Professional Documents

Culture Documents

76-1 P

Uploaded by

walkermountainOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

76-1 P

Uploaded by

walkermountainCopyright:

Available Formats

CALL 800-810-1053 FOR HELP

OPERATOR’S MANUAL PD02P-X

INCLUDING: OPERATION, INSTALLATION & MAINTENANCE RELEASED: 10-1-96

REVISED: 12-7-00

(REV. H)

1/4” DIAPHRAGM PUMP

1:1 RATIO (NON-METALLIC)

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

SERVICE KITS

Refer to Service Kit Chart to match pump material with Service Kits ofĆ

fered. The X" represents a variable digit of the Model Number.

637276 Air Valve Kit.

637313ĆXX for Pump Wet End Repair (model digits 7 and 11).

637314ĆXX for Pump Rebuild (model digits 7 and 11).

PUMP DATA

Models . . . . . . .see Model Description Chart" for ĆXXX".

Pump Type . . . . NonĆMetallic Air Operated Double Diaphragm.

Material . . . . . . .

see ``Model Description Chart".

Weight . . . . . . . .

Polypropylene . . . . . . 4.08 lbs (1.85 kgs)

Groundable Acetal . . . 4.64 lbs (2.10 kgs)

PVDF (KynarR) . . . . . 4.9 lbs (2.22 kgs)

Maximum Air Inlet Pressure . . . . . . . . . 100 p.s.i.g. (6.9 bar)

Minimum Air Inlet Pressure . . . . . . . . . . 20 p.s.i.g. (1.4 bar)

Maximum Outlet Pressure . . . . . . . . . . . 100 p.s.i.g. (6.9 bar) PD02PĆXXSĆXTX

Maximum Flow Rate . . . . . . . . . . . . . . . 4.6 g.p.m. (17.4 liters) 1/4'' DIAPHRAGM PUMP

Maximum Suction Lift . . . . . . . . . . . . . . 20 ft. (water)

Maximum Output Per Cycle . . . . . . . . . . 0.014 gallons (53 cc's)

Maximum Particle Size . . . . . . . . . . . . . clean fluid only MODEL DESCRIPTION CHART

Maximum Temperature Limits

Polypropylene . . . . . 35_ to 150_ F (2_ to 66_ C) PD02 P Ć X X S Ć X T X

Groundable Acetal . . 10_ to 180_ F (Ć12_ to 82_ C) CENTER BODY MATERIAL

PVDF (Kynar) . . . . . 10_ to 200_ F (Ć12_ to 93_ C) P - Polypropylene

Groundable . . . . . . . . . . . PD02PĆXDSĆDTX models only. INLET / OUTLET

Dimensional Data . . . . . . . . . . . . . . . . . see page 8. A - Single Inlet / Single Outlet

Noise Level @ 70 p.s.i., 60 c.p.m. . . . . . 59.8 db(A)¬ D - Single Inlet / Double Outlet

¬ The pump sound pressure levels published here have been updated to an Equivalent Continuous Sound E - Double Inlet / Single Outlet

Level (LAeq) to meet the intent of ANSI S1.13Ć1971, CAGIĆPNEUROP S5.1 using four microphone locations. H - Double Inlet / Double Outlet

NOTICE: All possible options are shown in the chart. However, certain

combinations may not be recommended, consult a representative or the WET END / FLUID CAP / MANIFOLD MATERIAL

D - Groundable Acetal

factory if you have questions concerning availability.

K - PVDF (KynarR)

P - Polypropylene

GENERAL DESCRIPTION HARDWARE MATERIAL

S - Stainless Steel

The ARO Diaphragm Pump offers high volume delivery even at low air presĆ

CHECK VALVE SEAT MATERIAL

sures, easy self priming, the ability to pump various viscosity materials and

D - Groundable Acetal

the ability to pass solids (as stated in the chart above). The pump is designed K - PVDF (Kynar)

to correspond to the needs of the user by offering a variety of wetted parts P - Polypropylene

configurations to handle almost any application. CHECK MATERIAL

Air operated double diaphragm pumps utilize a pressure differential in the T - T.F.E. (TeflonR)

air chambers to alternately create suction and positive fluid pressure in the

DIAPHRAGM / O" RING MATERIAL

fluid chambers. Flat checks insure a positive flow of fluid.

A - SantopreneR / E.P.R.

