Professional Documents

Culture Documents

700pxx Iseng1200 PDF

Uploaded by

kamlOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

700pxx Iseng1200 PDF

Uploaded by

kamlCopyright:

Available Formats

700 Series Pressure Modules

Instruction Sheet

Low

Differential

P

M

04 RE

0P SSU

70 RE

G

AN

R

E

1

U

D

O

/G

ID bar

PSPa 1

15 0 0 k

LE

High

Gage

P

M

06 RE

0P SSU

70 RE

G

AN

R

E

7

D

O

IG ar

PS 7 b

0 Pa

10 00 k

LE

U

yz1f.eps

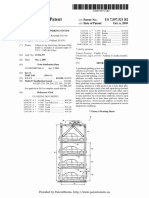

Figure 1.

Introduction

The Fluke 700 Series Pressure Modules allow you to measure

pressure with the Fluke 700 Series Process Calibrators. Read this

sheet before you use the pressure module. This sheet contains

specifications and information about how to avoid damaging the

pressure module. See the Calibrator Users Manual for operating

instructions.

The pressure module measures pressure using an internal

microprocessor. It receives operating power from and sends digital

information to the 700 Series calibrator.

Gage pressure modules have one pressure fitting and measure

pressure with respect to atmospheric pressure. Differential pressure

modules have two pressure fittings and measure the difference

between the applied pressure on the high fitting versus the low fitting.

Figure 1 shows the two types. A differential pressure module functions

like a gage module when the low fitting is open.

Compatibility of Pressure Modules with Fluke

Process Calibrators

Fluke-701, 702, 741, 743, and 744 Documenting Process

Calibrators: The Fluke-700P00 and P27 Pressure Modules are

completely compatible with these calibrators.

Fluke-716, 717, and 718 Pressure Calibrators: The Fluke-700P00

and P27 Pressure Modules will display pressure readings correctly on

716 Pressure Calibrators with firmware V1.2 or higher, or 717 and 718

Pressure Calibrators with firmware V1.3 or higher. To view the software

revision, power-on the calibrator while holding down the MAX key.

Read the REV number in the display. Contact your Fluke Service

Center for a free update of calibrators with lower revision numbers.

Reference PCN 4647.

PN 942735 July 1994 Rev.12, 11/01

1994-2001 Fluke Corporation. All rights reserved. Printed in USA

All product names are trademarks of their respective companies

Fluke-725 Multifunction Process Calibrators: The Fluke-700P00 and

P27 Pressure Modules will display correct pressure readings when

used with Fluke-725 Multifunction Process Calibrators at internal

software revision 1.9 and later. To view the software revision, power-on

the calibrator while holding down the 0% key. Read the REV number in

the display. Contact your Fluke Service Center for a free update of

calibrators with lower revision numbers. Reference PCN 4578.

Box Contents

Protecting Yourself from Pressure Releases

To avoid a violent release of pressure in a pressurized system, shut off

the isolation valve and slowly bleed off the pressure before you attach

or remove the pressure module from the pressure line.

Avoiding Overpressure Damage

Applying pressure in excess of the BURST PRESSURE specified on

the pressure module can destroy the pressure module. Burst pressure

is 3X full scale (2X for 700P09, 30X for 700P00).

Pressure module, strap, 1/4 NPT to 1/4 ISO metric adapters, instruction

sheet.

Table 1. Pressure Module Specifications

2

MODEL

FLUKE-700P00

FLUKE-700P01

FLUKE-700P02

FLUKE-700P03

FLUKE-700P04

FLUKE-700P05

FLUKE-700P06

FLUKE-700P27

FLUKE-700P07

FLUKE-700P08

FLUKE-700P09

1.

2.

3.

4.

5.

6.

