Professional Documents

Culture Documents

Irc-58 (2002)

Uploaded by

ashoknr0 ratings0% found this document useful (0 votes)

35 views8 pagesIRC-58

Original Title

IRC-58 (2002)

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentIRC-58

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

35 views8 pagesIrc-58 (2002)

Uploaded by

ashoknrIRC-58

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 8

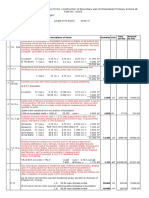

Design Parameters Notation Unit Value

1 Tyre Pressure q kg/cm2 8

2 Load Safety Factor LSF 1.2

3 98th percentile axle load P kg 8000

4 Design Period n Years 20

5 No. of CV the direction of predominent traffic A 3000

6 Traffic growth rate r 0.075

7 Soaked CBR of subgrade % 5

8 K value of subgrade soil ksubgrade kg/cm3 4.2

9 Thickness of DLC mm 150.00

10 Effective k of DLC sub-base keffective kg/cm3 20.80

11 Flexural Strength of Concrete S kg/cm 2

45

12 Modulus of Elasticity of concrete E kg/cm2 300000

13 Poisson's ratio m 0.15

14 Coefficient of thermal expansion a / 0C 0.00001

15 Spacing of contraction joints L m 3.75

16 Width of slab B m 3.5

Cumulative repetition in design life CTraffic ( 20 years) 47418626

Design Traffic = 25 % of the total repetitions of CV DTraffic 11854657

Trial slab thickness h cm 33

Cumulative fatigue life consumed 0.57

Thickness provided is Safe Against Fatigue Failure

Axle Load Data

Single Axle

Load class % of axle Expected Fatigue Life, Fatigue Life

Load x LSF Stress (kg/cm2) Stress Ratio

(tonnes) loads Repetitions N Consumed

< 10 30.00 3556397 12.0 0.00 e 0.00

10 23.30 2762135 12.0 0.00 e 0.00

12 22.00 2608024 14.4 0.00 e 0.00

14 10.80 1280303 16.8 17.64 0.39 e 0.00

16 4.80 569024 19.2 19.98 0.44 e 0.00

18 1.50 177820 21.6 21.98 0.49 1287000 0.14

20 0.60 71128 24.0 24.10 0.54 166000 0.43

0 0.0 0.00 e 0.00

0 0.0 0.00 e 0.00

0 0.0 0.00 e 0.00

0 0.0 0.00 e 0.00

Total 93.00 0.57

Tandem Axle

Load class % of axle Expected Fatigue Life, Fatigue Life

Load x LSF Stress (kg/cm2) Stress Ratio

(tonnes) loads Repetitions N Consumed

< 16 2.00 237093 19.2 0.00 e 0.00

16 0.50 59273 19.2 0.00 e 0.00

20 1.50 177820 24.0 0.00 e 0.00

24 1.80 213384 28.8 0.00 e 0.00

28 0.60 71128 33.6 0.00 e 0.00

32 0.30 35564 38.4 0.00 e 0.00

36 0.30 35564 43.2 19.38 0.43 e 0.00

0 0.0 0.00 e 0.00

0 0.0 0.00 e 0.00

0 0.0 0.00 e 0.00

0 0.0 0.00 e 0.00

Total 7.00 0.00

Check for Temperature Stresses (Ste)

Radius of Relative Stiffness l cm 81.53

L/l 4.60

Zone in which pavement is to be constructed 3

Temperature differential b/w top & bottom of pavement 21.01

Bradbury's coefficient C 0.58

Temperature stress Ste kg/cm2 18.28

Total Stress due to Temperature and Fatigue kg/cm 2

42.38

Slab is Safe against Edge Stress

Check for Corner Stress (Sc)

Radius of Equivalent circular contact of wheel a cm 26.52

Distance C/c between two Tyres S1 cm 31

Total Stress due to Corner stresses and Fatigue kg/cm2 13.36

Slab is Safe against Edge Stress

Design of Dowel Bars

Percentage of load transfer 40

Joint width z cm 2

Characteristic compressive strength of concrete cube (M-40 grade) fck kg/cm 2

400

Diameter of dowel bar b cm 3.2

Permissible bearing stress in concrete Fb kg/cm 2

292.28

Assumed spacing between dowel bars cm 25

Distance from the first dowel bar from the pavement edge cm 15

Assumed length of dowel bar cm 50

Dowel bars that are effective in load transfer from the point of application of load = 1.0xradius of relative stiffness