Pump cycling will begin as air pressure is applied and it will continue to pump G - Nitrile / Nitrile

and keep up with the demand. It will build and maintain line pressure and will T - T.F.E. (Teflon) / T.F.E. (Teflon) / Nitrile

stop cycling once maximum line pressure is reached (dispensing device

FLUID SECTION SERVICE KIT SELECTION PD02P Ć X X S Ć X T X

closed) and will resume pumping as needed.

Model PD02PĆXDSĆDTX: The Acetal material used in this pump contains EXAMPLE: MODEL # PD02PĆADSĆDTA 637313 Ć X X

FLUID SECTION SERVICE KIT # 637313ĆDA Wet End Material

Stainless Steel fibers. It's conductivity allows it to be connected to a suitable Diaphragm Material

ground. A ground screw is provided for this.

INGERSOLL-RAND COMPANY

P.O. BOX 151 D ONE ARO CENTER D BRYAN, OHIO 43506Ć0151

& (419) 636-4242 D FAX (419) 633-1674 E2000 D PRINTED IN U.S.A.

CALL 800-810-1053 FOR HELP

CALL 800-810-1053 FOR HELP

OPERATING AND SAFETY PRECAUTIONS

READ, UNDERSTAND, AND FOLLOW THIS INFORMATION TO AVOID INJURY AND PROPERTY DAMAGE.

S Disconnect air supply line and relieve pressure from the sysĆ

EXCESSIVE AIR PRESSURE HAZARDOUS MATERIALS

HAZARDOUS PRESSURE

tem by opening dispensing valve or device and / or carefully

STATIC SPARK

and slowly loosening and removing outlet hose or piping from

pump.

WARNING EXCESSIVE AIR PRESSURE. Can cause personĆ WARNING HAZARDOUS MATERIALS. Can cause serious

al injury, pump damage or property damage. injury or property damage. Do not attempt to return a pump to

S Do not exceed the maximum inlet air pressure as stated on the the factory or service center that contains hazardous material.

pump model plate. Safe handling practices must comply with local and national

S Be sure material hoses and other components are able to withĆ laws and safety code requirements.

stand fluid pressures developed by this pump. Check all S Obtain Material Safety Data Sheets on all materials from the

hoses for damage or wear. Be certain dispensing device is supplier for proper handling instructions.

clean and in proper working condition. CAUTION Verify the chemical compatibility of the pump

WARNING STATIC SPARK. Can cause explosion resulting wetted parts and the substance being pumped, flushed or reĆ

in severe injury or death. Ground pump and pumping system. circulated. Chemical compatibility may change with temperaĆ

S PD02PĆXDSĆDTX Groundable Acetal pumps: Use the pump ture and concentration of the chemical(s) within the

grounding screw provided. A screw terminal is provided on substances being pumped, flushed or circulated. For specific

the manifold. Connect a 12 ga. (min.) wire (66885Ć1 kit is availĆ fluid compatibility, consult the chemical manufacturer.

able) to a good earth ground source. CAUTION Maximum temperatures are based on mechaniĆ

S The pumping system and object being sprayed must be cal stress only. Certain chemicals will significantly reduce

grounded when it is pumping, flushing, recirculating or sprayĆ maximum safe operating temperature. Consult the chemical

ing flammable materials such as paints, solvents, lacquers, manufacturer for chemical compatibility and temperature limĆ

etc. or used in a location where surrounding atmosphere is its. Refer to PUMP DATA on page 1 of this manual.

conducive to spontaneous combustion. CAUTION Be certain all operators of this equipment have

S Use the pump grounding screw terminal provided. Use Aro been trained for safe working practices, understand it's limitaĆ

Part No. 66885Ć1 Ground Kit or connect a suitable ground wire tions, and wear safety goggles / equipment when required.

(12 ga. min.) to a good earth ground source.

CAUTION Do not use the pump for the structural support of

S Secure pump, connections and all contact points to avoid

vibration and generation of contact or static spark. the piping system. Be certain the system components are

S Consult local building codes and electrical codes for specific properly supported to prevent stress on the pump parts.

grounding requirements. S Suction and discharge connections should be flexible conĆ

S After grounding, periodically verify continuity of electrical nections (such as hose), not rigid piped, and should be comĆ

path to ground. Test with an ohmmeter from each component patible with the substance being pumped.

(e.g., hoses, pump, clamps, container, spray gun, etc.) to CAUTION Prevent unnecessary damage to the pump. Do

ground to insure continuity. Ohmmeter should show 100 not allow pump to operate when out of material for long periĆ

ohms or less. ods of time.

