Professional Documents

Culture Documents

Different Model of Bended Beam: Design Project 1 Simon Amboise

Uploaded by

Simon AmboiseOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Different Model of Bended Beam: Design Project 1 Simon Amboise

Uploaded by

Simon AmboiseCopyright:

Available Formats

Design Project 1 Simon AMBOISE

Different model of bended beam

Case 1 : Analytical results

Case 2 : Shell43 element presentation

Bending stress

Maximum deflection

Comparison with analytical results

Case 3 : Plane82 element presentation, bending stress and deflection

Comparison with analytical results

Case 4 : Solid45 element, comparison with analytical results

Comparison with analytical results

Conclusion : Comparaison between these 4 cases

Case 1 : Analytical results

Datas for I-200 : t h = 200 mm

L=2200 mm s = 90 mm

Allowable Stress: σ = 180 Mpa t = 11,3 mm

Young’s Modulus: E = 2.105 Mpa h g = 7,5 mm

Poisson’s Ratio: ν = 0,3

Moment of inertia: Jx = 2140 cm4

Section modulus: Zx = 214,0 cm3 g

The magnitude of allowable UDL q

Maximum deflection of the beam at the allowable UDL q

Case 2 : Shell43 element presentation

2 thickness : Boundary condition: Pressure:

94,55 Cst1 = g = 7,5 mm Y displacement = 0 on 2 lines q = 63,6694 kN/M and s = 90 mm

(0,0,0)

Cst2 = t = 11,3 mm Z displacement = 0 on 1 lines P = q/s = 0,7074 MPa

45

Element Size : 40 mm.

Case 2 : Shell43 element; Bending stress

Element size (mm) 320 160 80 40 20 10 5

maximum bending stress (Mpa) 163,691 172,133 173,426 173,839 173,871 173,89 173,891

Case 2 : Shell43 element, Maximum deflection

Element size (mm) 320 160 80 40 20 10 5

maximum deflection (mm) 4,502 4,743 4,807 4,849 4,88 4,896 4,904

Case 2 : Shell43 element, comparison with analytical results

4,95 320 160 80 40 10 182

4,9 180

20 5

4,85 178

4,8 176

4,75 174

4,7 172

4,65 170

4,6 168

20 5 4,55 166

320 160 80 40 10 4,5 164

4,45 162

300 250 200 150 100 50 0 300 250 200 150 100 50 0

Maximum deflection per element size Maximum bending stress per element size

Element size (mm) 320 160 80 40 20 10 5

maximum deflection (mm) 4,502 4,743 4,807 4,849 4,88 4,896 4,904

comparison with analytical value (mm) -0,035 0,206 0,27 0,312 0,343 0,359 0,367

% variation between these two values -0,771% 4,540% 5,951% 6,877% 7,560% 7,913% 8,089%

% variation with the previous result 5,0812% 1,3314% 0,8662% 0,6352% 0,3268% 0,1631%

maximum bending stress (Mpa) 163,691 172,133 173,426 173,839 173,871 173,89 173,891

comparison with analytical value (Mpa) -16,309 -7,867 -6,574 -6,161 -6,129 -6,11 -6,109

% variation between these two values 9,061% 4,371% 3,652% 3,423% 3,405% 3,394% 3,394%

% variation with the previous result 4,9043% 0,7456% 0,2376% 0,0184% 0,0109% 0,0006%

ELEMENT SIZE = 40 mm ν=0,3 ν=0 % variation

maximum deflection (mm) 4,849 4,779 1,444%

maximum bending stress (Mpa) 173,839 173,298 0,311%

Case 3 : Plane82 element presentation, bending stress and deflection

11,3

2 thickness : Boundary condition: Pressure:

