Professional Documents

Culture Documents

SHelflife of Glycol Ether

Uploaded by

engrsurifCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SHelflife of Glycol Ether

Uploaded by

engrsurifCopyright:

Available Formats

Glycol Ethers Storage and Handling

Either vertical or horizontal storage tanks may

be used. A vertical tank is more economical to

install and occupies less space. However, if

future compartmentation of the storage tank is

likely, a horizontal tank is easier to modify than

a vertical tank. Above-ground storage is always

recommended for ease of installation, maintenance, gauging, and piping arrangement.

Storage tanks for DOWANOL products should

meet the requirements of local, state, and federal regulations and guidelines for chemical

storage. Flash points of DOWANOL products

range from 90F for DOWANOL PM to 259F

for TBB. For instance, DOWANOL PM is

classified as a flammable liquid according to

the Department of Transportation (DOT) regulations, CFR 49. Other DOWANOL products

may be classified as flammable or combustible

liquids or are not regulated by the DOT. It is

important to keep in mind, however, that while

some glycol ethers are not regulated by the

DOT, all glycol ethers have flammability limits

which should be taken into consideration when

a flammability hazard is being assessed. (Note:

All local fire codes should be consulted when

installing storage facilities for DOWANOL

products. Also, to avoid the possibility of

induced static electricity, which can cause accidental ignition, all tanks, pumps, and transfer

lines used for DOWANOL glycol ether products should be fully grounded. Finally, fire hazards can be lessened by maintaining diking and

by removing all vegetation around storage

tanks.)

Refer to the material Safety Data Sheets and

Transportation Equipment data/Emergency

response sheet for each DOWANOL* glycol

ether and acetate for the most recent storage

and handling information for the product.

Storage of Glycol Ethers

The storage of glycol ethers presents no unusual

problems. They are very stable organic liquids

that have relatively low freezing points. Heated

storage is not normally required. The exception

is DOWANOL EPh and PPh, which freeze

below 55 F (13C).

Most glycol ethers do not present a significant

flammability hazard at normal storage temperature. They have relatively low vapor pressures.

The most volatile glycol ether products are

DOWANOL PM, PnP, and PMA which have

flash points of 88F, 118F, and 108F

respectively.

Storage Tanks: Material and Construction

The storage tanks used for DOWANOL glycol

ethers and acetates and blends of DOWANOL

products should be constructed of mild steel,

carbon steel, or stainless steel. Storage vessels

and piping constructed of aluminum and aluminum alloys should be avoided for

DOWANOL EB and DM glycol ethers. Plastic

tank linings are not recommended, because

these materials are often affected by

DOWANOL products.

PDF#110-00673

*Trademark of The Dow Chemical Company

Figure 1: Horizontal Storage Tank for

DOWANOL Products

changes in tank pressure, thereby reducing

moisture pickup from the outside air. The

overpressure relief and the breather should be

mounted on a flame arrestor. PVRV that contain moisture absorbent drying beds are also

available in long term storage. Moisture

pickup by glycol ethers and acetates can be

further reduced by nitrogen blanketing or

padding of the storage tanks. Nitrogen blanketing is recommended for quality and safety

reasons.

DRUM RECOMMENDATIONS

DOWANOL glycol ether products may be

stored in 55-gallon drums made of mild steel.

It is important to remember to replace the

drum cap securely after each withdrawal, or

the product will gradually pick up moisture

from the air.

To avoid the possibility of induced static

electricity, ground all tanks, pumps, and

transfer lines used for DOWANOL products,

and install a dip line as the product inlet line.

Float-type gauges with tape indicators or

differential pressure cells work well as level

indicators for glycol ethers and acetates.

Avoid drums constructed of galvanized metals

that may bring glycol ethers, especially

DOWANOL EB or DM, in contact with zinc

or tin since metal corrosion and discoloration

can result. Zinc is very reactive in contact

with some glycol ethers; hydrogen may be

produced. Copper and copper alloys, such as

bronze and brass, will cause discoloration via

decomposition with all glycol ether products.