S Submerse the outlet hose end, dispensing valve or device in S Disconnect air line from pump when system sits idle for long

the material being dispensed if possible. (Avoid free streamĆ periods of time.

ing of material being dispensed.) CAUTION Use only genuine ARO replacement parts to asĆ

S Use hoses incorporating a static wire. sure compatible pressure rating and longest service life.

S Use proper ventilation. NOTICE Replacement warning labels are available upon

S Keep inflammables away from heat, open flames and sparks. request: ``Static Spark & Diaphragm Rupture'' PN \ 94080.

S Keep containers closed when not in use.

WARNING Pump exhaust may contain contaminants. Can

cause severe injury. Pipe exhaust away from work area and WARNING = Hazards or unsafe practices which could

personnel. result in severe personal injury, death or

S In the event of a diaphragm rupture material can be forced out substantial property damage.

of the air exhaust muffler. CAUTION = Hazards or unsafe practices which could

S Pipe the exhaust to a safe remote location when pumping hazĆ result in minor personal injury, product

ardous or inflammable materials. or property damage.

S Use a grounded 1/4" min. i.d. hose between the pump and the

muffler. NOTICE = Important installation, operation or

maintenance information.

WARNING HAZARDOUS PRESSURE. Can result in serious

injury or property damage. Do not service or clean pump,

hoses or dispensing valve while the system is pressurized.

PAGE 2 OF 8 PD02PĆX

CALL 800-810-1053 FOR HELP

CALL 800-810-1053 FOR HELP

AIR AND LUBE REQUIREMENTS OPERATING INSTRUCTIONS

WARNING EXCESSIVE AIR PRESSURE. Can cause pump S Always flush the pump with a solvent compatible with the material

damage, personal injury or property damage. being pumped, if the material being pumped is subject to ``setting

S A filter capable of filtering out particles larger than 50 microns up" when not in use for a period of time.

should be used on the air supply. In most applications there is no S Disconnect the air supply from the pump if it is to be inactive for a

lubrication required other than the O" ring lubricant which is apĆ few hours.

plied during assembly or repair. S The outlet material volume is governed not only by the air supply,

S The pump can be rotated 360_ to suit the application. It may be but also by the material supply available at the inlet. The material

mounted upside down or on the wall with no effect on suction lift or supply tubing should not be too small or restrictive. Be sure not to

operating efficiency. The filter and regulator need to be oriented in a use hose which might collapse.

normal vertical direction to function properly.

S Pipe plugs are included for the material inlets. They can be MAINTENANCE

switched to accommodate piping requirements. However, the fluid

inlet must always be in the port closest to the mounting base. Refer to the part list on page 4 for Service Kit Information, parts view on

S When lubricated air is necessary, supply the air lubricator with a page 5 and Repair Procedures on page 6.

good grade of SAE 90 wt. nonĆdetergent oil and set the lubricator to S Certain ARO Smart Parts" are indicated which should be available

a rate not to exceed one drop per minute. for fast repair and reduction of down time.

S Service kits are divided to service two separate diaphragm pump

functions: 1. Air Section, 2. Fluid Section. The Fluid Section is diĆ

INSTALLATION vided further to match typical part Material Options.

S NOTICE: ReĆtorque fasteners prior to use. Refer to step #18 on S Provide a clean work surface to protect sensitive internal moving

page 6 for information. parts from contamination from dirt and foreign matter during serĆ

S Apply Teflon tape or pipe sealant to threads upon assembly to preĆ vice disassembly and reassembly.

vent leakage. S Keep good records of service activity and include pump in prevenĆ

S Secure the diaphragm pump legs to a suitable surface to insure tive maintenance program.

against damage by vibration.

S To avoid problems, install a particle fluid filter to screen out foreign

matter 1/32" (.79 mm) or larger in diameter.

S The pump is not recommended for submerged applications.

S When the diaphragm pump is used in a forcedĆfeed (flooded inlet)

situation, it is recommended that a Check Valve" be installed at the

air inlet.

S TeflonR is a registered trademark of the DuPont Company, S KynarR is a trademark of Penwalt Corp.,

S SantopreneR is a registered trademark of Monsanto Company, licensed to Advanced Elastomer Systems, L.P. S LubriplateR is a registered trademark of Lubriplate Division (Fiske Brothers)

PD02PĆX PAGE 3 OF 8

CALL 800-810-1053 FOR HELP

CALL 800-810-1053 FOR HELP

PARTS LIST / PD02P-X

Refer to the Kit Selection Chart on page 1 for proper ĆXX" for your model. Lubriplatepacket 94276 is included with all kits.

