Professional Documents

Culture Documents

Steam Linesizing Rev 1

Uploaded by

Anonymous YcAZv5qF67Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steam Linesizing Rev 1

Uploaded by

Anonymous YcAZv5qF67Copyright:

Available Formats

www.myChemE.

com

Standard Line Sizing Spreadsheet For Steam

Introduction

This spreadsheet can be used to calculate pressure drops in steam lines, taking account fittings (such as bends,

valves and other equipment items).

The spreadsheet is split into the following sections

- A "How to Use This Calculation" Worksheet

- The Pressure Drop Calculation Worksheet itself - marked "Calculation"

- A Theory Worksheet which presents the equations used in the calculation.

It is recommended that the user first reads the 'How to Use These Calculation' worksheet before starting a

calculation.

Revision

Rev. 1

Initial issue

20-Feb-10

Disclaimer: This calculation provides an estimate for estimating pressure drops in steam pipelines. We cannot be held

responsible for its use. As with all areas of process engineering, calculations should be checked by a competent engineer.

www.myChemE.com

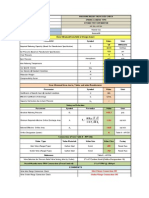

Standard Line Sizing Spreadsheet For Steam

Steam Properties provided by:

http://www.x-eng.com

See 'How to use these Calculation' worksheet for notes on its use.

Calculation Title:

From:

To:

Pressure & Temperature Data

Upstream Pressure

bar (g)

Temperature

degC

Steam Properties Data

Phase

Steam Viscosity

Cp

Steam Density

kg/m3

Pipe Data

Nominal Line Diameter

inches

Pipe Schedule

Pipe Material Type

Internal Diameter

inches

Internal Diameter

mm

Flowrates

Mass Flow

kg/h

m3/h

Volumetric Flow

Line Velocity

m/s

Pres drop per 100m

bar/100m

Line Losses

Pipe Length

m

Number of 90o bends

Number of valves

Check Valves

T-Piece straight run

T-Piece as elbow

Other Pressure Drops

Other Pressure Drops

bar

Summary

Total Pressure Drop

bar

Downstream Pressure bar (g)

1.00

200

#VALUE!

200

#VALUE!

200

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

2.00

80

Steel (New)

1.94

49.3

0.75

40

Steel (New)

0.82

20.9

0.75

40

Steel (New)

0.82

20.9

200

#VALUE!

#VALUE!

#VALUE!

200

#VALUE!

#VALUE!

#VALUE!

200

#VALUE!

#VALUE!

#VALUE!

120

25

5

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0.00

0.00

0.00

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

Notes

This spreadsheet calcluates pressure drop based on the upstream steam conditions. Consequently, the

calculated pressure drop will be an underestimate. To obtain reasonable accuracy ensure that the total pressure

drop is not more than 10% of the upstream pressure in each column. See "How to Use This Calculation" for

details.

Disclaimer: This calculation provides an estimate for estimating pressure drops in steam pipelines. We cannot be held

responsible for its use. As with all areas of process engineering, calculations should be checked by a competent engineer.

myChemE.com

r Steam

Revision 1

#VALUE!

200

#VALUE!

#VALUE!

#VALUE!

0.75

40

Steel (New)

0.82

20.9

200

#VALUE!

#VALUE!

#VALUE!

0

0

0

0

0

0

0.00

#VALUE!

#VALUE!

ns. Consequently, the

ensure that the total pressure

o Use This Calculation" for

We cannot be held

competent engineer.

www.myChemE.com

Standard Line Sizing Spreadsheet For Steam

Revision 1

HOW TO USE THIS CALCULATION

1.0

Introduction

This spreadsheet can be used to calculate pressure drops in steam pipelines, taking account of inline fittings

(such as bends, valves and other equipment items).

The spreadsheet has four columns which link from one to the next. This can be used to break a piping system

down into a number of component sections, if needed.

2.0

How to use this spreadsheet

2.1

Colour Coding

The following colour coding is used:

Boxes shaded light green require a user input.

Boxes shaded light blue give a calculated output.

2.2

Calculation Description

The spreadsheet leaves space to add a Calculation Title at the top, and a Notes Section at the bottom

of the sheet. At the top of the calculation column are two boxes ('To' and 'From') to indicate the pipe

route.