Pressure vacuum relief valves (PVRV) are

recommended for storage tanks containing

glycol ethers and acetates because they are

hygroscopic. Breathers allow for slight

Figure 2: Determining the Amount of Contents of Partially Filled Drums

Vertical

32

28

8

4

0

0

10

20

30

40

6

4

2

0

10

5

0

Depth (Inches)

12

24

Depth (Inches)

16

Depth (Inches)

Depth (Inches)

20

Horizonal

22

55

20

50

18

16

40

14

30

12

10

20

8

Remaining Gallons

Horizonal

20

16

12

8

4

0

0

50

10

20

30

40

Remaining Gallons

Remaining Gallons

50

32

30

28

26

24

22

20

18

16

14

12

10

8

6

4

2

0

55

50

45

40

35

30

25

20

15

10

5

0

Remaining Gallons

Vertical

for pipe dope on screwed piping, but they

work best when all cutting oil has been

removed from the threads. Ball valves with

plastic seals and seats of Teflon1 resin are

strongly recommended. Butyl rubber or

EPDM can be used for gaskets and packing.

Polyethylene and polypropylene storage

drums may be used if water contamination of

the glycol ether or acetate is not critical.

Drums made of these materials can provide

adequate shelf life for the product, but they

will absorb water through the drum walls.

Polyethylene storage drums should be product-dedicated, because glycol ethers and

acetates may be retained in the walls of the

drums over time. Figure 2 can be used to

determine the contents of partially filled

drums without removing the drum caps.

Cleaning and Maintenance

Sound maintenance procedures are vital to

proper storage and handling of DOWANOL

products. Maintaining diking around all

DOWANOL product storage tanks and

removing all vegetation from the area diminishes fire hazards. The maintenance and

prompt repair of the storage tanks and transfer

equipment piping and valves is critical for

safeguarding the quality of DOWANOL

products.

Auxiliaries

Pumps, lines, valves, and fittings of steel are

adequate for use with DOWANOL products.

If rated at the appropriate pressure, polyethylene and polypropylene pipes are adequate;

however, DOWANOL products should not be

allowed to stand in these pipes. PVC or fiberglass reinforced pipes are not recommended.

Avoid equipment constructed of aluminum

or aluminum alloys, galvanized metals, and

copper or copper alloys. Bronze and brass

fittings are acceptable for temporary or

minimum contact situations.

Storage tanks should be thoroughly cleaned

and dried before use. They should be

equipped with 18-inch manholes and a bottom drain. Good results can be obtained by

buffing and steaming the tank, then washing

with water and thoroughly air drying. Avoid

brushing or otherwise mechanically disturbing the surface of the tank after the tank has

been dried.

Centrifugal pumps work well for storage

systems, with packed pumps used for

intermittent service and mechanical seals

for continuous service.

To minimize the formation of rust, fill the

tank as soon as possible after cleaning. If the

cleaning is thorough, there will be less chance

for discoloration, even upon extended storage.

All equipment must be free of moisture

before operation. The chances of product

deterioration and/or discoloration are minimized when the equipment, including pumps,

lines, valves, fittings, and storage vessels,

cleaned thoroughly prior to use.

To minimize air contact and possible moisture pickup after cleaning, the tank may be

purged with dry nitrogen prior to filling. The

dry nitrogen is then displaced as the tank is

filled, and a pad remains on top to help extend

product quality.

Glycol ethers and acetates are difficult to

contain, due to low viscosities, and prone to

leak past defective fittings or packing.

Consequently, the installation of all fittings

and gaskets should be done carefully.

Aqueous graphite suspensions are preferred

Strict maintenance schedules for cleaning,

service, and replacement of auxiliary equipment used for DOWANOL products should

1

Trademark of E.I. Dupont de Nemours, Inc.

The greatest potential hazards in working

with glycol ethers and acetates are skin and

eye contact and vapor inhalation. Written

procedures are highly recommended, detailing how workers should wear the appropriate

protective equipment for their tasks and the

hazard potential involved.

be developed. Particular attention should be

paid to packings, gaskets, and other components of transfer equipment which may be

affected by glycol ether and acetate products.

Product Shelf Life

The quality of DOWANOL products can be

affected by storage conditions, temperature,

and time. Product deterioration can take the

form of lowered pH values and/or color

changes.

The Dow Chemical Company can provide

information and assistance to help you

develop or improve your own DOWANOL

glycol ether and acetate safe handling program. Our staff of specialists can help you

stay current on a wide variety of stewardship

issues, such as worker safety, waste handling

and disposal, environmental impact matters,

and regulatory compliance. Consult the current Material Safety Data Sheets for more

detailed information on the safe handling of

DOWANOL products.