177,4

Cst1 = g = 7,5 mm Y displacement = 0 on 2 points P = 0,7074 Mpa

Cst2 = s = 90 mm Z displacement = 0 on 1 point On line

Element size (mm) 320 160 80 40 20 10

maximum deflection (mm) 4,691 4,741 4,76 4,789 4,789 4,789

maximum bending stress (Mpa) 182,309 174,851 174,783 175,323 175,323 175,536

Case 3 : Plane82 element, comparison with analytical results

4,85

183

4,8 182

320 160 80 40 2010 181

4,75

180

4,7 179

178

4,65

177

4,6 176

175

4,55

174

320 160 80 40 2010 4,5 173

300 250 200 150 100 50 0 300 250 200 150 100 50 0

Maximum deflection per element size Maximum bending stress per element size

Element size (mm) 320 160 80 40 20 10

total nodes 84 205 487 1280 3873 15005

maximum deflection (mm) 4,691 4,741 4,76 4,789 4,789 4,789

comparison with analytical value (mm) 0,154 0,204 0,223 0,252 0,252 0,252

% variation between these two values 3,394% 4,496% 4,915% 5,554% 5,554% 5,554%

% variation with the previous result 1,0546% 0,3992% 0,6056% 0,0000% 0,0000%

maximum bending stress (Mpa) 182,309 174,851 174,783 175,323 175,323 175,536

comparison with analytical value (Mpa) 2,309 -5,149 -5,217 -4,677 -4,677 -4,464

% variation between these two values 1,283% 2,861% 2,898% 2,598% 2,598% 2,480%

% variation with the previous result -4,2653% -0,0389% 0,3080% 0,0000% 0,1213%

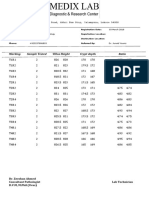

Case 4 : Solid45 element, bending stress and deflection

Element size (mm) 320 160 80 40 20 10

maximum bending stress (Mpa) 35,5 34,878 160,169 173,99 181,011 181,676

maximum deflection (mm) 0,387 0,538 4,211 4,703 4,918 4,958

Case 4 : Solid45 element, comparison with analytical results

320 160 80 40 2010 200

6

180

5 160

140

320 160 80 40 2010 4

120

3 100

80

2

60

1 40

20

0

0

300 250 200 150 100 50 0

300 250 200 150 100 50 0

Maximum deflection per element size Maximum bending stress per element size

Element size (mm) 320 160 80 40 20 10

maximum deflection (mm) 0,387 0,538 4,211 4,703 4,918 4,958

comparison with analytical value (mm) -4,15 -3,999 -0,326 0,166 0,381 0,421

% variation between these two values -91,470% -88,142% -7,185% 3,659% 8,398% 9,279%

% variation with the previous result 28,0669% 87,2239% 10,4614% 4,3717% 0,8068%

maximum bending stress (Mpa) 35,5 34,878 160,169 173,99 181,011 181,676

comparison with analytical value (Mpa) -144,5 -145,122 -19,831 -6,01 1,011 1,676

% variation between these two values 80,278% 80,623% 11,017% 3,339% 0,562% 0,931%

% variation with the previous result -1,7834% 78,2243% 7,9436% 3,8788% 0,3660%

Conclusion : Comparaison between these 4 cases

5 185

320 160 80 40 2010

4,9

180

4,8

4,7 175

Shell43

4,6 170

4,5 Plane82

320 160 80 40 2010 165

4,4 Solid45

4,3 Analytical 160

4,2

155

4,1

300 250 200 150 100 50 0

300 200 100 0

Maximum deflection per element size Maximum bending stress per element size

10 20 20000

10

18 18000

16 16000

14 14000

12 12000

Shell43

10 10000

Plane 82

8 8000

20 Solid45 20

6 6000

40 4 4000

80 40

320 160 2 320 160 80 2000

0 0

300 250 200 150 100 50 0 300 250 200 150 100 50 0

Calculating and meshing Time per element size Nodes per element size

You might also like

- Beml BH50 Electrical ManualDocument33 pagesBeml BH50 Electrical ManualveereshNo ratings yet