SERVICE KITS KIT NUMBER THESE ITEMS ARE INCLUDED IN THE KITS

DIAPHRAGM KIT 637313ĆXX 7 13 19 22 33 41 64

COMPLETE REBUILD KIT 637314ĆXX 7 13 19 22 33 41 64 102 111 119 137 144 146 147 161

AIR VALVE KIT 637276 102 111 132 134 135 137 145 146 178 179

DIAPHRAGM OPTIONS

7" 64" 19" 33" 13"

PD02PĆ Diaphragm O" Ring (2) Seal O" Ring (2) BackĆUp Ring

ĆXXX (2) [MTL] (.157" x 3.424" o.d.) [MTL] (4) [MTL] (.103" x .693" o.d.) [MTL] (2) [MTL]

ĆXXA 93808 [SP] ----- --- 94434 [E] 94437 [E] 95127 [T]

ĆXXG 93808ĆG [B] ----- --- 94434ĆG [B] 94438 [T] 95127 [T]

ĆXXT 93898 [T] 93947 [B] 94435 [T] 94438 [T] 95127 [T]

COMMON PARTS

PD02P Ć X X S Ć X T X POLYPROPYLENE ACETAL KYNAR

PD02PĆXPSĆPTX PD02PĆXDSĆDTX PD02PĆXKSĆKTX

ITEM DESCRIPTION (SIZE IN INCHES) QTY PART NO. [MTL] PART NO. [MTL] PART NO. [MTL]

j 1 Rod (2Ć13/16" long) (1) 93916 [C] 93916 [C] 93916 [C]

j 5 Washer (1Ć3/4" o.d.) (2) 93938 [Z] 94938 [Z] 93938 [Z]

j 6 Diaphragm Screw (1/4" Ć 20) (2) 93810Ć1 [P] 93810Ć2 [D1] 93810Ć3 [PK]

17 Manifold (Air Inlet) (1) 94246Ć1 [P] 94246Ć2 [G] 94246Ć4 [PK]

18 Manifold (1) 94247Ć1 [P] 94247Ć2 [G] 94247Ć4 [PK]

22 Disc (4) 94525 [T] 94525 [T] 94525 [T]

41 Spring Stop (4) 93814Ć1 [P] 93814Ć2 [D1] 93814Ć3 [PK]

43 Screw (#10 Ć 32 x 1") (4) 94436 [SS] 94436 [SS] 94436 [SS]

62 Nut (1/4" Ć 20) (6) 93828 [SS] 93828 [SS] 93828 [SS]

63 Pipe Plug (1/4 Ć 18 N.P.T.) (`) 93832Ć1 [P] 93832Ć2 [D2] 93832Ć3 [PK]

j 65 Fluid Cap (`) 94245Ć1 [P] 94245Ć2 [G] 94245Ć4 [PK]

j 66 Fluid Cap (w / one blocked tube) (`) 94344Ć1 [P] 94344Ć2 [G] 94344Ć3 [PK]

j 68 Air Cap (w / Groove d ) (1) 93804 [P] 93804 [P] 93804 [P]

j 69 Air Cap (w / Tongue Z ) (1) 93805 [P] 93805 [P] 93805 [P]

74 Pipe Plug (3/8 Ć 18 N.P.T.) (`) 94478Ć1 [P] 94478Ć2 [D2] 94478Ć3 [PK]

131 Bolt (1/4" Ć 20 x 6.375") (6) 94526 [SS] 94526 [SS] 94526 [SS]

AIR SECTION PARTS

ITEM DESCRIPTION (Size in Inches) QTY PART NO. [MTL] ITEM DESCRIPTION (Size In Inches) QTY PART NO. [MTL]

102 O" Ring (1/16" x 7/8" o.d.) (3) Y325Ć18 [B] 138 O" Ring (.103" x .818" o.d.) (1) 94760 [U]

103 Bushing (1) 93917 [D2] 144 U" Cup (1/8" x 5/8" o.d.) (2) Y186Ć45 [B]

110 U" Cup (1/8" x 13/16" o.d.) (1) Y186Ć54 [B] j145 Minor Valve Block (1) 93807 [R]

j111 Spool Asm. (Includes #110,#138,#180) (1) 67163 [D2] 146 O" Ring (1/16" x 5/16" o.d.) (2) Y325Ć8 [B]