RANGE

0 to 1.000 in H2O

0 to 0.249 kPa

0 to 0.002 bar

0 to 10.00 in H2O

0 to 2.49 kPa

0 to 0.02 bar

0 to 1.0000 psi

0 to 6.8900 kPa

0 to 6.89 E2 bar

0 to 5.0000 psi

0 to 34.000 kPa

0 to 0.3400 bar

0 to 15.000 psi

0 to 100.00 kPa

0 to 1.0000 bar

0 to 30.000 psi

0 to 200.00 kPa

0 to 2.0000 bar

0 to 100.00 psi

0 to 700.00 kPa

0 to 7.0000 bar

0 to 300.00 psi

0 to 2000.0 kPa

0 to 20.000 bar

0 to 500.00 psi

0 to 3400.0 kPa

0 to 34.000 bar

0 to 1000.0 psi

0 to 7000.0 kPa

0 to 70.000 bar

0 to 1500.0 psi

0 to 10000.0 kPa

0 to 100.000 bar

GAGE OR

DIFFERENTIAL

ISOLATED OR

NONISOLATED

REFERENCE

UNCERTAINTY

(23 3C)

STABILITY

(1 YEAR)

TEMP

(0 to 50C)

(% of Full Scale) 1 YEAR

TOTAL UNCERTAINTY

Differential

Nonisolated

0.300%

0.025%

0.025%

0.350%

Differential

Nonisolated

0.200%

0.050%

0.050%

0.300%

Differential

Nonisolated

0.150%

0.070%

0.080%

0.300%

Differential

Nonisolated

0.050%

0.020%

0.030%

0.100%

Differential

Nonisolated

0.025%

0.010%

0.015%

0.050%

Gage

Isolated

0.025%

0.010%

0.015%

0.050%

Gage

Isolated

0.025%

0.010%

0.015%

0.050%

Gage

Isolated

0.025%

0.010%

0.015%

0.050%

Gage

Isolated

0.025%

0.010%

0.015%

0.050%

Gage

Isolated

0.025%

0.010%

0.015%

0.050%

Gage

Isolated

0.025%

0.010%

0.015%

0.050%

Use of pressure zero function is required to achieve these specifications. Contact your Fluke Service Center for upgrade of your Fluke 701 or Fluke 702 V1.0, V1.1, or

V1.2 calibrator.

2

Available pressure units (psi, kPa, bar, inHg, mmHg, inH20, ftH20., kg/cm , mmH20, cmH20) are determined by the calibrator being used.

Accuracy specifications apply for 0 to 100% of full scale, 0 to 50C. 1% FS typical, -10 to 0C. On 700P00 only, specification applies from 15 to 35C.

Maximum Non-Destructive Pressure: 3X maximum rated pressure, including common mode pressure. (700P09: 2X, 700P00: 30X)

Maximum Common Mode Pressure: 3X maximum rated pressure. (700P09: 2X, 700P00: 30X)

Specifications reflect a confidence interval of 95%.

Avoiding Mechanical Damage

Performance Test

To avoid mechanically damaging the pressure module, never apply

more than 10 ft.-lbs. of torque between the pressure module fittings or

between the fittings and the body of the module. Always apply

appropriate torque between the pressure module fitting and connecting

fittings or adapters. Figure 2 shows the correct way and incorrect

ways to use a wrench when applying torque to the pressure module

fitting.

If you need to check that the pressure module meets its accuracy

specification, use a dead weight tester or suitable pressure calibrator.

The accuracy of the dead weight tester or pressure calibrator should

be at least 4X better than the 700 Series pressure specification.

Proceed as follows to verify that a pressure module is operating within

specification:

1.

E

10

DU

/G

MO

ID bar

PS a 1

15 0 kP

04 E

0P UR

ESS

PR

70

G

AN

R

LE

2.

3.

Set the dead weight tester to 20% of the pressure modules full

scale value.

4.

Make sure the reading agrees with the dead weight tester value

within the Total Uncertainty specification in Table 1.

Set the dead weight tester to 40, 60, 80, and 100% of full scale

and compare the respective readings.

If temperature sensitivity is of concern, repeat steps 1 through 5

at various controlled temperatures.

5.

6.

yz2f.eps

Figure 2.

Avoiding Corrosion Damage

To avoid damaging the pressure module from corrosion, use it only

with specified media as shown below:

Isolated modules: any medium that is compatible with type 316

stainless steel.