To safeguard DOWANOL products against

this product deterioration, develop product

inventory and use policies that put your

DOWANOL inventory into production prior

to the recommended shelf life limits noted on

Table 1.

Safe Handling

Develop, implement, and strictly enforce safe

handling procedures and practices for workers

in all operations involving DOWANOL products. The viability of your storage and handling program for these products relies on

close attention to worker safety issues.

The disposal of DOWANOL glycol ethers

must be carried out in strict accordance with

all local, state, and federal laws and regulations governing the disposal of hazardous

chemicals. For information, advice, and/or

assistance on the disposal of DOWANOL

glycol ethers, contact a local Dow representative or sales office, or write The Dow

Chemical Company, Specialty Chemicals

Department.

Customers are urged to develop, implement,

strictly enforce, monitor, and periodically

review and evaluate safe handling procedures

and practices in all handling and storage

operations involving DOWANOL glycol

ether products.

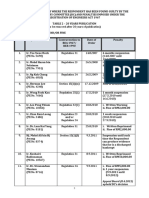

Table 1: Product Shelf Life

Lot Number

System

Conditions of Temperature

and Storage

DOWANOL PM, DPM, TPM,

PnB, DPnB, TPnB, PnP,

DPnP, TPnP, EB, DB, DM

glycol ether products

18 months Drums

6 months Bulk

Standard

Normal conditions Store below 90F.

Material is hygroscopic; should be in

closed containers.

Aluminum containers should be avoided.

Lowering of pH possible rise

in color on prolonged standing.

DOWANOL PPh, EPh

glycol ether products

18 months Drums

6 months Bulk

Standard

Store below 110F.

Aluminum containers should be avoided.

Develops yellow color.

Product/Shelf Life

Deterioration

Characteristics

Product Stewardship

Suggested Precautions

The Dow Chemical Company has a fundamental concern for all who make, distribute,

and use its product, and for the environment

in which we live. This concern is the basis for

our Product Stewardship philosophy by which

we assess the health and environmental information on our products and then take appropriate steps to protect employee and public

health and the environment. Our Product

Stewardship program rests with each and

every individual involved with Dow products

from the initial concept and research to the

manufacture, sale, distribution, use, and disposal of each product.

The following precautionary measures are

suggested for operations where contact with

DOWANOL PnB or DOWANOL DPnB

glycol ethers is likely:

Wear suitable eye protection, such as

chemical workers goggles (especially when

working with DOWANOL PnB) or safety

glasses with side shields.

Practice reasonable care, good housekeeping, and personal cleanliness to avoid

skin exposure.

Avoid prolonged or repeated breathing

of vapors of DOWANOL glycol ethers,

especially if the material is hot. Also, be

sure that adequate ventilation is provided

for workers handling or using glycol ethers

and acetates. Customers are urged to consult

the most recent Material Safety Data Sheets

for the current exposure guidelines.

Customer Notice

Dow encourages its customers and potential

users of Dow products to review their applications of such products from the standpoint

of human health and environmental quality.

To help ensure that Dow products are not

used in ways for which they are not intended

or tested, Dow personnel will assist customers

in dealing with ecological and product safety

considerations. A Dow salesperson can

arrange the proper contacts. Dow product literature, including Material Safety Data

Sheets, should be consulted prior to use of

Dow products. These may be obtained from a

Dow sales representative or sales office.

In the event of upper respiratory irritation,

use an air purifying organic vapor respirator.

First Aid Measures

Consult the current Material Safety Data

Sheet (MSDS) for the DOWANOL glycol

ether product in question for recommendations on procedures for emergency first aid.

*Trademark of The Dow Chemical Company

Glycol Ethers for Shipping Points

PLAQUEMINE

POWELL-DUFFERYN

BAYONNE

JOLIET

CHANNOHON

EDISON

LINDEN

BEDFORD PARK

LAKE RIVER

B B

P

B

P

B B B

B B

B B

B B

B B

B B

B B

P P

P P

P P

B B

B

B B

P P P P P

P P

P P P P

B

P

PROGLYDE* DMM

B

P

TPnB

B B B B

P P P

P

PnB

DPnB

PMA Elec Gr

EB Elec Gr

B B

P P

B B

B

P P

DPMA

DB Elec Gr

PMA

TPM

PM Elec Gr

PM

DPM

DM Mil Spec

PPh Low Ph

PPh

EPh Low Ph

EPh

EB

B B B

P P P

B

P

B

P

FREEPORT

LONGBEACH

DM

B

P

DPnP

B

P

PnP

MIDLAND

DB

DALPAD* A

Shipping Points for

DOWANOL* Glycol Ethers

B B

P P P P P

*MAKE TO ORDER ONLY

B=BULK

P=PACKAGE

*Trademark of The Dow Chemical Company

You might also like

- Bearing Failure AnalysisDocument26 pagesBearing Failure AnalysisengrsurifNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Palm Oil MillDocument52 pagesPalm Oil MillengrsurifNo ratings yet