119 O" Ring (.106" x .587" o.d.) (4) 15066 [B] 147 O" Ring (1/16" x 7/16" o.d.) (2) Y325Ć11 [B]

132 Gasket (1) 93809 [Kr] 161 O" Ring (3/32" x 9/16" o.d.) (2) Y325Ć110 [B]

134 Screw (#4 Ć 20 x 5/16") (3) 93942 [SS] 178 Trip Rod Assembly (Includes #119) (2) 65145 [D2]

j135 Valve Block (1) 93806 [R] 179 Sleeve Assembly (Includes #119) (1) 65144 [D2]

137 O" Ring (1/16" x 1" o.d.) (1) Y325Ć20 [B] 180 O" Ring (.106" x .587" o.d.) (1) 15066ĆU [U]

MATERIAL CODE

[B] = Nitrile [E] = EPR [P] = Polypropylene (Lt. Gray) [SS] = Stainless Steel

[C] = Carbon Steel [G] = Groundable Acetal (Dk Gray) High Density Polyprop. (Green) [T] = Teflon

[D1] = Acetal (Orange) [Kr] = Kraton [R] = Ryton [U] = Polyurethane

[D2] = Acetal (White) [PK] = Pure Kynar [SP] = Santoprene [Z] = Zinc

` Quantities will vary, depending on the inlet / outlet option selected (refer to chart on page 5).

V Smart Parts", keep these items on hand in addition to the Service Kits for fast repair and reduction of down time.

PAGE 4 OF 8 PD02PĆX

CALL 800-810-1053 FOR HELP

CALL 800-810-1053 FOR HELP

PARTS LIST / PD02P-X

69

1 103 144

13 144

33

B"

41 22

19

18

Logo Plate

(Tongue)

17

63

161

A"

147 43 ,

62 , 6,

7

64

5

68

(Groove)

74

131 ,

FIGURE 1

110 138 180 137 135 102 INLET / OUTLET FLUID CAP ITEM 63 ITEM 74

OPTIONS A" B" QTY QTY

SI / SO 65 65 (1) (1)

SI / DO 66 65 - (1)

DI / SO 65 66 (1) -

DI / DO 66 66 - -

111 132

. TORQUE REQUIREMENTS ,

146 NOTE: DO NOT OVERTIGHTEN FASTENERS

(6) / (5) Diaphragm nut / washer 75 Ć 85 in. lbs (8.5 Ć

9.6 Nm), use Loctite #242, tighten together.

178 (43) Torque to 20 Ć 25 in. lbs (2.3 Ć 2.8 Nm).

(62) / (131) Manifold bolts / nuts 70 in. lbs max (7.9

179 Nm max), tighten together alternately &

102 evenly, then reĆtorque.

145 134 , (134) Torque to 4 Ć 6 in. lbs (.45 Ć .68 Nm).

102

AIR VALVE SECTION LUBRICATION

FIGURE 2 Apply Lubriplate grease (94276) to all

119 (SHOWN 2X SCALE)

O" rings, U" cups & mating parts.

PD02PĆX PAGE 5 OF 8

CALL 800-810-1053 FOR HELP

CALL 800-810-1053 FOR HELP

PUMP DISASSEMBLY AND REASSEMBLY

GENERAL PUMP REPAIR NOTES: 5. Assemble diaphragm assemblies into air caps and torque to 75 Ć 85

S Tools needed to complete disassembly and repair: in. lbs (8.5 Ć 9.6 Nm), using 5/8" wrenches.

S 5/16" wrench or socket, 7/16" socket, 5/8" wrench or socket, 6. Assemble two (147) O" rings to the raised air passages, opposite

1/4" Allen wrench, 5/16" Allen wrench, spanner wrench, torque each other, inside (68) air cap.

wrench (measuring inch pounds), O" ring pick. 7. Set (A") fluid cap on the workbench, with the tube side" down.

S Once the pump is disassembled, you have the opportunity to clean 8. Assemble two (161) O" rings to counterbores in (A") fluid cap.

and inspect all parts for wear. Look for deep scratches on metallic 9. Assemble (22) disc and (41) spring stop to the check seat nearest the

surfaces and nicks or cuts in O" rings. Replace old parts with new top tube of (A") fluid cap (top tube has the shoulder on the outside).

ones as necessary. 10. Assemble (41) spring stop and (22) disc (disc on top) to check seat

S Take precautions to prevent cutting O" rings upon installation. nearest the bottom tube (shoulder on outside).

S Lubricate ``O" rings and U" cups with Lubriplate. A packet of this 11. Lubricate seal grooves in (17) air inlet manifold and assemble (19)

lubricant is included in each Service Kit. seals to grooves.

