Professional Documents

Culture Documents

Cost MVC

Uploaded by

Nithi AnandOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cost MVC

Uploaded by

Nithi AnandCopyright:

Available Formats

13me Congrs de Mcanique 11 - 14 Avril 2017 (Mekns, MAROC)

ECONOMICAL AND THERMAL STUDY OF A MECHANICAL VAPOR

COMPRESSION DESALINATION UNIT

M. IBRAHIMI, Y. AOURA, A. ARBAOUI

ENSAM, UMI Mekns. Email: ibrahimi.mouhsine@hotmail.fr

Rsum [7]. In practice, much higher energy is required by the

The Mechanical Vapor Compression (MVC) currently available desalination technologies.

desalination technology offers an interesting alternative Calculations of unit product cost depend on the process

for small-scale desalination of seawater to produce high capacity, site characteristics and design features.

quality distilled water with competitive cost. This paper Thermoeconomic design for a MEEMVC desalination

presents an economical and thermal study of single- process and exergy are developed and presented by A.S.

effect mechanical vapor compression unit. The aim of Nafey [8].

this work is to define, the parameters influencing on the This work presents an economical and thermal analysis

behavior of the desalination unit, to develop a knowledge for a MVC desalination unit. The effect of the MVC unit

base on the total cost of pure water in different range of capacity and temperature difference T on the total cost

operation. The proposed approach is based on MVC of clean water is investigated.

components and cost models. The results demonstrate

the inuence of the MVC unit capacity and temperature 2. System description

difference between condensing vapor and boiling brine Figure 1 shows the sequence of operations in an MVC

T on the total cost of clean water. A high T value system. The main components of the MVC unit are the

reduces the cost of heat transfer area, but simultaneously mechanical vapor compressor, evaporator/condenser heat

increases the cost of electric consumption. This study

exchanger, and a circulation pumps. The demister serves

confirms that the MVC desalination cost heavily

dependent on operating parameters. A good control of to filter the water vapor before joining the compressor.

these parameters can significantly reduce the total cost of The feed preheater is a plate type heat exchanger, which

pure water. recovers part of the sensible heat found in the distillate

and brine stream to heat the intake seawater. The thermal

Mots clefs: Desalination; Mechanical vapor energy recovered is then sprayed over the evaporator

compression; Cost; tubes of the evaporator/condenser. The feed temperature

1. Introduction is further increased to the brine boiling temperature and

subsequently evaporation commences. The produced

As freshwater scarcity continues to increase with the

increasing continuous of population, desalinating steam is drawn through the demister to the compressor in

seawater is becoming a necessity for meeting freshwater order to add an additional amount of superheat, increases

needs especially in the North Africa and other regions. the pressure and temperature of the steam by

Water scarcity is a threat to over 40% of the global compression. The superheated vapor that has passed

population [1]. The two major types of technologies that through the condenser heat exchanger tube releases its

are used around the world for desalination can be latent heat, which can be the heat source of the

broadly classified as either membrane such as reverse

osmosis (RO) or thermal including single effect evaporator. At the same time, the vapor is condensed

evaporation (SEE), multiple effect evaporation (MEE), into purified water. The condensed distillate product and

multi-stage flash (MSF), thermal vapor compression the brine stream flow through the preheaters where it

(TVC) and mechanical vapor compression (MVC) [2,3]. exchanges heat with the intake stream.

