Professional Documents

Culture Documents

WI14ME

Uploaded by

Vlad PopescuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WI14ME

Uploaded by

Vlad PopescuCopyright:

Available Formats

Data sheet WI 14ME

Water-to-water heat pump with stainless steel coil heat exchanger

Max. flow temperature: 55 C

Casing colour: White (similar to RAL 9003)

Brown-red design screen (RAL 3011)

Heat pump for heating purposes for indoor installation with integrated heat pump

manager. The control panel is integrated in a design screen and can also be used

as wired remote control using the wall mounting set (special accessories MS PGD).

Variable connection options for the ground water and heating connections on the

rear wall of the casing. Sound-optimised through insulated metal casing and double

vibration-isolated compressor. Economiser for high coefficients of performance

(COP). Integrated corrosion-proof and freeze-proof stainless steel coil evaporator.

Universal design with optional domestic hot water preparation and flexible

expansion possibilities for:

- Bivalent or bivalent-renewable operating mode

- Distribution systems with unmixed and mixed heating circuits

Integrated soft starter (from WI 14), integrated flow rate switch and load contactor

for a well water pump; flow sensor, return sensor, external sensor (standard NTC-2)

and dirt filter for ground water included in the scope of supply.

Technical data

Dimplex Water-to-water heat pump with stainless steel coil heat exchanger (Low temperature)

Order reference

WI 14ME

Heat pump code

Casing colour

Max. flow temperature

Lower operating limit heat source (heating operation) / Upper operating limit heat source (heating

operation)

Heat output W10/W35 / COP W10/W35

Heat output W10/W45 / COP W10/W45

Nominal power consumption according to EN 14511 at W10/W35

Sound power level

Refrigerant / Amount of refrigerant

Max. heating water flow rate / Pressure drop

Heat source flow (min.)

Dimensions (W x H x D)**

Weight

Rated voltage

Starting current

Fuse protection***

Connection heating

Heat source connection

3001

White (similar to RAL 9003)

55 C

7 to 25 C

13,50 kW / 4,70

13,40 kW / 3,80

2,87 kW

55 dB (A)

R407C / 1,9 kg

2,3 m/h / 22000 Pa

3,3 m/h

650 x 1445 x 575 mm

165 kg

1/N/PE ~230 V, 50 Hz

45 A

C 25 A

1 inch

1 inch

*Heat output and coefficient of performance (COP) according to EN 14511

**Please note that additional space is required for pipe connections, operation and maintenance.

***Die Absicherung ist als allpolige Trennvorrichtung auszufhren (gemeinsame Abschaltung aller Phasen)!

Glen Dimplex Deutschland GmbH

Dimplex Division

Am Goldenen Feld 18

95326 Kulmbach

Page 1/6

Subject to change and errors!

E-mail: dimplex@dimplex.de

Internet: www.dimplex.de

Internet: 18.12.2016

Phone: +49 (0)9221 709-201

Fax: +49 (0)9221 709-339

System accessories WI 14ME

Description

Article

Sample

number

item

WI 14ME

SYL 250

KOMP 32

SMF 32

353350

352260

362060

362140

1

1

PSP 100E

PSW 100

PSW 200

PSW 500

DDV 25

UPH 60-25

VTB 25

VTB 32

WWM 25

MMH 25

353360

351090

339830

339210

358390

367870

339870

367770

346600

348640

1

1

UPE 70-25PK

374700

UPE 100-25K

VSE 32-50

VSE 32-100

VSE 32-150

VSE 32-200

VSE 32-300

HDLR 450

HCT 300

374720

362520

362530

362540

362550

362560

337450

351210

SRX 080EM

SRX 120EM

SRX 140EM

SRX 180EM

367500

367510

367520

367530

WWSP 332

WWSP 442

WWSP 556

WWSP 432

SOL

PWS 332

CTHK 630

CTHK 631

FLH 25M

SVK 852

PWS 650

346610

372840

370080

PWD 750

349100

WPG 25

356030

UPH 60-25

DWV 32

367870

374780

NWPM

EWPM

LWPM 410

356960

356970

339410

RWPM

363370

AP PGD

FG 3115

NTC-10M

KRRV 003

356570

336620

363600

322070

DWV 32

374780

Order ref.