Nonisolated modules: dry, noncorrosive gasses only.

Recommended Measurement Technique

For best results, it is recommended that the module be pressurized to

full scale and then vented to zero pressure (atmosphere) prior to

zeroing and making measurements with the calibrator.

Note

Low range pressure modules may be sensitive to

gravity. For best results, pressure modules 30 psi and

below should be held at the same physical orientation

from the time they are zeroed until the measurement is

complete.

Read the pressure value with no externally applied pressure to

make sure the 0% of scale is correct. When reading the pressure

with a 700 Series, press the ZERO key to remove any zero

offset.

Connect the pressure module to a dead weight tester.

Pressure Calibration Kit

The Fluke-700PCK Pressure Calibration Kit makes it possible to

calibrate pressure modules at ambient temperature with a precision

pressure calibrator or dead weight tester at least 4x better than the

module specification. A 386 or better PC and Windows 3.1 or better

are required. The kit is an optional accessory available from your

distributor or Fluke.

Certifications

P Conforms to European Standard EN61010-1, EN61326.

LIMITED WARRANTY & LIMITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and

workmanship under normal use and service. The warranty period is one year and

begins on the date of shipment. Parts, product repairs and services are warranted

for 90 days. This warranty extends only to the original buyer or end-user customer

of a Fluke authorized reseller, and does not apply to fuses, disposable batteries or

to any product which, in Flukes opinion, has been misused, altered, neglected or

damaged by accident or abnormal conditions of operation or handling. Fluke

warrants that software will operate substantially in accordance with its functional

specifications for 90 days and that it has been properly recorded on non-defective

media. Fluke does not warrant that software will be error free or operate without

interruption.

Fluke authorized resellers shall extend this warranty on new and unused products

to end-user customers only but have no authority to extend a greater or different

warranty on behalf of Fluke. Warranty support is available if product is purchased

through a Fluke authorized sales outlet or Buyer has paid the applicable

international price. Fluke reserves the right to invoice Buyer for importation costs

of repair/replacement parts when product purchased in one country is submitted

for repair in another country.

Flukes warranty obligation is limited, at Flukes option, to refund of the purchase

price, free of charge repair, or replacement of a defective product which is

returned to a Fluke authorized service center within the warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center

or send the product, with a description of the difficulty, postage and insurance

prepaid (FOB Destination), to the nearest Fluke authorized service center. Fluke

assumes no risk for damage in transit. Following warranty repair, the product will

be returned to Buyer, transportation prepaid (FOB Destination). If Fluke

determines that the failure was caused by misuse, alteration, accident or

abnormal condition of operation or handling, Fluke will provide an estimate of

repair costs and obtain authorization before commencing the work. Following

repair, the product will be returned to the Buyer transportation prepaid and the

Buyer will be billed for the repair and return transportation charges (FOB Shipping

Point).

THIS WARRANTY IS BUYERS SOLE AND EXCLUSIVE REMEDY AND IS IN

LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING

BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE

FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL

DAMAGES OR LOSSES, INCLUDING LOSS OF DATA, WHETHER ARISING

FROM BREACH OF WARRANTY OR BASED ON CONTRACT, TORT,

RELIANCE OR ANY OTHER THEORY.

Since some countries or states do not allow limitation of the term of an implied

warranty, or exclusion or limitation of incidental or consequential damages, the

limitations and exclusions of this warranty may not apply to every buyer. If any

provision of this Warranty is held invalid or unenforceable by a court of competent

jurisdiction, such holding will not affect the validity or enforceability of any other

provision.

In Case of Difficulty

For service or calibration, call your nearest authorized Fluke Service

Center. To contact Fluke call one of the following telephone numbers:

USA: 1-888-99-FLUKE (1-888-993-5853)

Canada: 1-800-36-FLUKE (1-800-363-5853)

Europe: +31 402-678-200

Japan: +81-3-3434-0181

Singapore: +65-738-5655

Anywhere in the world: +1-425-446-5500

Or, visit Flukes Web site at www.fluke.com.

