Professional Documents

Culture Documents

To Study The Construction and Working of 4 - Stroke Petrol / Diesel Engine

Uploaded by

Banwari Lal PrajapatOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

To Study The Construction and Working of 4 - Stroke Petrol / Diesel Engine

Uploaded by

Banwari Lal PrajapatCopyright:

Available Formats

EXPERIMENT NO.

2

Aim: To study the construction and working of 4- stroke petrol / diesel engine.

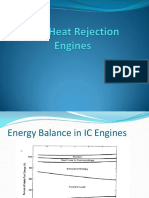

Theory: A machine or device which derives heat from the combustion of fuel

and converts part of this energy into mechanical work is called a heat engine.

Heat engines are broadly classified into internal combustion engines [I.C.

engines] and external combustion engines. Petrol and diesel engines fall under

the category of internal combustion engines as these are reciprocating heat

engines in which fuel mixed with correct amount of air is burnt inside a cylinder.

The gaseous products of combustion form the working substance which make

the piston move and produce mechanical work at the engine crankshaft. In

contrast, the combustion of fuel in external combustion engines (ex. Steam

engines) is external.

Classification of I.C. Engines:

I.C. engines can be classified as follows:

1. According to the number of strokes required to complete a cycle:

(i) 2 stroke engine (ii) 4 stroke engine

2. According to fuel used:

(i) Petrol engine (ii) Diesel engine

(iii) Gas Engine

3. According to thermodynamic cycle of operation:

(i) Constant volume or Otto cycle

(ii) Constant Pressure or Diesel cycle

(iii) Mixed or Dual cycle

4. According to the ignition system used:

(i) Spark Ignition engine (ii) Compression Ignition Engine

5. According to the number of cylinders:

(i) Single cylinder engine (ii) Multi Cylinder engine

6. According to arrangement of cylinders:

(i) Vertical engine (ii) Horizontal engine

(iii) In line engines (iv) V engines

(v) Radial engine

7. According to the cooling system:

(i) Air cooled engine (ii) Water cooled engine

8. According to the speed of the engine:

(i) Low Speed (below 400 rpm) (ii) Medium Speed (400 to 900 rpm)

(iii) High Speed (above 900 rpm)

9. According to lubrication system:

(i) Splash Lubrication (ii) Pressure Lubrication

10. According to field of application: (i) Stationary engine

(ii) Mobile engine.

Four Stroke Petrol Engine:

The cycle of operation in a four stroke petrol engine is completed in two

revolutions of crank shaft or four strokes of piston. Stroke is defined as the

distance traveled by the piston from one of the dead centers to the other dead

centre. It is also equal to two times the crank radius. Hence in a four stroke

engine work is obtained only during one stroke out of the four strokes of the

piston required to complete one cycle.

This engine works on Otto or constant volume cycle.

1. Suction stroke: To start with the piston is at or very near T.D.C. and the inlet

valve is open and exhaust valve is closed. As the piston moves from T.D.C. to

B.D.C. rarefaction is formed in the cylinder which causes the charge to rush in

and fill the space vacated by the piston. The charge consists of a mixture of air

and petrol prepared by the carburetor. The admission of charge inside the engine

cylinder continues until the inlet valve closes at B.D.C.

2. Compression stroke: Both the valves are closed and the piston moves from

B.D.C. to T.D.C. The charge is compressed up to a compression ratio of 5:1 to

9:1 and pressure and temperature at the end of compression are about 6 to 12 bar

and 250 C to 300 C respectively.

3. Working, Power or Expansion stroke: When the piston reaches T.D.C.

position, or just at the end of compression stroke, the charge is ignited by

causing an electric spark between the electrodes of a spark plug, which is located

some where in the walls of cylinder head. During combustion the chemical

energy of fuel is released and there is rise in temperature and pressure of gases.

The temperature of gases increases to about 1800 C to 2000 C and the pressure

reaches 30 to 40 bar. Up till now the volume of gases formed however remains

almost constant with both valves closed. Now the combustion products expand

and push the piston down the cylinder. The reciprocating piston motion is

converted into rotary motion of crankshaft by a connecting rod and crank.

