Professional Documents

Culture Documents

QA&QC D4010.15160.05-FIre & Jockey Rev01

Uploaded by

Non Etabas GadnatamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QA&QC D4010.15160.05-FIre & Jockey Rev01

Uploaded by

Non Etabas GadnatamCopyright:

Available Formats

QA/QC Inspection Checklist

design coordinates, inc. CP No. __________________

VECTOR THREE

Northgate, Cyberzone, Filinvest Corporate City,

Alabang, Muntinlupa City

Building Element/System: D40 Fire Protection Systems

Category: D4010.15330 Wet Pipe Fire Sprinkler System

Items to be Inspected: Pumps/Fire and Jockey

Date Inspected:

Supplier:

Location:

Non - Not Remarks / Due

Conform.

Conform. Avail.

N/A Open Close

ITEM / REQUIREMENT Corrective Actions Date

A SUBMITTALS:

A.1 Materials

1. Type :

2. Brand :

3. Origin :

4. Name plate data:

5. Conformance to NFPA 20 or

applicable standards

6. Factory test certificate

A.2 Shopdrawings

B PRE-INSTALLATIONS:

Location: is there adequate

space left around the

B.1 unit for operation,

maintenance, service

and inspection parts?

B.2 Storage:

b.2.1 Are pumps properly

prepared to prevent

rusting and bearing

damage?

b.2.2 Are bearings protected

by oil or grease?

b.2.3. Are pumps immediately

placed into service, or

removed from service

and stored properly,

prepared to prevent

rusting and bearing

damaged?

b.2.4 Are plugs at the top and

bottom of the casing

removed to prevent

internal rusting?

b.2.5 Are plugs reinstalled

before operation?

b.2.6 Is there rust proofing or

packing on the casing to

absorb moisture?

b.2.7 Is the dying agent

removed from the pump

when returned to

service?

DCI-QIC rev. 01 Page 1 of 3

QA/QC Inspection Checklist

design coordinates, inc. CP No. __________________

VECTOR THREE

Northgate, Cyberzone, Filinvest Corporate City,

Alabang, Muntinlupa City

Remarks /

Non - Not Due

ITEM / REQUIREMENT Conform.

Conform. Avail.

N/A Corrective

Date

Open Close

Actions

C INSTALLATIONS:

C.1 Foundation and Mounting:

c.1.1 Is foundation sufficiently

substantial to support

the base plate at all

points?

c.1. 2.Pump alignment

c.1.3 Are foundation made of

reinforced concrete?

c.1.4. Are foundation bolts of

suitable size?

c.1.5 Are pipe sleeves 2.5

times the size of the

anchor bolts??

c.1.6 Is the unit to be

mounted on fabricated

steel work or similar

structure?

c.1.7 Is the shaft of pump and

driver leveled?

C.2 Pump Piping

c.2.1 Is connection started

from pump to piping?

c.2.2 Are usage of bends

limited and of preferably

long radius?

c.2.3 Are suction and

discharge piping with

anchor/supports?

c.2.4 Eccentric reducer on

suction connection?

c.2.5 Is the isolation valve at

suction and discharge

line?

c.2.6 Is the non-slam check

valve in discharge line

between pump and

isolation valve.

c.2.7 Provision of suction and

discharge gauge

c.2.8 Automatic air

release valve at the high

point on the pump

casing

c.2.9 Provision for relief valve

c.2.10 Provision for flexible

coupling

c.2.11 Air relief valve @ the

lowest suction line

D OPERATION:

D.1 Coupling guard installed

D.2 Final alignment correct

D.3 Pump primed

D.4 Rotation

D.5 Lubrication

DCI-QIC rev. 01 Page 2 of 3

QA/QC Inspection Checklist

design coordinates, inc. CP No. __________________

VECTOR THREE

Northgate, Cyberzone, Filinvest Corporate City,

Alabang, Muntinlupa City

Remarks /

Non - Not Due

ITEM / REQUIREMENT Conform.

Conform. Avail.

N/A Corrective

Date

Open Close

Actions

D.6 Pipe work properly supported

D7 Voltage supply

D.8 Overload protection

D.9 Is the system clean?

Is the area around the pump

D.10

clean?

Is controller panel as

D.11

specified?