- Process Lines For Crude Palm Oil Production - tcm11 55437 PDFDocument24 pagesProcess Lines For Crude Palm Oil Production - tcm11 55437 PDFLim Zamora Gemota100% (1)

- Safety Design ConsiderationsDocument60 pagesSafety Design ConsiderationsVikrampriya MithraNo ratings yet

- Plain Bearings Failure Mode and RectificationDocument13 pagesPlain Bearings Failure Mode and RectificationengrsurifNo ratings yet

- ASTM D1160-06 - Vaccumm DistillationDocument18 pagesASTM D1160-06 - Vaccumm DistillationKamruzaman MiahNo ratings yet

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Transformer Is Gassing-What To DoDocument24 pagesTransformer Is Gassing-What To DoengrsurifNo ratings yet

- D5800 NOACK VolatilityDocument18 pagesD5800 NOACK VolatilityengrsurifNo ratings yet

- 10 Tips Refrigerant PipingDocument3 pages10 Tips Refrigerant PipingAndres CarrascoNo ratings yet

- Eastern Assurance Vs Secretary of LaborDocument2 pagesEastern Assurance Vs Secretary of LaborGui EshNo ratings yet

- TDS Ucarsol AP 814Document8 pagesTDS Ucarsol AP 814Elton SitumeangNo ratings yet

- Petroleum Refinery HSE ManualDocument11 pagesPetroleum Refinery HSE ManualFarrukh TouheedNo ratings yet

- TIL 1897 Controller Connectivity and Stalled Io Live ValuesStandard - TIL 1897Document13 pagesTIL 1897 Controller Connectivity and Stalled Io Live ValuesStandard - TIL 1897bali abdelazizNo ratings yet

- ASTM-D-6439 Flushing Turbine OilsDocument16 pagesASTM-D-6439 Flushing Turbine OilsNavneet PandeyNo ratings yet

- Petcoke Guide: Green, Calcined, Properties & HandlingDocument14 pagesPetcoke Guide: Green, Calcined, Properties & HandlingYevgeniy R100% (2)

- TRX Oil Test PropertiesDocument48 pagesTRX Oil Test PropertiesbibhooNo ratings yet

- 800 Fire and Safety DesignDocument31 pages800 Fire and Safety Designjhon smith100% (1)

- Foam Floating Roof Tank SystemsDocument2 pagesFoam Floating Roof Tank SystemsNeera JainNo ratings yet

- EDL Presentation Lube Oil Blending 04 13 EngDocument27 pagesEDL Presentation Lube Oil Blending 04 13 EngMark Temitope BrownNo ratings yet

- Lube Oil Blending PlantDocument2 pagesLube Oil Blending PlantengrsurifNo ratings yet

- KOROSIDocument35 pagesKOROSISaiful BahriNo ratings yet

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- Global Water Storage Tanks BrochureDocument44 pagesGlobal Water Storage Tanks Brochureعبد السميع بن أحمد100% (1)

- Industrial Insulation ManualDocument191 pagesIndustrial Insulation ManualHaris PrawotoNo ratings yet

- Boiler Preservation NalcoDocument4 pagesBoiler Preservation NalcoSushil Kumar71% (7)

- Court of Appeals Upholds Dismissal of Forcible Entry CaseDocument6 pagesCourt of Appeals Upholds Dismissal of Forcible Entry CaseJoseph Dimalanta DajayNo ratings yet

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Storage and Handling of NEODOL AlcoholsDocument7 pagesStorage and Handling of NEODOL AlcoholsGonzalo Zoé VázquezNo ratings yet

- Glycol Ethers Storage and Handling GuideDocument5 pagesGlycol Ethers Storage and Handling Guideabdur rafayNo ratings yet