Although these items are not strictly necessary, they help describe the calculation - this can be

invaluable it is to be checked by another engineer. The 'To' and 'From' Sections are particularly useful

if the calculation is split over several columns.

2.3

Pressure & Temperature Data

The user enters the upstream pressure and the steam temperature in the first column. The spreadsheet

then calculates the downstream pressure - based on the flow, physical property and pipeline data entered

(see below). The downstream pressure from the first column is transferred across to the upstream pressure

of the second column, thus allowing a pipework network to be built up.

The steam temperature is copied across to the other columns (although this can be overwritten, if required).

2.4

Steam Properties

The spreadsheet calculates steam properties (i.e. steam density and viscosity) using IAPWS Steam IF97

and IAPWS "Revised Release on the IAPWS Formulation 1985 for the Viscosity of Ordinary Water

substance".

These values use Macros taken from electronic steam tables provided from:

http://www.x-eng.com

IAPWS defines the water-steam thermodynamic system into 5 regions, these are:

Region 1 for the liquid state from low to high pressures,

Region 2 for the vapor and ideal gas state,

Region 3 for the thermodynamic state around the critical point,

Region 4 for the saturation curve (vapor-liquid equilibrium),

Region 5 for high temperatures above 1073.15 K (800 C) & pressures up to 10 MPa (100 bar).

The steam properties are calculated for region 2 only. For temperatures and pressures outside this range,

the spreadsheet returns an error message. A further discussion on IAPWS can be found here

IAPSW Link

Disclaimer: This calculation provides an estimate for estimating pressure drops in liquid pipelines. We cannot be held responsible for its use. As with all areas of

process engineering, calculations should be checked by a competent engineer.

www.myChemE.com

Standard Line Sizing Spreadsheet For Steam

2.5

Revision 1

Pipe Data

2.5.1

Nominal Pipe Diameter

The spreadsheet allows the user to choose from a range of nominal pipe diameters. Available

nominal pipe sizes are: ", ", 1", 1", 2", 3", 4", 5", 6", 8", 10", 12", 14", 16", 18", 20"

and 22".

2.5.2

Pipe Schedule

The spreadsheet allows the user to choose from a range of available pipe schedules

(thicknesses) - these are: 5S, 10S, 20, 30, 40, 60, 80, 100, 120, 140, 160, XS and XXS.

By entering the nominal diameter and schedule, the spreadsheet automatically retrieves the

correct internal diameter of the pipe. It should be noted that not all combinations of nominal

diameter and schedule are permissible; if the wrong combination is selected the spreadsheet

displays an error. A list of standard pipe sizes can be found by clicking on the link below:

List of Standard Pipesizes

On occasions, the user may wish to calculate a pressure drop for a non-standard pipe. In this

case, the user can simply over write the internal diameter cell on the spreadsheet (either in

inches or mm).

2.5.3

2.6

Pipe Schedule

The pressure drop per unit length is affected by the pipe surface roughness - which depends

on the materials of construction. The spreadsheet is provided with a range of possible pipe

material types: glass/tubing, steel (new), steel (corroded), concrete and riveted steel. By

selecting the piping material type, the spreadsheet automatically sets the surface roughness.

Flowrates

The user enters the required steam mass flowrate in kg per hour. The spreadsheet then calculates the

volumetric flowrate (in m3/s), the line velocity (m/s) and the pressure drop per unit length.

(in bar/100m).

The calculated line velocity and pressure drop per unit length can be used to assess whether the pipe

diameter is reasonable for the required flowrate.

2.7

Line Losses

The spreadsheet can now be used to determine the line losses (pressure drop) through the system. The

user enters the total pipe length, as well as the number of inline fittings (bends, valves and Tee-junctions).

The spreadsheet then calculates the line losses - see Summary Section below.

2.8

Other Pressure Drops

As well as line losses, the spreadsheet allows the user to enter other pressure drops not accounted for in.

the line losses. These could be:

-

Pressure drops due to orifice plates.

Pressure drops due to inline instrumentation.

Pressure drops due to control valves

Pressure drops due to equipment items

Changes in pressure as a result of changes in elevation are invariably negligible in steam lines and are

ignored.

Disclaimer: This calculation provides an estimate for estimating pressure drops in liquid pipelines. We cannot be held responsible for its use. As with all areas of

process engineering, calculations should be checked by a competent engineer.

www.myChemE.com

Standard Line Sizing Spreadsheet For Steam

2.9

Revision 1

Summary

The summary section provides a summary of the total pressure drop and the calculated downstream

pressure.

