Professional Documents

Culture Documents

E-Coating Process Final

Uploaded by

mpedraza-1Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

E-Coating Process Final

Uploaded by

mpedraza-1Copyright:

Available Formats

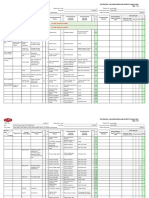

PROCESS FLOW DIAGRAM

Part No.: 1056329-002 ECL: 002 Rev: A

Part Name: Shield - Outer Rev. Date: 8/24/17 Date (Orig): Oct., 07, 2017

Prepared By: Lauren Ritter Department: Quality Date (Rev): Oct., 07, 2017

Customer: Kautex Textron PFD Type: Prototype

Symbol Instructions

(KCC, QCC)

(KPC, QCI)

Significant Product Significant Process

Store/Get

Class

Class

Op-

Operation Description Characteristics Characteristics

Inspect

Seq

Move

(Outputs) (Inputs)

Fab

Q

A Inspect a sheet of SMC 4

square feet

Manufacture and inspect SMC Material

10 1780grms - 1940grms

P/N: HS3502

See technical data sheet from

the provider.

Move the SMC to the maturation room. Controlled room temperature

20

P/N: HS3502 70F10F

Move to press. SMC HS3502 not more than 30 days

30

P/N: HS3502 from the date of manufacture

SMC: HS3502

Complete piece (4 mm +.5 / - Weight: 2.1 .1 lbs

40 Mold Part SC

.25) Tonnage: 150 100 tons

Time: 75 5 seconds

V

A

50 Move to table, Label Part, Inspect while cooling. SC Part has correct part number.

13 Mold byes

60 Sand mold byes. SC

See drawing

V

A

70 Deflash the part, Inspect Part. SC No sharp edges. Use 60 or 120 grit sandpaper

V

A

See criteria audit sheet. CMM

80 Final Inspection SC

6 pieces.

V

A

Meet quality requirements,

90 Pack the finished part and certify. SC including minimum dust on

parts/tote

100 Hold at shipping dock. Minimum dust prior load truck

V

A

110 Ship to Kautex SC Per orders

FEN-07-012 REV.B 2010/09/15 Page 1 of 1

You might also like

- Vendor Performance Report for AnchorDocument5 pagesVendor Performance Report for AnchoranhthoNo ratings yet

- Attn: Akebono Braxe Astra VietnamDocument5 pagesAttn: Akebono Braxe Astra VietnamanhthoNo ratings yet

- UncontrolledDocument31 pagesUncontrolledSerajahmad560% (1)

- Handling Manual for SPC Splice CrimpingDocument4 pagesHandling Manual for SPC Splice CrimpingTrần Long VũNo ratings yet

- Water Tank ItpDocument5 pagesWater Tank Itptuan mai vanNo ratings yet

- Water Tank ItpDocument5 pagesWater Tank ItpHgagselim SelimNo ratings yet

- Wenzhou Windmill Valve Co.,Ltd: Chemical Analysis of Material Certifaicate Inspection CertifaicateDocument1 pageWenzhou Windmill Valve Co.,Ltd: Chemical Analysis of Material Certifaicate Inspection CertifaicatePerumal Govindan100% (1)

- B Tech 6 Ce151019122826Document19 pagesB Tech 6 Ce151019122826srajan sonkesriyaNo ratings yet

- 003, SDLG G9290 SN 630027 Scarifier (Revised)Document1 page003, SDLG G9290 SN 630027 Scarifier (Revised)IhsanNo ratings yet

- Document Cover Sheet: China National Machinery Import and Export Corporation (CMC)Document8 pagesDocument Cover Sheet: China National Machinery Import and Export Corporation (CMC)VictorNo ratings yet

- SACEP - RTCC - Delivery #0971407-05Document12 pagesSACEP - RTCC - Delivery #0971407-05Ryan condeNo ratings yet

- Transformer: Quality Assurance PlanDocument9 pagesTransformer: Quality Assurance PlanRadhakrishnan VNo ratings yet

