathilNo ratings yet

- AMEE310 Lab5Document12 pagesAMEE310 Lab5tsunaseetNo ratings yet

- Energy Losses in BendsDocument8 pagesEnergy Losses in BendsVikramSingh0% (3)

- Can Select Only 3 Veg & 3 Non Veg Can Select Only 2 Veg & 2 Non Veg Veg Appertizers Main Course - VegDocument5 pagesCan Select Only 3 Veg & 3 Non Veg Can Select Only 2 Veg & 2 Non Veg Veg Appertizers Main Course - VegBIPIN SHARMANo ratings yet

- Rac Visit 1 ImageDocument4 pagesRac Visit 1 ImageBIPIN SHARMANo ratings yet

- 5 Minute Energy Guide Trilemma Issue 6Document17 pages5 Minute Energy Guide Trilemma Issue 6BIPIN SHARMANo ratings yet

- 16bma03um Fs Tilapia Culture - EnglishDocument2 pages16bma03um Fs Tilapia Culture - EnglishBIPIN SHARMANo ratings yet

- CalanderDocument2 pagesCalanderBIPIN SHARMANo ratings yet

- Home Assignment: 2 Power Plant Engineering: ME 413TLPDocument1 pageHome Assignment: 2 Power Plant Engineering: ME 413TLPBIPIN SHARMANo ratings yet

- En792Document12 pagesEn792BIPIN SHARMANo ratings yet

- Subject Task ScheduleDocument1 pageSubject Task ScheduleBIPIN SHARMANo ratings yet

- Prioritized Task List: High Priority TasksDocument1 pagePrioritized Task List: High Priority TasksBIPIN SHARMANo ratings yet

- Introduction To Finite Elements (Matrix Methods)Document46 pagesIntroduction To Finite Elements (Matrix Methods)Paulo FidelisNo ratings yet

- Lec 1Document14 pagesLec 1BIPIN SHARMANo ratings yet

- Outstanding Student LetterDocument3 pagesOutstanding Student LettersagarshiroleNo ratings yet

- November 2, 2006: - Bookkeeping - Presentations - Lecture "Economics of Product Development"Document60 pagesNovember 2, 2006: - Bookkeeping - Presentations - Lecture "Economics of Product Development"khurram08No ratings yet

- Home Assignment: 1 Power Plant Engineering: ME 413TLPDocument1 pageHome Assignment: 1 Power Plant Engineering: ME 413TLPBIPIN SHARMANo ratings yet

- FLX A201 ADocument2 pagesFLX A201 AOliver OrtegaNo ratings yet

- MAE 4021 Project Guide PDFDocument72 pagesMAE 4021 Project Guide PDFBIPIN SHARMANo ratings yet

- IELTS Deposit Slip TitleDocument1 pageIELTS Deposit Slip TitleBIPIN SHARMANo ratings yet

- Thermodynamic FormulasDocument17 pagesThermodynamic Formulasdaniebenade86% (28)

- Lecture 5 Non Ferrous Metals PropertiesDocument20 pagesLecture 5 Non Ferrous Metals PropertiesAmrit DangNo ratings yet

- Cmime Lab ManualDocument75 pagesCmime Lab ManualBIPIN SHARMANo ratings yet

- List 1: IELTS Academic WordlistDocument5 pagesList 1: IELTS Academic WordlistAnjana KumaraNo ratings yet

- TemplateDocument27 pagesTemplateBIPIN SHARMANo ratings yet

- VIT Mech Syallabus BEDocument18 pagesVIT Mech Syallabus BEBIPIN SHARMANo ratings yet

- 16 - Properties and Applications of Materials PDFDocument65 pages16 - Properties and Applications of Materials PDFmpcd07No ratings yet

- 2008 PDFDocument24 pages2008 PDFBIPIN SHARMANo ratings yet

- 2015 PDFDocument9 pages2015 PDFBIPIN SHARMANo ratings yet

- GATE - 2012 M.E: Mechanical Engineering: Free Study Materials For Mechanical Engineering and All Competitive Exams & JobsDocument22 pagesGATE - 2012 M.E: Mechanical Engineering: Free Study Materials For Mechanical Engineering and All Competitive Exams & JobsBIPIN SHARMANo ratings yet

- 2013 PDFDocument20 pages2013 PDFBIPIN SHARMANo ratings yet

- GATE - 2006 M.E: Mechanical Engineering: Free Study Materials For Mechanical Engineering and All Competitive Exams & JobsDocument25 pagesGATE - 2006 M.E: Mechanical Engineering: Free Study Materials For Mechanical Engineering and All Competitive Exams & JobsBIPIN SHARMANo ratings yet