Unlike water and other liquids, steam is compressible. Therefore, its density changes with pressure. If the

pressure drop calculated is too great, the density and line velocity will change appreciably. This will result in

errors in the calculation. It is worth noting that as this method uses the density at the upstream conditions,

the spreadsheet will under-estimate the actual pressure drop.

To obtain reasonable accuracy ensure that the total pressure drop in each column is no more that 10% of

the upstream pressure. If the pressure drop is greater than 10%, split the calculation over more than one

column (See Section 3, "Building a Piping Network" below).

3.0

Building a Piping Network

For pressure drop calculations down a single pipe, only the first column of the pressure drop calculation needs to

be used. The other three calculation columns can be ignored.

However, for more complex piping systems, the other calculation columns can be used to build up a piping network

This can be very useful if, for example, the user needs to determine pressure drop in distribution systems.

To make this easier, the downstream pressure of the first column is used as the upstream pressure of the second

column and so on. The physical property and flowrate data entered in the first column is copied across to the

other three columns to make it easier to set up a network - these values can be overwritten, if required.

Disclaimer: This calculation provides an estimate for estimating pressure drops in liquid pipelines. We cannot be held responsible for its use. As with all areas of

process engineering, calculations should be checked by a competent engineer.

Revision: 1

www.myChemE.com

Standard Line Sizing Spreadsheet For Steam

CALCULATION THEORY

1.0

Introduction

This spreadsheet can be used to calculate pressure drops in pipelines, taking account of inline fittings (such as

bends, valves and other equipment items. To use the spreadsheet, follow the instructions given in the "How to

Use this Spreadsheet" Worksheet.

This worksheet presents the equations and algorithms used in the calculation and discusses elements of fluid flow

theory.

2.0

Calculation of Pressure Drop

2.1

Determining Pipe Dimensions

Commercial pipes come in standard sizes, specified in terms of the nominal pipe diameter, and the pipe

schedule. The spreadsheet has this information already stored within the calculation worksheet, linked

to the internal diameter (in inches). The spreadsheet retrieves the correct internal diameter using a Lookup

command.

The internal diameter, d, (in metres) is used to calculate the cross-sectional flow area, A, (in square metres)

using Equation 1:

A =

2.3

d

4

Equation (1)

Determining Steam Properties

Steam physical properties (i.e. density and viscosity) are taken from IAPWS Steam IF97 and IAPWS

"Revised Release on the IAPWS Formulation 1985 for the Viscosity of Ordinary Water substance". More

information is available via the following link:

IAPSW Link

2.3

Determining the Line Velocity

The line velocity, u, (in m/s) is calculated using Equation 2:

u =

m

A

Equation (2)

Where:

m - Mass flowrate (in kg/s)

A - Cross-sectional flow area (in m2)

2.4

Calculation of the Reynolds Number

The Reynolds number is a dimensionless group giving a measure of whether to flow is laminar or turbulent.

It is used to estimate the friction factor (see below). A discussion on Reynolds Number and its importance

can be found via the following link:

Reynolds Number

The Reynolds number, Re, is calculated using Equation 3:

Re =

Where

u d

Equation (3)

- Viscosity (in Pa.s)

Disclaimer: This calculation provides an estimate for estimating pressure drops in liquid pipelines. We cannot be held responsible for its use. As with all areas

of process engineering, calculations should be checked by a competent engineer.

Revision: 1

www.myChemE.com

Standard Line Sizing Spreadsheet For Steam

2.4

Calculation of the Pipe Relative Roughness

The pressure drop from flow down a pipe - at least in turbulent flow - is affected by the roughness of the

pipe surface. Obviously, the pipe roughness is determined by the pipe materials of construction. The

spreadsheet provides typical pipe roughness values for a range of materials i.e.

Materials

Tubing/Glass

Steel (New)

Steel (Corroded)

Cast Iron

Concrete

Riveted Steel

Pipe Roughness

2.0E-06 m

5.0E-05 m

1.0E-03 m

2.6E-04 m

3.0E-04 m

5.0E-03 m

Table 1: Roughness values for different pipe materials

The effect of pipe roughness becomes less important as the pipe diameter increases, thus the spreadsheet

calculates the pipe roughness relative to the pipe diameter using Equation 4.