Item

Price

Heat pumps

Water-to-water heat pump with stainless steel coil heat exchanger

Elasticated sound insulation underlay strips

DN 32 double-sphere rubber expansion joint

DN 32 dirt trap

Hydraulic accessories

Built-under buffer tank*

Free-standing buffer tank 100 l*

Free-standing buffer tank 200 l*

Universal buffer tank (500 l)*

Dual differential pressureless manifold

Electronically controlled circulating pump with coupling relay

Manifold bar

Manifold bar (3-fold) for modules DN 25 and DN 32

Domestic hot water module/unmixed heating circuit module

Mixed heating circuit module with temperature sensor

Electronically controlled wet-running pump, p-v, fixed speed and

PWM signal

Electronically controlled wet-running pump, self-regulating

Ready-for-use DN 32 stainless steel Wellflex pipe

Ready-for-use DN 32 stainless steel Wellflex pipe

Ready-for-use DN 32 stainless steel Wellflex pipe

Ready-for-use DN 32 stainless steel Wellflex pipe

Ready-for-use DN 32 stainless steel Wellflex pipe

Immersion heater pipe assembly*

3 kW pipe heater

Heating accessories

Fan convector heating with EC fan

Fan convector heating with EC fan

Fan convector heating with EC fan

Fan convector heating with EC fan

DHW preparation accessories

Domestic hot water cylinder (300l) with temperature sensor*

Domestic hot water cylinder (400 l) with temperature sensor*

Domestic hot water cylinder (500l) with temperature sensor*

400l solar cylinder for heat pump*

Combination tank heating and domestic hot water preparation

Immersion heater 4.5 kW; ~230 V

Immersion heater 2.0 kW; ~230 V

FLH 25M flange heater

Safety valve combination

PWS 650 combination tank*

Combo tank for heating and domestic hot water preparation with

central flow*

Pump unit DN 25 for direct connection of the domestic hot water

cylinder

Electronically controlled circulating pump with coupling relay

3-way reversing valve DN 32*

361080

348620

363610

336180

349430

326660

367660

Control accessories

Extension for an Ethernet network connection

Expansion module WPM for a KNX/EIB connection

Extension for a Modbus RTU connection

Interface card for HPM for connection of Smart RTC and WPM Econ

PK/PKS 14/25 Econ

Remote control for WPM 2006/2007/EconPlus/R*

Outside temperature sensor with casing

Temperature sensor NTC-10 with metal sleeve

Thermostat for heating and domestic hot water

Accessories for passive cooling

3-way reversing valve DN 32*

Glen Dimplex Deutschland GmbH

Dimplex Division

Am Goldenen Feld 18

95326 Kulmbach

Page 2/6

Subject to change and errors!

E-mail: dimplex@dimplex.de

Internet: www.dimplex.de

Internet: 18.12.2016

Phone: +49 (0)9221 709-201

Fax: +49 (0)9221 709-339

System accessories WI 14ME

Description

Order ref.

Plate heat exchanger, copper-soldered

Article

Sample

number

item

WTU 50

362370

WPM Econ PK

RKS WPM

TPW WPM

RTK 601U

RTK 602U

360000

342220

350970

355610

355620

SST 25

348430

Item

Price

Control accessories (cooling)

Passive cooling controller

Room climate station for temperature and humidity measurement*

Dew point monitor*

Room temperature controller heating/cooling*

Room temperature controller heating/cooling

Solar thermal systems accessories

Heat exchanger station SST 25 for solar energy systems up to max.

10 m

* Other specific accessories available / required

Important information:

The combination of the components and the quantities indicated represent a non-binding sample system, which needs to be tested and individually

adapted as required. Pump dimensioning must be reviewed according to the pressure loss of the system and the minimum heating water flow rate of

the heat pump.

Glen Dimplex Deutschland GmbH

Dimplex Division

Am Goldenen Feld 18

95326 Kulmbach

Page 3/6

Subject to change and errors!