- Storage and Handling Neodol EthoxylatesDocument8 pagesStorage and Handling Neodol EthoxylatesSanjaykaNo ratings yet

- Storage and Handling PDFDocument3 pagesStorage and Handling PDFRadhakrishna MadabhushiNo ratings yet

- Divinylbenzene Storage, Handling and SafetyDocument19 pagesDivinylbenzene Storage, Handling and SafetyMehul DeshpandeNo ratings yet

- DOW™ Tin-Plating Process Products PDFDocument9 pagesDOW™ Tin-Plating Process Products PDFmarkNo ratings yet

- Refrigerants: Desirable Properties of A RefrigerantDocument2 pagesRefrigerants: Desirable Properties of A RefrigerantCamillus GulimNo ratings yet

- 6164-8 Foam StorageDocument3 pages6164-8 Foam Storagekhalidwy6342No ratings yet

- Dowf Rost: Engineering and Operating GuideDocument43 pagesDowf Rost: Engineering and Operating GuideninzauNo ratings yet

- Forbe Tanksvessels MLDocument5 pagesForbe Tanksvessels MLPrashant FayeNo ratings yet

- Desirable Properties of A Refrigerant: RefrigerantsDocument12 pagesDesirable Properties of A Refrigerant: RefrigerantsPraveen AbisakeNo ratings yet

- Butonal NX1129Document4 pagesButonal NX1129Liz AfanadorNo ratings yet

- Balmor Al Tank S: Global Water Storage SolutionsDocument36 pagesBalmor Al Tank S: Global Water Storage SolutionsIqbal AdamNo ratings yet

- Tank Linings Resistance GuideDocument7 pagesTank Linings Resistance Guideenrico100% (1)

- Delo Extended Life Coolant Antifreeze 5050Document5 pagesDelo Extended Life Coolant Antifreeze 5050Ravi SekhonNo ratings yet

- Aerosol Formulation Considerations: - Robert D. GeerDocument53 pagesAerosol Formulation Considerations: - Robert D. GeerVenu Gopal NNo ratings yet

- Tekor 1Document4 pagesTekor 1Iqbaal AbdurrokhmanNo ratings yet

- C02 Systems: Carbon Dioxide Storage Units (Urethane or Vacuum Insulated) Harry R. WatersDocument4 pagesC02 Systems: Carbon Dioxide Storage Units (Urethane or Vacuum Insulated) Harry R. Waterscryovikas1975No ratings yet

- GW SprinklersDocument18 pagesGW SprinklersmajdirossrossNo ratings yet

- Technical DataDocument29 pagesTechnical DataGregory StewartNo ratings yet

- Glutaraldehyde Bulk HandlingDocument4 pagesGlutaraldehyde Bulk HandlingnubblerNo ratings yet

- Alkali Boil Out Procedure by Natural Circulation MethodDocument31 pagesAlkali Boil Out Procedure by Natural Circulation MethodManoj PaneriNo ratings yet

- Product Handling Guide-FormaldehydeDocument4 pagesProduct Handling Guide-FormaldehydeBigbearBigbearNo ratings yet

- Rtaa SB 20Document5 pagesRtaa SB 20kulilin1100% (1)

- Installation, Operating and Servicing Instructions for ACV Hot Water TanksDocument10 pagesInstallation, Operating and Servicing Instructions for ACV Hot Water TanksmohamedkhalifehNo ratings yet

- Hvac Systems: Corrosion Protection SolutionsDocument10 pagesHvac Systems: Corrosion Protection SolutionsDejan LazarevicNo ratings yet

- New Seals With RGDDocument3 pagesNew Seals With RGDDichtomatik UKNo ratings yet

- Corrosion: ProblemsDocument3 pagesCorrosion: Problemshnk_soNo ratings yet

- PagesDocument139 pagesPagesednoguera87No ratings yet

- Safetygram-24 Hydrogen ChlorideDocument6 pagesSafetygram-24 Hydrogen ChlorideJorge Enriquez MejíaNo ratings yet

- Caustic SodaStore and HandlingDocument2 pagesCaustic SodaStore and HandlingargachoNo ratings yet

- Carte Tehnica Boilere CordivariDocument2 pagesCarte Tehnica Boilere CordivariStan Marius VictorNo ratings yet

- Osec B-Pak - Frequently Asked QuestionsDocument8 pagesOsec B-Pak - Frequently Asked Questionsalassy juyNo ratings yet