No. of dowel bars participating in load transfer when load is just over the dowel bar close to edge of slab 4

Total load transfer by dowel group 2.16 Pt

Load carried by the outer dowel bar Pt kg 1481.33

Check for Bearing Stress

Modulus of dowel/concrete interaction (dowel support) K kg/cm3 41500

Modulus of Elasticity of dowel E kg/cm 2

2000000

Moment of Inertia of Dowel I cm4 5.07

Relative stiffness of dowel bar embeded in concrete b 0.24

Bearing stress in dowel bar smax kg/cm2 274.47

The dowel bar spacing and diameter assumed is safe

Design of Tie Bars

Coefficient of friction f 1.5

Density of concrete kg/cm3 2400

Type of tie bar used (Plain/ Deformed) Plain

Allowable Tensile Stress in plain bars (as per IRC:21-2000) 1250

Allowable Bond Stress in plain tie bars 17.5

Diameter of Tie bar cm 1.2

Spacing and length of the plain bar

Area of steel bar/m width of joint to resist the frictional force at slab bottom As cm2/m 3.33

Cross sectional area of tie bar A cm2 1.13

Perimeter of the bar P cm 3.77

Spacing of tie bars 34.00

Provide at a spacing of 33 cm C/C

Length of tie bar L cm 42.86

Increase the length of 10 cm for loss of bond due to painting and another 5 cm for toletance in placement.