- For A System of Particles:: Week 13 Lecture Notes Impulse-Momentum Principle For A Rigid BodyDocument7 pagesFor A System of Particles:: Week 13 Lecture Notes Impulse-Momentum Principle For A Rigid Bodysuraj raiNo ratings yet

- WRC Data-ModifiedDocument40 pagesWRC Data-ModifiedGovindan KrishnamoorthybashyamNo ratings yet

- ISO Tank ProcedureDocument25 pagesISO Tank ProcedureRodrigo NunesNo ratings yet

- Meson Mudbox Cast Iron 482051Document1 pageMeson Mudbox Cast Iron 482051MostafaNo ratings yet

- Necchi Manuel de Service Bu-Bf Nova-Mira PDFDocument93 pagesNecchi Manuel de Service Bu-Bf Nova-Mira PDFSissyNo ratings yet

- DTC P1120/19 Accel. Position Sensor Circuit (Open/Short)Document7 pagesDTC P1120/19 Accel. Position Sensor Circuit (Open/Short)Jehuty88No ratings yet

- Screw Conveyor and Feeder Calculation FiDocument90 pagesScrew Conveyor and Feeder Calculation FiTheodoros AtheridisNo ratings yet

- Design For Torsion (Beams BS 8110)Document3 pagesDesign For Torsion (Beams BS 8110)dhanya1995100% (1)

- Din 472Document5 pagesDin 472Puspendra Singh Yadav0% (2)

- Astm Nos For PipingDocument6 pagesAstm Nos For PipingJessica HerringNo ratings yet

- University of The Philippines College of ScienceDocument10 pagesUniversity of The Philippines College of SciencecrizwiseNo ratings yet

- Smit Bracket Holding Power Strength CalculationsDocument7 pagesSmit Bracket Holding Power Strength Calculationsnavalzero910100% (1)

- Bomba Rexroth A10v 063 Ek1ds - 53R VSD 62 K15P PDFDocument68 pagesBomba Rexroth A10v 063 Ek1ds - 53R VSD 62 K15P PDFmarianoNo ratings yet

- PHP Project: Sport OfficeDocument22 pagesPHP Project: Sport OfficeSimon AmboiseNo ratings yet

- OK OK OK OK OK OK: !! Fill Only Blank White Cells !!Document7 pagesOK OK OK OK OK OK: !! Fill Only Blank White Cells !!Oleh NevynnyiNo ratings yet

- PH78400 0110Document20 pagesPH78400 0110rajuhaveriNo ratings yet

- Section Quantity Weight ChartDocument1 pageSection Quantity Weight ChartRanjit Kumar ShahNo ratings yet

- Pile/Conductor stick-up calculations API RP2A specificationsDocument5 pagesPile/Conductor stick-up calculations API RP2A specificationsSamsul Imran BahromNo ratings yet

- Hdpe Pipe Specifications PDFDocument5 pagesHdpe Pipe Specifications PDFawanarifNo ratings yet

- Is 8422-1 - 1977 - 5Document1 pageIs 8422-1 - 1977 - 5Svapnesh ParikhNo ratings yet

- Pengukuran Log Kayu RinoDocument12 pagesPengukuran Log Kayu RinoRino ReynaldiNo ratings yet

- Is 8422-2 - 1977 - 6Document1 pageIs 8422-2 - 1977 - 6Svapnesh ParikhNo ratings yet

- Astm f436 Type 1Document1 pageAstm f436 Type 1seenudesignNo ratings yet

- (MM) (Nos) Total KG (MM) (Nos) Total KG KG / PC KG / PC: HMG / Ministry of Local DevelopmentDocument1 page(MM) (Nos) Total KG (MM) (Nos) Total KG KG / PC KG / PC: HMG / Ministry of Local DevelopmentRanjit Kumar ShahNo ratings yet

- Orca Share Media1641072467542 6883156814902028291Document1 pageOrca Share Media1641072467542 6883156814902028291Ernad GarićNo ratings yet

- Adobe Scan 12 Jan 2024Document2 pagesAdobe Scan 12 Jan 2024Vikrant BeraNo ratings yet