- Sample Manufacturing Quality Plan Format: (Logo of Manufacturer)Document12 pagesSample Manufacturing Quality Plan Format: (Logo of Manufacturer)P.Manna100% (1)

- Om-03 Hose Handling Crane PDFDocument126 pagesOm-03 Hose Handling Crane PDFcpîndaruNo ratings yet

- LIQUID PENETRANT TESTING PROCEDUREDocument23 pagesLIQUID PENETRANT TESTING PROCEDURESerajahmad56No ratings yet

- Insulation WorksDocument2 pagesInsulation WorksBangkit SamosirNo ratings yet

- Lube Oil Cooler: PT Sks Listrik Kalimantan Kalteng 1Document21 pagesLube Oil Cooler: PT Sks Listrik Kalimantan Kalteng 1Muhammad AbyNo ratings yet

- Sky Mqap1Document1 pageSky Mqap1Kumara SubramanianNo ratings yet

- DN SampleDocument2 pagesDN SamplemohamadazizhudliNo ratings yet

- SACEP - RTCC - Delivery #0971347-02Document16 pagesSACEP - RTCC - Delivery #0971347-02Ryan condeNo ratings yet

- Well Handover CertificateDocument1 pageWell Handover Certificateeng7mohamed7hashimNo ratings yet

- MI Plan For NDC Expected Order Date 05-06-2018 Rev 1 With VF50 - String 3Document29 pagesMI Plan For NDC Expected Order Date 05-06-2018 Rev 1 With VF50 - String 3EduardNo ratings yet

- 1TB01005-005C17-HAH-MAT-ME-0002-C0-Material Submittal For LSS Skid 2 RDocument5 pages1TB01005-005C17-HAH-MAT-ME-0002-C0-Material Submittal For LSS Skid 2 RMAZHAR ALINo ratings yet

- Process Sheet: Rev. No. 01 (19/10/2015)Document6 pagesProcess Sheet: Rev. No. 01 (19/10/2015)Suraj RawatNo ratings yet

- F02. Weekly Quality Observation Report - LTCDWSW&CWSBGQMQISF02 REV-0Document4 pagesF02. Weekly Quality Observation Report - LTCDWSW&CWSBGQMQISF02 REV-0RamBinodSharmaNo ratings yet

- Reports Material Fiberline Up2 AjgDocument10 pagesReports Material Fiberline Up2 AjgAndika PradanaNo ratings yet

- 8" Kpak PLUS 70K Modules: High Productivity Zero Bypass Ultrafiltration Modules For Electrocoat PaintDocument2 pages8" Kpak PLUS 70K Modules: High Productivity Zero Bypass Ultrafiltration Modules For Electrocoat PaintjeffersonfriasNo ratings yet

- CN202400-8002 On/ Off Valves: C/o Chemetics IncDocument2 pagesCN202400-8002 On/ Off Valves: C/o Chemetics IncImam Zulfir RamandhaNo ratings yet

- Sac1.sop1.sop2 - Ls-01-FeDocument15 pagesSac1.sop1.sop2 - Ls-01-FeEvandro BorgesNo ratings yet

- GM Process SheetDocument4 pagesGM Process SheetSuraj RawatNo ratings yet

- CP-SS BLK-01Document5 pagesCP-SS BLK-01yogesh WakchaureNo ratings yet

- 10 MM AS0480104Document1 page10 MM AS0480104mamdouhNo ratings yet

- UncontrolledDocument31 pagesUncontrolledSerajahmad56No ratings yet

- AEPCOM-QAP-3281-58548 Rev 1Document3 pagesAEPCOM-QAP-3281-58548 Rev 1VIVEK TIWARINo ratings yet

- Released 208184011 01 Lempb 049Document49 pagesReleased 208184011 01 Lempb 049haifa ayachiNo ratings yet

