Professional Documents

Culture Documents

METRIC - 5.500 HWDP With 5.5FH DSTJ (7.000 X 3.500 TJ) Integral Conventional

Uploaded by

arun sidhuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

METRIC - 5.500 HWDP With 5.5FH DSTJ (7.000 X 3.500 TJ) Integral Conventional

Uploaded by

arun sidhuCopyright:

Available Formats

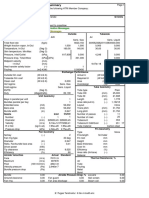

Heavy Weight Drill Pipe Performance Characteristics - METRIC Pipe Size and Weight: 5.500" X 3.

500" Heavy Weight

Workstrings International 2011 Version 1.0 Pipe Grade: 758 MPa Integral Heavy Weight

Range: 2

Tool Joint: 7.000" X 3.500" 5-1/2" FH DSTJ

Pipe Body

New New

(Nominal) (Nominal)

OD (mm) 139.7 Cross Sectional Area of Pipe Body (cm2) 91.21

Wall Thickness (mm) 25.40 Cross Sectional Area of OD (cm2) 153.28

ID (mm) 88.9 Cross Sectional Area of ID (cm2) 62.07

Calculated Plain End Weight (kg/m) 71.52 Section Modulus (cm3) 223.77

Polar Section Modulus (cm3) 447.54

Tensile Strength (kN) 6,920

Torsional Strength (N-m) 195,800

80% Torsional Strength (N-m) 156,600

Burst Pressure (MPa) 241.32

Collapse Pressure (MPa) 225.64

Tool Joint 758 MPa Material Yield Strength Drill Pipe Assembly with

5-1/2" FH DSTJ 5-1/2" FH DSTJ Connection

OD (mm) 177.8

ID (mm) 88.9

Pin Tong Length (mm) 609.6 Adjusted Weight (kg/m) 82.77

Box Tong Length (mm) 609.6 Approximate Length (m) 9.45

Torsional Strength (N-m) 115,500 Fluid Displacement (liters/m) 10.432

Max Recommended Make-up Torque (N-m) 60,900 Fluid Capacity (liters/m) 6.210

Min Recommended Make-up Torque (N-m) 40,800 Fluid Capacity (bls/m) 0.03906

Tensile Strength (kN) 6,602 Drift Size (mm) 85.73

Tool Joint/Drill Pipe Torsional Ratio (New Pipe) 0.59

Balance OD (mm) 164.6

Note: Minimum make-up is based on shoulder separation caused by bending

The technical information contained herein, including the product performance sheet and other attached documents, has been extracted from information available from the manufacturer and is for reference only and not a recommendation. The user is fully responsible for the accuracy

and suitability of use of the technical information. Workstrings International cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated based on uniform OD and wall

thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable operation limits. It is the responsibility of the customer and the end

user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per

Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

JCT 03-21-2011

You might also like

- Complete Resonance MathematicsDocument701 pagesComplete Resonance MathematicsRajendra Bisoi100% (6)

- Drill Collar, 4.5 IF (6.500 X 2.813) 110,000 (Psi)Document1 pageDrill Collar, 4.5 IF (6.500 X 2.813) 110,000 (Psi)juan moralesNo ratings yet

- BPOSDAGDocument27 pagesBPOSDAGIndustry Standard Structural DesignNo ratings yet

- DESIGN CODE IS:800-2007 SPLICE PLATEDocument2 pagesDESIGN CODE IS:800-2007 SPLICE PLATEmaheshbandhamNo ratings yet

- Base Plate Andf Anchor Bolt Design For Minor Axis MomentDocument2 pagesBase Plate Andf Anchor Bolt Design For Minor Axis MomentSunil Pulikkal100% (1)

- Volant Specs CRTi2-5.5 PDFDocument5 pagesVolant Specs CRTi2-5.5 PDFRaymond ChuNo ratings yet

- McosdagDocument25 pagesMcosdagIndustry Standard Structural DesignNo ratings yet

- System Information Idler Set DataDocument98 pagesSystem Information Idler Set DataHasan arif KısaalioğluNo ratings yet