Both technologies need energy to operate and produce

fresh water. The inception of commercial mechanical

vapor compression (MVC) units dates back to the early

1970s [4,5]. MVC units have been evolved to become a

mature technology over past decades. However, initial

costs, system design and energy consumption remain

challenging problems. An early report by Matz and

Fisher [4] in 1981 showed that either the RO or MVC

system has a definitive edge regarding total production

cost. However, expansion of the MVC process remained

limited. In 1994, only 200 MVC units with very small

unit capacity are reported by Zimmerman [6]. The

minimum theoretical energy required for separating the Figure1: single-effect mechanical vapor compression

salts-desalination, to produce freshwater is 0.7 kWh/m3 desalination unit

13me Congrs de Mcanique 11 - 14 Avril 2017 (Mekns, MAROC)

TABLE I. INPUT VARIABLES OF THE GLOBAL MODEL

3. Process modeling Input variables Values

At this step, an economic and thermal analysis was Intake seawater temperature, C 25

performed in order to calculate the produced unit volume Boiling brine temperature C 90

cost of the fresh water. The global model consists of the Xf/Xb 0.7

MVC components and cost models.

Efficiency of the vapor compressor 0.6

3

3.1 The MVC heat transfer model Culab , m- 0.1

Specific power consumption (W) is expressed in terms of Cuchem , m-3 0.02

the enthalpy difference of the compressed superheated

vapor Hs and the inlet vapor Hv.

W (H S HV )(1000/3600

) (1)

The heat transfer area of the evaporator, feed and

distillate preheater are calculated respectively from the

following relationship:

M d d M d C pv (Ts Td )

Ae (2)

U e (Td Tb )

M b C pb (Tb To )

Abh (3)

U bh ( LMTDbh)

M d C pd (Td To )

Adh (4)

U dh ( LMTDdh) Figure 2: Inuence of the temperature difference on the

specific power consumption and the heat transfer area.

The total heat transfer area is given by equations (5):

ATot Ae Abh Adh (5)

3.2 The water production cost model

The method adopted for calculating the unit production

cost Cu is the same as that used in [9,10]. The costs

included the unit electrical energy cost Cuee, the unit

labor cost Culab and the unit chemical cost Cuchem. The

unit production cost were analyzed using plant life =30

years, a plant availability f =0.9, and amortization

factor a =0.05783, with the interest rate=4%.

The unit production cost Cu is calculated by:

aCTC Figure 3: Inuence of the product flow rate on the power

Cu C uee C ulab C uchem (6) consumption and the total heat transfer area

365 fVMVC

Where CTC is the total capital cost.

Figure 2 shows the heat transfer area of the evaporator

The total capital cost is calculated by: Ae and the specific power consumption of the

CTC 1.15 CC Cpl Crest (7) compressor W versus the difference between condensing

vapor and boiling brine temperature T for Md=20 l/h.

Where Cc is the compressor cost, and Cpl is the cost of

As can be seen, Ae decreases strongly accordingly with

heat exchanger plates (evaporator, feed and distillate),

the increased value of T, and in the same time W

and Crest is the other direct costs (auxiliary equipment,

increases linearly with the increase of T, which is also

land, building construction and well construction).

consistent with the results reported in the literature

[11,12]. However, according to the previous works [11],

4. Results and discussion the operations with an elevated brine boiling temperature

An important aspect that can affect the sustainability of is desirable since it reduces W and decreases slightly Ae.

the model described above is to evaluate which are the This figure shows that the choice of T is an important

resulting costs of the water. The parameters used in the parameter from the economic point of view.

evaluation process are giving in Table 1.

13me Congrs de Mcanique 11 - 14 Avril 2017 (Mekns, MAROC)

In order to give more details on the parameters and electric energy consumption to design an efficient

influencing the MVC unit, Figure 3 shows the power desalination unit.

consumption and total heat transfer area as function of - The costs of water unit production can be

the product flow rate Md for T =8C. It can be seen that significantly reduced by the application of the developed

Atot and Pc both increase linearly with the increases of knowledge base, which is 1.5 m-3 for the considered

Md, which means that an economic study including the desalination case.

costs of the compressor and the heat exchangers is

necessary to bring out the propitious choose of product References

flow rat of the MVC unit. [1] International Water Management Institute. In

Water for food, water for life: a comprehensive

assessment of water management in agriculture,

Earthscan, 2007; 57.A. Auteur, Titre du livre,

Editeur, New York, anne.