S Do not overĆtighten fasteners. Refer to torque specification block 12. Assemble (17) air inlet manifold to (A") fluid cap, aligning fluid inlet

on page 5. with lower tube (shoulder on outside).

S ReĆtorque fasteners following restart. 13. Secure with two (43) screws. Torque to 20 Ć 25 in. lbs (2.3 Ć 2.8 Nm),

Service Kits available. From your local distributor. using a 5/16" wrench.

(Kits also include Lubriplate grease packet.) 14. Repeat steps 9 thru 13 for opposite end of pump. NOTE: The tubes

S SERVICE KIT: 637314ĆXX contains parts for a complete pump rebuild. are reversed on (B") fluid cap (top tube has outside shoulder).

S SERVICE KIT: 637276 contains parts to rebuild the air valve. 15. Assemble (33) O" rings and (13) backĆup rings to the outside shoulĆ

S SERVICE KIT: 637313ĆXX contains parts to rebuild the der of tubes of (A" and B") fluid caps.

diaphragms and checks. 16. Assemble (17) air inlet manifold and components into (68) air cap,

being sure to align groove in manifold with rib in air cap.

17. Assemble (18) manifold and components into (69) air cap, being

FLUID SECTION DISASSEMBLY sure to align groove in manifold with rib in air cap.

1. Place the pump on a flat workbench. 18. Assemble six (131) bolts and (62) nuts to pump and torque to 70 in.

2. Using 7/16" sockets, remove six (62) nuts and (131) bolts. lbs max (7.9 Nm max), using 7/16" sockets, hold the nut, torque the

3. Set the pump on end, with the air inlet" end up. bolt only. NOTE: Allow the pump to sit for at least 15 minutes, then

4. Using a flat blade screwdriver, remove (17) air inlet manifold and reĆtorque bolts to 70 in. lbs max (7.9 Nm max).

(A") fluid cap.

5. Remove (13) backĆup ring and (33) O" ring from (A") fluid cap. AIR VALVE SECTION DISASSEMBLY

6. Remove two (147) O" rings from (A") fluid cap.

7. Remove (18) manifold and (B") fluid cap. 1. Refer to Fluid Section Disassembly", steps 1 thru 9.

8. Remove (13) backĆup ring and (33) O" ring from (B") fluid cap. 2. Separate (68 and 69) air caps, releasing (103) bushing and logo

9. Using 5/8" wrenches on (6) diaphragm screws, unthread and reĆ plates.

move diaphragm assemblies. 3. Remove air valve assembly, (102, 137 and 146) O" rings and (144)

S NOTE: Air valve section can be repaired at this time, refer to Air U" cups from air caps.

Valve Disassembly". 4. Remove (111) spool assembly, (178) trip rods and (179) sleeve asĆ

10. Using a 5/16" wrench or flat blade screwdriver, remove two (43) sembly from (145) valve block.

screws from (17) air inlet manifold. 5. Remove O" rings and U" cup from (111) spool assembly.

11. Separate (17) air inlet manifold and (A") fluid cap. NOTE: (41) 6. Inspect (119) O" rings on (178) trip rods and (179) sleeve assembly.

spring stops and (22) discs may fall out. If not, remove at this time. 7. Remove three (134) screws, releasing (145) minor valve block and

12. Remove (19) seals and (161) O" rings. (132) gasket.

13. Disassembly of the opposite end of the pump is the same as the air

inlet" end, except for the following: a.) the opposite end does not

contain (161) O" rings and b.) the top tube has the outside shoulĆ

AIR VALVE SECTION REASSEMBLY

der, the bottom tube has the inside shoulder. 1. Assemble (132) gasket and (145) minor valve block to (135) valve

14. Wrap (1) rod in a shop rag and secure in a softĆfaced vise. block, securing with three (134) screws. NOTE: Torque to 4 Ć 6 in.

15. Using a 5/8" wrench, unthread (6) diaphragm screw from (1) rod. lbs (.45 Ć .68 Nm).

16. Using a 5/8" wrench on (6) diaphragm screw and a spanner wrench 2. Assemble (119) O" rings to (178) trip rods and (179) sleeve assembly.

on (5) washer, unthread and remove (6) diaphragm screw. 3. Assemble (178) trip rods and (179) sleeve assembly into (145)

valve block.

FLUID SECTION REASSEMBLY 4. Assemble (138 and 180) O" rings and (110) U" cup to (111) spool

assembly.