Pipe Relative Roughness =

Where:

2.5

Equation (4)

Pipe roughness (in m)

d - Pipe internal diameter (in m)

Calculation of the Fanning Friction Factor

The Fanning Friction Factor is a dimensionless number which, along with the pipe velocity, can be used to

estimate the pressure drop of flow down a pipe. It is a function of the Reynolds number and, for turbulent

flow, the pipe relative roughness. An introduction to the Fanning Friction Factor can be found via the

following link:

Fanning Friction Factor

The Fanning Friction Factor can be determined from Charts (Moody Diagram) or by using an empirical

equation. A number of Friction Factor Correlations are available in the literature, the one used in this

spreadsheet is the Churchill Correlation see Equations 5, 6 and 7.

fFanning = 2 x

8

Re

12

1

(A + B)1.5

Equation (5)

Where

1

A = 2.457 x ln

7

Re

0.9

+ 0.27 x

Equation (6)

and

B =

37530

Re

Equation (7)

The Churchill Correlation is used as it is applicable to both laminar and turbulent flow - this is not the case

all correlations.

It should be noted that the Fanning Friction Factor is NOT the same as other Friction Factors: i.e. Darcy

and Moody

Disclaimer: This calculation provides an estimate for estimating pressure drops in liquid pipelines. We cannot be held responsible for its use. As with all areas

of process engineering, calculations should be checked by a competent engineer.

Revision: 1

www.myChemE.com

Standard Line Sizing Spreadsheet For Steam

2.6

Calculation of the Pressure Drop per Unit Length of Straight Pipe

The pressure loss as steam flows down a straight length of pipe is given by the Darcy Equation. This

is expressed in Equation 8 below.

Pipe

4 fFanning LPipe

d

.u2

2

Equation (8)

Where

PPipe - Pipe line pressure drop (in Pa)

LPipe - Pipe length (in m)

An introduction to the Darcy Equation is given via the attached link:

Introduction to the Darcy Equation

It should be noted that the form of the equation presented via this link uses the Darcy Friction Factor, which

is four times larger than the Fanning Friction Factor. Equation 8 can be adapted to calculate the Pressure

per 100 metres by setting LPipe to 100 and converting from Pa to Bar - see Equation 9.

metres

4 fFanning x 100

.u2

Bar per 100m =

5

2

d x 10

Pa / bar

2.7

Equation (9)

Calculation of the Pressure Drop Through Pipe Fittings

The Pressure Drop through pipe fittings (e.g. Pipe bends, Valves, T-Pieces) can be expressed in terms of

a Resistance Coefficient, K, where:

Fittings

.u2

2

Equation (10)

N.B. It can be seen from Equations 8 and 10 that the Resistance Coefficient equates to (4f FanningL)/d for

a straight length of pipe. The spreadsheet uses the following Resistance Coefficients for different pipe

fittings

Fitting

90o Bends

Valve

Check Valve

Straight Tee piece

Thru' Tee Piece

Resistance Coeff, K

0.8

1.2

1.5

0.1

0.7

Table 2: Resistance Coefficient for different pipe fittings

Obviously, these values are approximate as K is affected by factors such as radius of the bend and the

valve design. A detailed list of Resistance Coefficients for different pipe fittings is given in Cranes' Flow

of Fluids book - see link below.

Flow of Fluids Technical Guide

The Line Losses value given in the spreadsheet is the sum of the PPipe and PFittings.

Disclaimer: This calculation provides an estimate for estimating pressure drops in liquid pipelines. We cannot be held responsible for its use. As with all areas

of process engineering, calculations should be checked by a competent engineer.

