Professional Documents

Culture Documents

FPD 1420 e

Uploaded by

mealysrOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FPD 1420 e

Uploaded by

mealysrCopyright:

Available Formats

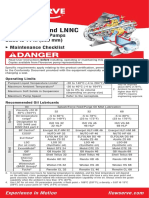

LNN, LNNV and LNNC

Axially Split Case Pumps

Sizes to 14 in (350 mm)

Maintenance Checklist

Read User Instructions before installing, operating or maintaining this pump.

Copies available from Flowserve pump representatives.

Specific requirements apply relating to the product certification, permit or conformity; refer

to the Conformity Document provided with the equipment especially when changing parts, e.g.,

changing a seal.

Operating Limits

1. Special construction

Pumped Liquid Temperature Limits1 -20 to 140C (-4 to 284F)

may be required

Maximum Ambient Temperature2 -20 to 40C (-4 to 104F) above 80C (176F).

Up to 3% by volume 2. Ambient temperature

Maximum Soft Solids in Suspension higher than 40C

(depending on pump size)

(104F) requires

Maximum Pump Speed Refer to the nameplate. engineering approval.

Recommended Oil Lubricants

Oil Splash/Force Feed/Purge Oil Mist Lubrication

Viscosity cSt @

32 32 68

Specification

40C (104F)

Oil temperature -5 to 65C -5 to 78C -5 to 80C

range3 (23 to 149F) (23 to 172F) (23 to 176F)

Designation to

ISO VG 32 ISO VG 46 ISO VG 68

ISO 3448 and

32 HLP 46 HLP 68 HLP

DIN51524 part 2

BP Castrol4 Energol HLP-HM 32 Energol HLP-HM 46 Energol HLP-HM 68

ESSO4 NUTO HP 32 NUTO HP 46 NUTO HP 68

ELFOLNA DS 32 ELFOLNA DS 46 ELFOLNA DS 68

ELF/Total4

Azolla ZS 32 Azolla ZS 46 Azolla ZS 68

LSC LSO 32 LSO 46 LSO 68

(for oil mist) (Synthetic oil) (Synthetic oil) (Synthetic oil)

ExxonMobil4 Mobil DTE 24 Mobil DTE 25 Mobil DTE 26

Brand

Q84 Q8 Haydn 32 Q8 Haydn 46 Q8 Haydn 68

Shell4 Shell Tellus 32 Shell Tellus 46 Shell Tellus 68

Chevron

Rando HD 32 Rando HD 46 Rando HD 68

Texaco4

Wintershall

Wiolan HS 32 Wiolan HS 46 Wiolan HS 68

(BASF Group)4

Fuchs4 Renolin CL 32 Renolin CL 46 Renolin CL 68

3. It normally takes two hours for bearing temperature to stabilize, and the final temperature will depend

on the ambient, r/min, pumpage temperature and pump size. Some oils have a very low pour point and

good viscosity index which extend the minimum temperature capability of the oil. Always check the grade

capability when the ambient is less than -5C (23F).

4. Use LSC for oil mist. Oil parameters provide: a flash point > 166C (331F); a density > 0.87 @ 15C

(59F); and a pour point of -10C (14F) or lower.

Experience In Motion flowserve.com

LNN, LNNV and LNNC

Maintenance Checklist

Oil Lubricated Bearings

Pumping Liquid Max. Bearing/Oil

Temperature Limit 5 Temperature Rise6

80C (176F) 40C (104F)

110C (230F) 50C (122F)

140C (284F) 60C (140F)

5. Maximum ambient of 40C (104F).

6. A continuously rising temperature, or an abrupt rise, indicates a fault.

Recommended Grease Lubricants 7

Grease Grade NLGI 2 8 NLGI 3 9

Temperature range C (F) -20 to 100 (-4 to 212) -20 to 100 (-4 to 212)

Designation Acc. to DIN KP2K-25 KP3K-20

BP Energrease LS-EP2 Energrease LS-EP3

Elf Multis EP2 Multis EP3

Fuchs RENOLIT EP2 RENOLIT EP3

Esso Beacon EP2 Beacon EP3

Mobil Mobilux EP2 Mobilux EP3

Q8 Rembrandt EP2 Rembrandt EP3

Shell Alvania EP2 Alvania EP2

Texaco Multifak EP2 Multifak EP3

SKF LGEP 2 N/A

7. For most operating conditions, high-quality grease having a lithium soap base and NLGI

consistency of No. 2 or No. 3 is recommended. The drop point should exceed 175C (350F).

