Professional Documents

Culture Documents

Cement Used On Site

Uploaded by

PulkitSainiDbspOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cement Used On Site

Uploaded by

PulkitSainiDbspCopyright:

Available Formats

Cement Used On Site

On Our site Portland Pozzolana Cement (PPC) was used for various

construction practices.

Portland Pozzolana cement (PPC) is manufactured by the intergrinding of OPC

clinker with 10 to 25 per cent of pozzolanic material (as per the latest

amendment, it is 15 to 35%). A pozzolanic material is essentially a silicious or

aluminous material which while in itself possessing no cementitious properties,

which will, in finely divided form and in the presence of water, react with

calcium hydroxide, liberated in the hydration process, at ordinary temperature,

to form compounds possessing cementitious properties. The pozzolanic

materials generally used for manufacture of PPC are calcined clay or fly ash.

Fly ash is a waste material, generated in the thermal power station, when

powdered coal is used as a fuel. These are collected in the electrostatic

precipitator The use of fly ash performs such a role. The pozzolanic action is

shown below:

Calcium hydroxide + Pozzolana + water → C – S – H (gel)

Portland pozzolana cement (PPC) was used in construction practices because

of following reasons:-

Produces less heat of hydration.

Offers greater resistance to the attack of aggressive waters than

ordinary Portland cement.

It reduces the leaching of calcium hydroxide when used in hydraulic

structures.

It is also useful in marine and hydraulic construction and other mass

concrete constructions like dam, bridge piers and thick foundation.

SAND

Sand is normally dredged from river beds and streams in the dry season when

the river bed is dry or when there is not much flow in the river. Under such

situation along with the sand, decayed vegetable matter, humus, organic

matter and other impurities are likely to settle down. But if sand is dredged

when there is a good flow of water from very deep bed, the organic matters

are likely to get washed away at the time of dredging.

The following limits may be taken as guidance:

Fine sand : Fineness Modulus : 2.2 - 2.6

Medium sand : F.M. : 2.6 - 2.9

Coarse sand : F.M. : 2.9 - 3.2

A sand having a fineness modulus more than 3.2 will be unsuitable for making

satisfactory concrete.

The sand which is used in mortar can be natural sand, or crushed stone sand or

crushed gravel sand. Sand or fine aggregate which is used in concrete is

somewhat different from sand which is used for masonry mortar. The role of

sand in mortar is to give the following properties such as

Strength

Workability

Water retentivity

Volume change

GRADING LIMIT

The particle size distribution of sand for use in masonry mortar should be

within the limits as given in the following table.

Grading Limit of Masonry Sand

Particle Size Percentage of Passing

4.75 mm 100

2.36 mm 90 – 100

1.18 mm 70 – 100

600 micron 40 – 100

300 micron 5 – 70

150 micron 0 – 15

If the sand does not conform to grading limit as specified above, then by

combining it with other sand we can get the desired grading.

You might also like

- Water Resources EngineeringDocument1,199 pagesWater Resources EngineeringVikaas Jha97% (35)

- AFE Previous Year QuestionsDocument8 pagesAFE Previous Year QuestionsPulkitSainiDbspNo ratings yet

- Article 1Document14 pagesArticle 1PulkitSainiDbspNo ratings yet

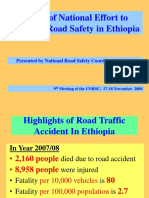

- Status of National Effort To Enhance Road Safety in EthiopiaDocument19 pagesStatus of National Effort To Enhance Road Safety in EthiopiaPulkitSainiDbspNo ratings yet

- PradeepDocument18 pagesPradeepPulkitSainiDbspNo ratings yet

- PPCMDocument9 pagesPPCMPulkitSainiDbspNo ratings yet

- Advanced Foundation EngineeringDocument16 pagesAdvanced Foundation EngineeringPulkitSainiDbspNo ratings yet

- Is A Trial Copy of This File Which Is Not Valuable and Unusable UnderstandDocument1 pageIs A Trial Copy of This File Which Is Not Valuable and Unusable UnderstandPulkitSainiDbspNo ratings yet

- Document EmptyDocument1 pageDocument EmptyPulkitSainiDbspNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Power and Water Utility Company For Jubail and Yanbu (MARAFIQ) Master Specification MQ-SP-C-2016 Project Name Date: 08 Mar 2011 Contract Number Page 1 of Revision 1Document10 pagesPower and Water Utility Company For Jubail and Yanbu (MARAFIQ) Master Specification MQ-SP-C-2016 Project Name Date: 08 Mar 2011 Contract Number Page 1 of Revision 1Azhar AliNo ratings yet