NOTE: Lubricate all O" rings, U" cups seals and their mating parts with 5. Assemble (111) spool assembly into (135) valve block, with small

94276 Lubriplate upon assembly. end of spool going into valve block first.

1. Place the new (7) diaphragms on the (6) diaphragm screw, with the 6. Assemble (102, 137 and 146) O" rings to valve block.

bowed side of the diaphragm oriented against (6) diaphragm screw. 7. Assemble (144) U" cups to (68 and 69) air caps.

2. Assemble (5) washer to (6) diaphragm screw and torque to 75 Ć 85 8. Place one (68 or 69) air cap on end, with legs down and seat valve

in. lbs (8.5 Ć 9.6 Nm), using a spanner wrench and a 5/8" wrench. block into air cap.

NOTE: Be sure not to strip the plastic nut. 9. Assemble logo plates and (103) bushing into air cap.

3. Assemble (1) rod to one of the diaphragm assemblies and tighten 10. Assemble other air cap to air cap, aligning logo plates, (178) trip rod

finger tight. and (103) bushing.

4. Models PD02PĆXXSĆXTT only: Assemble (64) O" rings into 11. Refer to Fluid Section Reassembly", steps 5 thru 18 to complete

grooves in (68 and 69) air caps. reassembly.

PAGE 6 OF 8 PD02PĆX

CALL 800-810-1053 FOR HELP

CALL 800-810-1053 FOR HELP

TROUBLE SHOOTING

Air Motor stalls. Air leaks from pump (other than exhaust).

S Check for blown diaphragm S Check for bolts not evenly or adequately torqued.

S Check for damaged O" rings on the spool. S Check for O" ring missing / damage between the fluid cap and the

S Check for damaged O" rings on the trip rod. air cap on the air inlet side.

S Check valve block gasket for leakage.

External fluid leaks from pump.

Air leaks from exhaust. S Check for bolts not properly torqued.

S Check for damaged O" rings on the valve block, spool or trip rod. S Check for damaged O" rings on the fluid cap tubes.

S Check gasket between valve blocks for leakage. S Check for damaged O" rings on the valve check.

S U" cups on connecting rod bushing are damaged or installed backĆ S Check for damaged diaphragm seal.

wards.

Pump operates but dispenses little or no fluid.

Fluid leaks from exhaust. S Check for obstruction in fluid line.

S Check for diaphragm damage. S Check for foreign matter clogging check assemblies.

S Check for diaphragm screws not adequately torqued. Note: Install a fluid screen on the material inlet hose if the problem

continues.

Low flow or pump continues to cycle after shutĆoff. S Suction line too small.

S Check for trapped air if the pump is oriented where the inlet check is S Check for air leakage at the air / fluid inlet pipe plugs. Use teflon

above the outlet check. Temporarily increase the flow or reĆprime tape or pipe sealant upon assembly.

the pump.

S Check for damaged seats or foreign matter clogging the check asĆ

sembly.

TYPICAL CROSS SECTION

PD02PĆX PAGE 7 OF 8

CALL 800-810-1053 FOR HELP

CALL 800-810-1053 FOR HELP

DIMENSIONAL DATA

Dimensions shown are for reference only. They are shown in inches and millimeters (mm).

END VIEWS

1Ć5/32" (30 mm)

11/16" (17 mm) 1/4 Ć 18 NPTF OUTLET

1/4 Ć 18 NPTF AIR INLET

1/4 Ć 18 NPTF OUTLET

4Ć17/32" 4Ć13/32"

(115 mm) (112 mm)

1Ć3/8" 1Ć9/32"

(35 mm) (32 mm)

1/4 Ć 18 NPTF EXHAUST 3/8 Ć 18 NPTF INLET 3/8 Ć 18 NPTF INLET

1Ć5/32" (30 mm)

5/16" (8 mm) SLOT 4Ć3/4" (121 mm)

11/16" (17 mm)

5Ć1/2" (140 mm)

SIDE VIEW

7Ć17/32" (191 mm)

5Ć5/8"

(143 mm)

6Ć1/2" (165 mm)

7Ć9/32" (185 mm)

PN 97999Ć681

PAGE 8 OF 8 PD02PĆX

CALL 800-810-1053 FOR HELP

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- 4 - Odd Hours - Dean KoontzDocument261 pages4 - Odd Hours - Dean KoontzJustinSnow80% (5)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- El Bill PDFDocument2 pagesEl Bill PDFvinodNo ratings yet

- Build Size and Aesthetics with the 6-Week Hype Gains Hypertrophy ProgramDocument21 pagesBuild Size and Aesthetics with the 6-Week Hype Gains Hypertrophy ProgramDanCurtis100% (1)

