Professional Documents

Culture Documents

FormmasterV Inno E

Uploaded by

Dado OgameCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FormmasterV Inno E

Uploaded by

Dado OgameCopyright:

Available Formats

INNOTOOL INNOTOOL

Florianstrae 17 71665 Vaihingen-Horrheim Germany Florianstrae 17 71665 Vaihingen-Horrheim Germany

Phone: +49-(0)7042-8316-0 Fax: +49-(0)7042-8316-26 Phone: +49-(0)7042-8316-0 Fax: +49-(0)7042-8316-26

E-mail: info@innotool.de E-mail: info@innotool.de

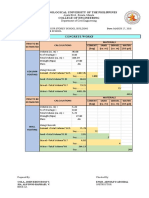

KC...Cutter Cutting Data KC...Cutter Tips & Ramping Angle

Recommended Cutting Values for CNHU06: At larger diameters cutting up and

down can be faster than Z-constant

cutting speed vc feed per tooth depth of cut width of cut

[m/min] machining.

ISO material fz ap ae

[mm] [mm] [mm]

semi-finish. finishing Especially on 90 shoulders.

unalloyed steel 200 - 250 300 - 500 0.1 - 0.3 0.3 - 0.8 0.1 x Dc

P alloyed steel <1100 N/mm2 180 - 250 300 - 450 0.1 - 0.3 0.3 - 0.8 0.1 x Dc

alloyed steel <1400 N/mm 2

180 - 220 250 - 400 0.1 - 0.3 0.3 - 0.8 0.1 x Dc Depending on the tool diameter,

ae can be selected greater than ap.

M stainless steel 100 - 180 200 - 250 0.1 - 0.25 0.2 - 0.6 0.1 x Dc

grey cast iron 220 - 280 300 - 600 0.15 - 0.3 0.3 - 0.8 0.1 x Dc

K cast iron 180 - 250 250 - 450 0.1 - 0.3 0.3 - 0.8 0.1 x Dc

Substrates / coatings:

N aluminum 500 - 1000 800 - 1500 0.1 - 0.15 0.3 - 0.8 0.1 x Dc

available

S super alloys 40 - 100 50 - 150 0.1 - 0.2 0.2 - 0.6 0.1 x Dc

coatings

application range

H hardened steel > 56 HRC 120 - 160 80 - 200 0.08 - 0.15 0.2 - 0.4 0.1 x Dc

IN 2005 general machining of high alloyed steel and tool steel (see respective cutting data)

Stock for finishing: 0.2 - 0.3 mm

IN 1030 general machining of unalloyed steel Vc = 80 % of stated values / wet machining

IN 05S for machining aluminum and plastics

IN 3005 for machining graphite (diamond coating on request)

Recommended Cutting Values for CNHU11:

cutting speed Vc feed per tooth depth of cut width of cut

ISO material [m/min] fz ap ae Ramping angles of Ramping angles of

semi-finish. finishing

[mm] [mm] [mm] CNHU06: CNHU11:

unalloyed steel 200 - 250 300 - 500 0.15 - 0.3 0.3 - 1 0.1 x Dc no. of inserts ramp. angle no. of inserts ramp. angle

tool tool

z max. z max.

P alloyed steel <1100 N/mm2 180 - 250 300 - 450 0.15 - 0.3 0.3 - 1 0.1 x Dc

alloyed steel <1400 N/mm2 180 - 220 250 - 450 0.15 - 0.3 0.3 - 1 0.1 x Dc 16 / R1 2 5 25 / R2 2 3

20 / R1 3 4 35 / R2 3 2

M stainless steel 100 - 180 200 - 250 0.1 - 0.25 0.3 - 0.8 0.1 x Dc

25 / R1 3 2 42 / R2 4 1,5

grey cast iron 220 - 280 300 - 600 0.15 - 0.3 0.3 - 1 0.1 x Dc

K cast iron 180 - 250 250 - 450 0.12 - 0.3 0.3 - 1 0.1 x Dc

35 / R1 4 1,5 52 / R2 5 1

42 / R1 5 1 66 / R2 6 0,8

N Aluminum 500 - 1000 800 - 1500 0.12 - 0.15 0.3 - 1 0.1 x Dc

80 / R2 7 0,6

S super alloys 40 - 100 50 - 150 0.12 - 0.2 0.3 - 0.8 0.1 x Dc Corner radius for CNHU06: 1 mm