E TESTING:

Manufacturers certified pump

E.1

test result

E.2 Field acceptance test

E.3 Controller acceptance test

General Notes, Comments and Recommendations:

Inspected by : Noted by : Concurred by :

________________________________ __________________________________ ________________________________

Construction Project Engineer / Architect Construction Project Manager Supplier

Distribution:

Supplier Customer/ Developer DCI File

Note: A separate Notice to Comply (DCI-NTC) can be issued to the supplier/contractor if the non-

conforming item may take time to rectify and complete.

DCI-QIC rev. 01 Page 3 of 3

You might also like

- Quality Alert 4 - Revised 2017Document2 pagesQuality Alert 4 - Revised 2017Faraj Khan100% (1)

- Giraffe Juice GamesDocument32 pagesGiraffe Juice Gamesgwyn022100% (3)

- Punch List For Fire Water Pump & Foam Pump PackageDocument4 pagesPunch List For Fire Water Pump & Foam Pump PackageGomathyselviNo ratings yet

- Work Inspection Checklists (11!06!2019)Document53 pagesWork Inspection Checklists (11!06!2019)Ram RamirezNo ratings yet

- Attachment A - Scope of WorkDocument7 pagesAttachment A - Scope of WorkMazhar MahadzirNo ratings yet

- Tutorial Sim MechanicsDocument840 pagesTutorial Sim MechanicsHernan Gonzalez100% (4)

- Checklist For T&C of Chemical Fire Suppression SystemDocument2 pagesChecklist For T&C of Chemical Fire Suppression Systembeho2000No ratings yet

- 24 Vibration IsolatorDocument22 pages24 Vibration IsolatorNon Etabas Gadnatam100% (1)

- 21 Great Answers To: Order ID: 0028913Document13 pages21 Great Answers To: Order ID: 0028913Yvette HOUNGUE100% (1)

- ITP - Fencing and Gates Installation Works - MAB1Document24 pagesITP - Fencing and Gates Installation Works - MAB1Vasilica Barbarasa100% (2)

- Dewatering Pump ChecklistDocument1 pageDewatering Pump ChecklistMD Abdullah100% (1)

- IKDC-BINKEI-FP-SAT-RFA-069 FA, Gas Suppression, Pre-ActionDocument33 pagesIKDC-BINKEI-FP-SAT-RFA-069 FA, Gas Suppression, Pre-ActionjendrikoNo ratings yet

- QAQC Procedure For Fabrication - Flare KOD Rev ADocument9 pagesQAQC Procedure For Fabrication - Flare KOD Rev ARajesh K Pillai100% (1)

- Continuity TestingDocument107 pagesContinuity TestingJohn Benedict MauricioNo ratings yet

- Avionics Shop Manual: Uncontrolled DocumentDocument53 pagesAvionics Shop Manual: Uncontrolled DocumentWallyNo ratings yet

- Hdpe FieldDocument44 pagesHdpe Fieldwesqui100% (1)

- Install Coiled Tubing Lift Frame & Injector HeadDocument8 pagesInstall Coiled Tubing Lift Frame & Injector HeadsamanNo ratings yet

- Smell Detectives: An Olfactory History of Nineteenth-Century Urban AmericaDocument35 pagesSmell Detectives: An Olfactory History of Nineteenth-Century Urban AmericaUniversity of Washington PressNo ratings yet

- Koc Design BasisDocument92 pagesKoc Design BasisgyanwapiNo ratings yet

- 1065 Electronic Safety Security Comprehensive Quality Plan SampleDocument20 pages1065 Electronic Safety Security Comprehensive Quality Plan SampleNon Etabas GadnatamNo ratings yet

- Method Statement For Gravel Surfacing Around New Lift Station IW-10ADocument6 pagesMethod Statement For Gravel Surfacing Around New Lift Station IW-10ANazirNo ratings yet

- Subsea Rigid Pipelines – Methods of InstallationFrom EverandSubsea Rigid Pipelines – Methods of InstallationRating: 5 out of 5 stars5/5 (1)

- Distribution PanelDocument5 pagesDistribution PanelSourav RanaNo ratings yet

- DRP001-OUF-STA-MTS-L-000-030-O1 - WMS Pickling and Passivation PDFDocument36 pagesDRP001-OUF-STA-MTS-L-000-030-O1 - WMS Pickling and Passivation PDFrodman823No ratings yet