- Emily-1 Project Fuel Terminal and Jetty Compaction Inspection ReportDocument9 pagesEmily-1 Project Fuel Terminal and Jetty Compaction Inspection Reportmuhammad sauqiNo ratings yet

- SFTCSHT (Sindo)Document1 pageSFTCSHT (Sindo)Tony CeNo ratings yet

- Anant Corr. MOM 7-08-18Document4 pagesAnant Corr. MOM 7-08-18Abhimanyu Singh ChundawatNo ratings yet

- Gen PNG STD 001 - 02Document40 pagesGen PNG STD 001 - 02Jose C. MelendezNo ratings yet

- SACEP - RTCC - Delivery #0971406-04Document16 pagesSACEP - RTCC - Delivery #0971406-04Ryan condeNo ratings yet

- MPS 3lpeDocument11 pagesMPS 3lpeabhishek_me03No ratings yet

- Qap 8000ce Reactor - Repat - 1Document2 pagesQap 8000ce Reactor - Repat - 1AliasgarNo ratings yet

- Install Cable Tray SupportsDocument3 pagesInstall Cable Tray SupportsMohammad Fazal Khan100% (1)

- Work Instruction For Core Assy & Taping Process of MT047Document4 pagesWork Instruction For Core Assy & Taping Process of MT047k.mehaboob bashaNo ratings yet

- A325M - M24x70Document3 pagesA325M - M24x70nam nguyengiangNo ratings yet

- KSB MIL Steam Vent Valve Spec SheetDocument36 pagesKSB MIL Steam Vent Valve Spec SheetNutan PowerNo ratings yet

- PT - ILC Calendar and RecordsDocument3 pagesPT - ILC Calendar and Recordsarko_fcNo ratings yet

- Itp STR Slpg-Q-0000-24001-032-001-4-ADocument11 pagesItp STR Slpg-Q-0000-24001-032-001-4-AsivagnanamNo ratings yet

- SACEP - RTCC - Delivery #0971542-11Document16 pagesSACEP - RTCC - Delivery #0971542-11Ryan condeNo ratings yet

- IECEx MSC 20.0002 00-SignedDocument7 pagesIECEx MSC 20.0002 00-Signedwaylon simsNo ratings yet

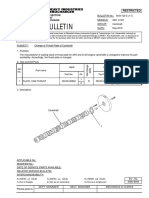

- Service Bulletin: Service Business Section Engine Department Engine & Energy DivisionDocument1 pageService Bulletin: Service Business Section Engine Department Engine & Energy DivisionFalgon IslamNo ratings yet

- Collar 9.5X10Document1 pageCollar 9.5X10Preetam KumarNo ratings yet

- 2024-1-U11-TA24-PIP-064-4-P11806-AD1-PP-UTTMDocument3 pages2024-1-U11-TA24-PIP-064-4-P11806-AD1-PP-UTTMinjoker fxNo ratings yet

- Model S1F Metallic Design Level 1: Service & Operating ManualDocument31 pagesModel S1F Metallic Design Level 1: Service & Operating ManualGonzalo IñiguezNo ratings yet

- Ajay Industrial Corporation LTD: ISO 9001:2015, EN ISO 14001:2015, OHSAS 18001:2007Document2 pagesAjay Industrial Corporation LTD: ISO 9001:2015, EN ISO 14001:2015, OHSAS 18001:2007Ankit SandhuNo ratings yet

- LSK-1055-15 Prov. MNS-030 To 34-15 42.5 N Lucky CementDocument1 pageLSK-1055-15 Prov. MNS-030 To 34-15 42.5 N Lucky CementMuhammad Hasan Anees Muhammad AneesNo ratings yet

- Reliance Industries heat exchanger inspection procedureDocument3 pagesReliance Industries heat exchanger inspection procedureRajnikant PatelNo ratings yet

- Rev 02Document3 pagesRev 02Suraj RawatNo ratings yet

- Advanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IIFrom EverandAdvanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IITatsuki OhjiNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDileep SinghNo ratings yet