- Output Summary for Air-Cooled Heat ExchangerDocument7 pagesOutput Summary for Air-Cooled Heat ExchangerVu TranNo ratings yet

- Especificaciones de Tuberia Pesada HW 5 1/2 F.HDocument1 pageEspecificaciones de Tuberia Pesada HW 5 1/2 F.HAlberto Cárdenas100% (1)

- Basic Weights Calc - ACHEDocument6 pagesBasic Weights Calc - ACHESiva ShankarNo ratings yet

- Design of Two Way Slab: Project Detail: Slab IdDocument6 pagesDesign of Two Way Slab: Project Detail: Slab Idmaheshu78No ratings yet

- m-3 ReportDocument72 pagesm-3 ReportHasan arif KısaalioğluNo ratings yet

- Hasen Design Summary 20 MetreDocument2 pagesHasen Design Summary 20 MetreAgshin PirimovNo ratings yet

- Davao City Hotel Beam DesignDocument14 pagesDavao City Hotel Beam DesignReyginald MarronNo ratings yet

- Drill Collar Performance SheetDocument1 pageDrill Collar Performance SheetИнженер Луис А. ГарсиаNo ratings yet

- HTRI Heat Exchanger Rating SummaryDocument6 pagesHTRI Heat Exchanger Rating SummaryCami Vander MeyNo ratings yet

- EncoderDocument56 pagesEncoderRefaat RaslanNo ratings yet

- HW 3.5 DatasheetDocument1 pageHW 3.5 DatasheetDaniel NavarroNo ratings yet

- Floor Slab DesignDocument1 pageFloor Slab DesignPre SheetNo ratings yet

- Generate Data Sheet for Oil Country Tubular GoodsDocument1 pageGenerate Data Sheet for Oil Country Tubular GoodsKuOneMohdAzrulNo ratings yet

- No. 3Document1 pageNo. 3Luis Alberto García CórdovaNo ratings yet

- PramonnoDocument1 pagePramonnoHariyono Rudi NovantoNo ratings yet

- 5.000 HWDP With NC50 (4.5IF) (6.625 X 3.0625 TJ) SpiralDocument1 page5.000 HWDP With NC50 (4.5IF) (6.625 X 3.0625 TJ) Spiralfaishal hafizhNo ratings yet

- Steel Beam Analysis & DesignDocument4 pagesSteel Beam Analysis & DesignTruong Phuoc TriNo ratings yet

- Laboratorium Pengujian Struktur Jurusan Teknik Sipil Politeknik Negeri Ujung PandangDocument2 pagesLaboratorium Pengujian Struktur Jurusan Teknik Sipil Politeknik Negeri Ujung PandangAndi untung zulfikar albarNo ratings yet

- Seal Gas - 1Document1 pageSeal Gas - 1bondsivamaniNo ratings yet

- Calculation Economizer - PL ProjectDocument12 pagesCalculation Economizer - PL ProjectXuan Man NguyenNo ratings yet

- Conveyor design for EUROCHEM KOVDORSKIY GOK M-2 projectDocument62 pagesConveyor design for EUROCHEM KOVDORSKIY GOK M-2 projectHasan arif KısaalioğluNo ratings yet

- RicisDocument1 pageRicisHariyono Rudi NovantoNo ratings yet

- m-1 ReportDocument58 pagesm-1 ReportHasan arif KısaalioğluNo ratings yet

- 6090AFM85 BrochureDocument2 pages6090AFM85 Brochureluisdavid01No ratings yet

- 4.000 HWDP With XT39 (4.875 X 2.5625 TJ) ConventionalDocument1 page4.000 HWDP With XT39 (4.875 X 2.5625 TJ) Conventionalsurendra kumarNo ratings yet

- ChocolatosDocument1 pageChocolatosHariyono Rudi NovantoNo ratings yet

- Chocolatos 2Document1 pageChocolatos 2Hariyono Rudi NovantoNo ratings yet

- m-4 ReportDocument47 pagesm-4 ReportHasan arif KısaalioğluNo ratings yet

- Combined Footing DesDocument7 pagesCombined Footing Desansar700No ratings yet

- Technical specifications for 15-inch punch he woofersDocument1 pageTechnical specifications for 15-inch punch he woofersAnthony Shawn BateNo ratings yet