- Bored PilingDocument3 pagesBored PilingAdonis AlabiNo ratings yet

- CalculationDocument24 pagesCalculationhablet1100% (1)

- Best Mesl StudoDocument15 pagesBest Mesl StudoJoenielNo ratings yet

- QA&QC D2020.15100.05-Water Supply Pumps Rev01Document3 pagesQA&QC D2020.15100.05-Water Supply Pumps Rev01Non Etabas GadnatamNo ratings yet

- QA/QC Inspection Checklist: Design Coordinates, Inc. CP No. - Vector ThreeDocument2 pagesQA/QC Inspection Checklist: Design Coordinates, Inc. CP No. - Vector ThreeNon Etabas Gadnatam100% (1)

- QA/QC Inspection Checklist: Design Coordinates, Inc. CP No. - Vector ThreeDocument2 pagesQA/QC Inspection Checklist: Design Coordinates, Inc. CP No. - Vector ThreeNon Etabas GadnatamNo ratings yet

- QA/QC Inspection Checklist: Design Coordinates, Inc. CP No. - Vector ThreeDocument2 pagesQA/QC Inspection Checklist: Design Coordinates, Inc. CP No. - Vector ThreeNon Etabas GadnatamNo ratings yet

- QA/QC Inspection Checklist: Design Coordinates, Inc. CP No. - Vector ThreeDocument1 pageQA/QC Inspection Checklist: Design Coordinates, Inc. CP No. - Vector ThreeNon Etabas GadnatamNo ratings yet

- QA&QC D2020.15060-Pipes & Pipe Fittings Rev01Document2 pagesQA&QC D2020.15060-Pipes & Pipe Fittings Rev01Non Etabas GadnatamNo ratings yet

- QA&QC D2020.15060-Pipes & Pipe Fittings EDITEDDocument4 pagesQA&QC D2020.15060-Pipes & Pipe Fittings EDITEDbryesanggalangNo ratings yet

- QA/QC Inspection Checklist: Design Coordinates, Inc. CP No. - Vector ThreeDocument1 pageQA/QC Inspection Checklist: Design Coordinates, Inc. CP No. - Vector ThreeNon Etabas GadnatamNo ratings yet

- QA/QC Inspection Checklist: Design Coordinates, Inc. CP No. - Vector ThreeDocument1 pageQA/QC Inspection Checklist: Design Coordinates, Inc. CP No. - Vector ThreeNon Etabas GadnatamNo ratings yet

- QA/QC Inspection Checklist: Design Coordinates, Inc. CP No. - Vector ThreeDocument1 pageQA/QC Inspection Checklist: Design Coordinates, Inc. CP No. - Vector ThreeNon Etabas GadnatamNo ratings yet

- Method Statement For Block Works - Rev01Document19 pagesMethod Statement For Block Works - Rev01rayNo ratings yet

- Fat - MSB Pmu JinjangDocument6 pagesFat - MSB Pmu JinjangFirdaus Muhammad100% (1)

- Observations & Comments Sheet (OCS) : Qatar Olympic CommitteeDocument2 pagesObservations & Comments Sheet (OCS) : Qatar Olympic CommitteeIbrahim SirpiNo ratings yet

- IDBC-ST-MSZZZ-NG0036 Rev B Cleaning and Flushing of Hydraul 1Document12 pagesIDBC-ST-MSZZZ-NG0036 Rev B Cleaning and Flushing of Hydraul 1Iqbal Safirul BarqiNo ratings yet

- Revision History: General Metal Container Corporation of The PhilippinesDocument5 pagesRevision History: General Metal Container Corporation of The PhilippinesJulian Paul Villaruel QuerubinNo ratings yet

- HFY-GEN-CP-SPC-0009 - B Specification For Corrosion Coupon - Code-ADocument15 pagesHFY-GEN-CP-SPC-0009 - B Specification For Corrosion Coupon - Code-ATahir FadhilNo ratings yet

- CHECKLIST-Booster Pump CommissioningDocument1 pageCHECKLIST-Booster Pump CommissioningPraveen LukoseNo ratings yet

- Observations & Comments Sheet (OCS) : Qatar Olympic CommitteeDocument2 pagesObservations & Comments Sheet (OCS) : Qatar Olympic CommitteeIbrahim SirpiNo ratings yet