8. NLGI 2 is an alternative grease and is not to be mixed with other grades.

9. Standard pre-packed grease for fitted antifriction bearings

Relubrication Intervals

Regreasing Via Grease Nipples 2000 hours (depends on severity of application)

Grease Change 4000 hours (depends on severity of application)

Oil Change 4000 hours or at least every 6 months 10

10. Oil levels need not be checked if pump is supplied with a constant level oiler, but regular checks need

to be made on those pumps that are fitted with a sight glass.

Recommended Fill Quantities11

Size Top-up Grease, g (oz) Oil

(LNN, LNNV Single Row Angular Contact (Both Types of Bearings),

and LNNC) Ball Bearing Thrust Bearing Double L (fl oz)

200-LNN-300

200-LNN-325 8 (0.28) 16 (0.56) 0.37 (12.5)

200-LNN-375

200-LNN-400

200-LNN-475

200-LNN-500

12 (0.42) 24 (0.84) 0.48 (16.2)

250-LNN-325

250-LNN-375

300-LNN-325

200-LNN-525

200-LNN-600

250-LNN-475

250-LNN-600

15 (0.53) 30 (1.06) 0.60 (20.3)

300-LNN-475

300-LNN-500

300-LNN-575

350-LNN-375

300-LNN-600

300-LNN-625

350-LNN-475 21 (0.74) 42 (1.48) 0.68 (23.0)

350-LNN-575

350-LNN-725

300-LNN-750

34 (1.2) 68 (2.4) 2.00 (67.6)

350-LNN-900

11. Where the pump is lubricated by oil mist, the amount of oil mist supplied (m /h) is normally calculated to

3

be at least the bearing bore diameter (mm) times the number of bearing rows divided by 25. The oil mist

should consist of at least 0.025 0.04% oil content. The pressure in the bearing housing must not exceed

0.01 bar (0.15 psi).

Vibration Velocity12

RMS,

Vibration Velocity Unfiltered mm/s (in/s)

Horizontal Pumps Vertical Pumps

Normal N 5.6 (0.22) 7.1 (0.28)

Alarm N x 1.25 7.1 (0.28) 9.0 (0.35)

Shutdown trip N x 2.0 11.2 (0.44) 14.2 (0.56)

12. Normal vibration level can be lower depending on sizes and applications. Alarm (1.25) and shutdown trip (2.0)

multiplier remain the same.

Stop/Start Frequency Recommended Torques

Motor Rating, Max. Stop/Starts Torque, Nm (lb-ft)

kW (hp) Per Hour Bolt Size,

in Pump Feet All Other

Up to 15 (20) 15 Fasteners Fasteners

M 16 (5/8) 170 (125) 84 (62)

15 (20)

10 M 20 () 340 (250) 165 (120)

to 90 (120)

M 24 (7/8) 590 (435) 285 (210)

90 (120) M 27 (1) 770 (570) 375 (275)

6

to 150 (200)

M 30 (11/8) 1100 (810) 540 (400)

Above 150 (200) Refer M 36 (13/8) 1840 (1350) 900 (660)

M 42 (15/8) 2000 (1475) 1410 (1040)

M 48 (17/8) 2240 (1650) 2060 (1500)

Impeller Clearance Settings13, 14, 15, 16 Bearing Specifications

Mean Radial Angular

Nominal Wear Size

Wear Ring Contact

Size Ring Diameter, (LNN, Single Row

Clearance, Thrust

mm (in) LNNV 17, 18 Ball Bearing

mm (in) Bearing

and LNNC)