- Environmental Engineering Concrete Structures IntroductionDocument76 pagesEnvironmental Engineering Concrete Structures IntroductiontroyscribdNo ratings yet

- Environmental Protection Agency (EPA) (Timeline and Role in Society)Document25 pagesEnvironmental Protection Agency (EPA) (Timeline and Role in Society)Abeera MalikNo ratings yet

- AAC Vs CLCDocument27 pagesAAC Vs CLCHariharan100% (4)

- Proposal by Asfaw ADocument34 pagesProposal by Asfaw ABelachew ZelekeNo ratings yet

- Museum Design Strategies for Composite ClimatesDocument21 pagesMuseum Design Strategies for Composite ClimatesSwapnali thorveNo ratings yet

- Rice Straw and Eggshell Ash As Partial ReplacementDocument7 pagesRice Straw and Eggshell Ash As Partial Replacement10 Rainer Jasper S. GASACAONo ratings yet

- Agricultural Wastes by Geoffrey S. Ashworth and Pablo Azevedo PDFDocument322 pagesAgricultural Wastes by Geoffrey S. Ashworth and Pablo Azevedo PDFEl RoyNo ratings yet

- Ruchi Soya IndustriesDocument8 pagesRuchi Soya IndustriesAkhilesh KumarNo ratings yet

- Building Technology 3Document25 pagesBuilding Technology 3Melaine A. FranciscoNo ratings yet

- Iswandaru WidyatmokoDocument83 pagesIswandaru Widyatmokokrisna monicaNo ratings yet

- The Most Professional Ultrafine Powder Equipment ManufacturerDocument90 pagesThe Most Professional Ultrafine Powder Equipment ManufacturerraeggaemanNo ratings yet

- Greenboro Polychem PVT LTDDocument57 pagesGreenboro Polychem PVT LTDMehdi MadaniNo ratings yet

- Concrete HandbookDocument42 pagesConcrete HandbookMilan Jankovic100% (2)

- Sequestering CO in The Built Environment: Calera CorporationDocument48 pagesSequestering CO in The Built Environment: Calera CorporationPassmore DubeNo ratings yet

- Civil Engineering Materials ConstructionDocument36 pagesCivil Engineering Materials ConstructionJerry Mors0% (1)

- Flame and Combustion Forcement Kilns KPK PDFDocument62 pagesFlame and Combustion Forcement Kilns KPK PDFPradeep KumarNo ratings yet

- Construction and Building Materials: F.N. Okoye, J. Durgaprasad, N.B. SinghDocument7 pagesConstruction and Building Materials: F.N. Okoye, J. Durgaprasad, N.B. SinghHasu MehtaNo ratings yet

- AP Environmental Science: Free-Response Questions Set 2Document6 pagesAP Environmental Science: Free-Response Questions Set 2Anita100% (1)

- Behaviour of Geopolymer Concrete ExposedDocument181 pagesBehaviour of Geopolymer Concrete ExposedJasson StathamNo ratings yet

- Framework For Durable ConcreteDocument8 pagesFramework For Durable ConcreteDai ThanhNo ratings yet

- Cementitious grout for post-tensioned bridgesDocument20 pagesCementitious grout for post-tensioned bridgestonykebbeNo ratings yet

- Fly Ash - WikipediaDocument12 pagesFly Ash - WikipediaBabar AliNo ratings yet

- Ground Improvement Techniques and Geosynthetics - IGC 2016 Vol.2Document403 pagesGround Improvement Techniques and Geosynthetics - IGC 2016 Vol.2Kamilly Protz100% (6)

- Alternatives of Sand PDFDocument27 pagesAlternatives of Sand PDFRaviteja100% (1)

- Advances in Concrete TechnologyDocument10 pagesAdvances in Concrete TechnologytusshaarpatilNo ratings yet

- Cement Replacement Wood WasteDocument9 pagesCement Replacement Wood WasteEva N. TayNo ratings yet

- Concrete Design MixDocument106 pagesConcrete Design MixRavi ValakrishnanNo ratings yet

- Final Year Project Proposal TitleDocument79 pagesFinal Year Project Proposal TitleOtieno Patrick OduorNo ratings yet

- Concrete Myth and RealityDocument2 pagesConcrete Myth and RealityManoj BalakrishnanNo ratings yet