100 / R2 8 0,5

H hardened steel up to 56 HRC 120 - 160 80 - 200 0.1 - 0.15 0.3 - 0.5 0.1 x Dc

Stock for finishing: 0.2 - 0.5 mm Corner radius for CNHU11: 2 mm

Order-No.: 7850330

You might also like

- Hydraulic ControlsDocument1 pageHydraulic ControlsDado OgameNo ratings yet

- Mjenjac Part ListDocument8 pagesMjenjac Part ListDado OgameNo ratings yet

- ZF Servocom EDocument4 pagesZF Servocom EAzizi AbdullahNo ratings yet

- Transmission Hydraulic SystemDocument1 pageTransmission Hydraulic SystemDado OgameNo ratings yet

- Group 13 Eppr ValveDocument5 pagesGroup 13 Eppr ValveDado OgameNo ratings yet

- Group 2 Hydraulic and Mechanical SystemDocument20 pagesGroup 2 Hydraulic and Mechanical Systemdeniden2013No ratings yet

- Group 4 Single OperationDocument10 pagesGroup 4 Single OperationDado OgameNo ratings yet

- Grupo 5 Operacion CombinadaDocument9 pagesGrupo 5 Operacion CombinadaJuan Pablo Leon RualesNo ratings yet

- Group 2 hydraulic and mechanical troubleshootingDocument20 pagesGroup 2 hydraulic and mechanical troubleshootinglevinton jose tobias genesNo ratings yet

- Ar Ar: Er-Softw Er-SoftwDocument65 pagesAr Ar: Er-Softw Er-SoftwDado OgameNo ratings yet

- Group 3 Pilot CircuitDocument8 pagesGroup 3 Pilot CircuitDado OgameNo ratings yet

- Hyundai Excavator CodesDocument13 pagesHyundai Excavator CodesPMV Dept94% (31)

- Group 11 Eppr ValveDocument3 pagesGroup 11 Eppr ValveDado OgameNo ratings yet

- HyundaiDocument10 pagesHyundainajafaliNo ratings yet

- Section 7 Maintenance StandardDocument21 pagesSection 7 Maintenance StandardDado OgameNo ratings yet

- Group 5 Combined Operation: 1. OutlineDocument9 pagesGroup 5 Combined Operation: 1. OutlineDado OgameNo ratings yet

- CETOP 5 NG10 Flow Control Module SpecsDocument1 pageCETOP 5 NG10 Flow Control Module SpecsDado OgameNo ratings yet

- Group 12 Monitoring System: 1. OutlineDocument14 pagesGroup 12 Monitoring System: 1. OutlineDado OgameNo ratings yet

- Section 3 Hydraulic SystemDocument2 pagesSection 3 Hydraulic SystemdanielNo ratings yet

- Group 9 Self-Diagnostic System: Outline 1Document3 pagesGroup 9 Self-Diagnostic System: Outline 1giapy0000No ratings yet

- Group 3 Pilot Circuit: RCV Pedal Remote Control Valve (LH Lever) Remote Control Valve (RH Lever)Document8 pagesGroup 3 Pilot Circuit: RCV Pedal Remote Control Valve (LH Lever) Remote Control Valve (RH Lever)Dado OgameNo ratings yet

- Cetop 5 / Ng10 Relief Valve Module: O-Rings 5 X - 111Document1 pageCetop 5 / Ng10 Relief Valve Module: O-Rings 5 X - 111Dado OgameNo ratings yet

- Cetop 5 / Ng10 Flow Control Module: O-Rings 5 X - 111Document1 pageCetop 5 / Ng10 Flow Control Module: O-Rings 5 X - 111Dado OgameNo ratings yet

- 3-2 Main CircuitDocument3 pages3-2 Main Circuitibnu malkanNo ratings yet

- 2 1Document21 pages2 1المهندسوليدالطويلNo ratings yet

- CETOP5/NG10 to CETOP3/NG6 Interface AdaptersDocument1 pageCETOP5/NG10 to CETOP3/NG6 Interface AdaptersDado OgameNo ratings yet

- Auxiliary Ecomat Cooling For Service RequirementsDocument1 pageAuxiliary Ecomat Cooling For Service RequirementsDado OgameNo ratings yet

- 272 Cetop 5 ng1 Shuttle ModuleDocument1 page272 Cetop 5 ng1 Shuttle ModuleDado OgameNo ratings yet

- 243 Cetop 5 ng1 Single Station ManifoldsDocument1 page243 Cetop 5 ng1 Single Station ManifoldsDado OgameNo ratings yet

- 251 Cetop 5 ng1 Cover and Crossover PlatesDocument1 page251 Cetop 5 ng1 Cover and Crossover PlatesDado OgameNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 2 Concrete Works CompuDocument14 pages2 Concrete Works CompuALFONSO RAPHAEL SIANo ratings yet