[2] O. Lefebvre, R. Moletta, Treatment of organic

pollution in industrial saline wastewater: a

literature review, Water Res. 40 (2006) 3671

3682.

[3] D.F. Zhao, J.L. Xue, S. Li, H. Sun, Q.D. Zhang,

Theoretical analyses of thermal and economical

aspects of multi-effect distillation desalination

dealing with high salinity wastewater,

Desalination 273 (2011) 292298.

[4] Matz R, Fisher U. A comparison of the relative

economics of sea water desalination by vapor

compression and reverse osmosis for small to

Figure 4: Inuence of the product flow rate and medium capacity plants. Desalination

temperature difference on the water unit production cost 1981;36:13751.

[5] Matz R, Zimerman Z. Low-temperature vapour

Figure 4 is a synthesis, which gives an idea of the compression and multi-effect distillation of

parameters influencing the behavior of the desalination seawater. Effects of design on operation and

unit cost, in order to develop a knowledge base on the economics. Desalination 1985;52:20116.

total cost of pure water. In addition, Figure 4 shows the [6] Z. Zimerman, Development of large capacity

inuence of the product flow rate and temperature high efficiency mechanical vapor compression

difference on the water unit production cost. The (MVC) units, Desalination, 96 (1994) 5158.

variation of the distillate flow rate as a function of the [7] Spiegler KS, El-Sayed YM. A desalination

water unit production cost define three areas: high, primer. Balaban Desalination Publications;

medium and constant variation of the cost. These results 1994

are in concordance with the values reported in literature [8] Nafey, A. S., Fath, H. E. S., & Mabrouk, A. A.

[10]. According to the study made above, the lowest T (2008). Thermoeconomic design of a multi-

value means a huge Ae value (i.e. high Cpl), small W effect evaporation mechanical vapor

value (i.e. small Cuee, Cc), and vice versa. The variation compression (MEEMVC) desalination

of Cu as a function of T reflects the importance of the process. Desalination, 230(1), 1-15.

choice of this parameter. As a summary, the operation [9] Lukic, N., Diezel, L. L., Frba, A. P., &

with temperatures differences ranged between 2 to 8 C, Leipertz, A. (2010). Economical aspects of the

drastically decreases the overall unit product cost. improvement of a mechanical vapour

However, the operation with a T=3C and Md =6.94 compression desalination plant by dropwise

Kg/s, gives the better results of Cu=1.5 m-3. condensation. Desalination, 264(1), 173-178.

[10] Lukic, N., Diezel, L. L., Frba, A. P., &

5. Conclusion Leipertz, A. (2010). Economical aspects of the

An investigation on the cost of a MVC desalination improvement of a mechanical vapour

system is presented in order to provide a knowledge base compression desalination plant by dropwise

on the total cost of pure water in different range of condensation. Desalination, 264(1), 173-178.

operation. Several conclusions can be drawn: [11] Ibrahimi, M., Arbaoui, A., Ouzizi, L., & Aoura,

- The power consumption and the total heat transfer Y. (2015, December). Embodiment design of a

area increase linearly with the increases of the product mechanical vapor compression desalination

flow rate. That means that is necessary to bring out the unit. In 2015 3rd International Renewable and

propitious choose of product flow rat of the MVC unit. Sustainable Energy Conference (IRSEC) (pp. 1-

- The operations with a high value of T reduce the 6). IEEE.

heat exchange area, therefore the cost of the evaporator [12] Zhou, Y., Shi, C., & Dong, G. (2014). Analysis

reduced too, but increase the power consumption. This of a mechanical vapor recompression

inferred that an optimization study is needed to find a wastewater distillation system. Desalination,

compromise between the congestion (investment cost) 353, 91-97.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Troubleshooting System TestsDocument4 pagesTroubleshooting System TestsIsmael KhalilNo ratings yet

- Chapter 16 Lime SofteningDocument10 pagesChapter 16 Lime SofteningPankaj SinghNo ratings yet