E-mail: dimplex@dimplex.de

Internet: www.dimplex.de

Internet: 18.12.2016

Phone: +49 (0)9221 709-201

Fax: +49 (0)9221 709-339

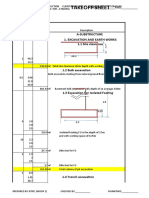

Water-to-water heat pump, Integration Diagram, Heat pump only

Note:

The given hydraulic integration

schematic is a schematic

representation of the key components

and serves as an aid for planning your

customized system. The current status

is available at all times under

www.dimplex.de/nc/en/professional/onli

ne-planner/hydraulic-integrations.html.

It does not contain all the required

safety devices, the components needed

to maintain constant pressure, or any

other additional valves which may be

required for maintenance and service

work as stipulated by EN 12828.

The heat pump manager settings and

any external regulation system which

may be connected must be adapted to

the present integration diagram.

Software updates may be required!

Glen Dimplex Deutschland GmbH

Dimplex Division

Am Goldenen Feld 18

95326 Kulmbach

Page 4/6

Subject to change and errors!

E-mail: dimplex@dimplex.de

Internet: www.dimplex.de

Internet: 18.12.2016

Integration Diagram: 30131020

Phone: +49 (0)9221 709-201

Fax: +49 (0)9221 709-339

Water-to-water heat pump, Integration Diagram, Heat pump only

System description:

Presettings:

In the case of a ground water heat source, it must be ensured that the required cold water flow is permanently available with a minimum

temperature of 7C. The required water quality must be maintained additionally. Water quality Approval of local water authorities for use of

ground water must be obtained!

Operating mode

Monovalent

Heating circuit 1

Yes

Heating circuit 2

No

A buffer tank connected in series is recommended for heat pump heating systems, to ensure the minimum heat pump runtime of 6 minutes for all

operating statuses.

Pre-configuration

Setting

Passive cooling function

No

In monovalent systems, the output of the heat pump covers the heat consumption of the building throughout the whole year - 100% - by itself.

High heat output during shut-off times and domestic hot water preparation is supplied by the heat pump. Normally, only brine-to-water and

water-to-water heat pumps are operated in monovalent mode.

DHW preparation

Yes

The heat exchanger in the hot water cylinder must transfer the maximum heat output at the maximum heat source temperature. In systems with

high hot water consumption (multiple dwellings, industrial applications) the cylinder must be set to the maximum peak demand while taking the

shut-off times into account. The maximum heat output and the maximum heating water flow must be adhered to!

heater

DHW preparation request by

Domestic hot water preparation flange

Swimming pool water preparation

Low-pressure brine

Sensor

Yes

No

Display

The contactor for the flange heater (E9) in the hot water cylinder should be dimensioned according to the output and must be supplied by the

customer. It is controlled (230 V AC) by the heat pump manager via terminals X1/N and J16/NO10. The maximum heat output of the heat pump

and the water flow are to be observed.

The dual differential pressureless manifold ensures that the required minimum water flow rate is maintained, independent of both the number of open heating circuits and of how the system is used. Hydraulic isolation is carried out using

two connections between flow and return; each connection is fitted with a check valve. The characteristic curve of the pump in the consumer circuit must be set in such a way that a maximum spread of 10 Kelvin is not exceeded, in order

to prevent unnecessary surging of the heat pump. Electronically regulated pumps must be operated at a constant pressure.

Glen Dimplex Deutschland GmbH

Dimplex Division

Am Goldenen Feld 18

95326 Kulmbach

Page 5/6

Subject to change and errors!

E-mail: dimplex@dimplex.de

Internet: www.dimplex.de

Internet: 18.12.2016

Integration Diagram: 30131020

Phone: +49 (0)9221 709-201

Fax: +49 (0)9221 709-339

Water-to-water heat pump, Integration Diagram, Heat pump only

Legend:

1.

1.1

1.2

1.3

1.4

1.5

1.6

1.7

2.

3.

3.1

4.

5.

6.

7.

8.

9.

10.

13.

15.

16.

17.