You might also like

- Ejercicio 246 PSV438 RESUELTODocument2 pagesEjercicio 246 PSV438 RESUELTOHumberto Ivan Gonzales TapiaNo ratings yet

- Valve Sizing SelectionDocument15 pagesValve Sizing SelectionbariNo ratings yet

- Case 2 - Tank Heat LossDocument86 pagesCase 2 - Tank Heat Lossahmad santosoNo ratings yet

- CFD Modeling Analysis of A Vertical Gas Liquid SeparatorDocument9 pagesCFD Modeling Analysis of A Vertical Gas Liquid SeparatorTanweer HussainNo ratings yet

- 6-Pressure Safety ValveDocument1 page6-Pressure Safety ValveFari NazariNo ratings yet

- Vertical Separator SizingDocument4 pagesVertical Separator SizingnemprrNo ratings yet

- Equivalent Length Calculator - RevADocument10 pagesEquivalent Length Calculator - RevArkrajan1502No ratings yet

- Orifice Flow Calculator For Gases, Steam, and VaporsDocument2 pagesOrifice Flow Calculator For Gases, Steam, and Vaporsbakhtyar21No ratings yet

- Separator SpeadsheetDocument8 pagesSeparator SpeadsheetShabrina GhassaniNo ratings yet

- Rupture Disks For Process Engineers - Part 2Document6 pagesRupture Disks For Process Engineers - Part 2Clarence AG YueNo ratings yet

- Liq Expansion CalculationsDocument4 pagesLiq Expansion CalculationsGary JonesNo ratings yet

- Thermal Expansion CalculationsDocument36 pagesThermal Expansion CalculationsAhmad MuzammilNo ratings yet

- Chemical Reactivity HazardsDocument101 pagesChemical Reactivity HazardsSandeep VermaNo ratings yet

- Sizing of Pressure Safety Valve: Project Name ClientDocument7 pagesSizing of Pressure Safety Valve: Project Name ClientAmit Bansal100% (1)

- PSV No. Cause Calculation:: ReferenceDocument3 pagesPSV No. Cause Calculation:: ReferencerevinNo ratings yet

- Stacks: Ammonia Injection: A Route To CleanDocument8 pagesStacks: Ammonia Injection: A Route To CleanZEN MA100% (1)

- Tank Pressure & Vacuum ProtectionDocument4 pagesTank Pressure & Vacuum ProtectionrodrigoperezsimoneNo ratings yet

- Control Valve DPDocument8 pagesControl Valve DPAmit SawantNo ratings yet

- PSV Sizing CalculationsDocument4 pagesPSV Sizing CalculationsAbelardo ContrerasNo ratings yet

- PSV SizingDocument8 pagesPSV SizingMinh DoNo ratings yet

- Ssags PSV SizingDocument5 pagesSsags PSV SizingEkundayo JohnNo ratings yet

- Pressure Relief Valve Sizing and Selection CheckDocument2 pagesPressure Relief Valve Sizing and Selection CheckGiftObionochieNo ratings yet

- Process Design of Solid-Liquid Separators (Project Standards and Specifications)Document10 pagesProcess Design of Solid-Liquid Separators (Project Standards and Specifications)nabilaNo ratings yet

- API Standards Guide Pressure Relief SystemsDocument1 pageAPI Standards Guide Pressure Relief SystemsKmt_AeNo ratings yet

- REL - Relationship Counseling GuideDocument117 pagesREL - Relationship Counseling GuidechenguofuNo ratings yet

- CRP Sampling Literature PDFDocument8 pagesCRP Sampling Literature PDFgullenariNo ratings yet

- Insulation ThicknessDocument2 pagesInsulation ThicknessShashi Kant KumarNo ratings yet

- Relief Load Calculation For Fire Case - As Per API 521Document1 pageRelief Load Calculation For Fire Case - As Per API 521ktejankarNo ratings yet

- Centrifugal Pump CalculatorDocument47 pagesCentrifugal Pump CalculatorJunior Mas Aguilar100% (1)

- P & I Design ERS Sizing MethodsDocument34 pagesP & I Design ERS Sizing MethodsYunping Huang100% (1)

- 7.2.24 - Breather ValvesDocument28 pages7.2.24 - Breather Valvessav33No ratings yet

- Calculation of The Built Up Back Pressure - LESERDocument4 pagesCalculation of The Built Up Back Pressure - LESERArjed Ali ShaikhNo ratings yet

- API 521 SummaryDocument4 pagesAPI 521 Summaryswathi100% (1)

- 5.4.3. Power Requirements For Pumping Liquids: 5.4. Pumps and CompressorsDocument3 pages5.4.3. Power Requirements For Pumping Liquids: 5.4. Pumps and Compressorsamir885No ratings yet

- P & I Design LTD: Emergency Relief System (Ers) Sizing Software Methods & PracticeDocument29 pagesP & I Design LTD: Emergency Relief System (Ers) Sizing Software Methods & PracticeATUL SONAWANENo ratings yet