- 10 Steps To Design An RO - NF Membrane SystemDocument5 pages10 Steps To Design An RO - NF Membrane SystemNithi AnandNo ratings yet

- Membrane Vessel Profiling: Warren Casey Toray Membrane USA, IncDocument10 pagesMembrane Vessel Profiling: Warren Casey Toray Membrane USA, IncNithi AnandNo ratings yet

- Water SofteningDocument20 pagesWater SofteningStefano SquadraniNo ratings yet

- Yojana-Tamil April '17Document52 pagesYojana-Tamil April '17Nithi AnandNo ratings yet

- FWQA FundamentalsDocument33 pagesFWQA FundamentalsNithi AnandNo ratings yet

- OTRDocument51 pagesOTRNithi AnandNo ratings yet

- Tamil Ilakkanam2Document113 pagesTamil Ilakkanam2thenmoli sundramNo ratings yet

- Mr. Manish Kharwade - PrajDocument41 pagesMr. Manish Kharwade - PrajNithi AnandNo ratings yet

- Yojana-February 17 TamilDocument52 pagesYojana-February 17 TamilNithi AnandNo ratings yet

- Sludge BedDocument6 pagesSludge BedNithi AnandNo ratings yet

- Yojana Tamil-Tittam JuneDocument52 pagesYojana Tamil-Tittam JuneNithi AnandNo ratings yet

- Evaporator BasicsDocument4 pagesEvaporator BasicsNithi AnandNo ratings yet

- Initial Site Audit Report Pepsico Sangareddy PMS-F-001Document7 pagesInitial Site Audit Report Pepsico Sangareddy PMS-F-001Nithi AnandNo ratings yet

- HW4 SolutionDocument2 pagesHW4 SolutionAshutoshKumarNo ratings yet

- Ion Exchange Design - Hand Calculation: Brian Windsor (Purolite International LTD)Document43 pagesIon Exchange Design - Hand Calculation: Brian Windsor (Purolite International LTD)Octiva100% (4)

- Form 3Document2 pagesForm 3Nithi AnandNo ratings yet

- How To Calculate Resin Capacity For Softener - Softening PlantDocument10 pagesHow To Calculate Resin Capacity For Softener - Softening PlantNithi Anand100% (4)

- Design Calculation For Softener UnitDocument12 pagesDesign Calculation For Softener Unitaraikun74775% (8)

- Anaerobic Treatment Systems Technical DesignDocument64 pagesAnaerobic Treatment Systems Technical DesignJizzlmanizzlNo ratings yet

- Lime Soda Ash SofteningDocument23 pagesLime Soda Ash SofteningNithi AnandNo ratings yet

- Hard Soft AcidsDocument24 pagesHard Soft AcidsMaheshNo ratings yet

- Mitsunobu Reaction: ReferencesDocument2 pagesMitsunobu Reaction: ReferencesNithi AnandNo ratings yet

- Final Mitsonobu Presentation1Document22 pagesFinal Mitsonobu Presentation1Nithi AnandNo ratings yet

- Final Mitsonobu Presentation1Document22 pagesFinal Mitsonobu Presentation1Nithi AnandNo ratings yet

- Fundamentals of Membrane For Water TreatmentDocument17 pagesFundamentals of Membrane For Water TreatmentGerald100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Density CalculationsDocument19 pagesDensity CalculationsRovy JunsayNo ratings yet

- Formal Letter FormatDocument2 pagesFormal Letter FormatKaif KhanNo ratings yet

- M. Kramer - Propagation and Damping of M +1 and M - 1 Helicon Modes in An Inhomogeneous Plasma ColumnDocument4 pagesM. Kramer - Propagation and Damping of M +1 and M - 1 Helicon Modes in An Inhomogeneous Plasma ColumnHimaszNo ratings yet

- NDEDocument65 pagesNDEAnonymous cEpicMl0% (1)