Fluke Corporation Fluke Europe B.V.

P.O. Box 9090

P.O. Box 1186

Everett, WA

5602 B.D. Eindhoven

98206-9090

The Netherlands

You might also like

- ConduitDocument77 pagesConduitkamlNo ratings yet

- Grafik QS CompleteDocument204 pagesGrafik QS CompletekamlNo ratings yet

- PyroSimManual PDFDocument155 pagesPyroSimManual PDFkamlNo ratings yet

- Fault Level CalculationDocument6 pagesFault Level Calculationmn_sundaraamNo ratings yet

- Breadfruit Project FINAL PDFDocument99 pagesBreadfruit Project FINAL PDFkamlNo ratings yet

- CycEL InstructionsDocument9 pagesCycEL InstructionskamlNo ratings yet

- GRAFIK Eye QS General PDFDocument20 pagesGRAFIK Eye QS General PDFkamlNo ratings yet

- CycEL InstructionsDocument9 pagesCycEL InstructionskamlNo ratings yet

- Sargent Duplicarver PDFDocument11 pagesSargent Duplicarver PDFkamlNo ratings yet

- Baby TractorDocument3 pagesBaby TractorFrenchwolf420No ratings yet

- Brick MakingDocument3 pagesBrick MakingkamlNo ratings yet

- 6.01 Brick MakingDocument15 pages6.01 Brick MakingRameez BedekarNo ratings yet

- 20060156658Document8 pages20060156658kamlNo ratings yet

- Fiberglass StructuresDocument12 pagesFiberglass Structureskaml100% (1)

- Cement MixerDocument3 pagesCement MixerGreg Phillpotts100% (5)

- PDFDocument35 pagesPDFkamlNo ratings yet

- PDFDocument10 pagesPDFkamlNo ratings yet

- Chemin CritiqueDocument1 pageChemin CritiquekamlNo ratings yet

- Articulated Jib Tower CraneDocument6 pagesArticulated Jib Tower CranekamlNo ratings yet

- Micro Scissor LiftDocument2 pagesMicro Scissor LiftkamlNo ratings yet

- Topic12 PDFDocument12 pagesTopic12 PDFkamlNo ratings yet

- 5069592Document2 pages5069592kamlNo ratings yet

- Electric Lift & Electric DriveDocument2 pagesElectric Lift & Electric DrivekamlNo ratings yet

- PatentStorm Document ResourceDocument12 pagesPatentStorm Document ResourcekamlNo ratings yet

- Provided by Patentstorm, HTTP://WWW - Patentstorm.UsDocument35 pagesProvided by Patentstorm, HTTP://WWW - Patentstorm.UskamlNo ratings yet

- Irsst Lift TruckDocument6 pagesIrsst Lift TruckEhab Yahia KhalelNo ratings yet

- 1.37662!CHRISGAS - D127 and D28 - Cost Estimate For A Biomass PlantDocument1 page1.37662!CHRISGAS - D127 and D28 - Cost Estimate For A Biomass PlantkamlNo ratings yet

- Schedule Dates Cbna Sheet 1 of 1Document7 pagesSchedule Dates Cbna Sheet 1 of 1kamlNo ratings yet

- Chemin CritiqueDocument1 pageChemin CritiquekamlNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Final Eligible Voters List North Zone 2017 118 1Document12 pagesFinal Eligible Voters List North Zone 2017 118 1Bilal AhmedNo ratings yet

- The Bedford Clanger May 2013 (The Beer Issue)Document12 pagesThe Bedford Clanger May 2013 (The Beer Issue)Erica RoffeNo ratings yet

- Product Bulletin VHP7104GSI S5Document2 pagesProduct Bulletin VHP7104GSI S5Wiliam SeguraNo ratings yet

- Keltbray Crude Oil and Gas LTDDocument2 pagesKeltbray Crude Oil and Gas LTDIana LeynoNo ratings yet

- 3G Ardzyka Raka R 1910631030065 Assignment 8Document3 pages3G Ardzyka Raka R 1910631030065 Assignment 8Raka RamadhanNo ratings yet