- Data For Call CenterDocument92 pagesData For Call CenterJoan HoyosNo ratings yet

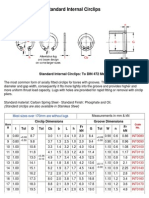

- Internal Circlip 240513 PDFDocument5 pagesInternal Circlip 240513 PDFReddy SadhanaNo ratings yet

- Experiment Number 1Document5 pagesExperiment Number 1haris shahNo ratings yet

- RESULT LAB 1 PcsDocument1 pageRESULT LAB 1 Pcsqasdinabatrisyia28No ratings yet

- Foot Valve Globe Style Model 302S6: MaterialDocument1 pageFoot Valve Globe Style Model 302S6: Materialmj5k2g7schNo ratings yet

- Cotton Baling PressDocument1 pageCotton Baling PressRadhakrishnan RbNo ratings yet

- E5 S2 16 MaletaDocument1 pageE5 S2 16 MaletaKay WhiteNo ratings yet

- Alfa Laval TJ TZ 89 Rotary Jet Head - Product Leaflet - Ese00327 PDFDocument4 pagesAlfa Laval TJ TZ 89 Rotary Jet Head - Product Leaflet - Ese00327 PDFVils ArabadzhievaNo ratings yet

- 167 Series IntensifiersDocument1 page167 Series IntensifiersLuis Eduardo Albarracin RugelesNo ratings yet

- Brushed Axial Fans: VA31-A101-46S Performance DiagramDocument3 pagesBrushed Axial Fans: VA31-A101-46S Performance DiagramJaskaran SinghNo ratings yet

- Rezultate ISADocument2 pagesRezultate ISAAdriana Boboc MinciuNo ratings yet

- Data Analysis Techniques For ManagersDocument14 pagesData Analysis Techniques For ManagersSajid hussain awanNo ratings yet

- IslmDocument10 pagesIslmBehzad KhanNo ratings yet

- TR Flex Fittings Sizes 4 36Document10 pagesTR Flex Fittings Sizes 4 36iytbwigxNo ratings yet

- Format Penilaian Keterampilan 2017Document14 pagesFormat Penilaian Keterampilan 2017stefanyNo ratings yet

- ISO 4017 Dimensions, Specifications, Standard, Weights, Equivalent & PDFDocument2 pagesISO 4017 Dimensions, Specifications, Standard, Weights, Equivalent & PDFsachin pukaleNo ratings yet

- Technical Guide H550-700XD SERIESDocument8 pagesTechnical Guide H550-700XD SERIESIvan ManuelNo ratings yet

- Flange Bolt Torque Sequence and Torque Table - A Complete Bolt Tightening ProcedureDocument16 pagesFlange Bolt Torque Sequence and Torque Table - A Complete Bolt Tightening Procedureal arabiNo ratings yet

- Flange Bolt Torque Sequence and Torque Table - A Complete Bolt Tightening ProcedureDocument34 pagesFlange Bolt Torque Sequence and Torque Table - A Complete Bolt Tightening ProcedureHoussemSoltanaNo ratings yet

- METRIC INTERNAL CIRCLIPSDocument5 pagesMETRIC INTERNAL CIRCLIPSJhonny BNo ratings yet

- Performance Data: Section: Date: December 2008Document26 pagesPerformance Data: Section: Date: December 2008cesar moraNo ratings yet

- API 6A Type 6B & 6BX FlangesDocument31 pagesAPI 6A Type 6B & 6BX FlangesEason NgNo ratings yet

- Marking Sample Tested Villus Height Crypt Depth RatioDocument1 pageMarking Sample Tested Villus Height Crypt Depth RatioMuhammad Ali TajNo ratings yet

- Spectacle Blind RF Class GuideDocument1 pageSpectacle Blind RF Class GuideFederico GonzálezNo ratings yet

- Heco Product Sheet 1272 Stainless Steel Welding Neck Flanges More Sealing Surfaces With TongueDocument3 pagesHeco Product Sheet 1272 Stainless Steel Welding Neck Flanges More Sealing Surfaces With TonguegabrielqueralesNo ratings yet