- Benfard's LawDocument5 pagesBenfard's LawMoises PedrazaNo ratings yet

- Bernoulli and Binomial Distributions ExplainedDocument19 pagesBernoulli and Binomial Distributions Explainedmpedraza-1No ratings yet

- Qs865atez Data GR&RDocument2 pagesQs865atez Data GR&Rmpedraza-1No ratings yet

- Balanceo de LineaDocument4 pagesBalanceo de LineaRamon ArevaloNo ratings yet

- Corporate Standard CPS0098: 1 ScopeDocument11 pagesCorporate Standard CPS0098: 1 Scopempedraza-1No ratings yet

- Mpaps G 9005Document8 pagesMpaps G 9005mpedraza-1No ratings yet

- MPAPS Master IndexDocument15 pagesMPAPS Master Indexmpedraza-1100% (3)

- Mpaps D 7130Document4 pagesMpaps D 7130mpedraza-1No ratings yet

- Mpaps S B 4.101 Gs PLDocument6 pagesMpaps S B 4.101 Gs PLmpedraza-1No ratings yet

- RequirementsDocument18 pagesRequirementsmpedraza-1No ratings yet

- Mpaps G 9012Document5 pagesMpaps G 9012mpedraza-1No ratings yet

- MS - PROJECT 2010 - Tutorial PDFDocument26 pagesMS - PROJECT 2010 - Tutorial PDFssuupp108No ratings yet

- Mpaps G-5Document21 pagesMpaps G-5mpedraza-1100% (2)

- CEMS G-5 Part 1ADocument7 pagesCEMS G-5 Part 1Ampedraza-1No ratings yet

- Auditoria Por CapasDocument23 pagesAuditoria Por Capasmpedraza-1No ratings yet

- Buffon's Needle Problem ExplainedDocument11 pagesBuffon's Needle Problem Explainedmpedraza-1No ratings yet

- MS - PROJECT 2010 - Tutorial PDFDocument26 pagesMS - PROJECT 2010 - Tutorial PDFssuupp108No ratings yet

- 00-4759 Process Control Requirements PDFDocument1 page00-4759 Process Control Requirements PDFmpedraza-1No ratings yet

- Cap I Tulo 8 CalidadDocument2 pagesCap I Tulo 8 Calidadmpedraza-1No ratings yet

- DOE Paint Pops On Seam: CMT Columbus, OHDocument13 pagesDOE Paint Pops On Seam: CMT Columbus, OHmpedraza-1No ratings yet

- Minimum Automotive Quality Management System Requirements For Sub Tier Suppliers 2nded Rev2Document8 pagesMinimum Automotive Quality Management System Requirements For Sub Tier Suppliers 2nded Rev2R JNo ratings yet

- 00-4759 Process Control RequirementsDocument1 page00-4759 Process Control Requirementsmpedraza-1No ratings yet

- CD6 Prototype PFMEADocument4 pagesCD6 Prototype PFMEAmpedraza-1No ratings yet

- CD6 Prototype Control PlanDocument3 pagesCD6 Prototype Control Planmpedraza-1No ratings yet

- E-Coating Process FinalDocument3 pagesE-Coating Process FinalGthulasi78No ratings yet

- How to Use the APQP WorkbookDocument19 pagesHow to Use the APQP Workbookmpedraza-1100% (1)

- Early Learning AaDocument34 pagesEarly Learning Aaabdu_ihsanNo ratings yet

- AtlasDocument44 pagesAtlasmpedraza-1No ratings yet

- Microsoft Word - Bk1-LESSONS 1Document78 pagesMicrosoft Word - Bk1-LESSONS 1Dali Soares De Sá NardeliNo ratings yet

- Research Paper Definition of TermsDocument6 pagesResearch Paper Definition of Termsea813c29100% (1)

- Digital Technology, Digital Cabbility and Organization Performance 2018Document19 pagesDigital Technology, Digital Cabbility and Organization Performance 2018Marwa ElghifaryNo ratings yet