During expansion the pressure drops due to increase in the volume of gases and

absorption of heat by cylinder walls.

4. Exhaust stroke: Theoretically exhaust valve opens at the end of working

stroke when the piston is at B.D.C. position. But actually exhaust valve begins to

open when about 85 % of the working stroke is completed. A pressure of 4 to 5

bar at this instant forces about 60 % of the burnt gases into the exhaust manifold

at high speed. The remaining burnt gases are cleared off the swept volume when

the piston moves from B.D.C. to T.D.C. During this stroke the pressure in side

the cylinder is slightly above the atmospheric value. Some of the burnt gases are

however left in the clearance space. The exhaust valve closes shortly after the

piston reaches T.D.C. The inlet valve opens slightly before the end of exhaust

stroke and the cycle repeats.

Four Stroke Diesel Engine:

The cycle of operation in a four stroke diesel engine is completed in two

revolutions of crankshaft or four strokes of piston using diesel oil as fuel. This

engine works on diesel cycle.

1. Suction Stroke: Starting of engine is done by an electric motor or manually.

In both cases the energy is supplied to the engine. In this stroke the inlet valve

opens and the outlet valve remains closed. Piston moves from T.D.C. to B.D.C.

and in this way a vacuum is created in the cylinder. This vacuum is filled by air

alone and piston reaches to B.D.C.

2. Compression Stroke: Both valves are closed. This time piston moves from

B.D.C. to T.D.C. Air is compressed in this stroke up to a compression ratio of

15:1 to 22:1 and a very high temperature is produced due to high pressure. The

high temperature is the only cause of combustion of the fuel. The piston takes

the power in this stroke from the flywheel. During this stroke the pressure and

temperature attain a high value of 40 to 60 bar and 600 C to 700 C.

3. Working Stroke: At the end of compression stroke or when the piston reaches

the T.D.C. position, a fine spray of diesel is injected in the cylinder through

injector. The fuel burns by the heat of compressed air and due to its burning the

power is produced. This power pushes the piston downward i.e. from T.D.C. to

B.D.C. The excess energy of the piston is stored in the flywheel of the engine,

which is further used for the remaining three strokes of the engine. The

reciprocating motion of the piston is converted into the rotary motion of the

crankshaft by connecting rod and crank. During expansion the pressure drops

due to increase in volume of gases and absorption of heat by cylinder walls.

4. Exhaust Stroke: The exhaust valve begins to open when about 85% of the

working stroke is completed. The force of piston coming from B.D.C. to T.D.C.

forces the burnt gases into the exhaust manifold. Some of the gases are forced

out due to higher pressure in the cylinder and the remaining gases are forced out

by the piston. Some of the burnt gases are however left inside the clearance

space. The exhaust valve closes shortly after T.D.C. The inlet valve opens

slightly before the end of exhaust and in this way the cycle repeats.

You might also like

- Diesel Engines 4th Edition by Tim BartlettDocument97 pagesDiesel Engines 4th Edition by Tim BartlettPor Pengleng100% (2)

- SUBARU Service ManualDocument7,318 pagesSUBARU Service ManualCharlie Souza100% (4)

- Wankel EngineDocument270 pagesWankel EngineFavanza Iliya100% (1)

- Combustion & Combustion ChamberDocument40 pagesCombustion & Combustion ChamberGODNo ratings yet

- (Ebook) The BG Tuning ManualDocument72 pages(Ebook) The BG Tuning ManualMuhammad Akbar PradiptaNo ratings yet

- Report of Marine Diesel PracticumDocument31 pagesReport of Marine Diesel PracticumPutu Widhi ApriliaNo ratings yet

- Solved ProblemsDocument15 pagesSolved ProblemsMichaelle Angela Arnedo70% (10)

- Cam AnalysisDocument7 pagesCam AnalysisSandeep Saini100% (1)

- 4 Stroke Petrol Engine Cut ModelDocument9 pages4 Stroke Petrol Engine Cut ModelZahid MughalNo ratings yet