- Bearings Simply Supported ShaftDocument8 pagesBearings Simply Supported ShaftRiyazuddin MahamadNo ratings yet

- Design-Horizontal air-cooled heat exchanger forced draft countercurrent crossflowDocument25 pagesDesign-Horizontal air-cooled heat exchanger forced draft countercurrent crossflowLuis AlexanderNo ratings yet

- Optimal Product Selection Tool: Select Model No. Calculation ResultDocument2 pagesOptimal Product Selection Tool: Select Model No. Calculation ResultAryo WicaksonoNo ratings yet

- Seismic Isolation Product Line-UpDocument9 pagesSeismic Isolation Product Line-UpSyafrul MubaraqNo ratings yet

- Technical Data Sheet TMK UP FMT 3.5 X 9.2 N80Document1 pageTechnical Data Sheet TMK UP FMT 3.5 X 9.2 N80earlangga rmpNo ratings yet

- DC 4.75 DatasheetDocument1 pageDC 4.75 DatasheetDaniel NavarroNo ratings yet

- Output Summary: SI UnitsDocument1 pageOutput Summary: SI Unitsdaboo sanatNo ratings yet

- Drill Pipe Performance Characteristics SheetDocument1 pageDrill Pipe Performance Characteristics SheetJeremias UtreraNo ratings yet

- Slab Design: Reinforcement DetailsDocument1 pageSlab Design: Reinforcement DetailsRooking Ewondo SfuutNo ratings yet

- Steel Member AnalysisDocument17 pagesSteel Member AnalysisBINTU SERUNJOGINo ratings yet

- Leadscrew - Design - XLS: EI cEI K F L LDocument6 pagesLeadscrew - Design - XLS: EI cEI K F L Ligualdi53No ratings yet

- Hes D3211-99a Mechnical Properties of Steel Bolts and ScreDocument12 pagesHes D3211-99a Mechnical Properties of Steel Bolts and ScrePreetam KumarNo ratings yet

- Sandy Drifterz, Vcet: Madurai, Tamil NaduDocument15 pagesSandy Drifterz, Vcet: Madurai, Tamil NaduNaveenNo ratings yet

- Beam design and analysisDocument5 pagesBeam design and analysisjanethNo ratings yet

- Brosur SAKAI Double Drum Atau Tandem Roller CR271Document2 pagesBrosur SAKAI Double Drum Atau Tandem Roller CR271nanapNo ratings yet

- Simply Supported Beam Example1Document4 pagesSimply Supported Beam Example1Truong Phuoc TriNo ratings yet

- My 2 Way Slab ExcelDocument18 pagesMy 2 Way Slab ExcelURVESHKUMAR PATELNo ratings yet

- CDS VAM TOP ® 2.875in. 7.8lb-ft T95 API Drift 56,63mmDocument1 pageCDS VAM TOP ® 2.875in. 7.8lb-ft T95 API Drift 56,63mmBaurzhanNo ratings yet

- Gas-Tight Premium Connection: 2.375 In. (60.33) 4.7 LBM/FT (6.99)Document1 pageGas-Tight Premium Connection: 2.375 In. (60.33) 4.7 LBM/FT (6.99)DiegoCaicedo1982No ratings yet

- Simulation Summary of Horizontal EconomizerDocument1 pageSimulation Summary of Horizontal EconomizerHariyono Rudi NovantoNo ratings yet

- Geometry: Geoconn - TsDocument1 pageGeometry: Geoconn - TsPapa AinunNo ratings yet

- Reliable Volvo DD22 and DD24 Double Drum CompactorsDocument4 pagesReliable Volvo DD22 and DD24 Double Drum CompactorsBruno MasieroNo ratings yet

- CDS VAM TOP ® 2.875in. 7.8lb-ft L80 Type 1 API Drift 56,63mmDocument1 pageCDS VAM TOP ® 2.875in. 7.8lb-ft L80 Type 1 API Drift 56,63mmBaurzhanNo ratings yet