- Keys To Biblical CounselingDocument7 pagesKeys To Biblical CounselingDavid Salazar100% (6)

- Performance and Mechanical Running Tests of Centrifugal CompressorsDocument5 pagesPerformance and Mechanical Running Tests of Centrifugal CompressorsVicky KumarNo ratings yet

- HBSE-Mock ExamDocument3 pagesHBSE-Mock ExamAnneNo ratings yet

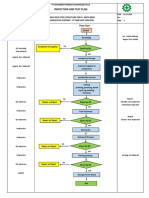

- Inspection and Test Plan: Flow Chart Start IncomingDocument1 pageInspection and Test Plan: Flow Chart Start IncomingSinden AyuNo ratings yet

- PE 560 Atomic Absorption Spectrophotometer ManualDocument176 pagesPE 560 Atomic Absorption Spectrophotometer ManualDavid Allan100% (1)

- DNV Rules For Electrical Instal at IonsDocument80 pagesDNV Rules For Electrical Instal at Ionsnzjohn100% (3)

- Chambal Cable Stayed Bridge Connecting ShoresDocument6 pagesChambal Cable Stayed Bridge Connecting Shoresafzal taiNo ratings yet

- Lesson 5 - The Problem of EvilDocument10 pagesLesson 5 - The Problem of Evilsemmerson4896No ratings yet

- Methodology For The Validation of Fuel Consumption in Diesel Engines Installed On Board Military Ships, Using Diesel Oil and Biodiesel BlendsDocument16 pagesMethodology For The Validation of Fuel Consumption in Diesel Engines Installed On Board Military Ships, Using Diesel Oil and Biodiesel BlendsErick RodriguesNo ratings yet

- Secondary AssessmentsDocument12 pagesSecondary Assessmentsapi-338389967No ratings yet

- Vastra Grah .Pvt. LTD: In-House Manufacturing FacaltyDocument2 pagesVastra Grah .Pvt. LTD: In-House Manufacturing FacaltySaurabh JainNo ratings yet

- Mole Concept: Chemfile Mini-Guide To Problem SolvingDocument18 pagesMole Concept: Chemfile Mini-Guide To Problem SolvingNaren ParasharNo ratings yet

- Indian Boyhood PDFDocument316 pagesIndian Boyhood PDFHasanNo ratings yet

- Catálogo SEDIVERDocument32 pagesCatálogo SEDIVEREnver Rojas DiazNo ratings yet

- Ulcus Decubitus PDFDocument9 pagesUlcus Decubitus PDFIrvan FathurohmanNo ratings yet

- Afforestation in Arid and Semi Arid RegionsDocument68 pagesAfforestation in Arid and Semi Arid RegionsMilian Marian SanduNo ratings yet

- 1 The Fifth CommandmentDocument10 pages1 The Fifth CommandmentSoleil MiroNo ratings yet

- Specialized Connective TissueDocument15 pagesSpecialized Connective TissueSebNo ratings yet

- Kloos Community Psychology Book FlyerDocument2 pagesKloos Community Psychology Book FlyerRiska MirantiNo ratings yet

- Rice Research: Open Access: Black Rice Cultivation and Forming Practices: Success Story of Indian FarmersDocument2 pagesRice Research: Open Access: Black Rice Cultivation and Forming Practices: Success Story of Indian Farmersapi-420356823No ratings yet

- Practical Research 1 Quarter 1 - Module 10: Through The SlateDocument10 pagesPractical Research 1 Quarter 1 - Module 10: Through The SlateMark Allen Labasan100% (1)

- Ielts Band Score 7Document2 pagesIelts Band Score 7Subhan Iain IINo ratings yet

- Catalogo Unidad Enfriadora Trane R-407C PDFDocument8 pagesCatalogo Unidad Enfriadora Trane R-407C PDFJUAN FRANCISCO AYALANo ratings yet

- Report Experiment 5 STK1211Document9 pagesReport Experiment 5 STK1211NurAkila Mohd YasirNo ratings yet

- CSK - W - My - Mother - at - Sixty - Six 2Document2 pagesCSK - W - My - Mother - at - Sixty - Six 2Aaron JoshiNo ratings yet

- Fiitjee JEE Adv p1 Phase II SolDocument10 pagesFiitjee JEE Adv p1 Phase II SolPadamNo ratings yet

- Atlas UC & BSPTCL Operational GSS & LinesDocument16 pagesAtlas UC & BSPTCL Operational GSS & LinesSandeep KumarNo ratings yet