- Apac2014 PDFDocument64 pagesApac2014 PDFDe El Eurey ShineNo ratings yet

- ExerciseDocument29 pagesExerciseamnaanwar20No ratings yet

- Performance AppraisalDocument43 pagesPerformance Appraisalamn_thkrNo ratings yet

- AM Train ASEAN National Assessor Draft 190115Document62 pagesAM Train ASEAN National Assessor Draft 190115Tiara Niken ANo ratings yet

- DrAshrafElsafty ResearchMehods ESLSCA July12Document297 pagesDrAshrafElsafty ResearchMehods ESLSCA July12mezo_noniNo ratings yet

- A Project Report On CustomerDocument13 pagesA Project Report On CustomerDrishti BhushanNo ratings yet

- Criteria-Based Assessment and Grading in Architecture Design StudioDocument8 pagesCriteria-Based Assessment and Grading in Architecture Design StudiolalecrimNo ratings yet

- Cost Management Homework: Key ConceptsDocument5 pagesCost Management Homework: Key ConceptsRaman ANo ratings yet

- pr2 of Jagers 12Document4 pagespr2 of Jagers 12Jeko Betguen PalangiNo ratings yet

- Review On Cold Formed StructuresDocument62 pagesReview On Cold Formed StructuresKannan Kandappan100% (1)

- SESI 5 Element of Research DesignDocument12 pagesSESI 5 Element of Research DesignStevia Tjioe100% (1)

- 19P. Studying Teacher Education A Journal of Self-Study of Teacher Education PracticesDocument11 pages19P. Studying Teacher Education A Journal of Self-Study of Teacher Education Practicesapi-3718445No ratings yet

- BIRCH: Balanced Iterative Reducing and Clustering using HierarchiesDocument33 pagesBIRCH: Balanced Iterative Reducing and Clustering using HierarchiesSpandan RoyNo ratings yet

- Status Report On Broadband and Broadcast Access in The State of Madhya PradeshDocument52 pagesStatus Report On Broadband and Broadcast Access in The State of Madhya PradeshVikas SamvadNo ratings yet

- Attitudes, Motivation, and Self-Efficacy in LearningDocument51 pagesAttitudes, Motivation, and Self-Efficacy in Learningpattymosq1992100% (1)

- Competency-Based Assessment of Industrial Engineering Graduates: Basis For Enhancing Industry Driven CurriculumDocument5 pagesCompetency-Based Assessment of Industrial Engineering Graduates: Basis For Enhancing Industry Driven CurriculumTech and HacksNo ratings yet

- International Statistical Institute (ISI)Document26 pagesInternational Statistical Institute (ISI)jhon jairo portillaNo ratings yet

- VECM JMultiDocument40 pagesVECM JMultijota de copasNo ratings yet

- CAPA For The FDA Regulated IndustryDocument34 pagesCAPA For The FDA Regulated Industrymanchorus69% (13)

- Entrepreneurial Mind Mr. Dee Jay LarroderDocument62 pagesEntrepreneurial Mind Mr. Dee Jay Larrodermarkangelo242001No ratings yet

- 3 E00003 PDFDocument5 pages3 E00003 PDFBeatrice IrizaNo ratings yet

- Part VI SummaryDocument80 pagesPart VI SummaryDiary JafNo ratings yet

- 4024 s15 QP 21Document24 pages4024 s15 QP 21Abukhalid al-ilmiNo ratings yet

- Brand RecallDocument4 pagesBrand RecallAmanNo ratings yet

- Geometry of CRBDocument4 pagesGeometry of CRBUma MageshwariNo ratings yet

- AR 8353 Anti Rape Law ResearchDocument8 pagesAR 8353 Anti Rape Law Researchmyxyn.myguel.medinaNo ratings yet

- KeterlambatanDocument5 pagesKeterlambatanArx HuntNo ratings yet

- Commercial - Awareness CIPSDocument7 pagesCommercial - Awareness CIPShuman and rightNo ratings yet