200-LNN-300 215 (8.5) (Heavy Duty)

200-LNN-325 240 (9.5) 200-LNN-300

200-LNN-375 215 (8.5) 200-LNN-325 6209 7209

200-LNN-400 200-LNN-375

240 (9.5)

200-LNN-475 200-LNN-400

200-LNN-500 215 (8.5) 200-LNN-475

200-LNN-525 200-LNN-500

6212 7212

200-LNN-600 240 (9.5) 250-LNN-325

250-LNN-325 250-LNN-375

250-LNN-375 300-LNN-325

250-LNN-475 264 (10.4) 200-LNN-525

250-LNN-600 200-LNN-600

0.3 (0.012)

300-LNN-325 300 (11.8) 250-LNN-475

300-LNN-475 330 (13.0) 250-LNN-600

300-LNN-500 300 (11.8) 6214 7214

300-LNN-475

300-LNN-575 350 (13.8) 300-LNN-500

300-LNN-600 300 (11.8) 300-LNN-575

300-LNN-625

350-LNN-375

300-LNN-750 330 (13.0)

300-LNN-600

350-LNN-375

300-LNN-625

350-LNN-475

350-LNN-475 6217 7217

350-LNN-575

380 (15.0) 350-LNN-575

350-LNN-725

350-LNN-725

350-LNN-900

300-LNN-750

13. Replace rings when radial clearances double to 6221 7221

0.6 mm (0.024 in), depending on pump size. 350-LNN-900

14. The above clearances are typically applicable for 17. LNNV pumps are supplied with a pair of double

CI/DCI casing and bronze impeller construction angular contact thrust bearings at upper bearing

(typically a non-galling combination). location and product lubricated sleeve bearings at

15. Clearances for non-metallic wear rings are smaller, the bottom.

typically 50 65% of those for the standard metal- 18. On LNNV, it is recommended that the bottom lubri-

lic rings shown above. cated bearing is renewed at a diametrical clearance

16. Clearances for SS/duplex/super duplex casing and of 0.5 mm (0.02 in).

impeller construction (typically a galling combination)

are wider, typically 50 65% more than those for

the standard metallic rings shown above.

Alignment

Align the pump and motor shaft to within 0.05 to 0.10 mm (0.002 to 0.004 in) TIR in parallel and

0.05 mm (0.002 in) per 100 mm (4 in) of coupling flange diameter as TIR angular misalignment.

For sales and product information, go to www.flowserve.com.

FPD-1420b (E) June 2012. 2012 Flowserve Corporation

LNN pumps are manufactured in: Arnage (France), Newark (U.K.), Taneytown, MD (USA), Rio de Janeiro (Brazil),

and Coimbatore (India).

USA and Canada Europe, Middle East, Africa Latin America Asia Pacific

Flowserve Corporation Flowserve Corporation Flowserve Corporation Flowserve Pte. Ltd.

5215 North OConnor Blvd. Parallelweg 13 Martn Rodriguez 4460 10 Tuas Loop

Suite 2300 4878 AH Etten-Leur B1644CGN-Victoria-San Fernando Singapore 637345

Irving, Texas 75039-5421 USA The Netherlands Buenos Aires, Argentina Telephone: +65 6771 0600

Telephone: +1 937 890 5839 Telephone: +31 76 502 8100 Telephone: +54 11 4006 8700 Telefax: +65 6779 2329

Telefax: +54 11 4714 1610

Experience In Motion flowserve.com

You might also like

- EchoDocument38 pagesEchomealysrNo ratings yet

- Control of Galloping Vibrations On High Voltage Overhead LinesDocument3 pagesControl of Galloping Vibrations On High Voltage Overhead LinesmealysrNo ratings yet

- Ms 341361 Shop ManualDocument110 pagesMs 341361 Shop ManualmealysrNo ratings yet

- Spare Parts List: Chain Saws 372 XP From 2018-04Document38 pagesSpare Parts List: Chain Saws 372 XP From 2018-04Vladut MariusNo ratings yet