Heat Pump

Air-to-water heat pump

Brine-to-water heat pump

Water-to-water heat pump

Reversible air-to-water heat pump

Reversible brine-to-water heat pump

Reversible water-to-water heat pump

Air-to-water heat pump split design

Heat pump manager

Parallel buffer tank

Buffer tank

Hot water cylinder

Swimming pool heat exchanger

Passive cooling station with cooling controller N6

Heating and silent or dynamic cooling

Fan convector with 4-wire connection

Cooling circuit only

Heating circuit only

Heat source

Hydraulic tower

Scalding protection

Hydro tower HWK 332

Domestic hot water distribution system:

DDV 25

DDV 32

EB KPV

KPV 25

MMB 25

MMH 25

VTB 25

WWM 25

Dual differential pressureless manifold (up to 2.0 m/h)*

Dual differential pressureless manifold (up to 2.5 m/h)*

Extension module for compact manifold (up to 2.0 m/h)*

Compact manifold with overflow valve (up to 1.3 m/h)*

In combination with EB KPV (up to 2.0 m/h)*

Mixer module, bivalent (up to 2.0 m/h)*

Mixer module for heating circuit

Manifold bar (up to 2.5 m/h)*

Hot water module / unmixed heating circuit (up to 2.5 m/h)*

* Recommended max. heating waterflow

Solarthermics:

SST 25

SOLPU 1

SOLCU 1

T1

T2

T3

Solar station for hot water

Solar station

Solar controller

Temperature sensor (collector sensor)

Temperature sensor (cylinder 1)

Temperature sensor (cylinder 2 /optional display function)

Glen Dimplex Deutschland GmbH

Dimplex Division

Am Goldenen Feld 18

95326 Kulmbach

B3

B4

B7

E9

E10

E10.1

E10.2

E10.3

E10.5

F7

F10

K20

K21

M11

M12

M13

M14

M15

M16

M17

M18

M19

M20

M21

M22

M25

N1

N2

N3

N12

N17.1

N17.2

N17.3

N17.4

R1

R2

R3

R4

R5

R9

R11

R13

SMF

TC

Y5

Y6

Y7

Y8

Y12

Y13

Page 6/6

Subject to change and errors!

E-mail: dimplex@dimplex.de

Internet: www.dimplex.de

Hot water thermostat

Swimming pool thermostat

Thermostat primary circuit

Flange heater, hot water

2nd heat generator (HG2)

Immersion heater

Oil/gas boiler

Solid fuel boiler

Solar energy system

Safety temperature monitor

Flow rate switch

Contactor for 2nd heat generator

Contactor for immersion heater hot water

Primary pump for heating operation

Primary pump for cooling operation

Heat circulating pump for main circuit

Heat circulating pump for heating circuit 1

Heat circulating pump for heating circuit 2

Auxiliary circulating pump

Cooling circulating pump

Hot water circulating pump

Swimming pool water circulating pump

Heat circulating pump heating /cooling circuit 3 still

Mixer

Mixer heating/cooling circuit 2

Circulating pump for heating and domestic hot water preparation

Heating controller

Cooling controller for reversible heat pumps

Room climate control stations

Solar controller

Cooling module general

Cooling module active

Cooling module passive

Solar module WPM Econ SOL

External wall sensor

Return flow sensor

Hot water sensor

Return flow sensor for cooling water

Temperature sensor for heating circuit 2

Flow sensor (antifreeze)

Flow sensor for cooling water

Sensor for heating circuit 3 / bivalent-renewable

Dirt trap

Room temperature controller

Three-way distribution valve

Two-way valve

Three-way mixing valve

Three-way valve (closing time max. 10 sec.)

External 4-way reversing valve

Three-way reversing valve

Internet: 18.12.2016

Integration Diagram: 30131020

Phone: +49 (0)9221 709-201

Fax: +49 (0)9221 709-339

You might also like

- Sesiune Iarna PDFDocument9 pagesSesiune Iarna PDFVlad PopescuNo ratings yet

- A Manual of GOTHIC MOLDINGSDocument214 pagesA Manual of GOTHIC MOLDINGSAndreea BirceaNo ratings yet

- Harta Predare Analiza2-ModelDocument1 pageHarta Predare Analiza2-ModelVlad PopescuNo ratings yet

- Analia SelisDocument2 pagesAnalia SelisVlad PopescuNo ratings yet

- MelodiiDocument1 pageMelodiiVlad PopescuNo ratings yet

- Foundations of Quantum PhysicsDocument11 pagesFoundations of Quantum PhysicsAlexandru DamocNo ratings yet