- Abb-Ele-Plt - 00014 Sat For Grounding V0Document4 pagesAbb-Ele-Plt - 00014 Sat For Grounding V0Ramiro Valencia HurtadoNo ratings yet

- Checklist For Installation of Underground Checmical Waste TanksDocument1 pageChecklist For Installation of Underground Checmical Waste TanksDiana Abu Hassan HatoumNo ratings yet

- Vendor Document Review Sheet (DECAL) : J3 Program-Offsites & Utilities, Jamnagar, India Project TitleDocument6 pagesVendor Document Review Sheet (DECAL) : J3 Program-Offsites & Utilities, Jamnagar, India Project TitlenisargkedarNo ratings yet

- DRC - Installation of Fire Dampers-Me-0008Document3 pagesDRC - Installation of Fire Dampers-Me-0008Altaf KhanNo ratings yet

- Observations & Comments Sheet (OCS) : Qatar Olympic CommitteeDocument2 pagesObservations & Comments Sheet (OCS) : Qatar Olympic CommitteeIbrahim SirpiNo ratings yet

- Control of Sewerage and Surface Water DrainageDocument4 pagesControl of Sewerage and Surface Water DrainageMichaelJamesBanawisNo ratings yet

- SOP Valve Cleaning: Project Name: Pipeline Operation and Maintenance Doc. NumberDocument4 pagesSOP Valve Cleaning: Project Name: Pipeline Operation and Maintenance Doc. Numberarif rhNo ratings yet

- Nghi Son 2 BOT Thermal Power Plant Project Design Query SheetDocument3 pagesNghi Son 2 BOT Thermal Power Plant Project Design Query SheetMr NgocNo ratings yet

- Adobe Scan 25-Oct-2022Document6 pagesAdobe Scan 25-Oct-2022himanshu koleyNo ratings yet

- Page 1 of 6 AUDITOR NOTE: 9001 F45.25 August 2009: Auditor Notes 6.2 Human ResourcesDocument6 pagesPage 1 of 6 AUDITOR NOTE: 9001 F45.25 August 2009: Auditor Notes 6.2 Human ResourcesnubeNo ratings yet

- C-SP-55-017 - Vertical Turbine PuDocument20 pagesC-SP-55-017 - Vertical Turbine PuEsteban Rios PitaNo ratings yet

- Qatar Olympic Committee HVAC Testing ProcedureDocument2 pagesQatar Olympic Committee HVAC Testing ProcedureIbrahim SirpiNo ratings yet

- Chap 07Document30 pagesChap 07Anbarasan PerumalNo ratings yet

- Method Statement For Self Watering PotsDocument10 pagesMethod Statement For Self Watering PotssanjayNo ratings yet

- Cilar Checklist: Maintenance Job DeskDocument1 pageCilar Checklist: Maintenance Job DeskedlistiantoNo ratings yet

- Adobe Scan 09-Mar-2023Document3 pagesAdobe Scan 09-Mar-2023himanshu koleyNo ratings yet

- Liquid Penetrant Test Procedure F1Document12 pagesLiquid Penetrant Test Procedure F1abrayalamNo ratings yet

- CSC IOM Manual BombaDocument18 pagesCSC IOM Manual BombaLuis Sánchez RoblesNo ratings yet

- Duqm Refinery Project EPC Package OneDocument11 pagesDuqm Refinery Project EPC Package Onekhaled saeedNo ratings yet

- 8D-RCA Report Analyzes Purge Gas Fan FailureDocument18 pages8D-RCA Report Analyzes Purge Gas Fan FailureFranklin YobuNo ratings yet

- Kuwait National Petroleum Company (K.S.C) Clean Fuels Project (CFP) KNPC Contract No. CFP/EPC/0054-MAB1 PSCJ Job No. JI-2025Document4 pagesKuwait National Petroleum Company (K.S.C) Clean Fuels Project (CFP) KNPC Contract No. CFP/EPC/0054-MAB1 PSCJ Job No. JI-2025arun kumarNo ratings yet

- Week 07 - Senior Management HSE Evaluation 7719Document18 pagesWeek 07 - Senior Management HSE Evaluation 7719wajiNo ratings yet

- A554 D 455 CV Sow Con 021Document4 pagesA554 D 455 CV Sow Con 021Non Etabas GadnatamNo ratings yet

- The Dow Chemical Company confidential drawingDocument1 pageThe Dow Chemical Company confidential drawingNon Etabas GadnatamNo ratings yet