- Valve SizingDocument38 pagesValve SizingEmmanuel JohnsonNo ratings yet

- CE Refresher: Steam Tables and Typical Liquid VelocitiesDocument1 pageCE Refresher: Steam Tables and Typical Liquid Velocitieshugo mendozaNo ratings yet

- Rupture Disk SizingDocument2 pagesRupture Disk Sizingabhishek shindeNo ratings yet

- Consequence AnalyserDocument23 pagesConsequence AnalyserGlacier RamkissoonNo ratings yet

- Vent Line Sizing Metric Calculation Results DP WarningDocument2 pagesVent Line Sizing Metric Calculation Results DP WarningAjay TiwariNo ratings yet

- Calculate Strainer Pressure DropDocument11 pagesCalculate Strainer Pressure DropBIDDU GHOSHNo ratings yet

- Limpet Coil On Dish Design As Per PD5500Document1 pageLimpet Coil On Dish Design As Per PD5500ABIDEEN BAMNENo ratings yet

- Minimum Submergence Required For Vortex Breaker - Industrial Professionals - Cheresources - Com CommunityDocument7 pagesMinimum Submergence Required For Vortex Breaker - Industrial Professionals - Cheresources - Com CommunitySHINo ratings yet

- PSV ReportDocument6 pagesPSV Reportanamaria ursuNo ratings yet

- 9.1 Overview: 9 Wiped Film EvaporatorDocument12 pages9.1 Overview: 9 Wiped Film EvaporatorNoman AslamNo ratings yet

- Entrainment Vortex BreakerDocument3 pagesEntrainment Vortex Breakerzorro21072107No ratings yet

- Centrif Pumps1 SpreadsheetDocument2 pagesCentrif Pumps1 SpreadsheetCast Ed Iv0% (1)

- Desuperheater Equipment&SystemDocument12 pagesDesuperheater Equipment&Systemquoctrangbk02No ratings yet

- Control Valve DatasheetDocument2 pagesControl Valve Datasheetcv.ekaputra 04No ratings yet

- Tank Venting Requirements (API 2000) 2Document3 pagesTank Venting Requirements (API 2000) 2RubensBoerngenNo ratings yet

- Vacuum Pump SizingDocument1 pageVacuum Pump SizingMuhammad HassamNo ratings yet

- Safety valve sizing calculationsDocument7 pagesSafety valve sizing calculationsjjirwinNo ratings yet

- Volume and Wetted Area of Partially Filled Vertical Vessels - Neutrium PDFDocument12 pagesVolume and Wetted Area of Partially Filled Vertical Vessels - Neutrium PDFdaimon_p100% (1)

- Calculate Vent Sizing for Storage TanksDocument5 pagesCalculate Vent Sizing for Storage TanksSteve WanNo ratings yet

- Vessel 2 Is To 1 Ellipsoidal VesselDocument3 pagesVessel 2 Is To 1 Ellipsoidal VesselHoang-Vu BuiNo ratings yet

- Gas Pipeline Blowdown Time CalculatorDocument7 pagesGas Pipeline Blowdown Time CalculatorKarun DasNo ratings yet

- Handbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7From EverandHandbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7No ratings yet

- Pages From IGEM-SR-25 Edition 2Document11 pagesPages From IGEM-SR-25 Edition 2komalrana20070% (3)

- JacketJacketed Vessels Overall Heat Transfer Coefficient CalculationDocument7 pagesJacketJacketed Vessels Overall Heat Transfer Coefficient Calculationkomalrana2007No ratings yet

- Ammonia Water Steam StrippingDocument17 pagesAmmonia Water Steam Strippingkomalrana2007100% (3)

- Flowrate 10 Line Size 40 (MM I.d.) Flowspeed 2.21 M/s (M /H)Document4 pagesFlowrate 10 Line Size 40 (MM I.d.) Flowspeed 2.21 M/s (M /H)komalrana2007No ratings yet

- Safe handling of industrial solventsDocument24 pagesSafe handling of industrial solventsE.ANANDAN100% (1)

- Tank padding calculation summaryDocument9 pagesTank padding calculation summarykomalrana2007100% (1)

- Very Good Presentation - ATEX IchemEDocument109 pagesVery Good Presentation - ATEX IchemEkomalrana2007100% (8)