- Chemie Dampf enDocument16 pagesChemie Dampf enmishtinilNo ratings yet

- Topas Brochure EnglishDocument20 pagesTopas Brochure EnglishkastanjebrunNo ratings yet

- TiN Coating Best for Valves in Severe ApplicationsDocument1,635 pagesTiN Coating Best for Valves in Severe ApplicationsDevendra BangarNo ratings yet

- APM002 Rotary EvaporatorDocument9 pagesAPM002 Rotary EvaporatorMukarram MudjahidNo ratings yet

- TOPAS Brochure E 2014 06 PDFDocument20 pagesTOPAS Brochure E 2014 06 PDFanon_936760200No ratings yet

- Closed Loop SystemDocument3 pagesClosed Loop SystemSubbarayan SaravanakumarNo ratings yet

- Chloroform: Handling, Storage and Safety: BackgroundDocument9 pagesChloroform: Handling, Storage and Safety: BackgroundFerran FontcubertaNo ratings yet

- Full DWT Product CatalogDocument11 pagesFull DWT Product CatalogAmir JoonNo ratings yet

- Engineering & Operating Guide - DOWTHERM SR-1 - 4000Document44 pagesEngineering & Operating Guide - DOWTHERM SR-1 - 4000carlone07No ratings yet

- Ardrox 185l TdsDocument3 pagesArdrox 185l Tdsstuart3962No ratings yet

- Giacomini - Modelo R850 Y R910 - Valvula EsfericaDocument14 pagesGiacomini - Modelo R850 Y R910 - Valvula EsfericaDiego Francisco Ancajima CuevaNo ratings yet

- Fluidos Termicos y Circuitos de CalentamientoDocument38 pagesFluidos Termicos y Circuitos de CalentamientoClaudio Antonio Figueroa PulgarNo ratings yet

- The Marvel of IndiaDocument189 pagesThe Marvel of IndiaengrsurifNo ratings yet

- How Much Do You Know About Heavy Duty CoolantDocument5 pagesHow Much Do You Know About Heavy Duty CoolantengrsurifNo ratings yet

- Understanding Vacuum Pump LubricantsDocument21 pagesUnderstanding Vacuum Pump LubricantsengrsurifNo ratings yet

- Engine Coolant Basics ExplainedDocument24 pagesEngine Coolant Basics ExplainedengrsurifNo ratings yet

- Oil For Gas EnginesDocument9 pagesOil For Gas EnginesengrsurifNo ratings yet

- Antioxidant Monitoring of Gas Engine OilsDocument15 pagesAntioxidant Monitoring of Gas Engine OilsengrsurifNo ratings yet

- Understanding Refrigerant Oils: Mineral OilDocument7 pagesUnderstanding Refrigerant Oils: Mineral OilengrsurifNo ratings yet

- 6 Major Cost Impacts of Hydraulic LeaksDocument7 pages6 Major Cost Impacts of Hydraulic LeaksengrsurifNo ratings yet

- Jenis2 Minyak Asas Dan KegunaannyaDocument18 pagesJenis2 Minyak Asas Dan KegunaannyaengrsurifNo ratings yet

- Lubricants Sweeten Sour Gas EnginesDocument26 pagesLubricants Sweeten Sour Gas EnginesengrsurifNo ratings yet

- mh1 Medias 011 en GB de PDFDocument55 pagesmh1 Medias 011 en GB de PDFDejanNo ratings yet

- HiTEC 2571 R&O Additive PackageDocument2 pagesHiTEC 2571 R&O Additive PackageengrsurifNo ratings yet

- Barden Bearing Failures Us enDocument15 pagesBarden Bearing Failures Us enIbrahimElKelany100% (1)

- Basic Transformer OilsDocument19 pagesBasic Transformer OilsengrsurifNo ratings yet

- Dissolved Gas Analysis and Oil Condition TestingDocument8 pagesDissolved Gas Analysis and Oil Condition Testingengesam2007No ratings yet

- CIRCLE Handbook 2nd Edition EN 25 Aug 2015 MASTER Rev02 Final New02 Edited PDFDocument100 pagesCIRCLE Handbook 2nd Edition EN 25 Aug 2015 MASTER Rev02 Final New02 Edited PDFentertainpurpNo ratings yet

- Turbine Lube Oil Components 2020Document4 pagesTurbine Lube Oil Components 2020engrsurifNo ratings yet