57.86 cm

Provide 58 cm length of tie bar

Table 2 Table 4 Table 6 Fig 4

Eff. K Eff. K

Soaked Allowable

k-Value k-value of over over Stress

CBR Repetitio L/l or B/l C

(kg/cm3) Subgrade 100mm 150mm Ratio

Value (%) n

DLC DLC

2 2.10 2.1 5.60 9.70 0 e 1.0 0.0000

3 2.80 2.2 6.19 10.29 0.45 62790000 1.1 0.0040

4 3.50 2.3 6.77 10.87 0.46 14335000 1.2 0.0080

5 4.20 2.4 7.36 11.46 0.47 5200000 1.3 0.0120

6 4.50 2.5 7.94 12.04 0.48 2400000 1.4 0.0160

7 4.80 2.6 8.53 12.63 0.49 1287000 1.5 0.0200

8 5.03 2.7 9.11 13.21 0.5 762000 1.6 0.0240

9 5.27 2.8 9.70 13.80 0.51 485000 1.7 0.0280

10 5.50 2.9 10.19 14.30 0.52 326000 1.8 0.0320

11 5.64 3 10.69 14.80 0.53 229000 1.9 0.0360

12 5.78 3.1 11.18 15.30 0.54 166000 2.0 0.0400

13 5.92 3.2 11.67 15.80 0.55 124000 2.1 0.0535

14 6.06 3.3 12.16 16.30 0.56 94100 2.2 0.0670

15 6.20 3.4 12.66 16.80 0.57 71200 2.3 0.0805

16 6.34 3.5 13.15 17.30 0.58 54000 2.4 0.0940

17 6.48 3.6 13.64 17.80 0.59 40800 2.5 0.1075

18 6.62 3.7 14.14 18.30 0.6 30900 2.6 0.1210

19 6.76 3.8 14.63 18.80 0.61 23400 2.7 0.1345

20 6.90 3.9 15.12 19.30 0.62 17700 2.8 0.1480

21 7.14 4 15.61 19.80 0.63 13400 2.9 0.1615

22 7.37 4.1 16.11 20.30 0.64 10200 3.0 0.1750

23 7.61 4.2 16.60 20.80 0.65 7700 3.1 0.2015

24 7.85 4.3 17.30 21.95 0.66 5830 3.2 0.2280

25 8.08 4.4 18.00 23.10 0.67 4410 3.3 0.2545

26 8.32 4.5 18.70 24.25 0.68 3340 3.4 0.2810

27 8.56 4.6 19.40 25.40 0.69 2531 3.5 0.3075

28 8.79 4.7 20.10 26.55 0.7 1970 3.6 0.3340

29 9.03 4.8 20.80 27.70 0.71 1451 3.7 0.3605

30 9.27 4.9 21.80 29.30 0.72 1099 3.8 0.3870

31 9.50 5 22.80 30.90 0.73 832 3.9 0.4135

32 9.74 5.1 23.80 32.50 0.74 630 4.0 0.4400

33 9.98 5.2 24.80 34.10 0.75 477 4.1 0.4680

34 10.21 5.3 25.80 35.70 0.76 361 4.2 0.4960

35 10.45 5.4 26.80 37.30 0.77 274 4.3 0.5240

36 10.69 5.5 27.80 38.90 0.78 207 4.4 0.5520

37 10.92 5.6 29.39 0.79 157 4.5 0.5800

38 11.16 5.7 30.97 0.8 119 4.6 0.6080

39 11.40 5.8 32.56 0.81 90 4.7 0.6360

40 11.63 5.9 34.14 0.82 68 4.8 0.6640

41 11.87 6 35.73 0.83 52 4.9 0.6920

42 12.11 6.1 37.31 0.84 39 5.0 0.7200

43 12.34 6.2 38.90 0.85 30 5.1 0.7400

44 12.58 5.2 0.7600

45 12.82 5.3 0.7800

46 13.05 5.4 0.8000

47 13.29 5.5 0.8200

48 13.53 5.6 0.8400

49 13.76 5.7 0.8600

50 14.00 5.8 0.8800

51 14.16 5.9 0.9000

52 14.33 6.0 0.9200

53 14.49 6.1 0.9310

54 14.66 6.2 0.9420

55 14.82 6.3 0.9530

56 14.98 6.4 0.9640

57 15.15 6.5 0.9750

58 15.31 6.6 0.9860

59 15.48 6.7 0.9970

60 15.64 6.8 1.0080

61 15.80 6.9 1.0190

62 15.97 7.0 1.0300

63 16.13 7.1 1.0347

64 16.30 7.2 1.0394

65 16.46 7.3 1.0441

66 16.62 7.4 1.0488

67 16.79 7.5 1.0535

68 16.95 7.6 1.0582

69 17.12 7.7 1.0629

70 17.28 7.8 1.0676

71 17.44 7.9 1.0723

72 17.61 8.0 1.0770

73 17.77 8.1 1.0773

74 17.94 8.2 1.0776

75 18.10 8.3 1.0779

76 18.26 8.4 1.0782

77 18.43 8.5 1.0785

78 18.59 8.6 1.0788

79 18.76 8.7 1.0791

80 18.92 8.8 1.0794

81 19.08 8.9 1.0797

82 19.25 9.0 1.0800

83 19.41 9.1 1.0795

84 19.58 9.2 1.0790

85 19.74 9.3 1.0785

86 19.90 9.4 1.0780

87 20.07 9.5 1.0775

88 20.23 9.6 1.0770

89 20.40 9.7 1.0765

90 20.56 9.8 1.0760

91 20.72 9.9 1.0755

92 20.89 10.0 1.0750

93 21.05 10.1 1.0725

94 21.22 10.2 1.0700

95 21.38 10.3 1.0675

96 21.54 10.4 1.0650

97 21.71 10.5 1.0625

98 21.87 10.6 1.0600

99 22.04 10.7 1.0575

100 22.20 10.8 1.0550

10.9 1.0525

11.0 1.0500

11.1 1.0450

11.2 1.0400

11.3 1.0350

11.4 1.0300

11.5 1.0250

11.6 1.0200

11.7 1.0150

11.8 1.0100

11.9 1.0050

12.0 1.0000

Zone I II III IV V VI

15 12.49 15.63 17.29 14.98 14.66 15.39

16 12.58 15.79 17.68 15.31 14.87 15.83

17 12.70 15.94 18.05 15.63 15.07 16.25

18 12.83 16.07 18.39 15.93 15.26 16.64

19 12.98 16.20 18.72 16.21 15.44 17.01

20 13.15 16.31 19.03 16.48 15.62 17.35

21 13.33 16.41 19.32 16.72 15.79 17.66

22 13.54 16.50 19.59 16.95 15.95 17.95

23 13.76 16.57 19.83 17.16 16.10 18.21

24 14.00 16.64 20.06 17.35 16.24 18.45

25 14.26 16.69 20.27 17.53 16.38 18.66

26 14.53 16.73 20.46 17.68 16.51 18.84

27 14.83 16.76 20.63 17.82 16.63 19.00

28 15.14 16.77 20.77 17.94 16.74 19.13

29 15.47 16.78 20.90 18.04 16.84 19.24

30 15.82 16.77 21.01 18.13 16.94 19.32

Zone 1 2 3 4 5 6

t 33.0 33.0 33.0 33.0 33.0 33.0

15.82 16.78 21.01 18.13 16.94 19.32

thicknes 33.0

zone 3.0

21.01