- Concreting PlantsDocument9 pagesConcreting PlantsSabrina MustafaNo ratings yet

- 71cryptocurrencies Have Become One of The Hottest Topics in The Financial WorldDocument2 pages71cryptocurrencies Have Become One of The Hottest Topics in The Financial WorldicantakeyouupNo ratings yet

- 0 Proposal Form Top Up SUBMITTED BY Markandeya Raju PDFDocument3 pages0 Proposal Form Top Up SUBMITTED BY Markandeya Raju PDFHOD (MVGR Civil)No ratings yet

- Bus 102 QuestionsDocument4 pagesBus 102 Questionsali2aliyuNo ratings yet

- Astm STP 855-Eb.1044238-1Document352 pagesAstm STP 855-Eb.1044238-1Jayanta Mondal100% (1)

- Frias Lindsay Iste Stds Self AssessmentDocument4 pagesFrias Lindsay Iste Stds Self Assessmentapi-572977540No ratings yet

- Innovative Uses of Housing Lifting Techniques-JIARMDocument16 pagesInnovative Uses of Housing Lifting Techniques-JIARMPOOJA VNo ratings yet

- Using the TreeView Control in Visual FoxProDocument5 pagesUsing the TreeView Control in Visual FoxProJulio RojasNo ratings yet

- Hofa Iq Limiter Manual enDocument8 pagesHofa Iq Limiter Manual enDrixNo ratings yet

- TeramisoDocument1 pageTeramisoNasriyah SolaimanNo ratings yet

- Focus ManualDocument597 pagesFocus ManualSabareesan SundarNo ratings yet

- Company Profile 2016 PDFDocument81 pagesCompany Profile 2016 PDFabioduncityNo ratings yet

- Institute of Actuaries of India declares CT1 exam resultsDocument18 pagesInstitute of Actuaries of India declares CT1 exam resultsRohit VenkatNo ratings yet

- Affidavit in Support of ComplaintDocument3 pagesAffidavit in Support of ComplaintTrevor DrewNo ratings yet

- Nca Lahore Nca Lahore Nca LahoreDocument1 pageNca Lahore Nca Lahore Nca LahoreSalman QaiserNo ratings yet

- ECS 1601 Learning Unit 7 Quiz: Key Concepts of the Circular Flow, Autonomous vs Induced Spending, Fiscal PolicyDocument4 pagesECS 1601 Learning Unit 7 Quiz: Key Concepts of the Circular Flow, Autonomous vs Induced Spending, Fiscal PolicyVinny HungweNo ratings yet

- We BradDocument528 pagesWe BradBudi SutomoNo ratings yet

- Gram-Charlier para Aproximar DensidadesDocument10 pagesGram-Charlier para Aproximar DensidadesAlejandro LopezNo ratings yet

- Household Services: Department of Education - Republic of The PhilippinesDocument21 pagesHousehold Services: Department of Education - Republic of The PhilippinesRina Vianney De Leon40% (5)

- List of Family Outing EpisodesDocument7 pagesList of Family Outing EpisodesFanny KesumaliaNo ratings yet

- Development Approach PlanDocument15 pagesDevelopment Approach PlanGaurav UpretiNo ratings yet

- StatProb11 Q4 Mod3 RegressionAnalysis v4Document21 pagesStatProb11 Q4 Mod3 RegressionAnalysis v4ALEX SARAOSOS100% (4)

- (Lecture 10 & 11) - Gearing & Capital StructureDocument18 pages(Lecture 10 & 11) - Gearing & Capital StructureAjay Kumar TakiarNo ratings yet

- United States v. James Lonzo Turner and Kevin Orlando Moore, 120 F.3d 271, 10th Cir. (1997)Document4 pagesUnited States v. James Lonzo Turner and Kevin Orlando Moore, 120 F.3d 271, 10th Cir. (1997)Scribd Government DocsNo ratings yet

- Breadtalk AR 2011Document158 pagesBreadtalk AR 2011Wong ZieNo ratings yet