- A554 D 455 CV Lis Doc 021Document7 pagesA554 D 455 CV Lis Doc 021Non Etabas GadnatamNo ratings yet

- 39CQ Iom 06302014Document20 pages39CQ Iom 06302014Non Etabas GadnatamNo ratings yet

- Work Proposal - PLDM - SanDocument2 pagesWork Proposal - PLDM - SanNon Etabas GadnatamNo ratings yet

- HR Form 11 - Request To Avail Work From Home OptionDocument1 pageHR Form 11 - Request To Avail Work From Home OptionNon Etabas GadnatamNo ratings yet

- A554 D 455 PM Lis Doc 004Document3 pagesA554 D 455 PM Lis Doc 004Non Etabas GadnatamNo ratings yet

- A554 D 455 PM Sow Con 005Document4 pagesA554 D 455 PM Sow Con 005Non Etabas GadnatamNo ratings yet

- Sanitary/Plumbing Works Construction Bulletin No. 1Document34 pagesSanitary/Plumbing Works Construction Bulletin No. 1Non Etabas GadnatamNo ratings yet

- 633559-M-E-D010-Stage 4 Pavilion-IFC SetDocument7 pages633559-M-E-D010-Stage 4 Pavilion-IFC SetNon Etabas GadnatamNo ratings yet

- 2TR Portable SpecsDocument1 page2TR Portable SpecsNon Etabas GadnatamNo ratings yet

- General Comprehensive Quality Plan & Manual Sample: Selected Pages Sample IncludesDocument28 pagesGeneral Comprehensive Quality Plan & Manual Sample: Selected Pages Sample IncludesJesseNo ratings yet

- Proposed Office For Pinacle ProjectDocument1 pageProposed Office For Pinacle ProjectNon Etabas GadnatamNo ratings yet

- PLV Pav Lasc 100DDDocument25 pagesPLV Pav Lasc 100DDNon Etabas GadnatamNo ratings yet

- 1 Gala CI Y-Strainer Cast Iron Fig 7101Document1 page1 Gala CI Y-Strainer Cast Iron Fig 7101Non Etabas GadnatamNo ratings yet

- 1067 Fire Suppression Comprehensive Quality Plan SampleDocument20 pages1067 Fire Suppression Comprehensive Quality Plan SampleNon Etabas GadnatamNo ratings yet

- FDA Certified GF+ β-PP-H Piping MaterialsDocument1 pageFDA Certified GF+ β-PP-H Piping MaterialsNon Etabas GadnatamNo ratings yet

- 1 Gala Ci Gate Valve Resilient Seated Nrs NRGV 3243Document1 page1 Gala Ci Gate Valve Resilient Seated Nrs NRGV 3243Non Etabas GadnatamNo ratings yet

- 9 PT-LSDocument11 pages9 PT-LSNon Etabas GadnatamNo ratings yet

- 1st Partial Round DuctDocument1 page1st Partial Round DuctNon Etabas GadnatamNo ratings yet

- 1 Gala Rubber Flexible Connector Flange Double Bellows GFLEX-F2 FlangeDocument3 pages1 Gala Rubber Flexible Connector Flange Double Bellows GFLEX-F2 FlangeNon Etabas GadnatamNo ratings yet

- Bronze Y-Strainer ThreadedDocument1 pageBronze Y-Strainer ThreadedNon Etabas GadnatamNo ratings yet

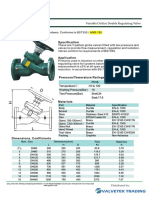

- 1 Gala Balancing Valve Variable Orifice FT Fig DRVF 1210-Df Pn16 65mm To 450mmDocument1 page1 Gala Balancing Valve Variable Orifice FT Fig DRVF 1210-Df Pn16 65mm To 450mmNon Etabas GadnatamNo ratings yet

- Bronze NRS Gate Valve Specifications and DimensionsDocument1 pageBronze NRS Gate Valve Specifications and DimensionsNon Etabas GadnatamNo ratings yet

- 1 FT Gala Rubber Flexible Connector Double Bellows GFLEX-GS THREADEDDocument2 pages1 FT Gala Rubber Flexible Connector Double Bellows GFLEX-GS THREADEDNon Etabas GadnatamNo ratings yet