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Certificate-10-"Hydrological Studies of Kishna RiverDocument26 pagesCertificate-10-"Hydrological Studies of Kishna RiverashoknrNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- NHAI LetterDocument1 pageNHAI LetterashoknrNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Mini Proj Sample Report BPPDocument50 pagesMini Proj Sample Report BPPashoknrNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Seminar Report On Self Sustainable BuildingDocument32 pagesA Seminar Report On Self Sustainable BuildingashoknrNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- S. Y. B. Tech. (Civil Engineering) - I, Semester-III: Course ContentDocument5 pagesS. Y. B. Tech. (Civil Engineering) - I, Semester-III: Course ContentashoknrNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Certificate 1 Biomedical Waste Management PVDDocument3 pagesCertificate 1 Biomedical Waste Management PVDashoknrNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Certificate-9-"SUITABLE CONDITIONS FOR ROOTZONE-UbaleDocument3 pagesCertificate-9-"SUITABLE CONDITIONS FOR ROOTZONE-UbaleashoknrNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Certificate-12-"Hydrological Studies of Chandrabhaga River'Document3 pagesCertificate-12-"Hydrological Studies of Chandrabhaga River'ashoknrNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Certificate-11-"Hydrological Studies of Panchaganga River'Document3 pagesCertificate-11-"Hydrological Studies of Panchaganga River'ashoknrNo ratings yet

- Certificate 1 Biomedical Waste Management PVDDocument3 pagesCertificate 1 Biomedical Waste Management PVDashoknrNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- PROJECT REPORT (ITS) - Mini Project-Bipin PatilDocument51 pagesPROJECT REPORT (ITS) - Mini Project-Bipin PatilashoknrNo ratings yet

- Justifications 17.9.18Document23 pagesJustifications 17.9.18ashoknrNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Biomediacal Waste Project FinalDocument43 pagesBiomediacal Waste Project Finalashoknr100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Certificate 1 Biomedical Waste Management PVDDocument3 pagesCertificate 1 Biomedical Waste Management PVDashoknrNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Justifications 17.9.18Document23 pagesJustifications 17.9.18ashoknrNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- S. Y. B. Tech. (Civil Engineering) - I, Semester-III: Course ContentDocument5 pagesS. Y. B. Tech. (Civil Engineering) - I, Semester-III: Course ContentashoknrNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Road Note No. 4 Method/DOE MethodDocument11 pagesRoad Note No. 4 Method/DOE MethodashoknrNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Po 1Document1 pagePo 1ashoknrNo ratings yet

- Grading & Surface Area of Aggregates ExplainedDocument22 pagesGrading & Surface Area of Aggregates ExplainedashoknrNo ratings yet

- Presented BY: Ashok KumarDocument50 pagesPresented BY: Ashok KumarashoknrNo ratings yet

- Po 1Document1 pagePo 1ashoknrNo ratings yet

- NHAI LetterDocument1 pageNHAI LetterashoknrNo ratings yet

- Raw Materials of Portland: - Lime - Silica - Alumina - Iron OxideDocument10 pagesRaw Materials of Portland: - Lime - Silica - Alumina - Iron OxideashoknrNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ACI MethodDocument57 pagesACI MethodashoknrNo ratings yet

- Lab Manual of Concrete Technology: Chetan S. PatilDocument76 pagesLab Manual of Concrete Technology: Chetan S. PatilashoknrNo ratings yet

- Proposals For IIC in WIT SolapurDocument1 pageProposals For IIC in WIT SolapurashoknrNo ratings yet

- External Audit Format - 25022021Document17 pagesExternal Audit Format - 25022021ashoknrNo ratings yet

- Chapter Name-Airport Obstructions Add Sections: 1) Imaginary Surfaces: A) Add Video B) Quiz C) Lecture Notes In-Video QuizDocument1 pageChapter Name-Airport Obstructions Add Sections: 1) Imaginary Surfaces: A) Add Video B) Quiz C) Lecture Notes In-Video QuizashoknrNo ratings yet

- Walchand Institute of Technology, Solapur B.E. Part-II 2018-19 (CBCS Pattern) In-Sem. Examination - IIIDocument2 pagesWalchand Institute of Technology, Solapur B.E. Part-II 2018-19 (CBCS Pattern) In-Sem. Examination - IIIashoknrNo ratings yet