- FTIR Condition Monitoring of In-ServiceDocument21 pagesFTIR Condition Monitoring of In-ServicesterilemovieNo ratings yet

- Catalogo Generale Cuscinetti A Sfere e A Rulli: CorporationDocument412 pagesCatalogo Generale Cuscinetti A Sfere e A Rulli: CorporationAlessandro ManzoniNo ratings yet

- 01 PartnershipDocument6 pages01 Partnershipdom baldemorNo ratings yet

- Petitioners: La Bugal-B'Laan Tribal Association Inc, Rep. Chariman F'Long Miguel Lumayong Etc Respondent: Secretary Victor O. Ramos, DENR EtcDocument2 pagesPetitioners: La Bugal-B'Laan Tribal Association Inc, Rep. Chariman F'Long Miguel Lumayong Etc Respondent: Secretary Victor O. Ramos, DENR EtcApple Gee Libo-onNo ratings yet

- Materi 5: Business Ethics and The Legal Environment of BusinessDocument30 pagesMateri 5: Business Ethics and The Legal Environment of BusinessChikita DindaNo ratings yet

- Ethics of UtilitarianismDocument26 pagesEthics of UtilitarianismAngelene MangubatNo ratings yet

- Written ComplianceDocument2 pagesWritten ComplianceKriselle Joy ManaloNo ratings yet

- CBCP Monitor Vol14-N12Document20 pagesCBCP Monitor Vol14-N12Areopagus Communications, Inc.No ratings yet

- Ad Intelligence BDocument67 pagesAd Intelligence BSyed IqbalNo ratings yet

- Vol 4Document96 pagesVol 4rc2587No ratings yet

- InwaDocument3 pagesInwadfgrtg454gNo ratings yet

- Land Acquisition Rehabilitation and ReseDocument19 pagesLand Acquisition Rehabilitation and Reseleela naga janaki rajitha attiliNo ratings yet

- Unintended ConsequencesDocument3 pagesUnintended ConsequencesBill George100% (1)

- Cignal: Residential Service Application FormDocument10 pagesCignal: Residential Service Application FormJUDGE MARLON JAY MONEVANo ratings yet

- BE Forms 1 and 1.1Document4 pagesBE Forms 1 and 1.1Mel Joy NatadNo ratings yet

- LIST OF HEARING CASES WHERE THE RESPONDENT HAS BEEN FOUND GUILTYDocument1 pageLIST OF HEARING CASES WHERE THE RESPONDENT HAS BEEN FOUND GUILTYDarrenNo ratings yet

- Companies View SampleDocument4 pagesCompanies View Samplesuresh6265No ratings yet

- Electrical FoundationDocument2 pagesElectrical FoundationterrenceNo ratings yet

- Riverscape Fact SheetDocument5 pagesRiverscape Fact SheetSharmaine FalcisNo ratings yet

- Business Studies PamphletDocument28 pagesBusiness Studies PamphletSimushi SimushiNo ratings yet

- Motion For Reconsideration Memorandum of Appeal Alvin AlcontinDocument3 pagesMotion For Reconsideration Memorandum of Appeal Alvin AlcontinFrancis DinopolNo ratings yet

- MC 2021-086 General Guidelines On The International Organization For Standardization ISO Certification of The PNP Office Units Revised 2021Document10 pagesMC 2021-086 General Guidelines On The International Organization For Standardization ISO Certification of The PNP Office Units Revised 2021Allysa Nicole OrdonezNo ratings yet

- Criminal Revision 11 of 2019Document2 pagesCriminal Revision 11 of 2019wanyamaNo ratings yet

- Heirs of Marcelino Doronio, Petitioners v. Heirs of Fortunato Doronio, RespondentsDocument2 pagesHeirs of Marcelino Doronio, Petitioners v. Heirs of Fortunato Doronio, RespondentsMichael DonascoNo ratings yet

- The Following Information Is Available For Bott Company Additional Information ForDocument1 pageThe Following Information Is Available For Bott Company Additional Information ForTaimur TechnologistNo ratings yet

- CHM580Document7 pagesCHM580Azreen AnisNo ratings yet

- 4 2 Pure BendingDocument13 pages4 2 Pure BendingRubayet AlamNo ratings yet

- Unified Soil Classification SystemDocument4 pagesUnified Soil Classification SystemRoch battousai100% (1)