- LCM and HCF (101-138)Document4 pagesLCM and HCF (101-138)Banwari Lal PrajapatNo ratings yet

- IC Engine MCQDocument16 pagesIC Engine MCQAkshat Singh Jhala100% (2)

- Construction & Working of 2-Stroke EnginesDocument4 pagesConstruction & Working of 2-Stroke Enginesbinoy_sarkar_123100% (2)

- Morse Test Determines IC Engine Cylinder PowerDocument7 pagesMorse Test Determines IC Engine Cylinder PowerParas kapoorNo ratings yet

- ICE Component Design Pistons 2021Document7 pagesICE Component Design Pistons 2021Sanjay PatelNo ratings yet

- Valve Timing Diagram of Four Stroke Cycle Petrol EngineDocument5 pagesValve Timing Diagram of Four Stroke Cycle Petrol EngineBIBIN CHIDAMBARANATHAN67% (3)

- Motor Ford Mazda 2013-2.5LDocument85 pagesMotor Ford Mazda 2013-2.5Lkilofome05No ratings yet

- LCM and HCF (001-050)Document5 pagesLCM and HCF (001-050)Banwari Lal PrajapatNo ratings yet

- Engine Performance Testing ParametersDocument39 pagesEngine Performance Testing ParametersashaNo ratings yet

- CHAPTER 5 Internal Combustion EngineDocument49 pagesCHAPTER 5 Internal Combustion EngineYann YeuNo ratings yet

- Automobile Engineering Lab ExperimentDocument7 pagesAutomobile Engineering Lab ExperimentNidhi BharatiyaNo ratings yet

- I C - Engines-NotesDocument15 pagesI C - Engines-Notessuhas_SCEMNo ratings yet

- 4-Stroke Final ReportDocument13 pages4-Stroke Final ReportVimal YadavNo ratings yet

- I C Engine Lab ManualDocument67 pagesI C Engine Lab ManualBikash ChoudhuriNo ratings yet

- Refrigerant Leakage and Its DetectionDocument8 pagesRefrigerant Leakage and Its DetectionDeepak0% (1)

- Study ExpDocument41 pagesStudy ExpNishant Nagle100% (1)

- 2 StrokeDocument8 pages2 StrokeUsama AnsariNo ratings yet

- Experiment No.:-8: Study The Working and Construction of The Reciprocating Air CompressorDocument6 pagesExperiment No.:-8: Study The Working and Construction of The Reciprocating Air Compressordhirendra singhNo ratings yet

- INTERNAL COMBUSTION ENGINES & TURBINESDocument24 pagesINTERNAL COMBUSTION ENGINES & TURBINESBanwari Lal Prajapat100% (1)

- Static and Dynamic Balancing: Experiment#2Document4 pagesStatic and Dynamic Balancing: Experiment#2Maqbool Khan100% (1)

- Stratified Charge Engine Tech An Cal PaperDocument18 pagesStratified Charge Engine Tech An Cal PaperVikas Kr Gupta100% (1)

- Four Stroke EngineDocument9 pagesFour Stroke Enginepawarsikander100% (3)

- Variable Copression Ratio EnginesDocument18 pagesVariable Copression Ratio EnginesNicole LucasNo ratings yet

- ACTUAL INDICATOR DIAGRAM FOR A FOUR STROKE CYCLE Diesel ENGINE PDFDocument3 pagesACTUAL INDICATOR DIAGRAM FOR A FOUR STROKE CYCLE Diesel ENGINE PDFBIBIN CHIDAMBARANATHAN100% (4)

- Journal Bearing ApparatusDocument6 pagesJournal Bearing ApparatusGurmeet Mehma67% (6)

- CYLINDER FINS Final ProjectDocument84 pagesCYLINDER FINS Final ProjectUttam Animireddy100% (1)

- Me6412 Thermal Engineering Laboratory Manual - IDocument126 pagesMe6412 Thermal Engineering Laboratory Manual - IBIBIN CHIDAMBARANATHAN100% (4)

- BDA 37201 Engineering Lab V: Thermodynamics Air Conditioning SystemDocument18 pagesBDA 37201 Engineering Lab V: Thermodynamics Air Conditioning SystemMuhd I-dilNo ratings yet