- Live Interactions Via Google Meet: Kameswari Chebrolu Department of CSE, IIT BombayDocument5 pagesLive Interactions Via Google Meet: Kameswari Chebrolu Department of CSE, IIT BombayAshok Kumar RajanavarNo ratings yet

- Piping Dead Legs: Plastic Pipe Is Particularly Susceptible To Freeze CrackingDocument3 pagesPiping Dead Legs: Plastic Pipe Is Particularly Susceptible To Freeze CrackingJithin FrancizNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Resume of Coolb215Document1 pageResume of Coolb215api-25059817No ratings yet

- 7th Congr Mat TestDocument6 pages7th Congr Mat TestAlireza KhodabandehNo ratings yet

- Chapter 1 - 5 PDFDocument43 pagesChapter 1 - 5 PDFYARLAGADDA_NANINo ratings yet

- Hvac Duct Static Pressure CalculationDocument9 pagesHvac Duct Static Pressure CalculationSharifur RehmanNo ratings yet

- VRF DX indoor, outdoor unit schedulesDocument10 pagesVRF DX indoor, outdoor unit schedulesnazile_05No ratings yet

- 8 STD - 01505 - enDocument4 pages8 STD - 01505 - en方綵樺No ratings yet

- Introduction To History of Contemporary ArchitectureDocument2 pagesIntroduction To History of Contemporary ArchitectureSaumya ShuklaNo ratings yet

- Reinforced Concrete Design Course OutlineDocument59 pagesReinforced Concrete Design Course OutlineBobby AguilarNo ratings yet

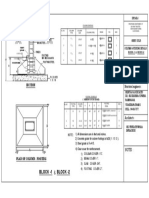

- Column & Footing Details Block-1 & Block-2Document1 pageColumn & Footing Details Block-1 & Block-2Sandeep VarmaNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Design Guide 31 - Castellated and Cellular Beam DesignDocument117 pagesDesign Guide 31 - Castellated and Cellular Beam DesignLCS100% (18)

- 2016CompositeList Web 142Document1 page2016CompositeList Web 142AnuranjanNo ratings yet

- C101 Electrolytic Tough Pitch CopperDocument2 pagesC101 Electrolytic Tough Pitch CopperMADDI MADHAV.No ratings yet

- 165 Portland Road Construction Management PlanDocument13 pages165 Portland Road Construction Management PlanOrchie DavidNo ratings yet

- Vectus PPRC Pipes and FittingsDocument13 pagesVectus PPRC Pipes and FittingsVeera CompressorNo ratings yet

- Gravity Based Structure FoundationDocument8 pagesGravity Based Structure FoundationHa NgNo ratings yet

- Composite Floor Deck Design PDFDocument4 pagesComposite Floor Deck Design PDFsaipodinNo ratings yet

- Boundary Wall NIT 3-1Document2 pagesBoundary Wall NIT 3-1Er Soumen Dey KhanNo ratings yet

- Micro Air 100 PDFDocument2 pagesMicro Air 100 PDFFrancois-No ratings yet

- EN ASME RuryDocument3 pagesEN ASME RuryGentelmanOnlyNo ratings yet

- S G209 CrosbyDocument1 pageS G209 CrosbyJS168No ratings yet

- Windmason Technical SpecificationDocument8 pagesWindmason Technical Specificationowais mirNo ratings yet

- The Ultimate Guide To Waterproofing SolutionsDocument9 pagesThe Ultimate Guide To Waterproofing SolutionsNippon Paint Total Coating and Construction SolutionsNo ratings yet

- Fiber Reinforced Plastics VesselsDocument5 pagesFiber Reinforced Plastics VesselsandreshuelvaNo ratings yet

- ACO Rail BrochureDocument21 pagesACO Rail BrochurePKNo ratings yet

- Fundamentals of Metal FormingDocument9 pagesFundamentals of Metal FormingGeorge CamachoNo ratings yet

- Rule 1220: Elevators & Related EquipmentDocument10 pagesRule 1220: Elevators & Related EquipmentMonjo CasiñoNo ratings yet

- Boiler ManualDocument68 pagesBoiler ManualAnwar AliNo ratings yet

- 2 Stresses in Pavements Solved Examples With Charts of FlexibleDocument17 pages2 Stresses in Pavements Solved Examples With Charts of FlexibleNahom Esh100% (1)

- TunnellingDocument37 pagesTunnellingrockyminNo ratings yet