- REHOME CatalogueDocument36 pagesREHOME CatalogueNelson VielmaNo ratings yet

- Lembar Perhitungan Rangka Atap: Nama ProyekDocument53 pagesLembar Perhitungan Rangka Atap: Nama ProyekAknu HandokoNo ratings yet

- MU19 Pinos Elasticos Din 1481 Iso 8752 TecemDocument1 pageMU19 Pinos Elasticos Din 1481 Iso 8752 Tecemmugiwara ruffyNo ratings yet

- International Standard: Hexalobular Internal Driving Feature For Bolts and ScrewsDocument6 pagesInternational Standard: Hexalobular Internal Driving Feature For Bolts and ScrewsanhthoNo ratings yet

- Structure Design For Horizontal ElementsDocument14 pagesStructure Design For Horizontal ElementsesNo ratings yet

- Armaturi, conducte si accesorii pentru sistemul de apa interior si exteriorDocument14 pagesArmaturi, conducte si accesorii pentru sistemul de apa interior si exteriorDenis-Petru DemetercaNo ratings yet

- Anneke Bawole - Standard DeviationDocument3 pagesAnneke Bawole - Standard DeviationAnne BawoleNo ratings yet

- Series: (Steel) ISO 16028 InterchangeDocument10 pagesSeries: (Steel) ISO 16028 InterchangeRhdh kldmkNo ratings yet

- ZG Series Positive Displacement Blowers & Vacuum Pumps SpecsDocument12 pagesZG Series Positive Displacement Blowers & Vacuum Pumps SpecsRoberto SanchezNo ratings yet

- Flakiness and Elongation 2Document1 pageFlakiness and Elongation 2Aman ullahNo ratings yet

- UntitledDocument4 pagesUntitledkhaledNo ratings yet

- Cross Recessed Pan Head Cross Recessed Pan Head Machine Screws, Machine Screws, Steel Steel Type H Type H (Phillips) (Phillips)Document10 pagesCross Recessed Pan Head Cross Recessed Pan Head Machine Screws, Machine Screws, Steel Steel Type H Type H (Phillips) (Phillips)DHEERAJ413No ratings yet

- Fig. 7444 PDFDocument2 pagesFig. 7444 PDFDanielNo ratings yet

- Liquid Chromatography Separation Mechanisms Zhang SlidesDocument22 pagesLiquid Chromatography Separation Mechanisms Zhang SlidesMandu ManNo ratings yet

- Fanal FF4 Specifications PDFDocument5 pagesFanal FF4 Specifications PDFANDRE CHEZSANo ratings yet

- Apostila MATLABDocument52 pagesApostila MATLABJoão Rafael Lima AmaralNo ratings yet

- Modal Analysis: Design Project 4 Simon AmboiseDocument11 pagesModal Analysis: Design Project 4 Simon AmboiseSimon AmboiseNo ratings yet

- CFX Laboratories 4 and 5 (2nd Version) - Simon Amboise and Vianney KiekenDocument17 pagesCFX Laboratories 4 and 5 (2nd Version) - Simon Amboise and Vianney KiekenSimon AmboiseNo ratings yet

- Simulink - Simon AMBOISEDocument14 pagesSimulink - Simon AMBOISESimon AmboiseNo ratings yet

- Parametric Method: Design Project 2 Simon AmboiseDocument7 pagesParametric Method: Design Project 2 Simon AmboiseSimon AmboiseNo ratings yet

- Buckling Analysis of Axially Compressed Columns: Design Project 3 Simon AmboiseDocument8 pagesBuckling Analysis of Axially Compressed Columns: Design Project 3 Simon AmboiseSimon AmboiseNo ratings yet