- 5.to Study of Gas Turbine Power Plant.Document3 pages5.to Study of Gas Turbine Power Plant.bhagchandt817No ratings yet

- Performance Test On Four Stroke Multi-Cylinder EngineDocument12 pagesPerformance Test On Four Stroke Multi-Cylinder EngineSridevi herleNo ratings yet

- Experiment No: Fuel Pump & Injectors AimDocument7 pagesExperiment No: Fuel Pump & Injectors Aimabbas bilalNo ratings yet

- Fuel-Air Cycles and Actual Cycles ch4Document18 pagesFuel-Air Cycles and Actual Cycles ch4Eezhar JumadiNo ratings yet

- Experiment No: 1: Thermal Engineering Lab ManualDocument8 pagesExperiment No: 1: Thermal Engineering Lab ManualmuralidharanNo ratings yet

- Six Stroke EngineDocument19 pagesSix Stroke EngineSai deerajNo ratings yet

- Acd Lab ManualDocument31 pagesAcd Lab Manualdestro29No ratings yet

- Working of I.C EnginesDocument14 pagesWorking of I.C EnginesHammad Hassan100% (5)

- Industrial Visit To Centralized Air Conditioning SystemDocument9 pagesIndustrial Visit To Centralized Air Conditioning SystemsoumikNo ratings yet

- Variable Compression Ratio ExperimentDocument7 pagesVariable Compression Ratio ExperimentMuruganNo ratings yet

- Introduction To Gas DynamicsDocument12 pagesIntroduction To Gas DynamicsAswin Varghese TharakanNo ratings yet

- Morse Test On Multi Cylinder Petrol EngineDocument4 pagesMorse Test On Multi Cylinder Petrol EnginealagurmNo ratings yet

- Sheatpoweer Steam Turbine22Document3 pagesSheatpoweer Steam Turbine22Omeed ArtsNo ratings yet

- Basic Mechanical Lab Manual PDFDocument60 pagesBasic Mechanical Lab Manual PDFNATIONAL XEROX0% (1)

- Centrifugal Pump Test Rig (With A.C Motor, 3 Speed With Step Cone Pulley)Document9 pagesCentrifugal Pump Test Rig (With A.C Motor, 3 Speed With Step Cone Pulley)Sandeep SainiNo ratings yet

- Valve Timing Diagram of Si and Ci EngineDocument5 pagesValve Timing Diagram of Si and Ci EngineAli100% (1)

- Experiment One-To Study The Cochran and Babcock and Wilcox BoilersDocument8 pagesExperiment One-To Study The Cochran and Babcock and Wilcox BoilersHasib IslamNo ratings yet

- Engine Testing LabDocument3 pagesEngine Testing LabSachi MensiNo ratings yet

- Gas Turbine - Seminar ReportDocument16 pagesGas Turbine - Seminar ReportVHD DevolopersNo ratings yet

- Qip Ice 21 Intake & Exhaust ValvesDocument32 pagesQip Ice 21 Intake & Exhaust ValvesChetanPrajapati100% (1)

- Design of Cooling SystemDocument5 pagesDesign of Cooling Systemsameerpatel15770100% (1)

- LHR EngineDocument31 pagesLHR Enginesarathkumar100% (2)

- Manual of Air Purge Level Indicator, DoneDocument8 pagesManual of Air Purge Level Indicator, DoneShoaib PathanNo ratings yet

- Lab 1 ReportDocument6 pagesLab 1 ReportStephen JonesNo ratings yet

- 2-Stroke Petrol EngineDocument5 pages2-Stroke Petrol EngineAbdullah iftikharNo ratings yet

- 2 CI Engine Normal and Abnormal Combustion-KnockingDocument9 pages2 CI Engine Normal and Abnormal Combustion-Knockingselvaraj9223No ratings yet

- Exp No 04 Working of High Pressure Boiler.Document6 pagesExp No 04 Working of High Pressure Boiler.Aasawari MahagaonkarNo ratings yet