- Equipment Schedule & Technical Summary Ests 1 PE-11 & PE-12 Passenger ElevatorsDocument5 pagesEquipment Schedule & Technical Summary Ests 1 PE-11 & PE-12 Passenger ElevatorsNon Etabas GadnatamNo ratings yet

- 1 Balancing Valve Bronze GALA-smDocument1 page1 Balancing Valve Bronze GALA-smNon Etabas GadnatamNo ratings yet

- CoverDocument1 pageCoverNon Etabas GadnatamNo ratings yet

- CTM Catalogue 2015-2016Document100 pagesCTM Catalogue 2015-2016Anonymous dXcoknUNo ratings yet

- Comparison of Waste-Water Treatment Using Activated Carbon and Fullers Earth - A Case StudyDocument6 pagesComparison of Waste-Water Treatment Using Activated Carbon and Fullers Earth - A Case StudyDEVESH SINGH100% (1)

- Airframe Exam Review QuestionsDocument23 pagesAirframe Exam Review QuestionsbirukNo ratings yet

- WORK ORDER TITLEDocument2 pagesWORK ORDER TITLEDesign V-Tork ControlsNo ratings yet

- The Importance of WritingDocument4 pagesThe Importance of WritingBogdan VasileNo ratings yet

- Mindfulness With Collegiate Gymnasts - Effects On Flow, Stress and Overall Mindfulness LevelsNicholas P. Cherupa,, Zeljka VidicDocument13 pagesMindfulness With Collegiate Gymnasts - Effects On Flow, Stress and Overall Mindfulness LevelsNicholas P. Cherupa,, Zeljka VidicGABRIELNo ratings yet

- Unit 3.1 - Hydrostatic ForcesDocument29 pagesUnit 3.1 - Hydrostatic ForcesIshmael MvunyiswaNo ratings yet

- J05720020120134026Functions and GraphsDocument14 pagesJ05720020120134026Functions and GraphsmuglersaurusNo ratings yet

- Sewer CadDocument10 pagesSewer CadAlvaro Jesus Añazco YllpaNo ratings yet

- Packing, Transportation and Marketing of Ornamental FishesDocument16 pagesPacking, Transportation and Marketing of Ornamental Fishesraj kiranNo ratings yet

- Schwarzschild Metric and Black Hole HorizonsDocument39 pagesSchwarzschild Metric and Black Hole Horizonsসায়ন চক্রবর্তীNo ratings yet

- ISO 17000 2004 Terms & DefintionsDocument6 pagesISO 17000 2004 Terms & DefintionsSelvaraj SimiyonNo ratings yet

- Information HandoutsDocument6 pagesInformation HandoutsPooja Marwadkar TupcheNo ratings yet

- Main Sulci & Fissures: Cerebral FissureDocument17 pagesMain Sulci & Fissures: Cerebral FissureNagbhushan BmNo ratings yet

- Chemistry 101 - The Complete Notes - Joliet Junior College (PDFDrive)Document226 pagesChemistry 101 - The Complete Notes - Joliet Junior College (PDFDrive)Kabwela MwapeNo ratings yet

- 16SEE - Schedule of PapersDocument36 pages16SEE - Schedule of PapersPiyush Jain0% (1)

- 2002 AriDocument53 pages2002 AriMbarouk Shaame MbaroukNo ratings yet

- 6.1.3 Final Exam - Exam (Exam)Document8 pages6.1.3 Final Exam - Exam (Exam)parker3poseyNo ratings yet

- 1 s2.0 S1747938X21000142 MainDocument33 pages1 s2.0 S1747938X21000142 MainAzmil XinanNo ratings yet

- TM500 Design Overview (Complete ArchitectureDocument3 pagesTM500 Design Overview (Complete ArchitectureppghoshinNo ratings yet

- Mayan Calendar End Date Sparks Doomsday SpeculationDocument16 pagesMayan Calendar End Date Sparks Doomsday SpeculationElfen RoxanneNo ratings yet

- Senior Design Projects 201-2020 - For Website - MEDocument5 pagesSenior Design Projects 201-2020 - For Website - MEYujbvhujgNo ratings yet

- Conductivity NickelDocument2 pagesConductivity Nickelkishormujumdar998No ratings yet

- G String v5 User ManualDocument53 pagesG String v5 User ManualFarid MawardiNo ratings yet