- An Overview of Fertilization and Irrigation ManageDocument7 pagesAn Overview of Fertilization and Irrigation ManagemealysrNo ratings yet

- Chainsaw Test DataDocument1 pageChainsaw Test DatamealysrNo ratings yet

- CS-315 Service DataDocument4 pagesCS-315 Service DatamealysrNo ratings yet

- Chain Saw Comparison ChartDocument1 pageChain Saw Comparison ChartmealysrNo ratings yet

- Pump Sizing CalculationDocument12 pagesPump Sizing CalculationLee Min Hyuk100% (3)

- AKE40 ManualDocument17 pagesAKE40 ManualBand Dvesto Plus CrepajaNo ratings yet

- Application IEC 60287Document117 pagesApplication IEC 60287roxi50100% (1)

- Chainsaw SpecsDocument3 pagesChainsaw SpecsmealysrNo ratings yet

- Bosch Electrical SawsDocument337 pagesBosch Electrical SawsmealysrNo ratings yet

- Trident FUSED OIL RMU up to 15.5kVDocument4 pagesTrident FUSED OIL RMU up to 15.5kVmealysrNo ratings yet

- Router Guide Cutters and Collets PDFDocument59 pagesRouter Guide Cutters and Collets PDFmealysrNo ratings yet

- Pump Life Cycle CostDocument19 pagesPump Life Cycle CostSAMEER100% (3)

- Woodworking GuideDocument4 pagesWoodworking GuideDraganNo ratings yet

- WEG HGF Low and High Voltage High Performance Electric Motor Range Broa017 Brochure EnglishDocument40 pagesWEG HGF Low and High Voltage High Performance Electric Motor Range Broa017 Brochure EnglishHatem AbdelrahmanNo ratings yet

- SR StreetlightsDocument48 pagesSR StreetlightsmealysrNo ratings yet

- Electrical Method Statement Guidance Note SA GN 8 (V1) Jan 2014Document7 pagesElectrical Method Statement Guidance Note SA GN 8 (V1) Jan 2014Adnan KhanNo ratings yet

- AC Interference On Pipeline ThesisDocument133 pagesAC Interference On Pipeline ThesisMn HjhjjNo ratings yet

- FPD 1420 eDocument4 pagesFPD 1420 emealysrNo ratings yet

- Medium Voltage SwitchgearDocument6 pagesMedium Voltage Switchgearmealysr100% (2)

- Magnetic Flowmeter Material Selection Guide: Technical Data Sheet TDS 3033 June 1993Document27 pagesMagnetic Flowmeter Material Selection Guide: Technical Data Sheet TDS 3033 June 1993mealysrNo ratings yet

- Siemens Lining Material Water WP PDFDocument4 pagesSiemens Lining Material Water WP PDFJorgeNo ratings yet

- Galvanic Corrossion & The Prevention.Document27 pagesGalvanic Corrossion & The Prevention.Jayakrishnan RadhakrishnanNo ratings yet

- Id 465Document180 pagesId 465mealysrNo ratings yet

- Rodenticides and fungicides for apple orchardsDocument8 pagesRodenticides and fungicides for apple orchardsmealysrNo ratings yet

- Transformer Fire Protection: Facilities Instructions, Standards, and Techniques Volume 3-32Document43 pagesTransformer Fire Protection: Facilities Instructions, Standards, and Techniques Volume 3-32GualaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Directional Soil Improvement Tech for Underground ProjectsDocument38 pagesDirectional Soil Improvement Tech for Underground ProjectsVanDuongNguyenNo ratings yet

- BeneFusion VP5 (New) Full-Press Operator's Manual V3.0 enDocument104 pagesBeneFusion VP5 (New) Full-Press Operator's Manual V3.0 enJairo Alberto Sarria Vargas100% (1)

- Close-Coupled Centrifugal PumpsDocument12 pagesClose-Coupled Centrifugal PumpsIan RidzuanNo ratings yet