- ENGINE KNOCKING AND DETONATION CAUSES AND REMEDIESDocument16 pagesENGINE KNOCKING AND DETONATION CAUSES AND REMEDIESm abdullahNo ratings yet

- Diesel EngineDocument14 pagesDiesel EngineAyşenur ÇetinNo ratings yet

- SteamTurbine NotesDocument17 pagesSteamTurbine Notesjust randomNo ratings yet

- Rac Lab FileDocument28 pagesRac Lab FileGovind AtwalNo ratings yet

- Unit-5: Reciprocating Compressors: 5.1 Uses of Compressed AirDocument12 pagesUnit-5: Reciprocating Compressors: 5.1 Uses of Compressed AirSamrudh Manjunath100% (1)

- Comparative Study of Four Stroke Diesel and Petrol EngineDocument7 pagesComparative Study of Four Stroke Diesel and Petrol EnginepandiyaNo ratings yet

- To Study The Construction and Working of 4 - Stroke Petrol / Diesel EngineDocument7 pagesTo Study The Construction and Working of 4 - Stroke Petrol / Diesel EngineBanwari Lal PrajapatNo ratings yet

- Unsteady State Heat TransferDocument27 pagesUnsteady State Heat TransferJOSE DAVID TORRES GONZALEZNo ratings yet

- Hindi Comp I SrajanDocument105 pagesHindi Comp I SrajanBanwari Lal PrajapatNo ratings yet

- VERBS: TENSES, ASPECTS, AND FUNCTIONSDocument96 pagesVERBS: TENSES, ASPECTS, AND FUNCTIONSSJK(T) LADANG TEMERLOH100% (1)

- Class V Paper EnvironmentDocument2 pagesClass V Paper EnvironmentBanwari Lal PrajapatNo ratings yet

- SSC Je 2010 Mechanical Paperq 151Document8 pagesSSC Je 2010 Mechanical Paperq 151Banwari Lal PrajapatNo ratings yet

- Class 9Document86 pagesClass 9bmbsnpNo ratings yet

- Bhartiya Rajvyavastha (Part-IV)Document14 pagesBhartiya Rajvyavastha (Part-IV)Banwari Lal PrajapatNo ratings yet

- Bharatiya Rajya Vyavastha-IIDocument107 pagesBharatiya Rajya Vyavastha-IIBanwari Lal PrajapatNo ratings yet

- BSER Raj Adhyan-3 PDFDocument110 pagesBSER Raj Adhyan-3 PDFBanwari Lal PrajapatNo ratings yet

- Current March (मार्च) by ankur yadavDocument11 pagesCurrent March (मार्च) by ankur yadavBanwari Lal PrajapatNo ratings yet

- BSER Raj Adhyan-4 PDFDocument158 pagesBSER Raj Adhyan-4 PDFBanwari Lal PrajapatNo ratings yet

- Age HindiDocument22 pagesAge HindiBanwari Lal PrajapatNo ratings yet

- Aptitude Mock Test 5Document13 pagesAptitude Mock Test 5Banwari Lal PrajapatNo ratings yet

- घटना चक्र.. दृष्टि वार्षिक one linerDocument15 pagesघटना चक्र.. दृष्टि वार्षिक one linerBanwari Lal PrajapatNo ratings yet

- Sankhayatmak AbhiyogitaDocument112 pagesSankhayatmak AbhiyogitaBanwari Lal Prajapat100% (2)

- 1 PsychologyDocument3 pages1 PsychologyBanwari Lal PrajapatNo ratings yet

- TEST PAPER 4 Sangya PrakranDocument13 pagesTEST PAPER 4 Sangya PrakranBanwari Lal PrajapatNo ratings yet

- 11 Personality 1Document19 pages11 Personality 1Banwari Lal PrajapatNo ratings yet

- Jit 1Document5 pagesJit 1Banwari Lal PrajapatNo ratings yet

- RTU MTech Admissions ScheduleDocument2 pagesRTU MTech Admissions ScheduleBanwari Lal PrajapatNo ratings yet

- Sanskrit I Iind Grade Teacher Reet 04Document10 pagesSanskrit I Iind Grade Teacher Reet 04Banwari Lal PrajapatNo ratings yet