- 2014 PDFDocument25 pages2014 PDFBIPIN SHARMANo ratings yet

- ICM User GuideDocument84 pagesICM User Guidewords2zhigang_612545No ratings yet

- HE Drilling JarsDocument32 pagesHE Drilling Jarsmr_heeraNo ratings yet

- Connection Design Steel Base Plate Bs5950 v2015 01Document4 pagesConnection Design Steel Base Plate Bs5950 v2015 01Anonymous j9PxwnoNo ratings yet

- LCD Interfacing PDFDocument37 pagesLCD Interfacing PDFPeeyush Kp100% (1)

- Application of Nitrous Oxide in AutomobilesDocument26 pagesApplication of Nitrous Oxide in AutomobilesMohammed NuhmanNo ratings yet

- Cessna 172Document4 pagesCessna 172James DeatoNo ratings yet

- HM130 5Document1 pageHM130 5AntonelloNo ratings yet

- Measure Runoff and Soil Loss at Erosion Plots in TanzaniaDocument19 pagesMeasure Runoff and Soil Loss at Erosion Plots in TanzaniaMohd Sofiyan Bin SulaimanNo ratings yet

- GMAT Practice QuestionsDocument8 pagesGMAT Practice QuestionswithraviNo ratings yet

- JavaDocument20 pagesJavaSivasakthi MarimuthuNo ratings yet

- Eiffic/Efuf (T:, RFRDT (FrrtfuDocument17 pagesEiffic/Efuf (T:, RFRDT (FrrtfuRamasubba RajuNo ratings yet

- EL Bay-O-Net Current-Limiting Fuse Assembly - CA132039ENDocument4 pagesEL Bay-O-Net Current-Limiting Fuse Assembly - CA132039ENfederico4thNo ratings yet

- Atlas Copco Compressed Air Manual: 8 EditionDocument25 pagesAtlas Copco Compressed Air Manual: 8 EditionRajNo ratings yet

- Operating Instruction Precision Balance: Kern EwDocument15 pagesOperating Instruction Precision Balance: Kern EwjohnNo ratings yet

- Effort Distribution On Waterfall and AgileDocument12 pagesEffort Distribution On Waterfall and Agileanandapramanik100% (2)

- CE-2101 Fluid Mechanics: Energy Consideration in Steady FlowDocument53 pagesCE-2101 Fluid Mechanics: Energy Consideration in Steady FlowShaheer RizwanNo ratings yet

- First Quarter - Curriculum Map - Science 8Document7 pagesFirst Quarter - Curriculum Map - Science 8Mich Hora100% (7)

- Custom Objects, Fields, Tabs, Related Lists, List ViewsDocument7 pagesCustom Objects, Fields, Tabs, Related Lists, List ViewsAjay GhugeNo ratings yet

- Technical manual for Felt Compulsion mountain bike suspension systemDocument15 pagesTechnical manual for Felt Compulsion mountain bike suspension systemDiogo SilvaNo ratings yet

- Valve Selection Guide For WWTPDocument11 pagesValve Selection Guide For WWTPsf wNo ratings yet

- WWW Mathworks inDocument7 pagesWWW Mathworks inRagini SharmaNo ratings yet

- Unit2.SP - Mill.setting and ImbibitionDocument15 pagesUnit2.SP - Mill.setting and ImbibitionHari kantNo ratings yet

- LC 72322Document13 pagesLC 72322thecanislupusNo ratings yet

- Welding robot aviation plug terminal definitionDocument4 pagesWelding robot aviation plug terminal definitionPhươngNguyễnNo ratings yet

- Uniform ForceDocument11 pagesUniform ForcearnoldistunoNo ratings yet

- SSC Questions On Ratio and Proportion PDFDocument7 pagesSSC Questions On Ratio and Proportion PDFRobert ShortNo ratings yet

- TVS Apache RTR 180 Service ManualDocument25 pagesTVS Apache RTR 180 Service ManualSandino JoseNo ratings yet

- Areas Related To CircleDocument32 pagesAreas Related To CircleGiorno GiovannaNo ratings yet

- Leviton ManualDocument82 pagesLeviton ManualRobby Larson100% (1)

- CH1 The Foundations - Logic and ProofsDocument106 pagesCH1 The Foundations - Logic and ProofsMOHAMED BACHARNo ratings yet