- CDocument3 pagesCSimon AmboiseNo ratings yet

- Matlab 8 SemDocument2 pagesMatlab 8 SemSimon AmboiseNo ratings yet

- Data BaseDocument2 pagesData BaseSimon AmboiseNo ratings yet

- Pro EngineerDocument3 pagesPro EngineerSimon AmboiseNo ratings yet

- Ansys-7 SemDocument2 pagesAnsys-7 SemSimon AmboiseNo ratings yet

- Matlab 8 SemDocument2 pagesMatlab 8 SemSimon AmboiseNo ratings yet

- Drives of MachinesDocument2 pagesDrives of MachinesSimon AmboiseNo ratings yet

- Ansys-8 SemDocument3 pagesAnsys-8 SemSimon AmboiseNo ratings yet

- EneResaConv MDocument2 pagesEneResaConv MSimon AmboiseNo ratings yet

- Fluent and CFX TascflowDocument2 pagesFluent and CFX TascflowSimon AmboiseNo ratings yet

- Programming LanguageDocument2 pagesProgramming LanguageSimon AmboiseNo ratings yet

- Visual BasicDocument3 pagesVisual BasicSimon AmboiseNo ratings yet

- PE Handbook Errata SheetDocument8 pagesPE Handbook Errata SheetFrancis ReyesNo ratings yet

- G LIT API-650-Tanks PDFDocument2 pagesG LIT API-650-Tanks PDFAlexanderNo ratings yet

- Douglas FiltroDocument68 pagesDouglas Filtrodont replyNo ratings yet

- Lecture 1 - IntroductionDocument30 pagesLecture 1 - IntroductionNguyễn QuốcAnhNo ratings yet

- Jgeen 22 00051Document35 pagesJgeen 22 00051d_diasol38No ratings yet

- Manual de Partes - Torito 2T FL PDFDocument54 pagesManual de Partes - Torito 2T FL PDFJuan José Falcon PonceNo ratings yet

- Study Plan: From TO College/ Company Degree/ TitleDocument3 pagesStudy Plan: From TO College/ Company Degree/ TitleMugundan N ManiNo ratings yet

- 200aetl 2000Document0 pages200aetl 2000Ray Cepeda MenaNo ratings yet

- Standard Drawing 3906 Slip Form Concrete Barrier F Shape Installation and ConstructionDocument1 pageStandard Drawing 3906 Slip Form Concrete Barrier F Shape Installation and Constructiondannychacon27No ratings yet

- Limit Switches: FeaturesDocument2 pagesLimit Switches: FeaturesNoUserNameNo ratings yet

- Ata 52Document70 pagesAta 52Geovanni Riquelme LooNo ratings yet

- Numerical Calculation of Buried Pipeline Impacted by Rockfalls and LandslideDocument10 pagesNumerical Calculation of Buried Pipeline Impacted by Rockfalls and LandslideGholamhossein Tavakoli MehrjardiNo ratings yet

- Proof Squash BallsDocument8 pagesProof Squash BallsMarshNo ratings yet

- Kershaw 12-12BridgeCraneDocument3 pagesKershaw 12-12BridgeCranecamelia_pirjan5776No ratings yet

- Fluid Mechanics Report on Buoyancy Force ExperimentDocument9 pagesFluid Mechanics Report on Buoyancy Force ExperimentLenrd RajNo ratings yet

- Sumitomo HSMDocument68 pagesSumitomo HSMEdisson Yanqui VivancoNo ratings yet

- Cosfb - Composite Slim-Floor Beam: Experimental Test Campaign and EvaluationDocument15 pagesCosfb - Composite Slim-Floor Beam: Experimental Test Campaign and EvaluationDima OvsiiNo ratings yet

- Ec Axial Fan - Axiblade: Nominal DataDocument1 pageEc Axial Fan - Axiblade: Nominal DataAykut BacakNo ratings yet

- Factors To Be Considered While Selecting A Hydraulic PumpDocument2 pagesFactors To Be Considered While Selecting A Hydraulic PumpS. ThivyanNo ratings yet

- Metodo de FuerzaDocument37 pagesMetodo de FuerzaJheysson Raphael Lopez guevaraNo ratings yet