- How to Optimize Your Website for Search EnginesDocument12 pagesHow to Optimize Your Website for Search EnginesBanwari Lal Prajapat100% (3)

- TEST PAPER 3 Sandhi PrakarnamDocument9 pagesTEST PAPER 3 Sandhi PrakarnamBanwari Lal PrajapatNo ratings yet

- Wa0072Document6 pagesWa0072Banwari Lal PrajapatNo ratings yet

- Jja Paper 2016Document8 pagesJja Paper 2016Banwari Lal PrajapatNo ratings yet

- Current Affairs General Knowledge Questions and Answers From January To May 2017 For Competitive Exams Entranciology PDFDocument102 pagesCurrent Affairs General Knowledge Questions and Answers From January To May 2017 For Competitive Exams Entranciology PDFJyoti SukhijaNo ratings yet

- Algebra (301-338) PDFDocument3 pagesAlgebra (301-338) PDFBanwari Lal PrajapatNo ratings yet

- Number System (051-100)Document5 pagesNumber System (051-100)Banwari Lal PrajapatNo ratings yet

- Valve Clearence R18Z1Document26 pagesValve Clearence R18Z1miguelNo ratings yet

- Introduction to Internal Combustion EnginesDocument46 pagesIntroduction to Internal Combustion Enginesranjith kumarNo ratings yet

- HGM-740 T5 BIO Heavy-Duty GeneratorDocument7 pagesHGM-740 T5 BIO Heavy-Duty GeneratorghostshotNo ratings yet

- Paper On Six Stroke EngineDocument8 pagesPaper On Six Stroke EngineAjinkya Deshpande0% (1)

- ICE EngineDocument102 pagesICE EngineyanNo ratings yet

- JU4H-UF34 ProposalDocument12 pagesJU4H-UF34 ProposalUmmeNo ratings yet

- Tecumseh Fast Moving Parts Guide PDFDocument50 pagesTecumseh Fast Moving Parts Guide PDFWilliam WebbNo ratings yet

- Internal Combustion Engines: Basic Mechanical Engineering, First Edition by DR Pravin KumarDocument23 pagesInternal Combustion Engines: Basic Mechanical Engineering, First Edition by DR Pravin KumarJawed ShaikhNo ratings yet

- Guascor Marine Diesel Engines and SystemsDocument9 pagesGuascor Marine Diesel Engines and SystemsYans BalNo ratings yet

- 2475Document20 pages2475Tiffany McdanielNo ratings yet

- MAN Diesel & Turbo Pressure and Tolerance DataDocument2 pagesMAN Diesel & Turbo Pressure and Tolerance DataAntonio Marcos SantosNo ratings yet

- Ekm Motor Class 2Document84 pagesEkm Motor Class 2Anonymous 4ylE57C6100% (1)

- Shell Mysella Productdatasheet3 72Document3 pagesShell Mysella Productdatasheet3 72Ahmed AlhawyNo ratings yet

- Performance Analysis of Petrol - HHO EngineDocument4 pagesPerformance Analysis of Petrol - HHO EngineNasirNo ratings yet

- Choose Shantui Wheel Loader For Your FutureDocument4 pagesChoose Shantui Wheel Loader For Your FutureRS Rajib sarkerNo ratings yet

- Internal Combustion Engine Cycles - ExamplesDocument16 pagesInternal Combustion Engine Cycles - Examplesmanjeet gajbhiye100% (1)

- Online Lab Manual MAAE2400 - Spt2020Document46 pagesOnline Lab Manual MAAE2400 - Spt2020AlexaNo ratings yet

- T225RS User Manual: WarningDocument4 pagesT225RS User Manual: WarningSimon CooperNo ratings yet

- SME5601 Advanced IC Engines Question BankDocument5 pagesSME5601 Advanced IC Engines Question BankJVCNo ratings yet

- Theories of FailureDocument18 pagesTheories of FailurenemidassNo ratings yet

- BME ManualDocument32 pagesBME ManualSudhanshuAtkareNo ratings yet