- DAB PUMPS S.p.A. Data Sheet for 1 NKV 20/8 S T E1 IE3 PumpDocument3 pagesDAB PUMPS S.p.A. Data Sheet for 1 NKV 20/8 S T E1 IE3 PumpAan AndianaNo ratings yet

- P100S Pressurised Water Temperature Control UnitDocument2 pagesP100S Pressurised Water Temperature Control Unitweb312_twNo ratings yet

- NLB 225 Series F PumpDocument2 pagesNLB 225 Series F Pumpjromero_rpgNo ratings yet

- High Pressure Grease Pumps for Long Distance DistributionDocument4 pagesHigh Pressure Grease Pumps for Long Distance DistributionSIVARAMANJAGANATHANNo ratings yet

- Reliable Hot Water Piping SystemDocument6 pagesReliable Hot Water Piping SystemAzher ANo ratings yet

- Pages From Grundfosliterature-3065923 5Document1 pagePages From Grundfosliterature-3065923 5selmir_9No ratings yet

- Fdocuments - in Is 6595-2-1993 Horizontal Centrifugal Pumps For Clear Cold 2018 11 15 FromDocument10 pagesFdocuments - in Is 6595-2-1993 Horizontal Centrifugal Pumps For Clear Cold 2018 11 15 FromAnupmaNo ratings yet

- D628 Maintenance ScheduleDocument3 pagesD628 Maintenance ScheduleDPNo ratings yet

- PG 6 - 14 Basis of Support StandardDocument10 pagesPG 6 - 14 Basis of Support StandardPankaj SahuNo ratings yet

- Brosura Volvo Ec140eDocument32 pagesBrosura Volvo Ec140ePirliteanuStefanAlexandruNo ratings yet

- Mobile Mixing Plants: M1 / M1.25 / M2.25 / M2.5 / M3Document12 pagesMobile Mixing Plants: M1 / M1.25 / M2.25 / M2.5 / M3Omprakash singh100% (1)

- F3521GLDocument2 pagesF3521GLRose Marie100% (1)

- Lorentz Ps2 PoolDocument4 pagesLorentz Ps2 PoolSINES FranceNo ratings yet

- Mechanical Seal UnderstandingDocument14 pagesMechanical Seal UnderstandingGanesh.MahendraNo ratings yet

- American Hudson 127mm-2015Document17 pagesAmerican Hudson 127mm-2015ing aprNo ratings yet

- Compressor Lubrication Best PracticesDocument22 pagesCompressor Lubrication Best Practicesengrsurif100% (1)

- Manual ADocument98 pagesManual ATri MaizonNo ratings yet

- 4.3 Cargo Transfer Procedure and Operational Considerations Before Cargo OperationsDocument13 pages4.3 Cargo Transfer Procedure and Operational Considerations Before Cargo OperationsHasan Cosalev100% (1)

- Astm D 3370 PDFDocument11 pagesAstm D 3370 PDFmilidarksNo ratings yet

- Practical Rotordynamics For Centrifugal PumpsDocument52 pagesPractical Rotordynamics For Centrifugal PumpsRavi Shankar100% (1)

- Hid Chapter 3 Lect. EDocument34 pagesHid Chapter 3 Lect. Eahmed jemalNo ratings yet

- Workshop Manual for 50cc 6-Speed DERBI EngineDocument71 pagesWorkshop Manual for 50cc 6-Speed DERBI EngineHellbent BikersNo ratings yet

- At Alo GueDocument40 pagesAt Alo GueSK100% (1)

- ASME - Performance Test CodesDocument1 pageASME - Performance Test CodesanoopkntpcNo ratings yet

- Equpment Assignment (Final Edited)Document58 pagesEqupment Assignment (Final Edited)Abdulbasit Aba BiyaNo ratings yet

- FPD 1420 eDocument4 pagesFPD 1420 emealysrNo ratings yet

- Machine Profiles: 789, 789B and 789C Construction and Mining TrucksDocument8 pagesMachine Profiles: 789, 789B and 789C Construction and Mining TrucksJavier Pagan TorresNo ratings yet