- Functional Gage DesignDocument32 pagesFunctional Gage DesignnaveedsidhuNo ratings yet

- IB MYP Chemistry Term End AssessmentDocument2 pagesIB MYP Chemistry Term End AssessmentKrishna Teja67% (3)

- R. L. Carlin Magnetochemistry 1986Document337 pagesR. L. Carlin Magnetochemistry 1986Surender Malik100% (1)

- Smaw 12 Module 1Document7 pagesSmaw 12 Module 1Francis Rico Mutia RufonNo ratings yet

- Pow Template Project 2020Document7 pagesPow Template Project 2020EdgarNo ratings yet

- OPGWDocument74 pagesOPGWAnonymous 3y4Z5cUNo ratings yet

- Tt3ultra PDFDocument7 pagesTt3ultra PDFMokni skanderNo ratings yet

- Lined Pipes and FittingsDocument6 pagesLined Pipes and Fittingspanait trofinNo ratings yet

- Chemistry: Pearson EdexcelDocument28 pagesChemistry: Pearson EdexcelThuvarakaNo ratings yet

- Curriculum Vitae: I Personal DataDocument10 pagesCurriculum Vitae: I Personal DataRachmat SirojudinNo ratings yet

- Surfactant FloodingDocument10 pagesSurfactant FloodinghkaqlqNo ratings yet

- System Sub Channel System For MarbleDocument4 pagesSystem Sub Channel System For MarbleWafaa abd elhamedNo ratings yet

- Mineral Dressing PDFDocument40 pagesMineral Dressing PDFArijit MondalNo ratings yet

- Aluminum-Clad Steel Stranded Conductor For Earth WireDocument14 pagesAluminum-Clad Steel Stranded Conductor For Earth WireMohamed AhmiedNo ratings yet

- Principles of A Permanent-Magnet Axial-Field D.CDocument6 pagesPrinciples of A Permanent-Magnet Axial-Field D.CHoang Hoang LeNo ratings yet

- Champion Lubricants Storage HandlingDocument6 pagesChampion Lubricants Storage HandlingIonut SomneaNo ratings yet

- Elementary Solid State Physics Omar PDF Free Halaman 15 46Document32 pagesElementary Solid State Physics Omar PDF Free Halaman 15 46Ihsania Ikrima KinantiNo ratings yet

- Schedule of Rates For Building Works in Sarawak 2018 PDFDocument56 pagesSchedule of Rates For Building Works in Sarawak 2018 PDFHayatoNo ratings yet

- Nexans MV Cables UK Brochure - 1Document48 pagesNexans MV Cables UK Brochure - 1Ra'fat HerzallahNo ratings yet

- Isocure: Concrete Curing AgentDocument1 pageIsocure: Concrete Curing AgentshafiullahNo ratings yet

- Gove Operations Process Flow Single PageDocument4 pagesGove Operations Process Flow Single PageMayke Cezar WippelNo ratings yet

- Life Estimation of Distribution Transformers Considering Axial Fatigue in Loose Winding ConductorsDocument16 pagesLife Estimation of Distribution Transformers Considering Axial Fatigue in Loose Winding ConductorsVictor MartinNo ratings yet

- Chemicalengineeringmagzinenov2012 PDFDocument77 pagesChemicalengineeringmagzinenov2012 PDF施君儒No ratings yet

- Environmental Health and Vessel Sanitation Preventive Procedure Instruction #11Document1 pageEnvironmental Health and Vessel Sanitation Preventive Procedure Instruction #11VizitiuAnisoaraNo ratings yet

- Magnetoplastic Effect in Nonmagnetic MaterialsDocument8 pagesMagnetoplastic Effect in Nonmagnetic MaterialsSeindahNyaNo ratings yet

- Item 510-1Document2 pagesItem 510-1Engineer LeeNo ratings yet

- 21.coordination Compound, D & F Block Transition ElementsDocument21 pages21.coordination Compound, D & F Block Transition ElementsQwerty100% (1)

- DR. L.R. KADIYALI & MR. S.C. SHARMA Presentation - IAHE-08112014-PART 1Document46 pagesDR. L.R. KADIYALI & MR. S.C. SHARMA Presentation - IAHE-08112014-PART 1Binayak KumarNo ratings yet

- From Internet: Pipe Burst Working Pressure Calculator Barlow's FormulaDocument5 pagesFrom Internet: Pipe Burst Working Pressure Calculator Barlow's FormulaDipakNo ratings yet