- LIEBHERR HAUSGERÄTE Data SheetDocument1 pageLIEBHERR HAUSGERÄTE Data SheetGonzalo GNNo ratings yet

- CH - 3 Mass Transfer CoefficientsDocument55 pagesCH - 3 Mass Transfer CoefficientsDivyamNo ratings yet

- C2 Cussler PDFDocument37 pagesC2 Cussler PDFGil PinheiroNo ratings yet

- 1 Science 8 Curriculum MapDocument2 pages1 Science 8 Curriculum MapMayumie Relata50% (4)

- Montalban Earth Dam: Permeability TestDocument20 pagesMontalban Earth Dam: Permeability TestMon MargalloNo ratings yet

- Momentum Applications in Open Channel Flow: Thanks To Prof. Sjwright, Um, For AnimationsDocument24 pagesMomentum Applications in Open Channel Flow: Thanks To Prof. Sjwright, Um, For AnimationsLTE002No ratings yet

- Gravity and Energy Multiple Choice PracticeDocument11 pagesGravity and Energy Multiple Choice PracticeJohnNo ratings yet

- Global Warming EssayDocument5 pagesGlobal Warming EssayTask MastersNo ratings yet

- CBM Technology: Coal Bed Methane Extraction and StorageDocument104 pagesCBM Technology: Coal Bed Methane Extraction and StorageAkhil GodavarthiNo ratings yet

- River Morphology - Garde - IndiaDocument502 pagesRiver Morphology - Garde - Indiaburreiro100% (4)

- Del Ridge Homes: Case StudyDocument3 pagesDel Ridge Homes: Case StudyChot ToNo ratings yet

- HW 2Document2 pagesHW 2miggleathogwartsNo ratings yet

- 4528.05.R380.02 ShellDocument22 pages4528.05.R380.02 ShellAnil B YadavNo ratings yet

- G-Study and Revision Skills - IGCSE Chemistry Scool CDDocument13 pagesG-Study and Revision Skills - IGCSE Chemistry Scool CDPrincess Kim100% (1)

- Chapter 11 - Chemical Reactions PDFDocument17 pagesChapter 11 - Chemical Reactions PDFapi-239855791No ratings yet

- Unit 2 Passive Solar Heating and CoolingDocument69 pagesUnit 2 Passive Solar Heating and Coolingam9128No ratings yet

- 3.3 Yield and Atom Economy of Chemical Reactions QPDocument23 pages3.3 Yield and Atom Economy of Chemical Reactions QPDiamond실비No ratings yet

- 21B9008 Raniya SC1241 Exp1-1Document5 pages21B9008 Raniya SC1241 Exp1-1raniyaNo ratings yet

- Second Quarterly Exam ReviewDocument12 pagesSecond Quarterly Exam ReviewJohn Dexter LanotNo ratings yet

- Newtons Laws of MotionDocument14 pagesNewtons Laws of MotionMakayla SalmonNo ratings yet

- Aerodynamics (Ameco)Document115 pagesAerodynamics (Ameco)July TadeNo ratings yet

- BuildingstoneDocument20 pagesBuildingstoneAlexander AsonkeyNo ratings yet

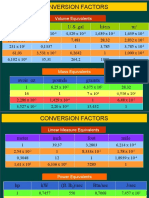

- CONVERSION FACTORS CHART FOR VOLUME, MASS, LENGTH, POWER AND MOREDocument8 pagesCONVERSION FACTORS CHART FOR VOLUME, MASS, LENGTH, POWER AND MORESamuel MahendraNo ratings yet

- Notes Baru SC UpsrDocument4 pagesNotes Baru SC UpsrAnonymous 2fiStzaNo ratings yet

- Science 8 Quarter3 Module 4Document15 pagesScience 8 Quarter3 Module 4Noeh PiedadNo ratings yet

- Astm D5229 - 2020Document20 pagesAstm D5229 - 2020Tamara Silvana CárcamoNo ratings yet