- EC3-611 Rack Controller and ECD-000 Display UnitDocument8 pagesEC3-611 Rack Controller and ECD-000 Display UnitMaria DazaNo ratings yet

- 3b4b4f16ac0bcdb8c58665b05a018b4dDocument8 pages3b4b4f16ac0bcdb8c58665b05a018b4dWicttor SantosNo ratings yet

- LAF TheoryDocument22 pagesLAF TheoryNeeraj MehtaNo ratings yet

- M.Tech M 2016Document133 pagesM.Tech M 2016Priya ApteNo ratings yet

- Grade 4Document6 pagesGrade 4Kimberly SalvadorNo ratings yet

- Tda 2170Document8 pagesTda 2170ricdem11_42047No ratings yet

- VTC 18MAT31 QP-Scheme-1Document55 pagesVTC 18MAT31 QP-Scheme-1Maithira HNo ratings yet

- GCSE Mini Test 4: Foundation Maths QuestionsDocument2 pagesGCSE Mini Test 4: Foundation Maths QuestionsSuiatz (Suiatz)No ratings yet

- Osmosis and Diffusion Lab VocabularyDocument3 pagesOsmosis and Diffusion Lab Vocabularydannyf09No ratings yet

- Physics Mtmar - EdoneDocument1 pagePhysics Mtmar - EdoneAllan Estrada BasugaNo ratings yet

- EditDocument2 pagesEditEvey HernándezNo ratings yet

- 23 Electronic TheodolitesDocument4 pages23 Electronic TheodolitesEmaNo ratings yet

- NS Meteorological Calculations GuideDocument3 pagesNS Meteorological Calculations GuidecagnashNo ratings yet

- Therm6.3 10211 ValidationDocument7 pagesTherm6.3 10211 ValidationJavierNo ratings yet

- Thermodynamics of Heating PDFDocument19 pagesThermodynamics of Heating PDFMatias MuñozNo ratings yet

- Int - Ph.D. Math - SCDocument11 pagesInt - Ph.D. Math - SCapi-26401608No ratings yet

- BASF Styrodur Basement Insulation PDFDocument20 pagesBASF Styrodur Basement Insulation PDFakajsiNo ratings yet

- Electrochemical Reactivation (EPR) For Detecting Sensitization of AISI Type 304 and 304L Stainless SteelsDocument9 pagesElectrochemical Reactivation (EPR) For Detecting Sensitization of AISI Type 304 and 304L Stainless SteelsAndres Carmona100% (1)

- Lesson 3-F5 PhysicsDocument14 pagesLesson 3-F5 PhysicsCheng WLNo ratings yet

- Sterilizers of ParenteralsDocument42 pagesSterilizers of ParenteralsHanuma KanthetiNo ratings yet

- SM04 Poster 82Document6 pagesSM04 Poster 82lkamalNo ratings yet

- Relativistic Time Dilation and The Muon ExperimentDocument6 pagesRelativistic Time Dilation and The Muon ExperimentConexão Terra PlanaNo ratings yet

- Metals 10 01121Document14 pagesMetals 10 01121dietersimaNo ratings yet

- Maximum Moisture Content MethodDocument9 pagesMaximum Moisture Content MethodGuilherme PrataNo ratings yet

- OTE 100 Years of Flotation Technology Eng WebDocument2 pagesOTE 100 Years of Flotation Technology Eng WebSoufi Badr100% (2)

- 30-10-2022 - Jr.C-IPL - Jee-Adv (2021-P2) - WTA-12 - Key & Sol'sDocument10 pages30-10-2022 - Jr.C-IPL - Jee-Adv (2021-P2) - WTA-12 - Key & Sol'sAdinarayana MallelaNo ratings yet

- MODEL QUESTIONS (Lasers and Optical Fibers) Oct-2023Document2 pagesMODEL QUESTIONS (Lasers and Optical Fibers) Oct-2023shettysohan79No ratings yet

- ETABS 2016 Tutorial: Determine Forces in a Pratt TrussDocument17 pagesETABS 2016 Tutorial: Determine Forces in a Pratt TrussOscarKonzultNo ratings yet