- Higher Algebra - Hall & KnightDocument593 pagesHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Metal Sleeves Vs Composites Wrapping in Piping RepairDocument7 pagesMetal Sleeves Vs Composites Wrapping in Piping RepairEmad A.Ahmad100% (1)

- Rules 7 & 8 NBC PDFDocument95 pagesRules 7 & 8 NBC PDFdrahcir100% (2)

- Architectural PhilosophyDocument5 pagesArchitectural PhilosophyCHichi OñidNo ratings yet

- Takeoff Sheet: 1. Excavation and Earth Works A-SubstructureDocument48 pagesTakeoff Sheet: 1. Excavation and Earth Works A-Substructuremamuka kassa100% (1)

- Curtain Wall Brochure MX VaDocument28 pagesCurtain Wall Brochure MX VaMk GonzalesNo ratings yet

- Chemrite PEJ FillerDocument2 pagesChemrite PEJ FillerICPL-RWPNo ratings yet

- Republic Act No 6541Document2 pagesRepublic Act No 6541Philip JohnNo ratings yet

- Army English Vocabulary and ExercisesDocument22 pagesArmy English Vocabulary and ExercisesLee ConeaNo ratings yet

- BCM Glass CasestudyDocument1 pageBCM Glass Casestudy1RW18AT020 TarunReddyNo ratings yet

- Caravan Frame Materials - Timber, Aluminum or CompositeDocument12 pagesCaravan Frame Materials - Timber, Aluminum or CompositeAnonymous 3idACuNo ratings yet

- Fire and Smoke Damper BasicsDocument10 pagesFire and Smoke Damper BasicsRolandNo ratings yet

- Electrical Design SystemDocument79 pagesElectrical Design SystemShaffiq Ridzuan88% (8)

- Vol 1 - Part D Section 4-FinalDocument10 pagesVol 1 - Part D Section 4-FinalAnonymous UUw70xirblNo ratings yet

- Floor Underlayment (Allied Custom Gypsum) PDFDocument12 pagesFloor Underlayment (Allied Custom Gypsum) PDFDonald EssenNo ratings yet

- Sample Construction and Material SpecificationsDocument10 pagesSample Construction and Material Specificationsrasputin0780803494No ratings yet

- Product Portfolio Systems and Solutions GuideDocument44 pagesProduct Portfolio Systems and Solutions GuideChris MedeirosNo ratings yet

- Sustainable building foundations guideDocument4 pagesSustainable building foundations guidek1l2d3No ratings yet

- ASHRAE Results-Summary-Spreadsheet-2018Document29 pagesASHRAE Results-Summary-Spreadsheet-2018mech_sahilNo ratings yet

- Final Construction Materials Price ListDocument40 pagesFinal Construction Materials Price ListEllerie MangayaNo ratings yet

- Inner Unit EstimateDocument35 pagesInner Unit EstimateMir MoNo ratings yet

- Commercial Building Estimate SheetDocument205 pagesCommercial Building Estimate SheetA.k. MishraNo ratings yet

- Hydra Form Building SystemsDocument22 pagesHydra Form Building SystemsVijesh KumarNo ratings yet

- 1562-2 Design and Installation of Sheet Roof and Wall CladdingDocument25 pages1562-2 Design and Installation of Sheet Roof and Wall CladdingVasko DrogriskiNo ratings yet

- HAREDA PAnchkulaDocument2 pagesHAREDA PAnchkulaAmit K. YadavNo ratings yet

- RaftDocument48 pagesRaftHariom KhungarNo ratings yet

- Government Engineering College Seminar on Types of PavementsDocument17 pagesGovernment Engineering College Seminar on Types of PavementsVinod BariaNo ratings yet

- cp1 2011Document1 pagecp1 2011rameshkaaNo ratings yet

- Draft BS en 16798 1 Energy Performance of BuildingsDocument67 pagesDraft BS en 16798 1 Energy Performance of BuildingsWilfrid DutruelNo ratings yet

- Bridge& Culvert Condition Survey Format - Hbroad32!55!1Document1 pageBridge& Culvert Condition Survey Format - Hbroad32!55!1vishnuNo ratings yet